It is possible or impossible to repair a gas boiler without a specialist

A typical gas boiler consists of many elements, which can basically be grouped into 3 groups:

- Burner.

- Blocks providing safety.

- A heat exchange unit equipped with several additional devices, which include a fan, a circulation pump and many others.

The structure of this mechanism can be simplified as follows.

If you detail the picture, you can find about 2 dozen different elements in the device.

The main danger during repairs is a possible gas leak. This can happen due to improper repair, dismantling or installation of equipment that is associated with the fuel supply.

Therefore, it is better to entrust the repair of these parts of the structure to a specialist. Also, do not troubleshoot the electronic equipment of gas boilers on your own. Automation is a specific device, therefore, without appropriate qualifications, it is almost impossible to correctly carry out restoration work and repair such equipment yourself.

What can be repaired by hand

All other elements can be repaired by yourself, for example:

- Flushing the heat exchanger performed manually (for this, the unit is dismantled, after which it must be correctly put in place). It is possible to carry out these works without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with traction (mechanical or chemical removal of blockages is performed).

- Fan repair pressurization by lubricating its bearings with technical oil.

In fact, it is possible to repair a gas boiler on your own only in those cases when it comes to mechanical damage or blockages that can be easily identified visually (or by smell).

The rest of the breakdowns are considered more serious, therefore they are eliminated with the help of a specialist, and not with your own hands.

Brief information about the system device

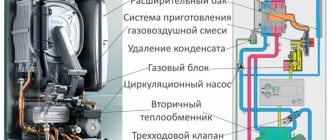

A gas heater is a rather complex unit. Its device is based on the following components and systems:

- the furnace in which the fuel is burned,

- air supply and combustion products removal systems,

- a heat exchanger in which the flame heats water or heat carrier,

- automation systems,

- security systems.

The firebox, or combustion chamber, can be open or closed. In the first case, the air necessary for fuel oxidation enters the firebox through the air intake on the body from the room in which the unit is installed. The combustion products are removed through a traditional chimney that rises above the roof. The thrust is formed naturally.

In a closed chamber, there is no air exchange between the indoor premises and the heater. Air enters from the street, and exhaust gas is removed back through a horizontal coaxial chimney that passes through the wall of the building. A fan is used to create thrust.

The heat exchanger can have one or two circuits. The first, closed loop is connected to the heating system, the circulation of the coolant in it is carried out using a pump. A second circuit can also be installed on the gas boiler, water from the water supply system passes through it and heats up. This circuit is open, water is supplied due to the pressure generated by the pumping station.

Automation and safety systems maintain the set temperature of the coolant and monitor the trouble-free operation of the device. In modern models, they are combined into a common computerized control system.

The security group includes the following subsystems:

- draft sensor, when the draft falls below the set level, it turns off the gas supply,

- an additional draft sensor in the exhaust duct protects against the ingress of combustion products into the room,

- the flame controller monitors the operation of the burner and switches off the supply when the flame goes out,

- the emergency valve releases the heating medium pressure if it exceeds the set value,

- a pressure sensor stops the unit if the pressure and flow rate of the heating medium falls below the set value, for example, in the event of a leak.

Automation and safety systems on boilers with an open chamber and natural circulation of the coolant can be mechanical - then the boiler does not require electricity to operate. More advanced and economical boilers require a constant power supply to operate the fan, circulation pump and control system.

The main causes of a gas boiler breakdown

Before figuring out how to repair a gas boiler with your own hands, it is useful to understand exactly why malfunctions occur. Correct understanding of the reasons will help to avoid the problem in the future. Practice shows that 4 harmful factors are most often affected:

- Electricity drops - this problem is especially relevant in remote settlements and villages. Modern equipment is necessarily equipped with stabilizers, as well as energy storage devices, which ensure the operation of the device for a short time even after the source is turned off. Therefore, if there are no such devices, you should purchase them in advance.

- Poor quality water - this problem arises in cases where the equipment is used not only for heating, but also for obtaining hot water for domestic purposes (double-circuit gas boiler). The equipment is not damaged by the water itself, but by the presence of salts in it, which increase the hardness. If the concentration of these insoluble substances is high enough, it can lead to equipment wear in as little as 1-2 seasons. Therefore, it is necessary to take care of the installation of filters that purify water.

- Installation errors can lead to rather serious consequences, including fatal breakdowns, failure of all equipment. Therefore, this work can only be entrusted to qualified specialists.

- Finally, a role can also be played by frosty winters... Usually, during such a period, the neighbors turn on the equipment at full capacity, and in this mode it works for a long time. As a result, the pressure in the gas pipeline system drops significantly, and the boilers begin to work largely in vain. At this point, you can use equipment that runs on a different fuel (for example, diesel). It makes sense to purchase it if the region has long, harsh winters.

Common breakdowns table

The most common breakdowns of a gas boiler are described in the table.

| problem | possible reasons | what to do |

| small burner flame | air entering the gas line or clogged nozzles | call the master |

| the burner goes out quickly | malfunction of the ionization electrode | |

| the flame comes off, the nozzle makes an abnormal noise | the draft is too strong (the flue pipe is high) or the pressure in the system is not adjusted | reduce cravings |

| the boiler does not turn on | various | you can turn the plug to change the contacts, and turn it on again |

| malfunction of automation and electronic equipment | different: it is difficult to eliminate on your own | call the master |

| incorrect operation, voltage drop | power drops | put the stabilizer |

| scale clogging | hard water | clean and put on the filter |

| overheat | clogging of the heat exchanger with soot | clean the mechanism by hand |

A video overview of possible combustion problems and their causes can be seen here.

Major error codes

During the operation of boilers, malfunctions are inevitable. Consider the main error codes for the Hermann gas boiler:

- Error e01 - no flame - it is possible to fix it yourself. It is possible that the burner flame went out unexpectedly or did not ignite in time. It is necessary to press the "reset" button, giving the command to the boiler to ignite.

In case of failure, you need to check whether the gas supply is open, whether it is in the cylinder. Incorrect power supply - in case of error 01, on the display - "reset" - you must press this button.If the problem persists, you need to check the correct connection of the phase, grounding and zero. If they are confused, the device may not see the flame, even if it is ignited. Possibly the neutral is out of balance.

- Error e02 - the safety thermostat has triggered - is eliminated independently. Overheating has occurred. The display usually shows “reboot”. Switch off the unit and press “reset” after complete cooling. If it does not help, call a specialist.

- Error e03 - the fuse responsible for removing smoke has tripped - can be eliminated. The smoke was removed incorrectly. Perhaps even a gust of wind. Press "reset". If error 03 persists, check the chimney.

- e05 - the heating temperature sensor is faulty - call a technician.

Temperature sensor (thermistor) for Hermann boilers

- e06 - DHW temperature sensor is out of order - call a technician. Usually the display shows “service”.

- e09 - the time has come for maintenance - to invite a specialist. This does not prevent the boiler from working - you can press "reset" and the problem will disappear for a few days. However, after three such presses - error 06 will remain on the display permanently.

- e10 - the sensor on the bottom of the boiler signals insufficient pressure - in case of error 10, you need to check the air release valves on the radiators - often the pressure in the system drops through them.

- e11 - an error inherent in the "SE" model - blocking by a device responsible for removing smoke - call a specialist. Disconnect from the mains, turn off the machine and apply voltage to the boiler again - if it does not work, you will have to contact the service center.

- e18 - water is being loaded into the heating system - eliminated automatically. Due to the pressure drop in the system, the boiler is loaded with water from the water supply. Wait until the end and the error should disappear.

Boiler feed tap Hermann

If the pressure is not restored three times within 24 hours, the boiler will go into lockout and the error code e19 or e21 will be displayed. Then the technician should be called. - e19 - the make-up was not completed on time - call a technician.

- e21 - the pressure in the heating system is below the permissible level - it is eliminated by a specialist. Sometimes this happens due to residues in the air system. A coolant leak is also possible.

- e22 - non-sequential saved data - call technician. The display usually shows "service".

- e24 - the safety thermostat gave an error signal - you can fix it yourself, if installed on the floor and an existing safety thermostat. The temperature under the appliance may be too high.

The thermostat specifically monitors its level in order to protect the owners from possible damage to the floor covering. In this case, the boiler will block heating, but will continue to heat water.

Safety valve Wait until the floor cools down, restore the thermostat and press "reset" - a delay of 30 seconds is possible. If it does not help, you should call a technician. - e33 - erroneous wiring configuration - error 33 is eliminated by the technician.

- e35 - inappropriate flame - can be eliminated by yourself. A special device blocks the boiler. IF DETECTES A FLAME WHEN it shouldn't be. You need to press the "reset" button. If the device stops again, call a specialist.

- e36 - common fuse has triggered - can be removed by the User. If pressing the "Overload" button does not help, call a technician.

- e38 - external temperature sensor is faulty - call a technician.

- e39 - possible freezing of the heat exchanger - call a specialist. Occurs when detecting water or heating sensors equal to or less than 0 degrees.The boiler starts to pump water in the system and if the temperature does not rise by 1 degree within 15 minutes, the error will remain.

- Error e42 is an error associated with the microprocessor. Overheating of the "return" is possible - call a specialist.

Other malfunctions

Hermann gas boilers, like most heating devices, consist of many electronic components that are responsible for the main parameters of their operation. But there is one breakdown that is inherent in almost all models.

Programmer for Hermann boilers

When switching to the "Summer" mode, the boiler does not want to switch to hot water. When it is in winter mode, it does not respond to the opening of the hot water tap. As a result, the circulation pump in the heating system does not turn off either.

In winter mode, if you open the hot water tap, the heating circuit does not turn off and hot water is taken from the heat exchanger. It is characteristic that with such a malfunction, the indicators do not show errors. The fault of this behavior of the device is the flow sensor.

A reed switch is installed on the cold water inlet, which is controlled by a float valve with a magnet. There is simply nothing to break in it. Therefore, if it is necessary to transfer the boiler from one mode to another, you should be extremely careful and take your time.

How to repair a boiler with your own hands: step by step instructions

After a specific breakdown has been accurately diagnosed, you can begin to eliminate it. Of course, in the event that there is confidence that this is a feasible task that does not require special skills and equipment.

Preparatory stage

- First of all, it is necessary to disconnect the device from the power supply, and also tightly shut off the gas valve. Even if the repair is not associated with elements directly in contact with fuel, this condition is mandatory.

- If it is difficult to estimate the time of restoration work, and they can theoretically take several hours, you should completely drain the water from the heating system or pour an antifreeze solution there (if it is not there). The fact is that during the repair, the air temperature in the room can drop to negative values, and the water will freeze.

- Safety precautions: along with shutting off the gas valve and de-energizing the system, it should be remembered that the working surface must cool down to an acceptable level before repairing. Otherwise, touching it may cause burns.

Cleaning the heat exchanger

If the boiler overheats, this may indicate 2 reasons:

- The automation that controls the operation of the device is faulty.

- The heat exchanger is clogged (soot deposits).

Automation is repaired only with the help of special equipment, which in most cases is not in the house. But it is quite possible to clean the heat exchanger yourself.

The sequence of actions is as follows:

- Turn off the boiler, let it cool down.

- Shut off the taps.

- Remove the front cover.

- The remaining water is discarded (open a hot water tap or a valve inside the mechanism to drain water from the heating system).

- Remove the heat exchanger.

- The heat exchanger is cleaned first mechanically, then - in a solution of vinegar and citric acid, taken in equal quantities (you can use a tablespoon per liter of water). Instead of a solution, you can also use special formulations purchased in the store.

- The heat exchanger is kept in such a mixture for 1-2 hours until it is completely cleaned.

- Then washed with running water and wiped dry.

- They put the heat exchanger back, close the lid, fasten all the parts.

Chimney cleaning

A decrease in draft and overheating of a gas boiler can certainly be associated with a clogged chimney. It is in this part of the system that the greatest amount of soot accumulates. However, the accumulation of dirt is quite rare, since the gas does not provide an abundant amount of waste.

DIY repair of double-circuit boilers

Especially often it is necessary to repair double-circuit boilers, since they work in an enhanced mode, heating the premises and storing hot water for domestic needs.

NOTE

During the repair of gas boilers, the dismantling of structures is almost always necessary. It must be carried out carefully, remembering the connection sequence, in order to then correctly assemble all the elements of the system.

Repair of a wall-mounted gas boiler (cleaning and flushing the heat exchanger with special means) is clearly shown here:

Gas boiler malfunctions: prevention

Obviously, a preventive measure is always better than repairing an already existing breakdown. Therefore, it is important to know about those methods of preventing gas boilers from malfunctioning, which will help to avoid trouble and practically guarantee that the problem will not be caught by surprise.

First of all, you should refer to the instructions from the manufacturer, where the rules for operating the mechanism are detailed. As a rule, they are practically the same for different models.

Cleaning the heat exchanger

This is the most vulnerable point in the boiler, since a large amount of soot periodically accumulates in it. The heat exchanger in most cases is made of stainless steel, less often of copper. It must be cleaned at least once every 3-4 years.

This is done with a wire brush. And if the mechanism is made of copper - a metal sponge, which is used for washing dishes. It is advisable to annually monitor its condition for contamination, especially after a cold winter, when fuel consumption increases significantly.

Pressure test

It is carried out periodically, several times a year. The optimum range for each model may vary slightly, but is usually between 1.0 and 2.0 bar (if the mechanism is cold). If the indicator drops regularly, it is preferable to immediately contact the service company.

Checking the water level

This is a very important requirement. After all, if the amount of moisture is less than the standard one, this can lead to a rather rapid wear of the mechanisms. The level is checked annually, especially often after repairs have been carried out, when moisture can evaporate faster than usual.

At the same time, every summer, before the start of the next heating season, all the liquid should be removed, and the parts and assemblies should be carefully examined for scale, dirt, damage and other malfunctions.

Proper care of the boiler

Includes the usual security measures:

- Do not direct water jets at the equipment, i.e. it can only be washed with a rag (by hand).

- It is not allowed to enter jets of air, steam, especially hot ones. Therefore, it is best not to place equipment in the kitchen.

- Also, do not place any objects on the surface of the unit.

- Shocks, mechanical influences, radiation, etc. are not allowed.

- If there is a long period of downtime (1 or several seasons), the equipment is prepared for it in advance. For example, you need to take care of frost protection, which is described in detail in the instructions for the gas boiler.

Thus, in some cases, there is indeed an opportunity to repair a gas boiler with your own hands.

But if the breakdowns are quite serious, or the malfunctions of gas boilers are not fully understood, there is only one way out - to invite a specialist from a service company.

Faults, repair and maintenance of gas boilers Herman

_______________________________________________________________________________

_______________________________________________________________________________

Hermann Habitat 2 boiler does not want to start. While holding the start button, the burner is working. But if you do not fix the button, the device fades out. Explain the cause of the breakdown? The thermoelectric converter is probably faulty or problems with the gas valve. There is also a decrease in gas pressure on the inlet line. In some cases, there is a lack of voltage on the control board. There was a problem recently. Firing up is difficult. The igniter ignites, but the main burner has no flame.Can't figure out what is the reason? Most likely, damage to parts of the ignition device. We advise you to check the device and clean the ignition unit. Why does the Herman Micra double-circuit gas wall-mounted boiler stop turning off at the moment when the heating reaches the required temperature? Heating goes up to 90 degrees, then a problem arises. After restarting, the situation starts again. We assume that the control board is malfunctioning, the boiler water temperature sensor is broken, the safety sensor button is broken. It is possible that there was a malfunction in the automation. I would like to know why it is not possible to raise the temperature of the coolant over 70 C? We need to set more, but the display says that this is the largest value. How should the heating be increased? When the unit does not perform the heating cycle temperature rise cycle, the following reasons can be assumed. In the adjustments, there is a limitation of the maximum heating temperature not higher than 70C. There was a decrease in the chimney draft speed. The Hermann Supermicra double-circuit boiler began to work unstably during the heating phase of the hot water supply circuit. Hot and cold water flows from the kitchen tap. Please help me, why is this happening? The factors of occurrence of the problem seem to be the following. There was a mixture of cold water due to the fact that the 3-way valve is inoperative. The heat exchanger is clogged with debris. You need to clean it up. Water often leaks from the tap at the bottom of the boiler. The unit itself does not start. What do we have to do? Apparently, the coolant is escaping from the safety valve. This circumstance indicates a high pressure in the system. In addition, the filling valve of the system may not be closed, or the expansion tank should be pumped in. Please tell me what is the reason that the pressure constantly rises, and at the same time the relief valve is triggered? Each time the heating icon appears on the screen in the heating mode of the device. How to be? There is a problem with the heating circuit temperature sensor. Termination of the corresponding circulation process in the heating line. What is the problem if the Habitat 2 boiler is often turned off? In particular, recently the piezo ignition could not work at all. The boiler was serviced that week. What could be? It looks like a functional disturbance has occurred in the chimney system. You need to diagnose the chimney. Incorrect operation of the electric ignition indicates damage to its parts due to a voltage drop or water leakage. Can anyone help sort out the chimney? Soon the second day, as there is a return thrust, while the smoke enters the room directly. I made the chimney myself. It consists of a metal tube. Probably, something was wrong. The unit normally heats the household water, but at the moment the heating is turned on, the water immediately comes to a boil, and the unit goes into a failure. What is this breakdown, and how to get rid of it? Presumably, the circulation pump is not working, electronic board failure, temperature sensor malfunction. At the same time, the filter mesh may become dirty. In hot water preparation mode, the boiler starts to dispense cold and hot water in turn. I don't understand what the problem is. How to set up water heating? Most likely, the heating system is dirty or it is necessary to clean the heat exchanger. In addition, there may be a breakdown of the pressure control relay, or the circulation pump has broken. The main reason may be an incorrectly manufactured chimney structure. Sometimes there is contamination with soot, which significantly reduces its efficiency. In addition, it is necessary to inspect the ventilation openings in the house. We use a wall-mounted gas boiler Hermann Micra. The unit sharply picks up the temperature above 96 degrees, and then it locks up with an error. Subsequently, when it cools down, it starts to automatically start.What is the reason for this? An overheating alarm means that there is no circulation process. First of all, it is necessary to check the radiator taps. They must be left open. Then an inspection is made for clogging of the filter, and you also need to make sure that the heat exchanger is not clogged. I launched this model in February this year. After about a few weeks, the device sometimes began to make a lot of noise. Please tell me why it makes a noise? Presumably the heat exchanger is clogged with limescale. If the water is hard, then later in the wall of the radiator tubes, limescale deposits are deposited. We expect to connect the Thesi boiler to heat the house. Please tell me what is the correct recommendation to start such a unit into operation? For the correct start-up of this equipment, you need to perform the following measures. Connect the power supply to the unit. Open the gas valve. Then we turn on the main burner. Next, adjust the desired temperature. We want to do maintenance. Instruct on how to properly drain the water from the device? In accordance with the passport, this procedure is carried out as follows. Disconnect the unit from the mains. We turn off the gas valve. Open the automatic air vent. We turn the tap to drain. Then remove any spilled water. Otherwise, it is allowed to drain the water through the relief valve. This valve is located at the bottom of the unit. Explain to me how the operation of a three-way valve can be diagnosed? I think this component does not open correctly. In the heating cycle, it cannot pump the last batteries, however, in the DHW mode, the pipe heats up to supply the coolant under the boiler. Of course, it is necessary to look at the 3-way valve for the presence of acidic stem in the intermediate position. We also recommend running diagnostics on your heating system. We use the Herman Micra 2 double-circuit boiler indoors. Until yesterday evening it operated without question. Now, 3 seconds after the start, the device began to go out. It seems that it cannot bring the coolant into the system. Tell me, what is this problem? The probable cause of this damage can be the ignition electrode, which does not register the fire, or a decrease in the circulation process. The other day there was a problem with such a model. In heating mode, it whistles. I decided to restart it - I succeeded, but it whistles anyway. Maybe someone can tell you why this is happening? Very often a loud whistle occurs when the pressure on the burner nozzles is not adjusted according to the instructions. It is required to check the gas pressure adjustments and correct if necessary. Water leaked into the gas boiler the other day, and it began to function with malfunctions. For example, if you set an arbitrary temperature, and heating occurs exclusively up to 26 degrees, Celsius, after which it turns off. Please tell me what could be out of order? If the electronic board has been flooded with water, it is likely damaged. It must be zeroed by linearly disconnecting the unit from the power supply. Then turn it back on and test its functionality. The Habitat 23 SE boiler is in operation. Now, at the moment of start-up, the wick is lit for 9 seconds, and the main burner does not catch the fire, and because of this, the device begins to extinguish. What is the best way to solve this problem? Probably there is a defect in the ignition unit or problems with the burner. In any case, check if the phasing is not lost when connecting to the power supply. Completed in the middle of this year, the connection of the same device. Somewhere after 3 months, a malfunction occurred in the DHW circuit, although the heating circuit is functioning smoothly. I tried to open a hot water tap, but it just displays the temperature, and does not even think about heating. What is the cause of the problem? The 3-way valve may be defective. It needs to be replaced. Could you tell me for what purpose the boiler is equipped with a safety thermal sensor? The temperature sensor prevents gas from entering the burner in case of overheating of the liquid in the DHW system.I need to wash and clean the main water heat exchanger on Micra 2. Explain how to properly remove it? The main heat exchanger can be freely removed from the device using a conventional screwdriver. Below is a description of the removal procedure. Drain the water from the appliance using the drain cock. Then we free the hot water supply system from water. Unscrew the fixing bolts of the main heat exchanger and remove it from the frame. Launched the wall-mounted boiler Herman Habitat. After about 4 months, the water pressure in the device dropped. Often he throws it off and stops. In other words, it does not hold pressure at all. Why doesn't he keep the pressure? If the unit does not gain water pressure, the make-up valve is probably leaking. If a shutdown occurs and the pressure drops to zero, then the 3-way valve has broken. Explain how to clean the cold water filter? First, drain the hot water circuit. Second, unscrew the flow sensor nut. Then we take out the sensor and filter from the cavity. After that, we remove the accumulated debris and dirt. The unit, at start-up, made a humming sound before that, but at this time the noise has become stronger. At first, the sound quickly disappeared, but now it is heard longer. Has anyone observed this issue? The formation of excessive rumble indicates the presence of limescale inside the body of the heat exchanger, which is heated unevenly due to different wall thicknesses. The more the heat exchanger is clogged, the more pronounced the rumble, and, accordingly, the heat output decreases. The device seems to be working, although water, apparently, does not circulate in the system. The return pump is very hot. What could have happened? Apparently, the mud filter is clogged or the tap is shut off somewhere, which interferes with the passage of the coolant. The circulation pump could also have broken. What is hot water not made from? The tap water is barely warm. Can you explain what happened? Damage search is conducted in several directions. Alternatively, there is a malfunction of the DHW temperature sensor, it is necessary to replace the sensor. It is also very likely that the power adjustments for heating water have gone astray. I constantly observe the cessation of the flame when ignited. The burner is clean, everything is normal with the chimney, the draft is excellent. Where can I find the problem? The device does not detect a flame due to a poor pulse from the ignition control unit. It is necessary to inspect the wiring from the ionization sensor to the electrode. You probably need to tighten it up. There may be a defect in the sensor insulation and must be replaced.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler is turned off with an E35 error (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve.Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

Westen Pulsar D boiler startup problem.Piezo ignition works, but there is no flame, after crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to look for a malfunction?

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos. Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow. What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and then it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m. When firing up, it does not turn off, the temperature rises, if I am not mistaken, the automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When it works on a unit, it beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out.Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently started showing error 14. How can you fix the breakage?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?