WITHThere is an opinion that gravitational heating is an anachronism in our computer age. But what if you built a house in an area where there is no electricity yet or the power supply is very intermittent? In this case, you will have to remember the old-fashioned way of organizing heating. Here's how to organize gravitational heating, and we'll talk in this article.

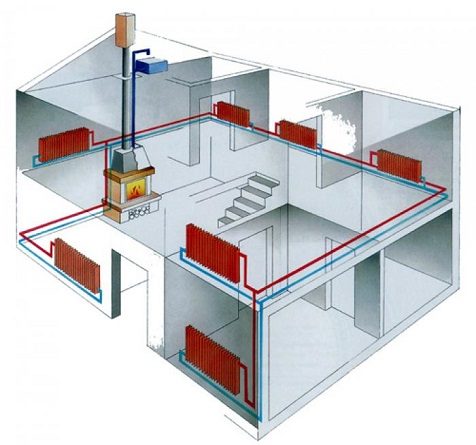

Gravity heating system

The gravitational heating system was invented in 1777 by the French physicist Bonneman and was designed to heat an incubator.

But only since 1818, the gravitational heating system has become ubiquitous in Europe, although so far only for greenhouses and greenhouses. In 1841, the Englishman Hood developed a method of thermal and hydraulic calculation of natural circulation systems. He was able to theoretically prove the proportionality of the circulation rates of the coolant to the square roots of the difference in the heights of the heating center and the cooling center, that is, the height difference between the boiler and the radiator. The natural circulation of the coolant in heating systems has been well studied and had a powerful theoretical foundation.

But with the advent of pumped heating systems, scientists' interest in the gravitational heating system has steadily faded away. Currently, gravitational heating is superficially illuminated in institute courses, which led to the illiteracy of specialists who install this heating system. It's a shame to say, but installers building gravitational heating mainly use the advice of "experienced" and those meager requirements that are set out in the regulatory documents. It is worth remembering that regulatory documents only dictate requirements and do not provide an explanation of the reasons for the appearance of a particular phenomenon. In this regard, among specialists there are a sufficient number of misconceptions, which I would like to dispel a little.

First meeting

Have you ever wondered what makes water flow through radiators?

In an apartment building, everything is clear: there circulation is created by a pressure difference between the supply and return pipelines of the heating main. It is clear that if the pressure is higher in one pipe and less in the other, the water will start moving in the circuit that closes them with each other.

In private houses, heating systems are often autonomous, using electricity or the heat of combustion of various types of fuel. In this case, the coolant is driven, as a rule, by a heating circulation pump - an impeller with a low-power (up to 100 watts) electric motor.

But electric pumps appeared much later than water heating. How did you manage without them before? Surely this experience can be used now ...

Once upon a time, boilers were not equipped with pumps. The heating, however, worked.

Natural circulation of heated water was used. Thermal expansion gives rise to the so-called convection: when heated, any substance decreases its density and is displaced by the surrounding denser masses upward. If we are talking about a closed volume - to its upper point.

If you create a contour of the appropriate shape, convection can be used to constantly move the coolant in it in a circle.

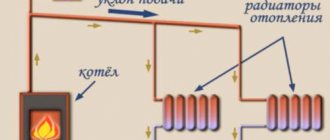

A system with natural circulation is, in simple terms, two communicating vessels connected by pipes (heating circuit) in a ring. The first vessel is a boiler, the second is a heating device.

Please note: to be precise in analogies, the first vessel where convection sets water in motion, it would be more correct to name the boiler together with the accelerating manifold - the vertical section of the circuit starting from the boiler. The greater the total height of this vessel, the greater the speed it will give to the rising coolant.

In the boiler, water, warmed up, rushes up. Nature abhors a void and is replaced by colder (and denser) radiator water. The hot coolant enters the radiator and cools down there, gradually sinking into its lower part and then for a second cycle into the boiler.

Several measures will speed up circulation in a closed system:

- The boiler is lowered as low as possible in relation to the heating devices. If possible, it is taken to the basement.

The circulation speed in the circuit linearly depends on the height H in the diagram.

- The booster manifold usually ends at the ceiling or even in the attic. An expansion tank for heating is installed there.

- A constant slope from the expansion tank towards the boiler will also promote circulation. The cooling water will move along the gravity vector all the way through the heating devices.

In addition, when designing such a heating system with your own hands, you need to understand one thing. The circulation rate is influenced by two interacting factors: the differential in the circuit and its hydraulic resistance.

What does the last parameter depend on?

- From the diameter of the filling... The larger it is, the easier it is for water to flow through the pipe.

- From the number of turns and bends of the contour... The more of them, the greater the resistance of the circuit to the flow. That is why they try to make the contour as close as possible to a straight line (as far as the shape of the building allows, of course).

- From the number and types of valves... Each valve, gate valve, check valve resists the flow of water.

Consequence: the shut-off valves themselves in the main heating circuit must have a gap in the open state that is as close as possible to the lumen of the pipe. If the circuit is opened by a valve, then only and exclusively with a modern ball valve. The narrow strokes and the complex shape of the screw valve will provide a much higher head loss.

When open, the ball valve has the same clearance as the pipe leading to it. The hydraulic resistance to water flow is minimal.

Typically gravity systems are made open, with a leaky expansion vessel. It not only accommodates the excess of the coolant when heated: air bubbles are displaced into it when the discharged system is filled. When the water level drops, it is simply refilled into the tank.

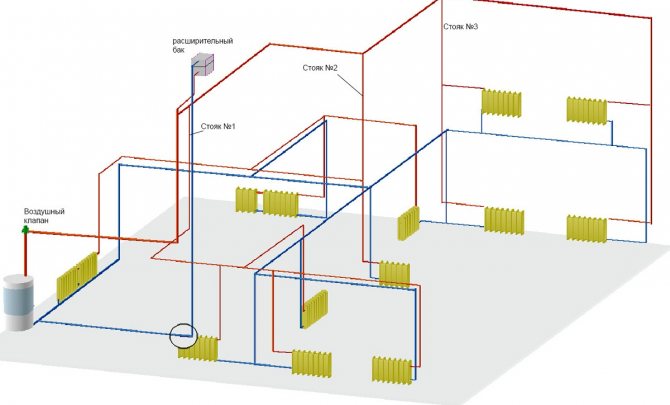

Classic two-pipe gravity heating

In order to understand the principle of operation of a gravitational heating system, consider an example of a classic two-pipe gravitational system, with the following initial data:

- the initial volume of the coolant in the system is 100 liters;

- height from the center of the boiler to the surface of the heated coolant in the tank H = 7 m;

- distance from the surface of the heated coolant in the tank to the center of the radiator of the second tier h1 = 3 m,

- distance to the center of the radiator of the first tier h2 = 6 m.

- The temperature at the outlet from the boiler is 90 ° C, at the inlet to the boiler - 70 ° C.

The effective circulating pressure for the second-tier radiator can be determined by the formula:

Δp2 = (ρ2 - ρ1) g (H - h1) = (977 - 965) 9.8 (7 - 3) = 470.4 Pa.

For the radiator of the first tier, it will be:

Δp1 = (ρ2 - ρ1) g (H - h1) = (977 - 965) 9.8 (7 - 6) = 117.6 Pa.

To make the calculation more accurate, it is necessary to take into account the cooling of water in the pipelines.

Advantages and disadvantages

Benefits of a gravitational heating system:

- high reliability and fault tolerance of the system.A minimum of uncomplicated equipment, durable and reliable materials, wear elements (valves) rarely fail and are replaced without problems;

- durability. Time-tested - such systems have been operating for half a century without repair or even maintenance;

- energy independence, because of which, in fact, gravitational heating systems are still popular. In areas without power supply or where it is often disrupted, only stove heating can be an alternative to gravitational heating;

- simplicity of the system design, its installation and further operation.

Disadvantages of a gravitational heating system:

- high thermal inertia. A large amount of coolant requires a significant time to warm it up and fill all radiators with hot water;

- uneven heating. As it moves through the pipes, the water cools down and the temperature difference between the batteries is significant, and, accordingly, the temperature in the rooms. You can compensate for this disadvantage by installing a circulation pump with parallel connection, if the house has electricity, and use the pump as needed;

- large length of pipelines. The longer the pipeline, the greater the pressure drop in it;

- high price. Large pipe diameters result in high system consumables costs. Although large diameter pipes are also a source of heat;

- high probability of defrosting the system. Some of the pipes run through unheated rooms: the attic and the basement. In frosts, the water in them can freeze, but if antifreeze is used as a coolant, then this disadvantage can be avoided.

Piping for gravity heating

Many experts believe that the pipeline should be laid with a slope in the direction of movement of the coolant. I do not argue that ideally this should be so, but in practice this requirement is not always met. Somewhere the beam gets in the way, somewhere the ceilings are made at different levels. What will happen if you install the supply pipeline with a reverse slope?

I am sure that nothing terrible will happen. The circulating pressure of the coolant, if it decreases, then by quite a small amount (a few pascals). This will happen due to the parasitic influence that cools down in the upper filling of the coolant. With this design, air from the system will have to be removed using a flow-through air collector and an air vent. Such a device is shown in the figure. Here, the drain valve is designed to release air at the time the system is filled with coolant. In operating mode, this valve must be closed. Such a system will remain fully functional.

Dynamic parameters of the coolant

We proceed to the next stage of calculations - analysis of the consumption of the coolant. In most cases, the heating system of an apartment differs from other systems - this is due to the number of heating panels and the length of the pipeline. The pressure is used as an additional "driving force" for the flow vertically through the system.

In private one- and multi-storey buildings, old panel apartment buildings, high-pressure heating systems are used, which makes it possible to transport the heat-releasing substance to all sections of the branched, multi-ring heating system and raise water to the entire height (up to the 14th floor) of the building.

On the contrary, an ordinary 2- or 3-room apartment with autonomous heating does not have such a variety of rings and branches of the system; it includes no more than three circuits.

This means that the transportation of the coolant takes place using the natural process of water flow. But circulation pumps can also be used, heating is provided by a gas / electric boiler.

We recommend using a circulation pump for heating rooms over 100 m2.The pump can be mounted both before and after the boiler, but usually it is placed on the “return” - lower temperature of the medium, less airiness, longer pump service life

Specialists in the field of design and installation of heating systems define two main approaches in terms of calculating the volume of the coolant:

- According to the actual capacity of the system. All, without exception, the volumes of the cavities where the hot water flow will flow are summed up: the sum of individual pipe sections, radiator sections, etc. But this is a rather time consuming option.

- By boiler power. Here the opinions of experts differed greatly, some say 10, others 15 liters per unit of boiler power.

From a pragmatic point of view, you need to take into account the fact that the heating system will probably not only supply hot water for the room, but also heat water for the bathroom / shower, washbasin, sink and dryer, and maybe for a hydromassage or jacuzzi. This option is simpler.

Therefore, in this case, we recommend setting 13.5 liters per unit of power. Multiplying this number by the boiler power (8.08 kW), we obtain the calculated volume of water mass - 109.08 liters.

The calculated speed of the coolant in the system is exactly the parameter that allows you to select a certain pipe diameter for the heating system.

It is calculated using the following formula:

V = (0.86 * W * k) / t-to,

Where:

- W - boiler power;

- t is the temperature of the supplied water;

- to - water temperature in the return circuit;

- k - boiler efficiency (0.95 for a gas boiler).

Substituting the calculated data into the formula, we have: (0.86 * 8080 * 0.95) / 80-60 = 6601.36 / 20 = 330kg / h. Thus, in one hour, 330 liters of coolant (water) are moved in the system, and the capacity of the system is about 110 liters.

The movement of the cooled heat carrier

One of the misconceptions is that in a system with natural circulation, the cooled coolant cannot move upward. I also disagree with these. For a circulating system, the concept of up and down is very conditional. In practice, if the return pipeline rises in some section, then somewhere it falls to the same height. In this case, the gravitational forces are balanced. The only difficulty is in overcoming local resistance at bends and linear sections of the pipeline. All this, as well as the possible cooling of the coolant in the sections of the rise, should be taken into account in the calculations. If the system is correctly calculated, then the diagram shown in the figure below has the right to exist. By the way, at the beginning of the last century, such schemes were widely used, despite their weak hydraulic stability.

Two in one

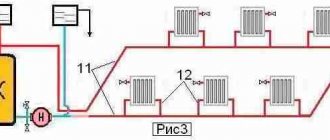

All the above problems of the gravity circuit can be solved by upgrading it with a pump insert. At the same time, the system will retain the ability to work with natural circulation.

When doing this work, it is worth adhering to a few simple rules.

- A valve or, which is much better, a ball check valve is placed between the tie-ins of the outlets on the pump. When the pump is running, it will not allow the impeller to drive water in a small circle.

- A sump is required in front of the pump. It will protect the rotor and pump bearings from scale and sand.

- The pump connection is limited by a pair of valves, which will allow you to clean the filter or remove the pump for repair without losing the coolant.

In the photo, the bypass between the inserts is equipped with a ball check valve.

Location of radiators

They say that with the natural circulation of the coolant, the radiators, without fail, must be located above the boiler. This statement is true only when the heating devices are located in one tier. If the number of tiers is two or more, the radiators of the lower tier can be located below the boiler, which must be checked by hydraulic calculation.

In particular, for the example shown in the figure below, with H = 7 m, h1 = 3 m, h2 = 8 m, the effective circulating pressure will be:

g · = 9.9 · [7 · (977 - 965) - 3 · (973 - 965) - 6 · (977 - 973)] = 352.8 Pa.

Here:

ρ1 = 965 kg / m3 is the density of water at 90 ° C;

ρ2 = 977 kg / m3 is the density of water at 70 ° C;

ρ3 = 973 kg / m3 is the density of water at 80 ° C.

The resulting circulating pressure is sufficient for the reduced system to work.

Gravity heating - replacing water with antifreeze

I read somewhere that gravitational heating, designed for water, can be painlessly switched to antifreeze. I want to warn you against such actions, since without proper calculation, such a replacement can lead to a complete failure of the heating system. The fact is that glycol-based solutions have a significantly higher viscosity than water. In addition, the specific heat capacity of these liquids is lower than that of water, which will require, other things being equal, an increase in the circulation rate of the coolant. These circumstances significantly increase the design hydraulic resistance of the system filled with coolants with a low freezing point.

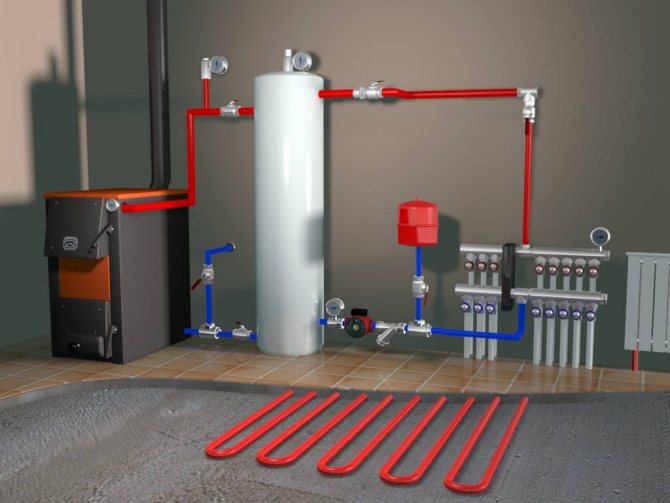

Implementation of a heating system with natural circulation of the heat carrier

After the heat engineering calculation of the building has been completed, you can proceed to the selection of heating devices and their selection. On the first floor, in one of the rooms, let's say there is a warm floor in the bathroom and toilet. The system is still planned to be gravitational and non-volatile, therefore, a large area of underfloor heating should not be done. After the performed heat engineering calculation, we will determine the temperature graph of the coolant, from which we will proceed. We will choose a standard schedule for water heating systems 95 supply and 70 - return, we will slightly correct it for a certain margin in the future and errors in the inaccuracies of calculations and measurements, we will bring it to 80 to 60. Next, in residential premises, we will mentally install radiators, we will determine the places where there will be radiators and what kind, and we will immediately think over the routing of heating pipes, the places where the pipes will go. Radiators will need to be installed taking into account the heat needs of the premises. If there is a warm floor in the bathroom, then the radiator must be installed taking into account the fact that the warm floor will work for you as needed, take into account that the system must be non-volatile. That is, the radiator should provide 70-80% of the required heat in the room. In living quarters, in rooms, it is also necessary to take into account the direction of the prevailing wind and the cardinal points where the walls go. The same applies not only to the first floor, but also to the second. Much depends on the correct placement of heating devices. Also, one must not forget about the installation of heating devices or a device at the front door. In the kitchen, you can reduce the estimated power of heating devices by 10-15%. There are other sources of heat: gas or electric stove, oven, bread maker, refrigerator, etc.

Heat engineering calculation and selection of heating devices, and their calculation is absolutely the same for a system with any circulation urge. The only thing is that with a gravitational system, it is also necessary to take into account the cooling of the coolant and keep in mind that on the upper floor, the temperature of the coolant is higher than on the lower one, by 5-12C, depending on the type of risers, their length and the height of the building.

Using an open expansion tank

Practice shows that it is necessary to constantly top up the coolant in an open expansion tank, as it evaporates. I agree that this is really a big inconvenience, but it can be easily eliminated. To do this, you can use an air tube and a hydraulic seal, installed closer to the lowest point of the system, next to the boiler. This tube serves as an air damper between the hydraulic seal and the coolant level in the tank.Therefore, the larger its diameter, the lower the level of level fluctuations in the water seal tank will be. Particularly advanced craftsmen manage to pump nitrogen or inert gases into the air tube, thereby protecting the system from air penetration.

Equipment

A gravitational system is possible as a closed system, not communicating with atmospheric air, and open to the atmosphere. The type of system depends on the set of equipment that it lacks.

Open

In fact, the only necessary element is an open expansion tank.

It combines a couple of functions:

- Holds excess water when overheated.

- It removes steam and air generated during the boiling of water in the circuit into the atmosphere.

- Helps to top up water to compensate for evaporation and leakage.

In those cases, when in some areas of the filling the radiators are located above it, their upper plugs are equipped with air vents. This role can be played by both Mayevsky taps and simple water taps.

To reset the system, in most cases it is supplemented with a branch leading to the sewer or easily outside the house.

Closed

In a closed gravity system, the functions of an open tank are distributed over a pair of free devices.

- The diaphragm expansion tank of the heating system provides the possibility of expansion of the coolant during heating. In most cases, its amount is taken equal to 10% of the total system volume.

- The pressure relief valve relieves excess pressure when the tank is overfilled.

- A manual air vent (for example, the same Mayevsky valve) or an involuntary air vent is responsible for air venting.

- The pressure gauge shows pressure.

It is fundamentally important: in the gravitational system, at least one air vent must be at its highest point. Unlike the forced circulation scheme, here the airlock simply will not allow the coolant to move.

In addition to the above, a closed system in most cases is equipped with a jumper with a cold water system, which allows it to be filled at the end of the discharge or to compensate for water leakage.

Using a circulation pump in gravity heating

In a conversation with one installer, I heard that a pump installed on the bypass of the main riser cannot create a circulation effect, since the installation of shut-off valves on the main riser between the boiler and the expansion tank is prohibited. Therefore, you can put the pump on the bypass of the return line, and install a ball valve between the pump inlets. This solution is not very convenient, since every time before turning on the pump, you must remember to turn off the tap, and after turning off the pump, open it. In this case, the installation of a check valve is impossible due to its significant hydraulic resistance. To get out of this situation, the craftsmen are trying to remake the check valve into a normally open one. Such "modernized" valves will create sound effects in the system due to constant "squelching" with a period proportional to the speed of the coolant. I can suggest another solution. A float check valve for gravity systems is installed on the main riser between the bypass inlets. The valve float in natural circulation is open and does not interfere with the movement of the coolant. When the pump is turned on in the bypass, the valve shuts off the main riser, directing all flow through the bypass with the pump.

In this article, I have considered far from all the misconceptions that exist among specialists installing gravitational heating. If you liked the article, I am ready to continue it with answers to your questions.

In the next article I will talk about building materials.

RECOMMEND TO READ MORE:

Gravity heating types of heating somatic schemes

Natural circulation heating schemes are of two types: one-pipe and two-pipe. Older houses had only one pipe in their heating system.But nowadays, a two-pipe heating system with a bottom or top dilution is most often used. What are the main differences between the schemes? One-pipe gravity heating is considered the simplest. The pipeline is placed under the ceiling of the premises, and the return loop is placed under the floor. On the positive side, a small number of components required for the functioning of the system can be noted. It also features simple installation. As an advantage, we can note the possibility of its operation when installing the boiler and radiators at the same level. Usually, in a two-story house, such a scheme is rarely used, because it does not allow the house to warm up evenly. However, this can be corrected by installing volumetric pipes and radiators on the ground floor. When installing a one-pipe circuit, control valves are not provided, which means that it will not be possible to regulate the temperature.

A two-pipe heating system is more complicated both in operation and in the device, because it involves several heating circuits. One of them is intended for the flow of hot coolant, the other for the cold one. In this case, you will need a lot more components. The dead-end heating system of a two-story house will necessarily require insulation of the main riser to avoid heat loss. For a two-pipe system, it is necessary to use pipes of a large diameter, at least 32 mm, otherwise the hydraulic resistance will impede the gravity circulation.