Among the numerous equipment that is involved in the operation of underfloor heating systems, you can find a small device that plays an important role in the control and regulation of the heating system. This is a servo drive, an electromechanical device, without which automatic temperature control for a warm water floor is not possible.

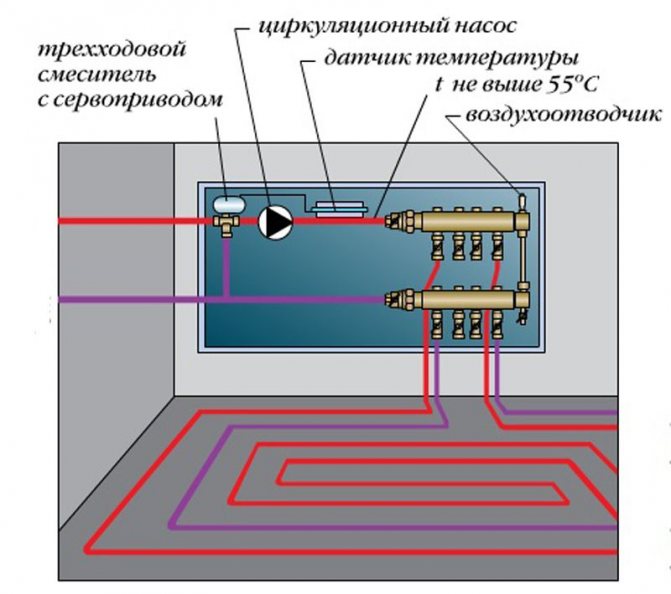

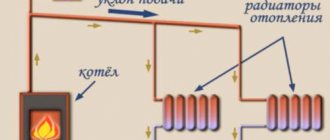

The device is based on an electrothermal reaction to a change in the heating temperature of the coolant in the main supply pipe and the subsequent mechanical action, which in the complex provides the opening or closing of the flow of hot water into the heating circuits. Servos or servomotors, officially in the language of professionals, the device is called an electrothermal servo drive, today they are present in almost all autonomous heating systems. New suburban residential buildings, cottages and summer cottages equipped with underfloor heating have underfloor heating, which is controlled by servo drives. It is the servo drive installed for the warm floor on the collector that performs the task of adjusting the coolant flow in the water floor heating system.

Existing types of servo drives today

Among the regulators existing today, which have become widespread in everyday life, the following servos are found. All devices can be divided into several types. Each variety has a different principle of action and functionality. By the type of construction, the devices are of two types:

- closed;

- open.

By the names you can judge the principle of action. Closed servos are characterized by an open position when there is no power supply. The incoming signal activates the mechanical part, blocking the access of water to the system. For open view devices, the principle of operation is in reverse. In the normal state, the servo is closed, only with the arrival of a signal, the mechanical part is activated, opening the flow of water into the pipeline. It is up to you to judge which type is best suited for domestic use, evaluating the capabilities of your own heating system and the climatic conditions outside the window. Normally open servos are most often used in our country.

On a note: if the device fails, the coolant in the pipeline continues to circulate, leaving the floor warm for a certain time. This feature is especially relevant for country houses located in a cold climatic zone.

According to the method of power supply, servomotors are divided into devices that are powered by a constant current of 24V and devices that are connected to a conventional 220V AC power supply. Servo drives with 24V supply are equipped with inverters.

Often, consumers use another, rather rare type of device. We are talking about devices that are set in a normal position, depending on the technological requirements of the heating system. Such servos are called general purpose servos and can change functionality from normally open to normally closed and vice versa.

All three types of servomotors can be connected to the manifold. The only condition is the correct setting, balancing and operating conditions of the heating system.

Criteria for choosing the type of servo

In this section we will try to answer the question. What is the basis for the choice of devices of one type or another.

If you decide to equip your heating system "warm water floor" with servo drives, take into account the operating parameters of your heating.In what position should the valve be most of the time. In a situation when for you a warm floor is the main option for heating living quarters, when hot coolant constantly enters the pipeline, rely on a normally open servomotor. This type is ideal for a long heating season.

On a note: in case of interruptions in the electrical supply, the failure of the device will not stop the circulation of warm water in the heating water circuits. The warm floor will continue to be supplied with a coolant with prepared water.

For regions with warm climates, a normal closed servomotor is suitable. If you are not afraid of defrosting the heating circuit, and you periodically turn on the floor heating, this device will quite cope with its functions.

Important! The servo drive for underfloor heating with smooth adjustment has an electronic type regulator. Such devices more accurately respond to changes in the temperature of the coolant flow, smoothly moving the stem to the required position. Infinitely variable servomotors are designed for underfloor heating, in which it is often necessary to dose the volume of the incoming flow.

In most cases, such devices are not used in home heating systems with underfloor heating. Therefore, when purchasing, pay attention to whether or not the installation of an electronic regulator is required for the device. If the instructions say that such equipment is necessary, then you are dealing with an electronic servo drive. Let's say right away that it is impractical and unprofitable to use such a device at home.

Be sure to read: how to make a water floor from a gas boiler?

Selection rules

The main thing to pay attention to when choosing a servo motor is its type and how compatible the device is with the thermostat. The best option is a universal device that copes well with the work of an open and closed servo.

The advantage of a universal device is that, if necessary, a specialist can replace a closed servo drive for a warm floor with an open one and vice versa. And there will be no difficulties during installation.

The quality of the device is also an important point. Experts advise not to buy a servo drive at points of sale that do not have special certificates. All devices must be accompanied by certain documents that guarantee quality. It is better to choose popular manufacturers that have won the trust of users.

The device and principle of operation of servomotors

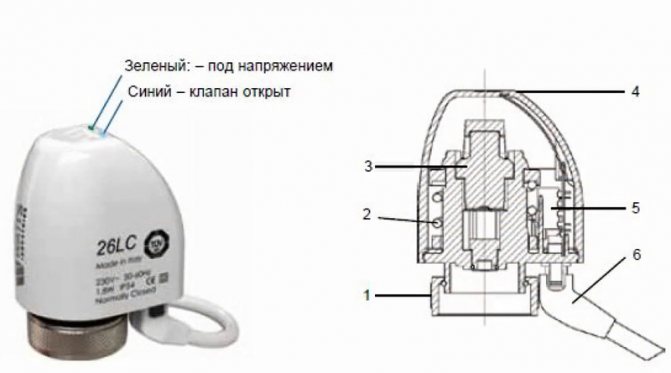

The main working element of the servo is the bellows. Those. same part as for 3-way valve. A small in size, sealed cylinder with an elastic body is filled with a substance that is sensitive to temperature. Depending on whether the temperature rises or falls, the volume of the substance changes accordingly. Figure - the diagram clearly demonstrates the structure of the servo motor, where the bellows occupies the main place.

The bellows is in close contact with the electrical heating element. Receiving a signal from the thermostat, the heating element is switched on from the mains and switched on in operation. Inside the bellows, the substance heats up and expands. Thus, the increased cylinder begins to press on the rod, changing its position and blocking the path of the coolant flow. Evaluating the work of the servo, we can conclude that the device is not equipped with any motors, there are no gears and transmission links in it. The usual working relationship is "heat and electricity". Hence the common name for devices, thermoelectric controllers.

In order for the valve to open again, the whole process is repeated only in the opposite direction. Lack of power will cause the heating element to stop working.Consequently, the substance inside the cylinder cools down, decreasing in volume. The pressure on the stem decreases, it rises, acting on the valve, and, therefore, hot water access to the system opens.

On a note: the substance placed inside the cylinder is toluene, which has high thermodynamic characteristics. A nichrome thread acts as an electric heating element.

Having familiarized yourself with the principle of operation of the device, it is important to remember that a certain time is required for the mechanical action of the valve. Despite the fact that when a signal from the thermostat is received, the heating element begins to heat the substance inside the cylinder. The time required for changes in the physical state of the fluid is 2-3 minutes, so the valve is not activated immediately.

For reference: when choosing a servo drive model, pay attention to the parameters of the heating element and the heating time of the liquid indicated in the passport of the device.

Unlike heating, liquid cooling is slower. The reverse process, i.e. it will take not 2-3 minutes to close the valve, but 10-15 minutes. In case of overheating, each servomotor should automatically shut down. For this, an emergency shutdown mechanism is provided in the design.

For example: the servo drives used in the work of the collector group are not all equipped with cylinders and cylinders with a substance. There are models in which thermoelements play this role, resembling a spring or a plate, which are heated under the action of the same heating element. Expanding, these parts act, again, on the stem, ultimately bringing the valve into working condition. You can determine in what position the valve is located by changing the appearance of the servo. The pull-out element signals the operation of the device. If this does not happen, then your appliance is not connected correctly or the heating system is working intermittently.

For reference: a servo motor that is hot to the touch means that in this case the device is closed and turned off. If the device is cool to the touch, therefore, the valve is open, the coolant circulates normally through the water circuits of the warm floor.

In this article, I will show you how to understand the operation of 3-way valves and servos (electric actuators).

What is a valve?

Valve

Is a mechanism that serves to pass or not pass a liquid or gas from one space to another. Moreover, the valve can be open or closed by a certain percentage. That is, the valves can serve to regulate the passage of liquids or gases. The movement of liquid or gas is carried out by the pressure difference between the sides of the valve.

There are two most common types of valves in a heating system:

Saddle (saddle) type

- has a bushing and a volumetric body itself, which blocks the passage.

Ball (or rotary) type

- has a body, which, due to its rotation, leads to the opening or closing of the passage.

Ball valves have the highest flow capacity in relation to the seat type valve. That is, in ball valves, less hydraulic resistance is achieved.

Valves are:

Two-way valves

- have two connections on opposite sides of the valve. For example, they serve to pass a liquid or gas on one circuit. That is, they close or open one branch of the water supply or heating system.

Three-way valves

- They have three connections. Serves mainly for mixing or separating liquid or gas streams. The main work of the three-way valve is necessary either to obtain a certain temperature or to redirect flows. In heating systems, temperature control is needed to regulate the indoor climate.The redirection of flows usually serves to redirect the heated heating medium from the heating system to the indirect heating boiler. There are many other tasks as well ...

Four-way valves

- They have four connections. Do the same job as 3-way valves. But there may be other tasks as well.

Communication between servos and valves

In a heating system, there are several ways of interconnection between valves and valve control elements (servo and thermomechanics):

1. Thermostatic mixer

- usually called a mechanism that has both a valve and a device that changes the position of the valve in automatic mode. Varies depending on the temperature of the liquid or gas. This device has a mechanism that, under the influence of temperature, changes the elastic force and because of this, the valve moves. This valve does not require electricity, depending on the actuator. The temperature is adjusted by turning the knob. Typically some valves are designed for a small temperature range. Up to 60 degrees maximum. There may be exceptions from other manufacturers.

2. Ways to use individual elements without resorting to servos. For example, a thermostatic valve with a thermal head. There are thermal heads that have a remote sensor.

3. Valves and servos are separate elements. The servo is attached to the valve and adjusts the valve.

What is a Servo Drive?

Servo

Is a device that performs the work of valve movement. The valve, in turn, either passes or does not pass liquid or gas. Or it passes it in a certain amount, depending on the pressure, valve position and hydraulic resistance.

What kind of servos are there?

There are also thermal drives, which are also called servo drives.

Read more: Collector servo drive. Choice and rules of connection.

But in this article we will analyze only electric drives (servos)

Electric drives come in two directions:

A complete package (kit) is when a full set of functions is already embedded in the device. For example, the kit already has a temperature controller, an electric thermal sensor. It is possible to immediately adjust it to the desired temperature. Setting the test time for valve movement. It is connected directly to the AC 220 Volt with a frequency of 50 Hertz. Standard for Russia. It is possible to adjust it in different directions of the ball valve movement. It is possible to adjust it to rotate 90 or 180 degrees. Any value can be set, even 49 degrees or 125 degrees. And this is done inside a black box. Look for details in the instructions.

Such a servo drive makes ESBE 99K2 more: Three-way valve with servo ESBE

This I told you one of the options. Of course, there are a dozen other options ... Servos also differ in the speed of closing and opening valves. This example is used to continuously adjust the valve to mix flows of different temperatures in order to obtain a control temperature.

This option serves to redirect the coolant flows.

Read more about this: Three-way valve to redirect the flow of the heating medium

This option is used to redirect the heating agent flow from the boiler either to the direction of radiator heating or to heating the indirect heating boiler. The specified servo needs a 220 volt signal. Moreover, there are three contacts. One is common and the other two are for traffic redirection. The easiest option when you need to redirect the flows in the heating system on demand from the thermostat of the indirect heating boiler.

Servos are of the type of movement to a saddle valve type or to a ball (rotary) valve type.

If you are going to select a servo to a valve, be sure to check the type of movement of the servo. Also, the seated type of the servo is not always the same for all types of seated valves. With rotary ball valves, there seems to be a universal standard, but with globe valves, everything is not so simple. There is no one standard.

Electric drive as a separate link in automation.

Consider the analogue servo drive from Valtec art. VT.M106.R.024

Such a servo requires a constant 24 volt power supply and a 0 to 10 volt control signal.

That is, if the voltage is 0 Volts, then the swing mechanism is in the 0 degree position. If 5 volts then 45 degrees. If 10 Volts then 90 Degrees.

Such a servo drive is supplied with a signal from a special controller, which has the function of supplying a signal of 0-10 volts. Depending on the temperature and the temperature setting of the controller, the controller supplies a different voltage from 0 to 10 volts. There is a rotation setting: hourly and counterclockwise. Of course, in order to find more detailed information about the signals and the wiring diagram, ask the manufacturer for a passport with a detailed signal control diagram.

I will repeat ... What are indicated in this article, not all signals are described. There are many other signals ...

What is a controller?

Controller

- this device is designed to control signals for various logic tasks. The controller is the brain of an automatic system. It determines, depending on the program, which signals need to be given at this or that moment.

There are a variety of controllers that perform different tasks.

For a heating system, the following tasks are usually performed:

The most common task is to get the set temperature of the coolant.

Depending on the temperature, receive a signal (for example, turn off the boiler or pump). The controller may contain a contact relay. That is, dry contact. With this contact relay, signals can be set to receive any voltage. For example, 220 volts to turn on or off a pump or send a signal to a servo to redirect flows.

You can also use the controller to shutdown the boiler in cases of critical temperatures. The signal from the controller is sent to power the powerful contactors, which in turn power the powerful electric boilers.

The cheapest TPM series controller

Aries sells them a lot of interesting things you can pick up. owen.ru

The logic of the work is very extensive ... In the future I also plan to write and develop useful material on automation systems for heating and water supply systems. Record your E-mails to receive notifications about new articles.

| Like |

| Share this |

| Comments (1) (+) [Read / Add] |

A series of video tutorials on a private house

Part 1. Where to drill a well? Part 2. Arrangement of a well for water Part 3. Laying a pipeline from a well to a house Part 4. Automatic water supply

Water supply

Private house water supply. Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Pumping station of water supply How to choose a pump for a well? Setting the pressure switch Pressure switch electrical circuit Principle of operation of the accumulator Sewerage slope for 1 meter SNIP Connecting a heated towel rail

Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of a radial distribution of a heating system Diagram with a heat pump and a solid fuel boiler - logic of operation Three-way valve from valtec + thermal head with a remote sensor Why does the heating radiator in a multi-apartment building do not heat well? home How to connect a boiler to a boiler? Connection options and diagrams DHW recirculation.Principle of operation and calculation You do not correctly calculate the hydraulic arrow and collectors Manual hydraulic calculation of heating Calculation of a warm water floor and mixing units Three-way valve with a servo drive for DHW Calculations of DHW, BKN. We find the volume, power of the snake, warm-up time, etc.

Water supply and heating constructor

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servos and three-way valves work Three-way valve to redirect the flow of the heating medium

Heating

Calculation of the heat output of heating radiators Radiator section Overgrowth and deposits in pipes worsen the operation of the water supply and heating system New pumps work differently ... connect an expansion tank in the heating system? Boiler resistance Tichelman loop pipe diameter How to choose a pipe diameter for heating Heat transfer of a pipe Gravitational heating from a polypropylene pipe Why do they not like single-pipe heating? How to love her?

Heat regulators

Room thermostat - how it works

Mixing unit

What is a mixing unit? Types of mixing units for heating

System characteristics and parameters

Local hydraulic resistance. What is CCM? Throughput Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, DN and PN? Plumbers and engineers need to know these parameters! Hydraulic meanings, concepts and calculation of heating systems circuits Flow coefficient in a one-pipe heating system

Video

Heating Automatic temperature control Simple top-up of the heating system Heating technology. Walling. Underfloor heating Combimix pump and mixing unit Why choose underfloor heating? Water heat-insulated floor VALTEC. Video seminar Pipe for underfloor heating - what to choose? Warm water floor - theory, advantages and disadvantages Laying a warm water floor - theory and rules Warm floors in a wooden house. Dry warm floor. Warm Water Floor Pie - Theory and Calculation News to Plumbers and Plumbing Engineers Are you still doing the hack? First results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - orientation of the wall?

Regulations

Regulatory requirements for the design of boiler rooms Abbreviated designations

Terms and Definitions

Basement, basement, floor Boiler rooms

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial water pollution Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building? Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms divided according to their location?

Personal experiences of hydraulics and heat engineering

Introduction and acquaintance. Part 1 Hydraulic resistance of the thermostatic valve Hydraulic resistance of the filter flask

Video course Calculation programs

Technotronic8 - Hydraulic and thermal calculation software Auto-Snab 3D - Hydraulic calculation in 3D space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Hydraulic Calculation Tasks

Head loss in a straight pipe section How does head loss affect flow rate?

Miscellaneous

Do-it-yourself water supply of a private house Autonomous water supply Autonomous water supply scheme Automatic water supply scheme Private house water supply scheme

Privacy Policy

Installing the servo. Features and nuances

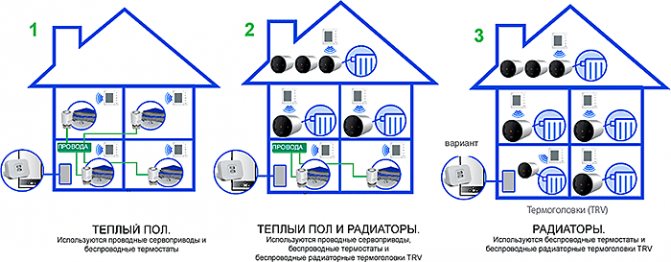

Before installing the servo, decide which type of thermostat the device will have to interact with. In cases where the thermostat controls the operation of one water circuit, both devices are directly connected with wires. When it comes to using a multi-zone thermostat, a device that serves several pipelines at once, the servo motors are connected as follows.

To correctly connect all the wires and terminals, a floor heating switch is used. The functions of this device include the connection and connection of devices for various purposes in a single circuit. In addition to the distribution and connecting function, the switch also plays the role of a fuse. In situations where all the shut-off valves of the water circuits are closed, the switch cuts off the power to the circulation pump.

The switch is very convenient when heated floors are powered by an automated autonomous gas boiler. The figure shows how thermostats and servo drives are connected to a single control system.

How to choose a servo drive for a warm floor?

From the point of view of an ordinary user, the main selection parameter will be the temperature range supported by the device. Even budget models operate in the range from 0 to 60 ºС, which is the optimal value to ensure a comfortable microclimate. You should also return to the question of how to connect a warm floor to the heating system so that it works correctly in the future. The quality of the connection depends on how correctly the adapter was chosen. In addition, the cross-section of the wire that feeds the collector system is also taken into account.

Servo mounting location, thermostatic valve to be mounted on the manifold.

Important! When the heating system is operating, underfloor heating from a solid fuel boiler, such a switch function as turning off the pump is fraught with stopping the heating device itself. Installing a bypass and a bypass valve will prevent you from stopping the pump and running the heater at idle.

Summarizing

The use of servo drives allows to achieve high flexibility in the regulation of the heating system. At the same time, the cost of such a device is low, and the ease of installation only adds to its popularity. Such a heating system will allow you to adequately and quickly respond to the slightest change in temperature in the house (see also the article “Heating Installation: Tips for Choosing Autonomous System Components”).

The video shows an example of installing a servo drive on a heating manifold.

Did you like the article? Subscribe to our channel Yandex.Zen

findings

It should be noted that thanks to the advent of modern devices and devices, the control and adjustment of underfloor heating has become an ordinary and simple process. The design of many devices used for the operation of heating circuits is not particularly complicated. The principle of operation of many components and assemblies is also clear. This can be said with certainty about servos as well. Most of the devices are reliable, practical and easy to use. Thanks to the servomotors, it became possible to fully automate the underfloor heating control system, to make the conditions for using heating equipment simple and understandable.

Choosing a simpler option, you can get by with the installation of conventional control valves. Automatic regulators, temperature sensors and servo drives, a category of devices that work for your comfort and safety.Installing additional devices such as a switch and a bypass valve will make your heating system as efficient and safe as possible.

Servo connection

Installation of a servo is easier than installing a water floor heating as such. Typically, such devices are mounted in any position that will be acceptable and convenient from the point of view of operation. Before installation, it is important to make sure that the fit thread matches the product-specific standard - this should be taken into account if the accessory was purchased separately. Now you can go directly to the question of how to connect a warm floor to the heating system, and with it the servo. Underfloor heating is introduced into the general heating infrastructure through the aforementioned manifold system, which also includes the regulator. The drive adapter must be screwed onto the valve, and then the regulator itself must be put on it so that the corresponding latches are triggered.