Home / Gas boilers

Back to

Published: 03/04/2020

Reading time: 7 minutes

0

428

The Danko brand is known in the CIS countries for its gas boilers. The first Danko boiler was produced in the Ukrainian city of Rivne in 2002.

Today the company sells heating products on the markets in Russia, Belarus and Moldova, significantly expanding the brand's lineup.

- 1 About the manufacturer 1.1 Official site, where to see all models and factory instructions

- 6.1 The wick goes out

About company

is engaged in the production of heating equipment of various types - it produces gas, electric and solid fuel boilers, columns and converters. The first products entered the market in 2002. The batch consisted of only 49 pieces of equipment. Today the company has about 850 thousand units of products sold. The production uses advanced equipment of foreign firms from Italy, Denmark, Finland.

Specifications

The technical characteristics of the Danko gas boiler are excellent. The devices are easily repaired, assembled, and use does not cause absolutely any difficulties. The unit does not imply a difficult connection, since the design has built-in automation, which greatly simplifies the entire process of setting up heating equipment. Upgraded models have maximum efficiency.

The height of the Danko boiler has been slightly reduced. This allows the structure to be positioned at the level of the kitchen furniture.

The company's developers are constantly improving the technical parameters. The new boilers boast better draft, allowing for better removal of combustion products. In addition, devices are now warmed up much faster, and less fuel is consumed. The heat exchanger is very reliable.

Ukrainian-made gas boilers are specially designed for operation in domestic conditions. Judging by the reviews of the owners, the cost and high quality are the main advantages of these boilers.

Benefits

- The assembly is carried out in accordance with European technologies.

- Good technical characteristics - the manufacturer reaches a high level of efficiency and economy due to innovative technologies used in production.

- It works stably and without noise.

- Can be used in a heating system without forced circulation - it works non-volatile.

- Simple installation - you can handle it yourself, without the help of specialists.

- The kit includes instructions explaining how to light the device, how to connect it to the heating system, how to carry out repairs and maintenance, as well as other useful information.

- Equipped with reliable automation that ensures the safety of the equipment.

- The coil is made of copper. Water heats up quickly.

- The heat exchanger is made of steel. It is characterized by high heat dissipation.

- Three years warranty. Cast iron work on average 25, steel - 15 years.

User's manual

After starting the boiler, before the heating system warms up, condensate collects on the walls of the combustion chamber, which begins to drain into the furnace and the main burner on the bottom.

In this case, the temperature of the coolant should be increased to 70C in this mode, the condensation process will stop. It is also not allowed to take water for hot water supply from the heating system.

During the operation of the boiler, the temperature of the coolant and its pressure are monitored. It is necessary to periodically check the vacuum in the boiler and the combustion quality of the nozzle.

For long-term trouble-free operation of the boiler unit, a water purification filter is placed in the device before supplying the network to the device, and from time to time the heating circuit is rinsed with clean tap water.

The boiler operates in automatic mode. The user is only required to keep the body clean, fill and drain water from the system, and start the boiler if necessary.

The temperature is adjusted in operating mode, according to the user's own feelings. The boiler is started either with the help of a piezo ignition system, or manually according to the principle of a gas stove. To turn on the boiler using piezo ignition, turn the knob to the ignition position.

The knob of the thermostat must be turned until it is aligned with the "asterisk" icon and at the same time it must be sunk all the way down.

Pressing the piezo ignition button several times, light the burner, but hold the thermostat knob for another 10-15 seconds. If the attempt is unsuccessful, repeat the procedure.

For maintenance and repair of the boiler, call a master from the service center. Unauthorized intervention in the structure will automatically void the warranty contract.

How to choose?

Boilers are divided into the following types:

- Double-circuit wall. Their main advantage is their low weight and compactness. Combustion chamber - any type. Ignition is electronic. The device is protected from water freezing, there is a self-diagnosis of malfunctions. Rated power 23.3 kW. The wall version is capable of heating an area up to 210 sq. Consumes 2.76 cubic meters. gas per hour. The capacity of the membrane tank is 6 liters.

- Double-circuit floor. In them, the developers provide for protective automation, which stops the operation of the device in the absence of fuel, with insufficient traction, when the flame is extinguished. The power varies between 20-40 kW, and the heated area is 180-360 square meters. A wide model range is represented by modifications with heat exchangers made of cast iron or steel. The floor-standing version costs from 10 to 20,000 rubles - depending on the power and the used automation.

- Parapet. Water heating is provided. There is a sealed chamber. Chimney execution. The parapet version has piezo ignition and automatic protection. Burners - microflame. Heats 60-140 sq. M.

- Steel flooring. Single or double circuit. The flue is vertical / horizontal. 8-24 kW. Area - 701-90 sq.

- Cast iron floorboards. Open combustion chamber. They are used in closed and open heating systems. The type of circulation is any, natural or forced. High heat dissipation of the cast iron heat exchanger. 16-50 kW. Area - 150-460 sq.

A little about production

Danko gas boilers are almost entirely manufactured using imported equipment - it is supplied from Japan, Finland, Denmark and other countries. This made it possible to improve the quality of products and make them more reliable and durable. The production involves modern assembly and metalworking machines, powder coating equipment, cutting equipment and much more. Most of the operations are automated, but some are done manually.

Danko boilers are presented in two categories:

- Floor standing models - a wide range of equipment with power from 8 to 96 kW;

- Parapet (wall) models - wall samples with closed combustion chambers with a capacity of 7 to 15 kW.

The manufacturer also manufactures additional equipment - these are thermostats, programmers, kits for converting Danko boilers to liquefied gas and water converters.

The lineup

The line is presented in five series:

- Wall mounted. Two modifications - 23 ZKE and 23 BKE. Double-circuit modifications.Each circuit has its own heat exchanger. For heating - copper, for hot water - steel.

- Parapet. 8 modifications - 7, 10, 12.5 and 15.5 kW. They are distinguished by their compactness. Single-circuit. No smoke. Can be installed in apartments with an area of 140 sq. M. The heat exchanger is made of steel.

- Steel. 22 models differ in power, number of circuits and location of chimneys.

- Cast iron. All have an open cell. Cast iron radiators last about 25 years.

- With a pump. 4 modifications. They work for space heating and hot water heating. Steel heat exchangers. Related security systems.

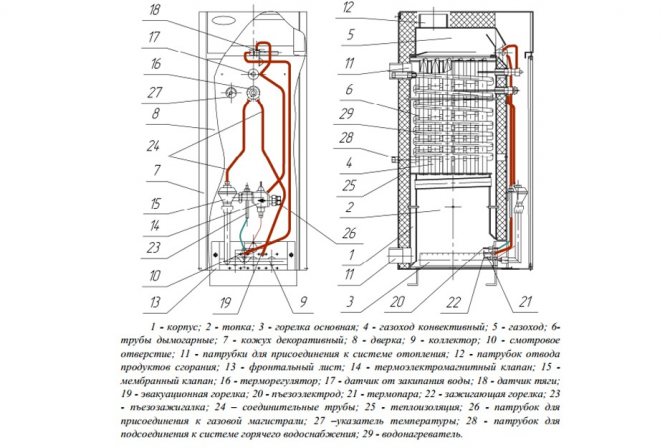

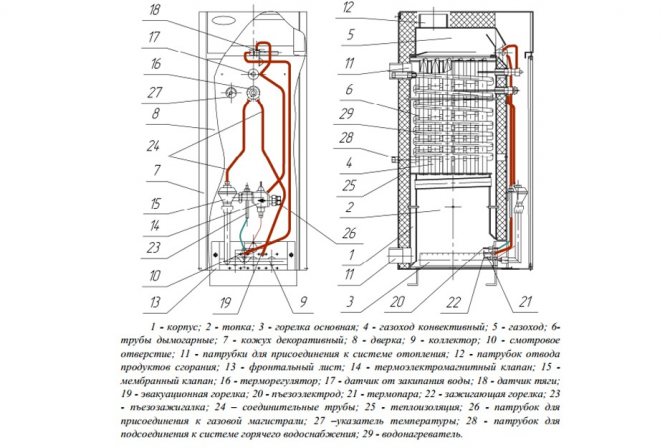

Boiler device on the example of Danko 10/12

The model has a built-in water heater - it can be used for heating a private house and heating hot water. Exterior - rectangular cabinet. The facade is equipped with a door that closes and opens access to the elements responsible for ignition. Consists of:

- burners;

- heat exchanger;

- gas automation;

- decorative casing.

The automatic unit is responsible for supplying fuel to the burners - the main and igniting ones, and for adjusting the water temperature. The gas supply stops immediately if:

- the flame is extinguished;

- gas pressure has become below the permissible value;

- there is no draft in the chimney;

- the coolant temperature has reached 90 ° C.

Double-circuit modifications consist of structural elements:

- chimney channel;

- blower fan;

- gas burner;

- heat exchangers - primary and secondary;

- hydraulic unit;

- connecting fittings;

- pump for forced circulation of water;

- expansion tank;

- an automation unit that controls the units of the apparatus.

A distinctive feature is that all components are produced by European companies. This is a plus in favor of the reliability and economy of Danko brand products.

Ignition

On the eve of starting the unit into operation, you need to fill the heating system with a coolant, preferably soft water. After that, T is brought several times to 90 C in order to maximize the release of dissolved oxygen from it.

Filling is carried out very slowly without interruption in order to prevent the formation of air pockets in the network.

We offer you to familiarize yourself with Electrode heating boiler for a private house

The order of ignition of the Danko boiler unit:

- Check the draft in the chimney system and the absence of gas pollution in the room.

- Air the furnace for at least 10 minutes, the valve at the entrance to the boiler must be closed.

- Check the pressure of the gas fuel in front of the boiler - less than 3000 Pa.

- With the help of the automatic system "KARE" with the boiler valve closed on the gas pipeline, turn the handle of the temperature sensor until it stops counterclockwise.

- The gas cock was opened.

- Press the start button of the thermoelectric valve and hold it down, press the piezo button until the burner starts to burn steadily.

- The water is heated to 80C, while the pressure in the water network is monitored, the quality of the burner is checked, the torch should be bluish.

Additional systems

In the device of gas heaters, the manufacturer additionally provided:

- water temperature sensors - triggered when boiling, turning off the system;

- a protective block that cuts off the gas supply when the wick decays;

- a block that stops the operation of the equipment in the absence of traction;

- traction control unit - for adjusting the flame;

- multidimensional protection block - disables the device in case of any type of threat;

- intelligent block - for the distribution of fluid flows.

Major problems

The main malfunction of the Danko floor-standing gas boiler is the spontaneous damping of the burner.

It can be caused by various reasons:

- Stopping the gas supply (in the main line, or simply forgot to open the gas valve on the boiler itself).

- There were problems with the gas equipment - breakdown of automation, failure of the gas valve, and other problems.

- Back draft in the chimney, strong wind or drafts inside the building.

If the gas supply is interrupted, contact the gas service for the necessary information. If problems arise with the gas equipment, you must call the master from the service center, which has permission to do such work.

Dealing with drafts or reverse thrust is more difficult, since they are often caused by external causes that cannot be influenced. In any case, it is necessary to ensure high-quality and stable air exchange in the room, to exclude drafts and a sharp change in the direction of air flows.

You also need to monitor the condition of the chimney and promptly clean it from soot and soot.

Potential malfunctions in the boiler unit and methods for their elimination are described in the instruction manual included in the delivery. List of probable defects. Why the boiler may not turn off and the methods of correction are included in a special table.

We suggest that you familiarize yourself with How to attach a boiler room to a house with your own hands

The wick goes out

For boilers equipped with “SIT” automatics, when, when the boiler is fired up, the pilot burner goes out, and restarting does not give results, then one of the probable reasons for the failure is poor contact of the power terminals and the primary draft sensor.

To eliminate the failure, you need to disconnect the connection from the sensor, carefully tighten the terminal, after having cleaned the contacts, connect the wire and restart the burner.

Reasons why the burner may go out:

- Gas outlet to the boiler unit is closed.

- Low gas pressure in the network.

- Airiness of the pipe section in front of the boiler.

To purge the gas pipeline, you need to press the button on the gas shutoff valve and hold it for 60 seconds, after which the device is restarted.

If the pilot burner goes out after the user releases the start button or the igniter fails to ignite, check the operation of the thermocouple, which may be outside the combustion zone or there is a leak in the thermocouple junction at the thermoelement inlet.

In this case, it will be necessary to adjust the position of the thermocouple in relation to the pilot burner flame, it must wash at least 4 mm of the thermocouple sensor.

To do this, clean the connection point of the thermocouple with the thermoelement, tighten the nut manually to the stop and press it by 1/4 of a turn with a gas wrench.

Installation

It is necessary to take into account the rules for installing gas equipment:

- The power is selected according to the heating.

- There must be at least 25 cm between the body, installed on a fire-resistant horizontal platform, and a non-combustible wall.

- The apparatus can be placed near non-combustible walls if they are sheathed with steel sheet.

- The width of the passage in front of the facade is from 1 m.

- To improve the circulation of water, the installation should be carried out below the level of the heating devices.

- The expansion tank is located at the very top of the system.

- The minimum chimney length is 5 m.

- By placing the chimney outside, it has to be insulated.

- The diameter of the flue gas outlet must be larger than the diameter of the flue gas outlet.

- At the junction of the boiler and chimney, it is necessary to seal with a solution of cement or clay.

Boiler installation

Installation of Danko gas boilers and connection to the gas main is quite easy to carry out. For comfortable operation, the housing assumes left and right connections. When installing, it is very important to follow the following expert advice:

- Gas supply is regulated manually by means of automatic equipment. To increase the power of the unit, set the required mode using a rotating wheel.

- Wall mounted gas boiler Danko is mounted using anchor bolts. During operation, the maximum weight of the device is 80-100 kg. It turns out that the fasteners must be very reliable in order to withstand such a load.With the correct installation of the boiler, possible excessive fuel consumption and other malfunctions can be excluded.

- To minimize gas consumption, an external temperature sensor can be used. The operation of the device consists in determining the ambient temperature, as well as auto-adjusting the specified mode of the boiler equipment. The temperature sensor works in this way: it records the ambient temperature and transmits information to the controller. Automation detects changes and introduces them to the specified temperature regime. As a result, the gas consumption becomes lower.

- Chimney - can be connected to a classic and coaxial smoke evacuation system.

Fire safety requirements for the installation of parapet devices are not as high as for atmospheric models. Therefore, it is recommended to install models with a closed combustion chamber in apartments.

The article described all the distinctive features of the brand's heating devices, the installation of boilers, considered their possible malfunctions of work: why the Danko gas boiler goes out, fades out and takes a lot of fuel. Take note of the recommendations of experts, reviews of the owners, and the heating unit will serve you for a long time.

Operation and maintenance

Commissioning is possible after acceptance by gas service representatives. The installation diagram is attached to the instructions. Installation is quite simple, but it is better to trust specialists. Gas workers who take the device into operation are instructed accordingly. The modification is selected according to the project carried out by the gas service, in which the power of the apparatus and its type must be noted. Safety regulations:

- The device can be serviced by those who have listened to the instruction.

- In the event of a breakdown, immediately close the taps.

- If you smell gas, close the valve, open windows and call the gas workers.

- Keep the device clean and in good working order.

- Clean the chimney as often as instructed in the instructions.

- Check that the system is full on a weekly basis - if there is water in the expansion tank.

- At the end of the service life of the device specified by the manufacturer, invite a specialist for advice - whether it can be further used.

How to light a Danko gas boiler

Designation of boiler control elements.

- Turn the mechanical temperature regulator counterclockwise until it stops.

- Make sure that the valve on the gas inlet is open.

- Press and hold the start button, then press and release the piezo button (it may take several clicks, repeat until the ignition burner lights up). Hold the start button for at least 30 seconds until the burner extinguishes when released. If the boiler has not been previously adjusted, it may be necessary to adjust the air flow by turning the nut on the ignition burner until the burner flame turns blue.

- Turn the knob of the thermostat clockwise until the main burner turns on, then set the desired power.

The start-up process is slightly different for complete sets with different automatics, the algorithm is described in detail in the operating instructions, an electronic copy of which is attached in the description of each model on the official website.

What are the problems?

The simplicity of Danko's design allows its owners to independently carry out minor repairs. One of the most common problems is blowing out the burner. This is especially common in strong winds. Usually no malfunction is found, the wind is the culprit of the problem, but it is better to check the following points:

- Is there a non-return valve installed in the flue. If not, then there will be no reverse thrust, which is why attenuation occurs.

- If the chimney is installed incorrectly, it becomes clogged with soot and other combustion products - it must be cleaned.

It happens that an extraneous noise is heard before attenuation or an increased fuel consumption is observed - this may indicate a failure of the controller. The task is to repair or change a spare part.

Important! If you do not want to face the damping of the flame, choose not a single-circuit, but a double-circuit boiler - wall-mounted or floor-standing. 2-contour models have no such disadvantages.

Another common problem is ignition fading. It goes out due to the operation of the thermostat, which shuts off the gas supply if the burner does not heat up to the desired temperature.

Owner reviews of Danko gas boilers: advantages and disadvantages

| Benefits | disadvantages |

| Affordable, not high cost | Noisy operation, especially in comparison with models of foreign manufacturers |

| Reliability - in practice, cases of work for more than 8, 12 and even 15 years are not uncommon | Modifications with a horizontal flue suggest the possibility of flame damping in strong winds |

| High technical characteristics and efficiency | The need for regular cleaning and maintenance (at least annually). In the absence of cleaning, problems with the automation are possible |

| Energy independence - the equipment works regardless of the availability of electricity. | According to the owners' reviews, double-circuit models, with high water consumption, do not always cope with its heating |

| Efficiency - in models with a power of up to 20 kW, gas consumption is in the range of 0.8-1.7 cubic meters. m / hour | |

| The range includes models with a cast iron heat exchanger, which has a service life of more than 25 years. In other models it is made of stainless steel | |

| Due to the simplicity of design and automation, they are easy to use |

Model overview

Danko-8 S

A new improved model, which, unlike previous versions, has a vertical chimney. The heat exchanger also has an improved design. The tubular radiator is made of 3 mm thick steel. Thanks to design changes, the developers have achieved:

- reduction in size;

- acceleration of warming up;

- simplifying the connection of the chimney;

- improved traction;

- increasing efficiency.

Single-circuit. Outdoor type. Open combustion chamber. Designed for heating a room of 70 sq. M. Specifications:

- Thermal power - 8 kW

- Efficiency - 92%

- Weight - 50.5 kg.

Installed imported safety automation. Also, imported low-flame injection-type burners are used - they are made of stainless steel. The flame remains stable even if the pressure in the pipes drops to 635 Pa.

18 sun

Single-circuit option. Outdoor installation. Open camera. 18 kW. The efficiency is 92%. Heats up to 179 sq. M. Weighs 66 kg. The Evrosit automatics were used.

16 HP

Single-circuit floor-standing device. 16 kW. Open type combustion chamber. There is no auto-ignition. Consumption - 1.9 m3 / h. The modification is quite weighty - 97 kg. Efficiency 90%. Heats water up to 90 ° C.

Popular models

Gas steel boiler Danko-12

The Danko 12C floor-standing boiler with a thermal power of 12 kW is in demand on the market. It is made of steel. It is intended only for heating. Has Eurosit gas automatics. In modern conditions of gas supply, this energy-saving unit perfectly meets the requirements of consumers.

Consider the technical characteristics of the Danko 12C gas boiler.

| Power | 12 kWt |

| Heated area | 110 m² |

| Maximum coolant temperature | 90 ° C |

| Recommended heating medium temperature | 60-80 ° C |

| Nominal gas consumption | 1.4 m³ / h |

| Connection of pipes to the heating system | 50 mm |

| Connection to the gas supply system | 15 mm |

| Nominal pressure of natural gas | 1274 Pa |

| Overall dimensions of the boiler HxWxD | 850x297x497 mm |

| Chimney diameter | 110 mm |

| Efficiency | 92% |

| Boiler weight | 57 kg |

Equipment for heating and heating hot water - double-circuit gas boiler Danko 10UVS. The model is distinguished by its new wall-mounted boilers with mechanical control.The power of the device is 10 kW, which can easily heat an area of 100 m². The efficiency is 90%, the consumption of natural gas is up to 1.2 m³ / h. The unit has a minimum number of control elements and is made in a neat rectangular case. The kit includes a chimney. The control does not cause difficulties - it is enough to set fire to the igniter and set the required level of heating. The boiler is supplied with detailed start-up instructions.

Double-circuit gas boiler Danko-10

Technical characteristics of Danko 10UVS.

| Power | 10 kW |

| Heated area | 100 m² |

| Max. hot water outlet (at dt = 35 ° С) | 220 l / h |

| Gas consumption (max. In continuous mode) | 1.2 m³ / h |

| Gas supply automation | Sit (Eurosit, Italy) |

| Working pressure in the heating system | 0.1 MPa |

| Hot water connection | DN 15 mm |

| Nominal pressure of natural gas | 1764 Pa |

| Overall dimensions of the boiler HxWxD | 690х540х320 mm |

| Chimney diameter | 240 mm (270 mm) |

| Efficiency | 90% |

| Supply and return connection | DN 40 mm (left and right) |

Another popular model is the Danko 15C / CP single-circuit gas boiler with a capacity of 15 kW. Designed for heating residential and other premises with a total area of up to 140 m². They have a steel structure and a vertical flue. The main welded tubular heat exchanger is made of high quality steel with a thickness of 3 mm. In modern conditions of gas supply, an economical Ukrainian-made boiler perfectly satisfies the needs of users. By installing a circulation pump, a more uniform heating of the heating system is achieved, therefore, a comfortable room temperature is provided with less gas consumption.

Single-circuit gas boiler Danko-15 С / СР

Technical characteristics of Danko 15С / СР.

| Power | 15 kWt |

| Gas supply automation | Sit (Eurosit, Italy) |

| Heated area | up to 140 m² |

| Nominal gas consumption | 1.7 m³ / h |

| Efficiency | 92% |

| Temperature control range | 60 - 90 ° C |

| Heating circuit operating pressure | 0.2 - 1.9 bar |

| Chimney diameter | 125 mm |

| Gas supply pipe diameter | 1/2″ |

| Diameters of pipes of the heating system | 1 1/4″ |

| Overall dimensions of the boiler HxWxD | 850x405x540 mm |

| The weight | 71 kg |