Old technology problems

Many people know that boilers without connected pumps are often directly connected to the collector, and it is instead of this option that such a hydraulic arrow with a collector is most often used (manufacturing diagram below). These devices were simply removed from boilers with pumps, as a result of which they were installed on each separate heating circuit, but in fact, this option can not be used in all situations, since if at the moment there is still a guarantee on the boiler, then in In this case, it will not be possible to remove the pumps from it, and if we are talking about a cast-iron boiler, then in the case of such a dismantling of its components, when the heating is first turned on, even individual sections of the boiler may burst, unable to withstand such a temperature difference.

findings

In this article, we looked at various ways to make a water arrow with your own hands. The first, steel, are widely demanded by specialists due to their durability and functionality. Second, polypropylene arrows are cheaper. However, they are not as reliable as metal ones (they can break from the temperature difference).

The structure of the hydraulic arrow in the section is the same in most homemade crafts. A more advanced device has hydraulic arrows produced by specialized companies. As for the alternative, then again it is worth paying attention to the products of manufacturers. In any case, proceed from your resources and acquired skills, but remember, a free couple of hours can turn into a day or a week.

What this technology gives

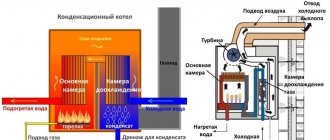

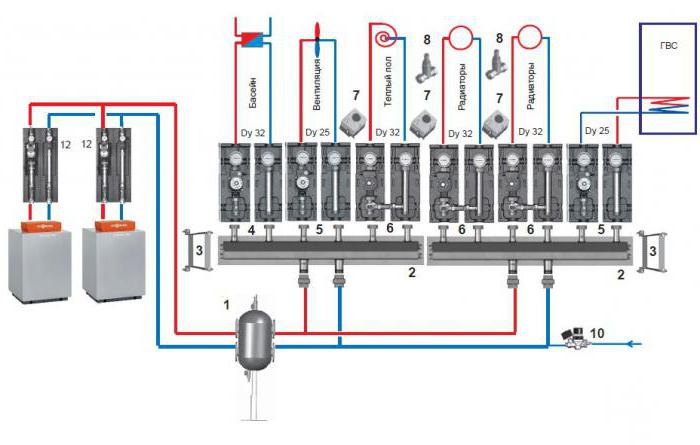

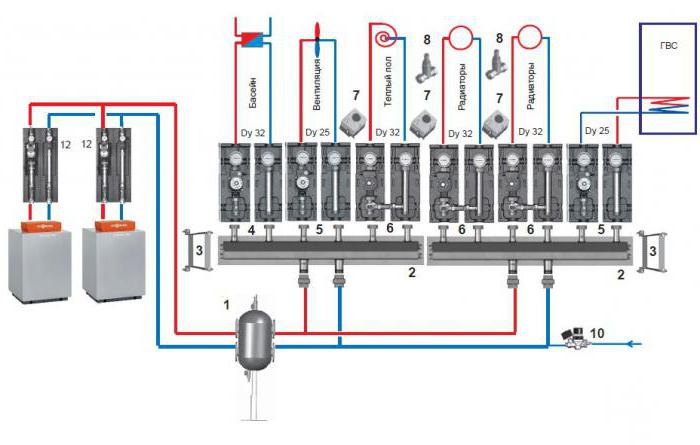

To get rid of all this, today a specialized hydraulic arrow with a manifold is used (the manufacturing scheme is presented in the article). This device is intended to separate the hydraulics, and more precisely, it divides the boiler directly from the rest of the heating system. Thus, for example, a hydraulic arrow with a manifold (the manufacturing diagram is illustrated) can provide a single pump in the boiler, while several more such units of different capacities are installed in the system.

How does it work

The device of such equipment is extremely simple. At the moment, we will not disassemble any high-tech devices, but consider only the main options for implementing such a technology.

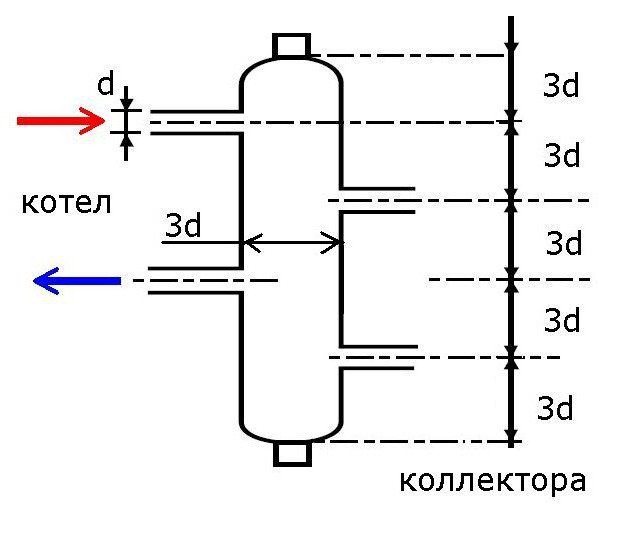

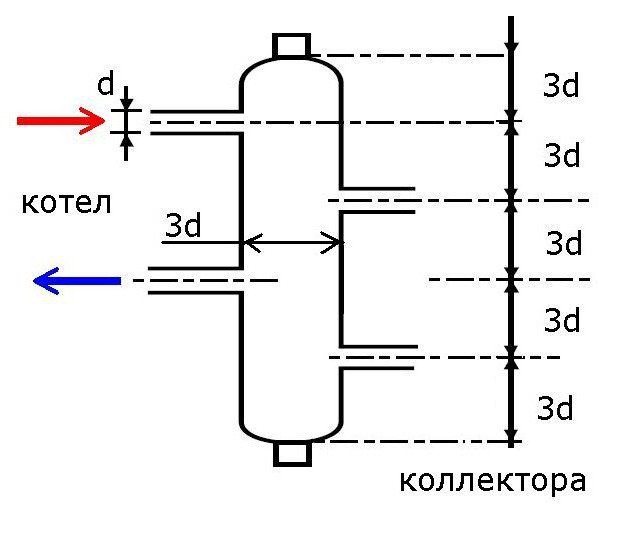

In principle, it is enough to use a standard piece of pipe from which the hydraulic gun (hydraulic separator) is made. The calculation of the hydraulic arrow will allow you to understand what basic characteristics such a device should have and what materials are best used for its manufacture.

What is its purpose

First of all, the designers try to proceed from the fact that the arrow is intended specifically to separate the hydraulics. In the overwhelming majority of cases, manufacturers today are trying to produce boilers equipped with their own pumps, and such devices are quite powerful.

For example, there are boilers with a closed combustion chamber in which built-in pumps are installed. The power of such devices can be approximately 300 watts, but in fact it will not be enough to completely push through the heating system if it is required to provide an object for 1000 m2, namely, such equipment is approximately designed for such an average heating area.

In this regard, it is necessary to install additional pumps, as well as use combined systems. It is in such a situation that, instead of help, the pump that is originally used in the boiler will simply interfere, and it is in such cases that a hydraulic arrow can be used (purpose, calculation, manufacturing - more on this later in the article). At the same time, it is worth noting the fact that such high-power equipment in the majority of cases is initially supplied with a factory hydraulic arrow in the kit, or at least there is a fairly accurate instruction on how to connect it.

If you take smaller boilers, then basically the same story is with them, but in this case you will have to make your own.

DIY polypropylene water gun

Another popular material used in the manufacture of water shooters is polypropylene. We have already talked about it in the material do-it-yourself heating collector. From the point of view of operation, polypropylene is inferior to steel. Still, it is based on polyethylene, albeit of special strength, but it has the property of melting at high temperatures. In heating systems, the parameters change constantly, and if this happens quickly and unexpectedly (for various reasons), then breakdowns cannot be avoided.

In addition, there are nuances in polypropylene welding.

The pipe is also selected according to the rule of three diameters, which often leads to difficulties, especially in high-capacity heating systems. In this regard, a polypropylene hydraulic arrow is usually mounted in low-power home boilers.

Often in boiler rooms you can find a combined option - a steel hydraulic arrow and polypropylene collectors. Do not forget, the wording of the names is different for different craftsmen and manufacturers. Hydro arrows often appear in video tutorials, although in reality we have ordinary combs.

The cost price of a polypropylene hydraulic arrow is about 1,000 rubles, provided that you have all the fittings and a welding machine.

Where is it installed

The hydraulic arrow is installed on floor-standing boilers without a built-in pump to ensure effective protection of the boiler against a large temperature difference during the first start of the heating system. For example, using this equipment, standard steel boilers can be protected from the generated condensate, while cast iron devices can be protected from the possibility of failure of individual sections.

To exclude such unpleasant situations, a specialized hydraulic arrow is used. The drawing and diagram of the boiler room in this case play an important role, since depending on the characteristics of the heated object, you need to choose the appropriate equipment. The only thing worth noting is that you also need to use an additional pump for various floor standing boilers.

Example

Initially, a person in his house wants to get an almost ideal heating system, having spent reasonable money on it, and in this case it all starts with the boiler. For a small private house, you can choose a standard double-circuit boiler with a closed chamber, which will be mounted on the wall. At the same time, it is necessary to correctly understand that in the overwhelming majority of cases, to ensure the normal distribution of the coolant in this system, it may be necessary to individually manufacture the heating collector of the hydraulic arrow. In such a situation, a completely standard question arises: will their pumps be used and what needs to be done with the device in the boiler?

It is quite natural that many people in such situations prefer to simply dismantle the pump from the boiler so that it does not spoil the installed hydraulics of the system, but in fact, the design of some devices is made in such a way that it is unlikely to be possible to do this procedure. It is in such situations that the connection between the boiler and the collector becomes the ideal solution.

Features of stainless steel heating collectors

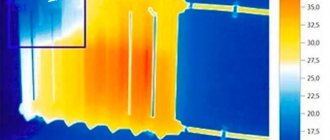

Heating collectors are responsible for the separation and distribution of the heating medium. The first provides hydro arrow... The vertical structure communicates with the boiler through the inlet and outlet connections. It is in it that the fluids of the primary and secondary lines are mixed. Thus, the temperature balance is maintained. Hot and cold water mixes to form a new stream that is safe for the system.

Inside the arrow is set separator, it is also made of stainless steel. Needed to clean the coolant. The fact is that, circulating along the contours, the liquid accumulates various impurities and air. Foreign substances have a negative effect on the operation of the devices. Mechanical particles clog valves, bends and other moving parts, and air bubbles provoke oxidation processes. Cast iron heat exchangers are starting to rust. As a rule, this process is irreversible.

How is the installation carried out in such a situation?

Initially, a diagram of the distribution manifold is drawn. As an example, consider the following situation:

- Two contours of underfloor heating.

- The system will use an indirect heating boiler circuit, two spare circuits for a heat pump or a separate electric boiler, as well as a hydraulic arrow circuit, that is, 5 circuits.

In this case, there is nothing difficult in how to draw a collector diagram - it is enough to have at least some understanding of how such a system works.

How to choose a distribution manifold?

The combs have a similar design - they have standard choke threads and bore diameters. Connection can be carried out using several types of pipelines and fittings. The difference may be the permissible number of fittings - it varies between 2-12 pieces. The combs can be easily grouped together to provide the required number of bends.

Distribution heating manifold designed for servicing underfloor heating

In distribution manifolds intended for servicing underfloor heating, mechanisms must be provided to regulate the intensity and temperature of the working flow on each branch. These devices can be manual or automated. In the case of radiators, such elements are not necessary, since control can be carried out directly on each battery.

The choice may be influenced by the base material:

- collectors made of stainless steel are sold in a high price segment, but the price is justified by the quality - the products have the largest service life among analogues. The combs withstand increased pressure, they are equipped with air removers, end cap nuts for servicing the ball valve, control valves;

- low-cost polymer products are characterized by insufficient strength, it is not advisable to use them in heating systems, since they do not have the necessary indicators of thermal expansion;

- the most popular are the brass series - inexpensive and at the same time functional.

If you have certain skills, you can assemble the distribution manifold yourself, but in the case of using metal, it is necessary to minimize the likelihood of rust entering the system.

Manufacturing and calculation

It is worth noting the fact that you can independently adjust the power that your hydraulic arrow will have. How to calculate the power, you need to proceed directly from the characteristics of your room and the devices used.

If you do not need the power of the device you purchased, then in this case it will be possible to reduce the threads in diameter, but at the same time make a longer arrow. In some situations, it is advisable to reduce the total power of the purchased equipment in power by up to two times, since, for example, 80 kW devices are not needed in every home, and in such cases it would be quite optimal to leave equipment with a capacity of 40 kW or more.

How to arrange it

Some who use the scheme for making a hydraulic arrow with their own hands prefer to install it in the immediate vicinity of the boiler, but many experts say that mounting this device on a manifold is also a good option, which ultimately allows you to achieve a complete and harmonious design that will further easy to use, check and maintain.

In this case, the boiler can be installed approximately three meters before the installation point of the arrow, while the boiler supply and return lines can be mounted through the floor if there is a floor heating cake in the house. Otherwise, there are no fundamental differences in where your arrow will be mounted, and the main thing in this case is the installation of equipment with a suitable power and always in a vertical state. If you are making a hydraulic arrow for a heating system (diagram / calculation above), in which a boiler is installed without a safety valve, then it is recommended to weld an inch thread to the top of the device for mounting a special safety group.

It is also recommended to weld a small thread in the lower part to ensure proper drainage and filling of the arrow. An obligatory practical condition is the insertion of specialized couplings for thermometer installation into the “boiler, hydraulic arrow and collector” system. In the process of further operation, this can make your life easier, as it will allow you to easily monitor the state of the heating system.

Appointment of a hydraulic arrow

Hydro arrows

The purpose of the hydraulic arrow, or hydraulic valve, is divided into the main function and the auxiliary ones. It depends on the design of the device. The main one is to correctly distribute the coolant flows. The need for this may arise in the following situations:

- In a heating system operating from one heating device, and having two or more circuits that require different flow rates of the coolant. Especially if the second circuit is larger than the main one. In this case, it is absolutely unprofitable to increase the intensity of the boiler operation. This will not only lead to unnecessary fuel consumption, but also significantly reduce the service life of the heater. Not to mention the fact that in rooms heated by the main circuit, it will simply be too hot.

- The heating system has several different circuits. Radiators, underfloor heating and so on. The hydraulic arrow will allow all of them to work without negatively affecting each other, and if one of them is turned off, the rest will continue their work without unnecessary loads and thermal shocks.

- The heating system has several circuits, each of which operates with a circulation pump. The hydraulic valve will ensure their work independently of each other.

- There are several heating boilers in the heating system.

- Also, the hydraulic arrow makes it possible to turn off one circuit, regardless of the others. For example, to carry out some kind of repair work.

- The hydraulic distributor dampens heat shocks during system start-up and emergency shutdown. A necessary condition if there are cast iron elements in the system, which may become unusable due to sudden temperature changes.

There are only two auxiliary functions, but they also play a very important role:

- The hydraulic arrow makes it possible to bleed air from the heating system through a specially installed valve.

- It also serves as a storage device for rust, scale and other types of deposits, which, thanks to it, are easily removed.

As you can understand, a do-it-yourself hydraulic arrow mounted in the heating system is a very useful thing, which allows you to regulate the operation of heating and carry out repair work on time, without turning off the boiler.

How to make it

If you have a standard welding machine and experience with such equipment, then in this case there is nothing difficult in welding a full-fledged hydraulic arrow yourself. However, you need to correctly understand the fact that in the process of performing this work, you need to take into account a large number of subtleties.

Nowadays, there is nothing difficult in finding a drawing of a hydraulic arrow, but at the same time you need to correctly understand that all such drawings are different, and there is no specific template. Each specialist sees the structure of a hydraulic arrow differently, but there are certain rules that are followed by absolutely everyone.

The arrow itself is a certain metal container, to which the pipes are welded, designed to connect to the boiler and provide supply and return. Also, consumer pipes are built into the system.

Optionally, you can use the branch pipes intended for the automatic air vent in the upper part of the installed arrow. In the lower part, a tap pipe is installed to ensure the removal of various sludge and dirt. Among other things, in some place you can also put a pipe for making up water in the system.

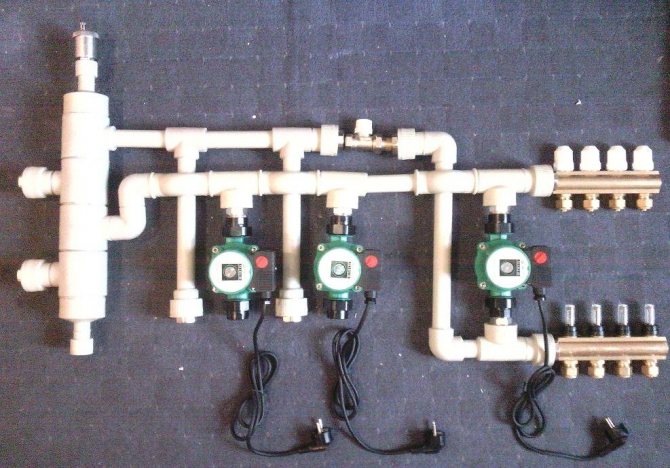

How to make a do-it-yourself heating distribution manifold?

The product design is based on the number of heating circuits used. It is necessary to take into account the location of the heating boiler, the specifics of the nozzles, the features of heating and indirect circuits, plans for a possible increase in their number in the future, the points of heat distribution.

An example of a do-it-yourself heating distribution manifold

When drawing up the project, it is also necessary to take into account that each circuit has two pipes - for supply and return. It will be necessary to note the additional equipment - a drain valve, an expansion tank, a group of thermostats, a filling valve, a make-up valve.

The next step is spatial modeling. We'll have to figure out the specifics of connecting pipes to the collector, usually taps for indirect heating and connection with a solid fuel boiler are formed at the ends, for electric and gas wall-mounted boilers, the branch pipe is cut from above. All the information collected is taken into account when drawing up the collector drawing (graph paper is useful here). Between adjacent pipes, you need to maintain a distance of 10 cm, as practice shows, a maximum of 20 cm.

The most convenient material for self-assembly of the comb is a square or regular pipe profile. To perform the marking, it is advisable to prepare a ruler, caliper, core. With the help of a gas cutter, holes are made into which nozzles will be cut in the future. In these seats, you need to insert pipe cuttings equipped with threads.

The workpieces are fixed by welding - first by roughing, by the second method the entire perimeter is processed. Next, you need to equip the resulting body with brackets for hanging the comb on the wall. The joints must be cleaned from rust and scale. The structure is coated with a degreasing compound, paint and varnish are applied successively.

After 2-3 days, when the layers of paint are completely dry, the collector can be mounted on the prepared place and connected to the incoming, outgoing circuits. As a result, an effective tool is formed that can fully coordinate the complex heating system of a private household.

First rule

The most important rule that must always be followed is the so-called "rule of three diameters", that is, the diameter of the hydraulic arrow you installed should be three times larger than this parameter for the nozzles. If you want the hydraulic separator to be able to fully perform its main functions, that is:

- separate sludge from the system;

- remove gases;

- equalize the hydraulic difference;

- supply heated water to the boiler in order to ensure its greater durability.

Many people prefer to save money and make their own hydraulic arrows from polypropylene, but in fact this is an absolutely wrong decision, taken mainly by people who have little understanding of the features of the operation of such equipment.

It is for this reason that it is worth using only full-fledged metal pipes, which allow you to fully realize the potential of such a technology and will really show themselves effectively throughout the entire service life of such a system.