Connection diagrams

Before you install a heating radiator yourself, decide on the method of connecting it to the network. The most commonly used schemes are:

- Lateral (one-sided) installation diagram of heating radiators, in which the pipe supplying the hot coolant is connected to the upper branch pipe of the heater. The outlet pipe joins the lower one. This ensures high heat transfer. When connected the other way around, when the supply pipe is connected from below and the outlet pipe is connected from above, the heat transfer is significantly reduced. This connection in a one-pipe system requires the installation of a jumper to facilitate the operation of the system.

- Second, the diagonal connection of the heating radiator is as follows. The pipe supplying the hot coolant is connected to the upper branch pipe of the battery, and the "return" is connected at the bottom, on the opposite side of the heating device. Such a connection is advisable if the battery is long and has a large number of sections. Diagonal design guarantees maximum heat dissipation. But if the supply pipe is connected from below, and the outlet pipe is connected from above, the heat transfer will decrease by 6-10%.

- The last method - connecting the heating radiators from the bottom - is used when the consumer wants to hide the heating pipes in the wall, in the floor or near its surface. With it, the straight and return pipes are connected from the bottom of the radiator, but from different sides of it. Such a connection scheme (otherwise called "Leningrad") is characterized by aesthetics, as well as low heat transfer. Heat losses are up to 15%.

You can ask experts how much it costs to install a heating radiator, and, perhaps, agree to their services. Experienced craftsmen will tell you which connection scheme to choose, and what auxiliary elements are needed for installation.

To do this, first, the coolant is drained from one radiator, which changes if it can be localized by closing the valves at the inlet; or from the entire one-pipe system. When carrying out work in an apartment building, you should contact the housing office so that its employees drain the water from the riser on which the replacement is being made. After that, you can remove the old radiator.

To install a heating radiator yourself, you must first install shut-off and control equipment on it.

After installation, the connections need to be crimped.

Having familiarized yourself with how to properly install heating radiators, you should think about whether you need to do this work yourself. If you do not have the skills to install heating devices, it is better to hire professionals, having previously found out the prices for the installation of heating radiators in the village where they will be installed.

From all of the above, it follows that the installation of heating batteries can be quite simple if you initially prepare well for it and study all the instructions attached to the device. After completing all the procedures in the established sequence, the heating system will be durable and will last for more than a decade.

- How to pour water into an open and closed heating system?

- Popular floor-standing gas boiler of Russian production

- How to properly bleed air from a heating radiator?

- Expansion tank for closed-type heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

2016–2017 - Leading portal for heating. All rights reserved and protected by law

Copying of site materials is prohibited. Any copyright infringement entails legal liability. Contacts

Independent assembly of sections

It is often necessary to add or replace part of the sections in the battery. Mark in advance which specific segments are to be replaced and prepare the instruments.

You will need a radiator wrench, and nipples and gaskets (hollow elements with left or right double-sided threads).

- Lay out the sections on a flat surface (preferably on the floor) with the right side to your side.

- Remove the end holes from the plugs.

- Place the gasket over the non-threaded part of the nipple.

- Gently screw the nipple two to three turns into the manifold.

- Using light pressure, align the nut with the hole of the segment to be connected.

- Tighten the nipple with a wrench. The multidirectional threads will pull both battery sections together. With correct tightening, the gasket will reliably compress at the joint to the desired limit.

- The lower and upper nuts must be tightened by the same number of turns in turn. Then you will avoid distortions.

- Before installing the radiator in the heating system, make sure the tightness of the joints by letting water through the hose into the radiator. The joints must be dry.

Electrical heating installation recommendations

If you are doing electric heating in your home for the first time, it will be useful to know some features:

- all work must be done with the electricity off;

- an air vent must be installed on each radiator - this will help you get rid of air congestion during operation;

- expansion tank - the highest point in the system, usually installed in the attic or above the boiler;

- since an electric boiler cannot do without electricity, it would be good to get a generator in case of an unexpected power outage, it is especially necessary in those houses where there are frequent outages;

- before the first start, you need to power the system and check the connections for leaks; then all electrical appliances can be connected.

In general, the electric heating system is quite simple to install and use and is a good choice for country houses.

from 2000

Installation of a heating system in the house.

In a private house, it is advisable to think over the heating system in advance, even at the stages of design and construction of the house. When installing a boiler room, as well as when laying out a heating system, this can bring significant benefits to you.

It is possible to foresee in advance a variety of technical niches intended for collectors, risers; it is advisable to use a separate room for the boiler room. It is possible to find a way out of any situation with minimal losses thanks to modern technologies. This is beneficial provided that the house has already been built.

To start work on the installation of heating systems in the house, an important condition must be fulfilled - windows must be installed in the house, and a roof must also be arranged. In the modern world, heating pipes must be laid with hidden wiring, that is, in special grooves or in the floor.

It is advisable to lay pipes on the floor in a screed. If this is not possible, pipes can be laid directly in the walls. Very often, wall laying is used in houses on the second floor, where most often the floor is wooden.

The installation of heating in the country house must be carried out until the moment when the screed is poured, the walls must already be plastered. The radiators should be hung up to the plaster, as often the radiators have to be leveled, and for this you will have to pick out the plaster and correct the conclusions.Many owners of private houses use heating installation, which is carried out in two stages: at the first stage, pipe outlets are carried out with a margin, at the second stage, plaster is made, radiators are hung and connected. This method of installation takes much longer.

For maximum accuracy, it is advisable to use a specific technology. The radiators should be hung first, the film should not be removed from the radiators, it should remain in place until the heating system is started. When making conclusions to radiators from the walls, it is necessary to outline the boundaries of the strobes in advance, only after that it is necessary to remove the radiators and grind them. After the complete preparation of the strobes, you need to hang the radiators, make a complete wiring of the heating pipes, connect them to the radiators.

Then it is necessary, using alabaster or a special solution, to fix the wiring at the exit points from the walls. Radiators can be removed after these solutions are completely dry. One important recommendation must be followed - radiators should be stored as far as possible from finishing work. Radiators should not be left at the repair site, as the film will not be able to protect them from damage and dirt.

Hidden wiring can be done even after finishing work is completed. Pipes can be run along the walls in a special box. This method is called "skirting board". Many Western pipe manufacturers already immediately offer a ready-made plinth wiring system, where absolutely all components and materials are thought out. But all this can be done by yourself. To do this, it will be enough to use a plastic box, similar to the one used for electrical wires.

It is advisable to conduct tee piping only along the walls, but at the same time you need to retreat about fifteen centimeters. In order to properly drain the system, slopes towards the taps were previously used. In modern systems, this method is completely optional.

The only requirement for piping is that there are no air pockets. If such a condition cannot be met, then an automatic air vent will need to be installed at the top point.

A bit of theory

Without going into the complexity of physical processes, let's try to simply describe any heating system.

It looks like a closed circle of highways along which the coolant moves. Usually it is water, less often special liquids or steam. Accordingly, the system has:

- device that heats water at the beginning of the cycle

- coolant pipeline

- devices that transfer heat from the system to heated rooms

Giving off heat due to heat transfer and cooling in this way, the coolant returns back to the heater. Here it is reheated and the whole cycle repeats. And so many times.

Wood, coal, peat, gas, fuel oil and others can be used as fuel.

Other types of gaskets

In the photo there are silicone seals.

Less commonly used, but no less effective seals, just like those described above, are suitable not only for domestic purposes.

The modern radiator intersection gasket is not destroyed even when exposed to aggressive substances.

- Silicone accessories can withstand quite high temperatures. Due to their good ductility, they successfully compensate for the expansion of metal sections under the influence of heat. Most often found in systems with low pressures and loads.

- Fluoroplastic analogues are made from heat-resistant polymers. They do not require additional lubricants and do not react to hot water or antifreeze.

- Cardboard gaskets are also in demand.They are impregnated with oil paint to enhance their service life and positive properties. More often, the instruction recommends installing them in the spaces between the sections in bimetallic and aluminum batteries.

Choosing a heating system for your home

The issue of choosing a heating system was determined initially. You can, of course, practice your eloquence about creating energy-saving systems that are fashionable today, solar panels, wind generators or something else. But if we seriously talk about creating a working system with your own hands that gives enough heat for your home, then you need to discard fantasies and get to work.

The main and most affordable type of fuel is gas, which is both cheaper and more efficient than others. Therefore, if there is gas, it is necessary to unambiguously choose a heating system that runs on this fuel. If it is not there, then you have to think about other options.

In fact, all modern systems are similar to each other and differ only in the type of fuel, coolant, the method of laying the lines and the type of connection of heating devices. And, of course, we will talk about an autonomous system that is not connected with centralized communications (city, from the boiler room and others).

And one more detail. You need to decide whether you will only heat the premises, or you will still need hot water supply. In the first case, a single-circuit boiler is needed, in the second, a double-circuit one.

Consider an autonomous water heating system with a double-circuit boiler that runs on natural gas.

Selection of gaskets by purpose

When choosing gaskets for connecting sections, so that they meet the following requirements:

- The material should adhere microscopically as closely as possible to the surfaces that it seals.

- Products must be resistant to corrosion and chemical attack.

- Resistance to pressure and temperature of the working medium is required.

It is better to buy these products and all components immediately upon purchasing a radiator.

The intersectional radiator gasket serves as a sealing element in these heaters. It prevents leaks at the joining points of the sections, thereby extending the battery life and improving the quality of heating.

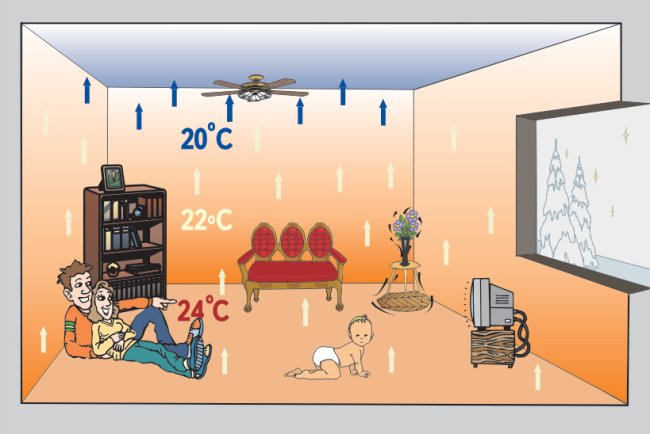

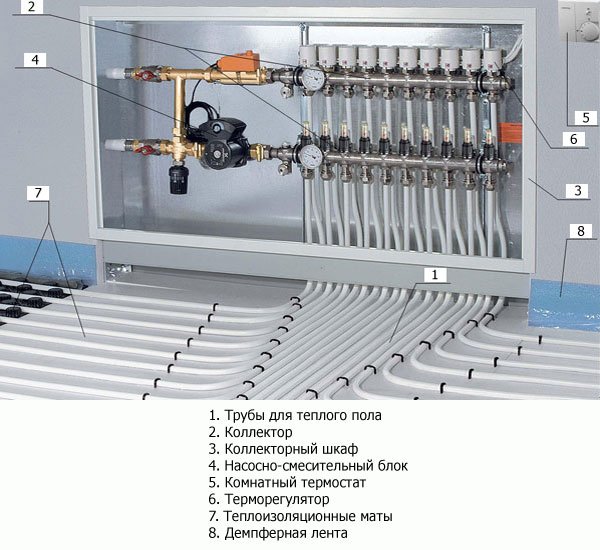

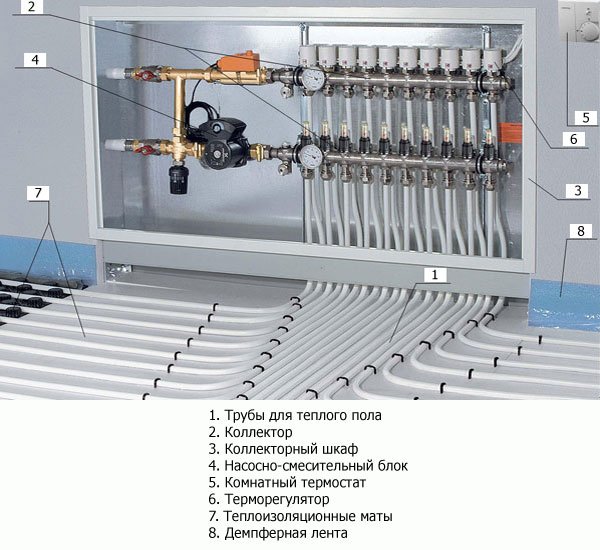

Installation of warm water floors

Underfloor heating allows you to evenly distribute heat energy and achieve significant savings. Click to enlarge.

Water underfloor heating implies the use of a heated coolant as the main source of thermal energy, which heats the room by passing through pipes laid in the floor.

Warm water floors are most commonly found in country houses. This situation is due to a number of good reasons.

Firstly, it is forbidden to install underfloor heating in an apartment connected to a central heating system due to the threat of an increase in hydraulic resistance.

Secondly, you should not make a connection to the pipelines of the hot water supply system, since the water, after passing through the underfloor heating system, returns to the common hot water supply riser already cooled.

Thus, in a city apartment, it is most advisable to use an electric warm floor, and in a country house - a water one. Water heating of warm floors should be used exclusively in insulated buildings and premises.

It is not necessary to carry out preliminary waterproofing work (most component manufacturers do not insist on this procedure).

Varieties of water floors

Underfloor water heating can be of the following types:

- Concrete.

- Floor-standing.

The first option involves laying a water floor using a concrete screed, the second - without laying a screed.

Flooring floors can be installed on aluminum plates through a polystyrene spacer (polystyrene system) or on a subfloor or logs (wood system).

In this article, we will dwell in detail on the sequence of installation of a concrete water floor, since it was he who received the greatest distribution and popularity.

Typical composition of a hot water heating system

Almost any heating system that includes a warm floor (water) is represented by the following main elements:

- Polymer or metal-polymer pipelines.

- Thermal insulation materials.

- Circulation pump.

- Shut-off valves (ball valves) and control valves (control valves).

- Collectors, fittings and fasteners.

The heating system, which performs an auxiliary function, can not only be assembled by hand, but also provides for an independent preliminary calculation.

The composition of the heating system. Click to enlarge.

In the case when the main source of heat is heating, represented exclusively by one water-heated floor, it is recommended to order the development of a design solution from specialized specialists.

Gaskets for heating radiators: varieties, problems, replacement method

The instruction divides seals for radiator sections into flat in shape and volumetric analogs required for different designs of interfaces.

- Flat seals are made of sheet materials (paronite, rubber, leather, plastic) using a punching method using dies, punching knives. Cutting with lasers and circular knives is also used.

- A volumetric gasket for a cast-iron radiator and analogues made of other metals is made using thermoforming from polyvinyl chloride or vulcanization from raw silicone and rubber.

Stamping machine.

The price of the stamps themselves is high - these are complex devices that consist of many elements made very precisely. In addition to them, a press is needed for work, a stamp is put on it.

Before the manufacturing process, the dimensions of the gasket are taken into account. The larger it is, the more massive the stamp, and the more powerful the press.

This method is similar to the previous one, but the tool is simpler and cheaper. The manufacturing process is inexpensive and fast. But the breeches do not last long, because of this, the method is optimal for the manufacture of medium and small batches of seals.

- This method is used to make large and only round spacers.

- This requires special equipment, it is relatively cheap and has high performance.

- Standard blades are used as cutting devices.

- The listed circumstances make it possible to produce seals with your own hands in any quantities.

Laser cutting

In this case, there is no need to purchase a special tool. On standard machines, gaskets of any shape can be produced.

This method could be one of the most profitable, if there is more than one drawback. Not all materials can be cut without problems with a laser. The only way out is to significantly reduce the cutting speed, which makes the process more expensive.

Thermoforming

Automatic thermoplastic.

This method requires a thermoplastic machine with a mold for molding products. The molding press is quite expensive. To "beat back" its cost, the production of thermoformed seals must be large-scale, serial or mass.

For small batches, the technology is advisable only when the gaskets cannot be produced in another way. It should be noted that only PVC products can be produced using this method.

Vulcanizing

Vulcanization of products is carried out on thermo-presses in special molds. Such forms are not as expensive as analogs for injection molding machines. This reduces the cost of products.

At the same time, the vulcanization technology itself is long-term, which affects the cost of production. However, it is impossible to obtain high-quality silicone and rubber gaskets in another way.

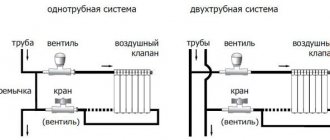

Types of heating systems

The level of heat supply directly depends on the type of heating system in an apartment or house. According to the pipe connection diagram, 3 types of systems can be distinguished: one-pipe, two-pipe system and using a collector.

Two-pipe system

A two-pipe heating system assumes the supply of hot coolant to each radiator separately (parallel connection), one pipe at a time. Thus, they all warm up to the same temperature. And the cooled liquid enters a separate return pipe and moves to the boiler for reheating. In this case, the rules for installing heating radiators are simplified. Indeed, for replacement, only one old radiator can be disconnected from the system.

Varieties of products

As a rule, all components are purchased with the purchase of the batteries themselves. In a hardware store, consultants are required to know which gaskets are specifically required for bimetallic radiators, and which ones are specifically needed for cast iron products. But usually the client only goes for spare parts. Based on this, it does not hurt to prepare in order to buy what you need.

Paronite elements

They are made from compressed rubber with additives of asbestos powders and fibers.

An intersectional radiator gasket of this type is much more often used in apartments with central heating.

- Remarkably withstands temperature conditions of + 85-100? ...

- The most popular is the product made according to GOST No. 15180-86. For the production used paronite PMB, PON-B and PC, and reinforced paronite.

- Products are made by cutting on a press or cutting with circular scissors and a plotter.

Non-specialized paronite gaskets

- Such seals are effective for pipelines with liquid and gaseous media.

Note! Such gaskets for cast iron heating radiators are used in pipes with water, steam, various solutions, and oils. They do not react to inert gases, ammonia in various states, alcohol, nitrogen, oxygen.

- They are calculated for temperatures from -50? up to +450 ?.

- They are supplied with PON-B and GOST markings No. 15180-86.

Oil-resistant analogs

- It is recommended for pipelines carrying oily liquids and gases.

- It is better to use them where there is a coolant, which is a technical oil, and oil products, hydrocarbons in a liquefied or gaseous state, molten wax, coke oven gas, nitrogen, oxygen.

- Temperature range from -50? up to +450 ?.

- Marked as PMB.

Acid Resistant Modified Rubber

- Keeps tightness in flange connections of pipelines carrying aggressive connections, for example, antifreeze.

- The gaskets work effectively when interacting with alkalis and acids, organic solvents and various gases.

- Can withstand -50? up to +250 ?.

- Supplied with PC brand.

Reinforced products

- The gasket for the cast-iron radiator equipped with a reinforcing mesh is mounted in the intersection space of household batteries as well.

- Steam, water, various gases, oily substances, the seal holds excellently.

- Temperature range -50? up to +450 ?.

- PA marked.

Some conclusions

The main conclusion from all that has been said is that a do-it-yourself heating system of a private house is a completely feasible task. To solve it, you just need to remember that:

- To implement the plan, it is required to observe the rules for carrying out work established by the norms. First of all, this concerns the project and various calculations.

- If you have a project, it is very easy to find the necessary equipment, and it is much easier and more efficient to carry out the work.

- The quality of work directly depends on adherence to technology. If you want to do everything yourself, it will take some time to study.

- Each stage of work should end with a check of the tightness and operability of the system.

- When carrying out hidden work, connections and pipelines should not be covered with finishing materials without checking them under pressure.

And finally. It is unlikely that it will be possible to delve into such a question in a couple of evenings, lying on the couch. But the gradual and systematic study of the installation of the heating system is within the power of everyone.

Each of us is trying to create the most convenient and comfortable environment in the house. After all, it is the house that is the place where we return after a hard and stressful working day, the place where relatives and friends are waiting for us. But it is very problematic to imagine comfort without warmth in the house. That is why the installation of heating in a private house, which our company offers, is such an urgent and demanded service that allows you to create a really warm and cozy atmosphere.

Criterias of choice

Thinking about what type of gasket to choose for cast-iron radiators, they initially take into account what material they are made of, then exact geometric dimensions will be required.

This information consists of:

- The size of the inner diameter of the gasket (d), mm;

- outer diameter size (D), mm;

- product thickness (S), mm.

It is necessary to pay attention to the fact that D / d must exactly correspond to the output data of the sectional connections. The edges of the gaskets must not protrude during installation, otherwise it may cause battery leakage.

List of common gasket placement failures:

- Lateral displacement of the seal is likely to occur during placement, especially when the thread line contains a deviation from the channel end surface.

- Paronite loses its elasticity during long-term operation in a high thermal environment. In this connection, intersectional seals form a leak after a certain number of heating / cooling cycles during the next cooling of the device.