Do I need a pump for a warm water floor

The pump circulates water in the circuit, thanks to which the surface heats up evenly and protects the house from heat loss, which is especially important for regions with extremely frosty winters. The installation of such a device is required, but not in all cases. It is believed that if the floor area is small (up to 40-50 m2), such a device does not need to be mounted.

In all other options, installation of the pump is necessary, and not only for reasons of comfort, but also due to some technical features:

- Often, pipes with a small cross-section are used for heating, therefore, large heat losses occur in them. Because of this, the boiler itself will overheat, more solid fuel will be needed.

- Certain types of flooring do not tolerate high temperatures - for example, laminate, oak deforms. Therefore, they need an even distribution of heat, which is what the water pump provides. In the calculation of such schemes, the mixing unit must be taken into account, which allows maintaining the desired mode.

- The walls of the house are made of one material, which has the same heat capacity. However, floors are most often made from different materials. For example, the bathroom has a ceramic coating, while in other rooms the floors can be self-leveling. Since the heat capacities differ, it becomes necessary to distribute heat evenly.

Attention! More often than not, you should not rely on the floor contour and the heater group to operate from the same boiler. The parameters of these systems are noticeably different.

Calculator for calculating a warm floor and its installation

There are purchases that are made not for a year, but for decades. The underfloor heating system, which provides a comfortable microclimate in the house all year round, is one of them. Every person who is going to install underfloor heating with their own hands wants to make the right choice, to accurately calculate all costs - and this is natural.

If you are a beginner in the construction industry and doubt whether you can make all the calculations correctly, use a special online calculator. Thanks to him, you can evaluate the range of upcoming work, the optimal amount of material for a warm floor. Using it is very simple. To do this, you need to select "Calculation of underfloor heating" in the "Building calculators" section and enter all the data that the site asks for.

The automatic program instantly calculates the data required to create a project:

- power of the underfloor heating circuit (total and W / m²);

- pipe length;

- the volume and thickness of the mortar for the finishing screed;

- the optimal amount of sand, cement, fiber and plasticizer;

- feed rate, water consumption, etc.

The method of coefficients is taken as the basis for the calculator's operation: reference, pre-made calculations are taken into account, which change depending on the changes made by the user. When issuing results, the type of flooring, air temperature, the step of laying the warm floor under the tile or laminate and other parameters are taken into account.

Underfloor heating power

For an approximate calculation of the power, an analysis of heat loss is carried out, its ratio taking into account the total area and the average temperature in the room during the cold time of the day. Based on this data, the builder, whether it is a professional or an amateur, must make a markup of the passage line. Power is one of the most important criteria for choosing the right paving technology.

- in rooms characterized by low temperature and high humidity, the specific power indicator is 170 W / m²;

- for rooms with low humidity, a power of 130-140 W / m² will be enough;

- if a warm floor is used as the main heating of the room, the optimal indicator will fluctuate between 160-220 W / m².

An unmistakably designed floor heating scheme is a guarantee of long-term and efficient heating. Thanks to our online calculator for underfloor heating, you can create a reliable heating system that will last for decades.

Underfloor heating with concrete screed

When planning to lay it, it is necessary to take into account the further expansion of the concrete after heating. When choosing a thermal insulation option, experts recommend giving preference to expanded polystyrene or expanded polystyrene. Further:

- After it, a damper tape is laid to compensate for the expansion.

- Reinforcement mesh is laid, to which the pipes of the circuit are attached.

- At the final stage, the structure is poured with concrete.

The peculiarity of this technology is heat retention. Otherwise, it can flow through the cracks to the lower floors.

Floor heating

A distinctive feature of this method is the absence of any screed. During installation, the cover rests on aluminum plates. Between them and the floor itself, there is a gasket, made of cardboard or polyethylene. Those who plan to equip such a floor should take into account some of the nuances:

- It is important to use additional insulation, and place polystyrene mats on it.

- The option of installing the floor of the polystyrene system is possible, when heat distribution plates and pipes are placed in the connectors.

- The underfloor heating system is installed on concrete or potential floor.

It is a good option for rooms with low ceilings and insufficiently strong floor slabs, when it is not possible to install a concrete screed.

Warm floor with wooden elements

Suitable for prefabricated or so-called panel houses. You can use chipboard panels with pipe channels or heat-conducting plates, which alternate with chipboard layers.

- Each element will be attached to the base with a self-tapping screw every 2 cm.

- Plates need to be placed in gaps and separated.

- Pipes are installed, and at the end they are covered with a floor covering.

This option is intended for a rough wooden floor on logs, when you need to create an additional source of heating.

What to consider when calculating

The key thermal and hydraulic parameters of the online calculator are designed for a water-heated monolithic floor using a cement-sand mortar. In order for the result to meet your expectations as much as possible, it is necessary to take into account that underfloor heating cannot always be used as the main source. This is preferable for regions with southern climates. In addition, then you cannot do without the additional use of energy-efficient materials.

The calculations obtained on the site will be useful to those who are going to equip a warm floor on their own in a private house. As for apartments, this method is not always suitable for them. In the presence of autonomous heating, it will be possible to regulate the heating, which cannot be said about the possibilities with a central heating system.

What pump is needed for underfloor heating

For a house with a typical area (up to 250-300 m2) and 1-2 floors, you can choose a pump equipped with a wet rotor, the impeller of which is submerged in water. This ensures low noise and durability (no need to constantly lubricate the mechanism). If the house has a large area or more than 2 floors, it is better to consider a model with a dry rotor. Therefore, it is necessary to clarify how exactly they differ:

- Wet rotor are devices with medium power, they are optimally suited for rooms up to 250-350 m2. The impeller of the mechanism is directly in the water. The equipment works quite quietly, while it consumes little energy and lasts a long time.

- Dry rotor - particularly powerful options. They are used on surfaces with an area of 250 m2 and more and require cleaning and lubrication. If the house has 3 or more floors, it should also be considered a dry rotor.

Wet rotor pumps are suitable for standard houses with an average floor space

Screed thickness over floor heating pipes

The purpose of the screed over the pipes for underfloor heating is to take the load from people and objects in the heated room and evenly distribute heat from the pipes over the floor surface.

The minimum permissible screed thickness above the pipe is 30 mm if reinforced. At a lower thickness, the screed will have insufficient strength. Also, the small thickness of the screed does not provide uniform heating of the floor surface - there are strips of hot floor above the pipe and cold between the pipes.

It is not worth pouring a screed thicker than 100 mm, because this increases the inertia of warm floors, excludes the possibility of rapid regulation of the floor temperature. With a large thickness, the temperature of the floor surface will change after a few hours, or even days.

Based on these conditions, the optimal thickness of the underfloor heating screed is 60-70 mm above the pipe. The addition of fiber and plasticizer to the solution allows the thickness to be reduced to 30-40 mm.

Up

How to calculate the pump power for a warm floor

You can estimate this parameter according to the main technical characteristics, which are indicated by 2 numbers, for example: 25/40. The first value characterizes the thread diameter - in this case 25 mm, the second - the head: 40 dm or 4 m (that is, 0.4 atm). The choice depends on the floor area.

| up to 150 m2 | 25/40 |

| 150-260 m2 | 25/60 |

For an accurate calculation of the pressure, you can apply the following formula:

Nap = (C * D + k) / 1000, where:

- Hap - pressure;

- С - resistance (determined by 1 meter);

- D - pipe length;

- k - coefficient (characterizes the power reserve).

Important! If the area of the house is more than 250 m2, you can install 2 devices with a pressure of 25/40, you should not take it "with a margin", that is, with a high pressure, since it is impractical. Heating will be about the same, but noise and energy costs will increase significantly.

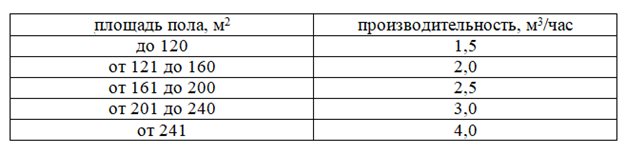

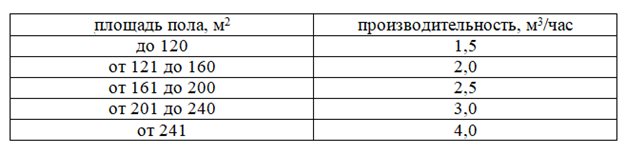

The capacity is determined by the volume of water passed per unit of time (m3 per hour). The selection of a suitable pump for underfloor heating can be done using the table.

An accurate calculation of the main characteristics of a pump for a warm floor can be done based on the following equality:

Explanation of the formula:

- Q - productivity;

- P is the power of the device;

- t1 is the temperature of the water or other medium in the return pipe;

- t2 is the temperature of the water or other media in the supply.

For houses with a larger area, the same principle works - it is better to install 2 pumps with average indicators than 1 device with high performance. In this case, you will need to calculate the indicator of each device, and then summarize the values obtained.

It is better to buy sufficiently efficient floor pumps (15-20% more than the calculated one) - this will help in the event of an abnormally cold winter or weak insulation of the house

Savings due to underfloor heating

Underfloor heating will allow us to enjoy a high level of comfort at a low water temperature in the system. Since the entire floor surface becomes a radiant surface, the consumer can be given the same sense of well-being, even if the air temperature is about 2 ° C lower. The consumer feels that he lives in an environment that heats up to 20 ° C - 21 ° C, in fact the thermometer only shows 18 ° C. Less heat dissipates from the environment, which gives us a very interesting energy saving that meets the new standards that energy saving.

This low inlet water temperature will also allow the use of alternative energy sources (solar energy using storage tanks, energy generated by heat pumps or extraction from industrial processes).An insulating panel or striking plate motherboard serves an important function in soundproofing as it absorbs noise between different floors. Thus, if we compare this system to a traditional radiator system in terms of initial cost, we must take note of this important component.

How to choose a pump for underfloor heating

It is recommended to consider several criteria:

- Technical characteristics (it is necessary to make preliminary calculations according to the formulas described above and determine the appropriate model).

- The pump body material is better cast iron, stainless steel or organic polymers. It is these materials that last the longest due to their high anti-corrosion properties.

- The presence of a built-in thermostat protects the impeller from scale and deposits that form due to exposure to hot water.

- Brand - Germany (Wilo) and Denmark (Grundofs) are the most reliable. Budget options with an optimal price / quality ratio - Poland (DAB) and China (Sprut). Also popular are Italian manufacturers (Lowara, Pedrollo) and the Japanese brand Ebara.

- High-speed floor pump - usually models operate at 3 speeds, which is especially convenient for a large heating area, as well as 2-3-storey buildings.

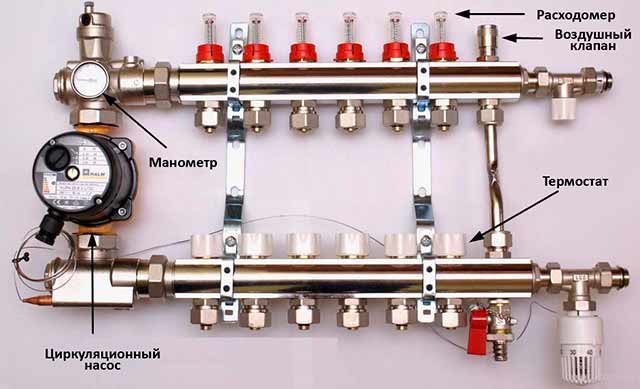

The principle of operation and the device of the pump

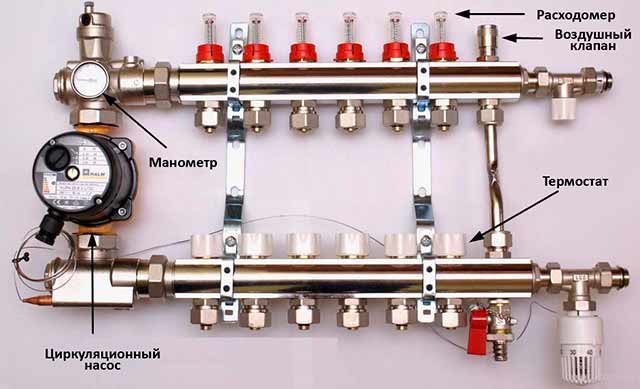

Almost all pump models have very similar designs. The circulation pump device for heating consists of the following basic elements:

- a case made of highly durable material. In the vast majority of models, metal is used for these purposes (stainless steel, cast iron, bronze). But a number of models have cases made of plastic;

- housings have branch pipes to which branch and supply pipes are connected. Unlike household pumps, industrial products have flanges instead of nozzles, the diameters of which exceed 40 mm. This is because they have to work with longer contours;

- the movement of the coolant along the highways is achieved by rotating the impeller blades fixed on the drive motor shaft. The best currently recognized impellers are made of a material such as technopolymer. This is primarily due to its highest wear resistance;

- the drive motor is fixed to the pump casing. Most often - on one of its side surfaces. The coolant supplied to the casing is captured by a rotating impeller and discharged under a certain pressure into the supply line of the pipeline (underfloor heating). The pump casings of some models are additionally equipped with an air evacuation system. But there are few such models. In most cases, a special nut on the body is provided to remove air from the system. Unscrewing it, the accumulated air is removed.

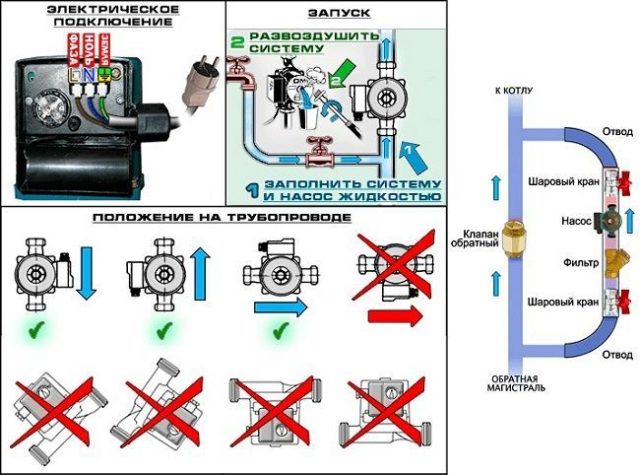

Where is the pump for underfloor heating installed?

Before connecting the pump to the underfloor heating, it is important to determine the optimal place for its installation. There are 2 options for this:

- At the feed - that is, next to the mixing unit.

- On the return line - that is, in front of the boiler.

In a conventional system, installers always use the second option - it is optimal to place the pump in front of the boiler, from where it will give water flow, which will ensure its uniform heating. But in the case of underfloor heating, it is better to choose installation on the supply. This is done in order to avoid air entering the system as much as possible.

Important! If the floor pump is too noisy (rotary), it is better to install it under the floor. For medium-sized premises (1-2 floors, up to 300 m2), the equipment can be placed in other places.

Marking and body material

These are two or three digits of the type: 25/40, 25 / 60-130 or 32/80, etc. The first number is the inlet / outlet diameters in millimeters. That is, in the given marking, the connecting dimensions are 25 mm and 32 mm. The second number is the lifting height that this model provides. In the example shown, these are 4 meters, 6 meters and 8 meters.If we translate atmospheres, then this is 0.4 atm, 0.6 atm, 0.8 atm. The third number is the installation length, that is, the size of the entire device from one end to the other. In our example, this is 130 mm.

Decoding of the labeling of circulation pumps

Now let's decide on the body material. If the pipes are chosen correctly, then there should be no problems: the system is closed and there is little oxygen, so it will be possible to install a unit from any material. But if you have not taken into account oxygen permeability and this active oxidizer is present in the system, then the cast-iron case is contraindicated for your system. Then put with a stainless steel or polymer body.

As for the firms. It is best to take equipment from European manufacturers. When choosing a pump for a water heated floor, it is better not to save money: your comfort and the presence of heat in the house depend on how stably this element works. Choose the best firms with the best reputation. The German campaigns Grundfos and Wilo have proven themselves well. But in the case of Wilo, you need to look at the country for which the products are made: those that go to the CIS and China market fail more often. So be careful.

How to install a pump on a warm floor

After the location is selected, you should proceed with the installation. The algorithm of actions is as follows:

- First, a bypass is installed in the mounting place - a bypass pipe.

- To do this, you need to cut the main pipe.

- Form a thread at its ends.

- Install the ball valve and install the pump.

- Open the tap for water access.

- Open the air bleed screw.

- After installing the circulation pump on a warm floor, it is imperative to test the system. First, the operation is checked at low speed.

Scheme of the correct installation of the pump for underfloor heating

Criterias of choice

In order for the circulation pump to ensure the uninterrupted and effective functioning of the water heated floor, it is necessary to pay attention to a few more indicators when selecting it, in addition to performance and pressure.

Average energy consumption of the underfloor heating pump

- Multiple speeds. Usually three are enough, allowing you to quickly adjust the degree of heating of the coolant.

- Electricity consumption. The most economical are advanced pump models equipped with a module for automatic regulation of the intensity of work depending on the degree of heating of the coolant.

- Noise background. For residential premises, this indicator is important. Small-sized versions of pumps with a wet rotor are practically not a cause for concern.

An important criterion is the manufacturer. Among the large companies that have the image of reliable partners producing high-quality pumps, the following well-known brands can be noted:

Selection of a pump for underfloor heating

- Grundfos (Denmark);

- Ebara (Japan);

- DAB (Italy);

- Halm (Germany);

- Lowara (Italy);

- AlfaStar (Poland);

- Pedrollo (Italy);

- Wilo (Germany).

Circulation pumps of the Wester brand (China) are in demand, which, at a relatively low cost, are of good quality.

Among the positive reviews of consumers, one can single out a large number sent to the address of the Grundfos brand (Denmark). Pumps of this company, with simple maintenance and a fairly high price, attract private developers for long-term flawless work.

Maintenance rules for a pump for a warm water floor

The pump for underfloor heating is durable, provided that it is correctly installed and there is no factory defect. However, it also needs maintenance. During operation it is necessary:

- Periodically (1-2 times a month) bleed air from the circuit using a special tap. If you have to do this too often, there are installation errors. It is recommended to install additional separators or air valves.

- Lubricate the working mechanism annually - this is especially necessary for a pump with a dry rotor.

- As for a wet rotor, it is necessary sometimes (for example, once every 2-3 years) to clean it from scale and other deposits.

Important! The pressure and temperature should not be drastically changed. If a place is frozen (or after a long break), heating is carried out very slowly so that the water gradually acquires the desired temperature.

Calculation taking into account furniture

Experts recommend laying underfloor heating only where there will be no bulky pieces of furniture - cabinets, fireplaces, sofas, etc. Accordingly, it is necessary to take into account when calculating the place where there will be no warm floor. For this we use the formula:

(S - S1) / H x 1.1 + D x 2 = L

In this formula (all values are in meters):

- L - Required pipe length;

- S - the total area of the room;

- S1 - The total area of the room, where there will be no warm floor (empty areas);

- H - Step between pipes;

- D - The distance from the room to the collector.

An example of calculating the length of pipes for underfloor heating with empty sections

- The length of the room is 4 meters;

- The width of the room is 3.5 meters;

- The distance between the pipes is 20 cm;

- The distance to the collector is 2.5 meters;

The room contains:

- Sofa measuring 0.8 x 1.8 meters;

- Cabinet measuring 0.6 x 1.5 meters.

We calculate the area of the room: 4 x 3.5 = 14 sq. M.

We consider the area of empty areas: 0.8 x 1.8 + 0.6 x 1.5 = 2.34 sq. M.

We substitute the values into the formula and we get: (14 - 2.34) / 0.2 x 1.1 + 2.5 x 2 = 69.13 running meters of pipes.