The choice of a heat generator for heating and hot water supply of a country house depends on many factors, first of all, on the availability of a gas main. The use of a heating installation on liquid fuel is most often due to the lack of access to the centralized gas supply system.

Modern heating boilers, using diesel fuel as an energy carrier, have high efficiency and allow to ensure complete autonomy of the heating system of a private house. In addition, some models of diesel boilers can operate on fuel oil, waste engine oil and other liquid combustible mixtures, including liquefied gas.

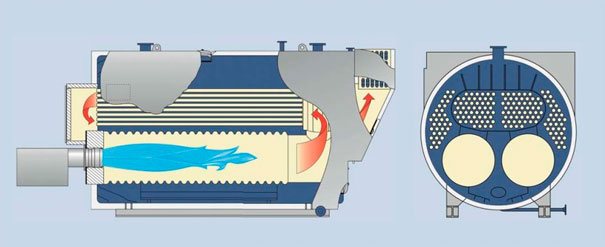

The device and principle of operation of a diesel boiler

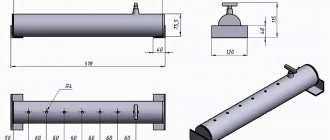

The design of units using liquid fuels as an energy carrier provides for the following main elements:

- Housings with built-in combustion chamber;

- A burner in which a combustible mixture is formed;

- One or two heat exchangers;

- Fuel pump;

- Filtration systems;

- Thermal sensors;

- Electronic control unit and settings.

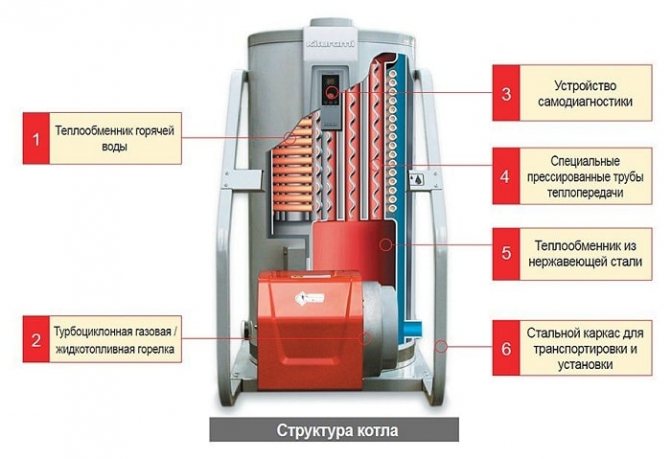

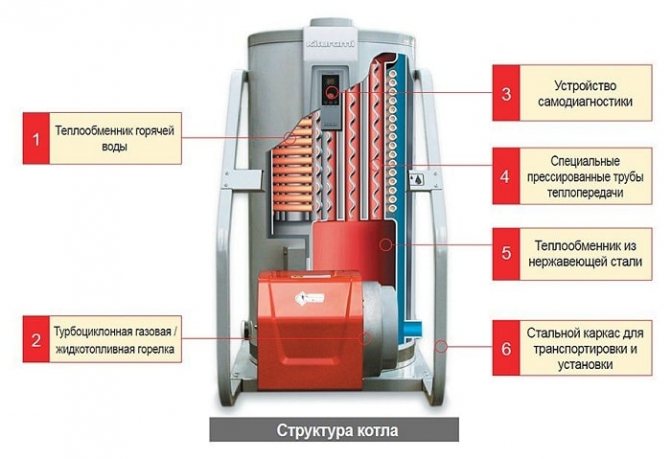

The material for the manufacture of heat exchangers can be steel or cast iron. Some premium diesel boilers are equipped with heat exchangers made of high-alloy heat-resistant steels.

Principle of operation

The fuel entering the burner is mixed with air, thus forming a fuel mixture, which is sprayed through the nozzle in the combustion chamber. The completeness of fuel combustion depends on the correct adjustment of the burner itself and the quality of the nozzle. The fuel mixture that has entered the combustion chamber is ignited by a spark generated by an automatic control system (ACS), and the heat released during the combustion process is transferred to the coolant through the walls of the heat exchanger.

The coolant temperature is monitored by a system of temperature sensors installed in the combustion chamber. Upon reaching the set temperature mode, the ACS turns off the burner, and when the coolant is cooled, the combustible mixture is automatically ignited. The exhaust gases are discharged through the chimney.

Burners of diesel heating boilers can be fan and forced draft. In fan burners, overpressure is generated by a special built-in fan. The performance of such modules is quite high, but the operation of the units is accompanied by an increased noise level.

In forced draft burners, a turbine is installed instead of a fan. The use of turbocharging can significantly increase the productivity of the installation and achieve complete combustion of the combustible mixture. Exhaust gases can be removed from the combustion chamber both naturally, due to the draft generated in the chimney, and forcibly, using a fan.

Another design feature of a diesel fuel boiler for heating a private house is the possibility of changeover to work with other types of fuel, in particular, natural gas, for this you just need to replace the gas diesel burner.

Types of diesel heaters

Diesel heat guns are divided into two types: direct and indirect heating. They differ not only in design features, but also in their power and scope.

Therefore, choosing the right equipment should be based not only on the area of the room that needs to be heated, but also take into account the presence of people or animals in it.

Heat guns of direct heating

They are arranged as described in the previous paragraph: the fan blows air, which passes through the chamber, where the fuel enters. The combustible mixture ignites and heats the air, which then exits the combustion chamber. In such models, combustion products enter the supplied air, therefore, direct-flow heaters cannot be used where people work or animals are located for a long time.

Where are these heat generators used? They are good for heating uncrowded industrial halls, basements, warehouses, open construction sites and other premises with low thermal insulation. In addition, they are often used to dry facades or screeds in the cold season, as well as to dry plaster or cladding.

Features of direct heating guns:

- good power - up to 220 kW;

- high efficiency - the indicator is close to 96%;

- the air can be heated up to 450 ° С;

- relatively low cost;

- the presence of odor and soot as a result of combustion.

Heat guns of indirect heating

They differ from the previous version in that their combustion chamber is isolated. The blown air does not come into contact with the burner, it passes through the heated pipe system. Soot and carbon monoxide are removed from the system through a chimney that can be directed outside. The principle of their operation does not change: the fan passes the flow through the chamber heated by the combustion of fuel.

Indirect heat generators can be used in rooms and workshops where people work. They are also good for greenhouses and livestock farms - thanks to the removal of carbon monoxide, they are safe for people, animals, plants. It is important to remember that although combustion products do not enter the air stream, good ventilation is still needed in such rooms.

Features of indirect heat guns:

- relatively low power - up to 85 kW;

- efficiency can reach a maximum of 60%;

- the air is heated up to 60-120 ° C;

- the cost of the units is higher than that of direct type heaters;

- there is no burning smell, can be used in residential and work premises.

Advantages and disadvantages of diesel boilers

Like any other equipment, diesel boilers have their own strengths and weaknesses. The advantages of such units include:

- The device is fully automated and can function autonomously without operator intervention. The duration of continuous operation is solely due to the capacity of the fuel tank.

- With proper operation of the automation, the boiling of the coolant is almost impossible, since the power of the installation can be instantly reduced to a minimum by turning off the fuel supply.

- When stored, liquid fuel takes up much less space than a supply of coal, firewood or pellets.

- Possibility of using waste oil and other liquid combustible waste as an energy carrier.

- Unlike gas boilers for heating a private house, the installation of diesel heating equipment does not require coordination with the relevant services and can be done on its own.

Along with these indisputable advantages, significant disadvantages should be noted:

- Since the operation of a diesel boiler without an automatic control system is impossible, it is necessary to ensure uninterrupted power supply to the installation. Despite the fact that electricity consumption is minimal, this still creates certain difficulties.

- The cost of standard diesel fuel for heating systems is significantly higher than the cost of wood and coal.

- To avoid fuel thickening at low temperatures, pipelines need high-quality thermal insulation.

- When storing fuel in an underground tank, in the event of a leak, soil and groundwater poisoning may occur.

- The need to create a boiler room, since the operation of a diesel installation is associated with an increased noise level and the possibility of unpleasant odors.

- Regular delivery of fuel and the organization of a special storage facility is required.

Despite the above disadvantages, diesel boilers are most widely used in summer cottages and private houses due to the possibility of autonomous operation, high efficiency and ease of installation.

Diesel heat generators

Diesel generators are a capacious term that includes heat generating units of various power, design, method of heat exchange with a heated medium, operational purpose, which are united by a common functional purpose - using the thermal energy of burning diesel fuel.

In the heating equipment market, the segment of diesel heat generators in different shares is formed by:

- portable and mobile (portable and mobile) diesel generators - heat guns of various capacities, sizes and form factors, which use direct heat exchange by radiation and convection between the burner flame / combustion gases and the heated medium.

The direct contact of the torch and the burnt gases with the heated medium as a whole determines the operational purpose of heat guns - for local or general heating of non-residential premises, surfaces, open space areas where the concentration of burnt gases in the air is not important. As a rule, heat guns are equipped with flame burners of a fan or fan-compressor type and an open (conventionally) combustion chamber made of heat-resistant stainless steel with a good reflective surface on one side, which makes it possible to achieve high efficiency of heat exchange by radiation;

- conventionally stationary diesel heat generators - furnaces (heating and heating-cooking) with evaporative or gasification burners (see more details about evaporative and gasification burners in this material).

In such furnaces, mixed heat exchange with the environment is used - radiation through a door window closed with heat-resistant glass, radiation and convection through the walls of the metal body-combustion chamber, convection through the walls of smoke tubes. Diesel furnaces are produced in limited quantities, mainly due to the low efficiency of the evaporative / gasification burners and the practical lack of the required level of control / management over the combustion and heat transfer processes;

- conditionally stationary diesel heat generators - air heaters with gasification burners, sometimes - evaporative burners with droppers, equipped with a vertical combustion chamber made of heat-resistant stainless steel, a fuel tank and automation.

In fact, such air heaters are an improved modification of diesel furnaces with automatic control / management of fuel supply and heat exchange by radiation / convection between the flame / burnt gases and the environment through the walls of the combustion chamber and the walls of the smoke channel. The efficiency of air heaters with gasification / evaporation burners and automation is higher than that of diesel furnaces, but significantly lower than that of hot water boilers and boilers with blowing burners of mechanical, pneumatic and rotary fuel atomization (see more details about blowing burners with mechanical, pneumatic and rotary by spraying fuel in this material);

- specialized diesel heat generators - heating / cooking-heating furnaces and smart models of boilers for yachts, as well as diesel air heaters for vehicles (see more details about compact (smart) boilers for yachts in this material).

In such diesel heat generators, both gasification and blower burners can be used, as a rule, mono-fuel without a preheating chamber, and a reserve fuel tank is either absent or of small capacity and is connected by a fuel line to the fuel storage tank on the yacht / car.Heat exchange takes place by radiation and convection, but in most yacht furnaces and in all car heaters - through the walls of the combustion chamber / smoke channels with room / space air without an intermediate heat carrier. Both furnaces for yachts and car air heaters are automated to a certain extent, but the efficiency of the units rarely exceeds 70-75%;

- stationary diesel heat generators - domestic hot water boilers of floor-standing or wall-mounted design - typical, low-temperature and condensing with blower fan or fan-compressor burners of mechanical or pneumatic method of fuel atomization, both mono-fuel and multi-fuel, less often - rotary burners or combined dual-fuel gas-diesel burners (see this resource for more information on mono-fuel, multi-fuel and dual-fuel burners).

The design arrangement of blast burners in low-temperature and condensing boilers can be horizontal or vertical, in typical hot water boilers - horizontal, sometimes hot water boilers are performed in the same body with a boiler-heat exchanger, as well as an internal or external heat exchanger for condensing water vapor from flue gases to increase efficiency the operation of the boiler unit (video of the built-in heat exchanger here, video of the external one for condensation of flue gas vapors in this material).

Leading manufacturers of hot water boilers complete their products with air-to-gas systems (LAS) for operation using external air heated by burnt gases without air flow from the room and, accordingly, unnecessary heat losses (see this material), as well as intelligent level automation with the ability self-diagnostics of the boiler and the heating system as a whole, operation in energy-saving mode and control / management from remote controls, remotely from a PC, Netbook, AppleMacBook, Notebook, Internet tablets, iPhone, iPodTouch, smartphones and communicators via LAN and / or external Internet channels with an output via Ethernet gateways, Ethernet-Fast, Ethernet-Arcnet, Ethernet-FDDI, Wi-Fi, Wi-Max, 4G, 3G, EDGE via Modbus, BACnet, CAN, LON, PLR, DP, Ext. Off, Ext. Min., SBM, Ext. Off / SBM Industrial Ethernet (see smart automation video here and in this material). Heat exchange in hot water boilers by radiation and convection using an intermediate heat carrier - water circulating in the jacket of the boiler unit made of cast iron or heat-resistant stainless steel and internal / external heat exchangers for condensing steam from flue gases;

- conditionally stationary diesel heat generators - floor / wall air heaters with mono-fuel or multi-fuel blowing fan or fan-compressor burners of mechanical or pneumatic method of fuel atomization.

As a rule, heat exchangers of air heaters are made of heat-resistant stainless steel, less often of cast iron, and heat exchange is carried out by radiation and convection through the walls of the heat exchanger between the burner torch / flue gases and room air, forcibly circulating in the heat exchange channels.

Basically, air heaters are focused on zoned heating of hangars, car washes, car services, manufacturing workshops and warehouse / industrial premises, but can be used in systems with fan coil units for heating residential buildings;

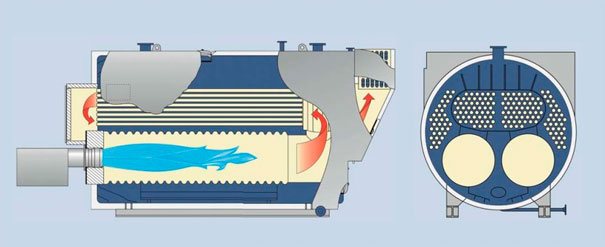

- stationary diesel heat generators - steam and hot water boilers and boilers with blower fan-compressor burners - mono-fuel, multi-fuel and dual-fuel gas-diesel.

As a rule, they are performed with large-scale tubular heat exchangers, one or two combustion chambers for flame burners, are fully automated and controlled from the control panel of the automated process control systems (APCS), automated control and management systems (ACS) or Bulding Management Systems according to protocols Modbus, BACnet, CAN, LON, PLR, DP, Ext. Off, Ext. Min., SBM, Ext. Off / SBM Industrial Ethernet.

The "industrial" purpose of such boilers is formed both by the capacity of the heat exchanger and by the power of the fuel burner / burners, although by design and method of atomization / combustion of diesel fuel, the burners are de facto typical and similar to fuel burners of domestic hot water boilers.

specializes in deliveries to the Moscow region of air heaters and hot water boilers using waste oils from the world's leading manufacturers. All air heaters and hot water boilers of BiKoms Holding are in fact universal and, when equipped with an appropriate mono-fuel burner or using a multi-fuel burner, can effectively operate on almost all types of liquid fuel - diesel and heating oil, synthetic and vegetable waste oils (and their mixtures), as well as fuel oil and mixtures of fuel oil / diesel fuel with natural gas (when equipped with dual-fuel gas-oil or gas-diesel burners).

Fuel consumption of diesel heating boilers

Since the cost of diesel fuel is quite high, fuel consumption is one of the most important characteristics of the installation. Excessive energy consumption leads to a significant increase in material costs for heating the house. Increased fuel consumption can occur due to the following reasons:

- Incorrect burner adjustment

... Complete combustion of fuel is possible only with the optimal ratio of fuel and oxygen in the combustible mixture, otherwise the consumption of diesel fuel increases significantly. - Fuel thickening

... With a significant drop in temperature and insufficient thermal insulation of the supply pipelines, the viscosity of the diesel oil increases, which inevitably leads to an increase in fuel consumption. - Failure of the nozzle or injector

... Under the influence of high temperatures, the injector nozzle gradually burns out, which leads to incorrect atomization of the combustible mixture and, as a result, to an increase in fuel consumption. - Climatic conditions

... In severe frosts, more diesel fuel is required to maintain a given temperature regime.

There are a number of ways to reduce diesel fuel consumption while ensuring the required temperature balance in the house, these include:

- Careful burner adjustment. The use of specially developed software allows to reduce the fuel consumption of a diesel heating boiler for a private house by 10-15%.

- The use of room temperature sensors and automation that monitors changes in external temperatures reduces fuel consumption by 15%.

- Thermal insulation of external storage facilities and supply lines.

- The correct choice of power characteristics of the unit.

When these conditions are met, the consumption of diesel fuel is reduced by 25 - 30%.

Determination of the average fuel consumption

At the household level, with a sufficient degree of accuracy, it can be assumed that with a power of 10 kW, a diesel boiler consumes 1 liter of fuel per hour, provided that the heat is consumed exclusively for heating the house. In the case of using a double-circuit boiler, the consumption of diesel fuel increases by an average of 30%.

Considering that to heat 10 m2 of living space, approximately 1 kW of thermal power is required for the efficient operation of the heating system in a house with an area of 100 m2, a heat generator with a capacity of 13-15 kW is required. Such an installation consumes 1.3 - 1.5 liters of diesel fuel per hour, therefore, from 30 to 32 liters will be consumed per day. Provided that it operates in the nominal mode for the entire heating season, the fuel consumption will be from 4.5 to 5 tons.

Features of the choice of diesel heat guns (TOP-8 models)

First of all, you need to decide whether you need a direct or indirect heater. If people will work in the room, direct-flow heat generators cannot be used. They are suitable only for technical and industrial premises, where no one is for a long time.Here is a roundup of the top eight diesel heat gun models of both types.

Master BV 110 E

A small indirect heater, powered by diesel or kerosene, which can heat a room up to 900 cubic meters. It has an excellent battery life of up to 24 hours.

The device can be additionally equipped with a thermostat. The main feature of the model is a simplified fuel supply and electronic combustion stabilization.

Characteristics:

- power - up to 33 kW;

- fuel consumption - 2.71 l / h;

- tank volume - 65 l;

- weight - up to 77 kg.

Master BV 470 FSR

A more powerful model from a Polish manufacturer for heating large utility rooms. Several hoses can be connected to it for better air flow distribution.

The heater runs on diesel fuel or kerosene. Battery life - up to 12 hours. Please note that the fuel tank is not supplied in the kit - it is more convenient to select a container of a suitable volume separately.

Characteristics:

- power - up to 134 kW;

- fuel consumption - 11.3 l / h;

- tank volume - up to 140 l;

- weight - 225 kg.

Zitrek BJD-30

A small direct-type heat generator from a renowned Czech company supplying construction equipment. It can be used to heat rooms from 650 to 1,000 cubic meters.

A thermostat is already built into it, the device is also equipped with automatic flame control: if the fire goes out, the heat gun will automatically turn off. Battery life - up to 16 hours.

Characteristics:

- power - up to 30 kW;

- fuel consumption - 2.4 l / h;

- tank volume - 38 l;

- weight - 22 kg.

Renza BGO-20

A small direct-flow heat gun from a famous Chinese brand. Among its advantages are its compact size and relatively low weight, so it can be easily transported even in the trunk of a car.

The heater can be used indoors up to 25 cubic meters. The model comes with a built-in thermostat and flame control. The device can work up to 10 hours at one gas station.

Characteristics:

- power - up to 20 kW;

- fuel consumption - 1.9 l / h;

- tank volume - 19 l;

- weight - 14 kg.

Ballu BHDP-10

Compact portable version of the heat generator with direct heating. It weighs only 10 kg and is equipped with a special carrying handle, so it can be used for drying walls in small spaces.

The maximum heated area is up to 70 cubic meters. The model is equipped with a built-in thermostat, fuel level indicator and a special stand.

Characteristics:

- power - 10 kW;

- fuel consumption - 0.8 l / h;

- tank volume - 12 liters;

- weight - 10 kg.

Elitech TP 120 DP

Direct-flow diesel cannon from a Chinese manufacturer. It can heat technical rooms up to 790 cubic meters. Convenient model on wheels - it is easy to transport on the construction site, despite its heavy weight.

Additionally built-in thermostat and digital display with temperature indicator. The maximum temperature to which the air is heated is 450 ° C.

Characteristics:

- power - 120 kW;

- fuel consumption - 11.4 l / h;

- tank volume - 110 l;

- weight - 74 kg.

Kerona P-3000E-T

Another compact and relatively light model of a direct type heat generator from a well-known Korean brand. The device can heat a room up to 200 cubic meters continuously for 12 hours.

The equipment is equipped with overheating protection, flame control, temperature sensor. Thanks to the handle and platform on casters, the heater can be easily moved to the desired location.

Characteristics:

- power - 29 kW;

- fuel consumption - 3.2 l / h;

- tank volume - 38 l;

- weight - 25 kg.

Renza BGO-80В

Heat gun with indirect air heating. Like other models of the Chinese brand, the device is equipped with a simplified fuel supply system, flame stabilization and a built-in thermostat.

The flue is not included in the standard package. Due to its high power, the heat generator can be used in rooms up to 1,200 cubic meters. Battery life - up to 10 hours.

Characteristics:

- power - 80 kW;

- fuel consumption - 6.6 l / h;

- tank volume - 68 l;

- weight - 56.7 kg.

Criteria for choosing a diesel heating boiler

When choosing a diesel heat generator, special attention should be paid to the following aspects:

Thermal power of a diesel boiler. In general, it is generally accepted that for effective heating of an area of 10 m2 in the middle lane, 1 kW / h of thermal energy is needed, in cold regions this figure can be 1.3 - 1.4 kW / h.

The ability to adjust the temperature. There are three main types of liquid fuel plants:

With a single-stage burner, operating constantly at maximum speed;

With a two-stage burner capable of operating in 50 and 100% modes:

With an adjustable burner that allows for a wide range of settings, which significantly reduces energy consumption.

Fuel consumption. It is this indicator that determines the economic feasibility of using a diesel installation, in addition, on the basis of these data, it is possible to prepare in advance the necessary fuel supply for the entire heating season.

In addition, one should take into account the possibility of creating a DHW circuit and reconfiguring the installation to use natural gas, in the case of supplying a centralized line.

Specifications

The performance and overall effectiveness of heat guns is determined by several characteristics. The main one is the heating power, which in the case of indirect action models can reach 85 kW. Units with direct action have a higher potential - about 100 kW. However, standard modifications usually operate with a power in the range of 20-40 kW. As for the power consumption of the fan, it averages 150-200 watts. The volume of the tank also matters. Its capacity determines how many diesel heat generators will support autonomous operation. Usually this figure is in the range of 15-25 liters. Fuel consumption varies from 1 to 2 l / h.

Features of maintenance of a diesel boiler

Even with a correctly adjusted burner, during operation, soot and ash settle on the inner surface of the combustion chamber and the surface of the heat exchanger. Even a small amount of these deposits significantly reduces the intensity of heat transfer, so a layer of soot with a thickness of 2 mm reduces the efficiency of the installation by 10 - 12%. To prevent this, it is necessary to regularly clean the combustion chamber, heat exchanger and flue pipe.

In addition, special attention should be paid to adjusting the burner, since the completeness of fuel combustion and, as a result, the amount of incomplete combustion products deposited on the walls depends on the correct ratio of fuel and oxygen in the combustible mixture.

It is also important to timely flush or replace the air / fuel nozzle to ensure maximum performance. The use of high-quality fuel can significantly reduce the deposition of soot and ash on the walls of the heat exchanger and combustion chamber.

Timely cleaning of the device and correct operation will extend the life of the diesel boiler and ensure the efficient operation of the heating system.

Top 5 best diesel boilers

At the end of 2020, the following models of diesel heating units for a private house were in greatest demand:

ACV mini

The device is compact and economical. The connection to the boiler allows for efficient hot water supply, and the ease of maintenance and reliability have made the installation very popular. The model is equipped with a thermostat, a thermomanometer and a winter-summer dual-mode regulator to reduce fuel consumption. The door of the combustion chamber is removable, which greatly simplifies the maintenance of the installation, and high-quality thermal insulation with mineral wool reduces heat loss.

Specifications:

| Options | Units | Value |

| dimensions | mm | 575x375x500 |

| Weight | Kg | 65 |

| Chimney diameter | mm | 80 |

| Heating area | m2 | 150 |

| Thermal power | kw | 16 |

| Working volume | l | 17 |

| Price | Thousand. rub. | 46 |

De Dietrich GT 123

The unit is distinguished by high performance and high coolant temperature. The diesel boiler is equipped with a three-way exhaust gas exhaust system, a turbulizer and asymmetric channels located horizontally, which makes it possible to increase the efficiency of the combustion products removal.

Specifications:

| Options | Units | Value |

| dimensions | mm | 840x575x1065 |

| Weight | Kg | 135 |

| Working volume | l | 19 |

| Thermal power | kw | 21 |

| Chimney diameter | mm | 125 |

| Heated area | m2 | 190 |

| Price | Thousand. rub. | 72 |

Buderus Ljgano G125-40 SE

The installation is extremely demanding on the quality of diesel fuel, the fuel used must comply with European standards, in particular DIN 51-630. A branded boiler can be provided as an optional extra.

The device is distinguished by high durability and reliability in operation, as well as simplicity and ease of control and adjustment. Connection to various exhaust systems is provided. In addition, the noise level during operation is significantly reduced.

Specifications:

| Options | Units | Value |

| dimensions | mm | 915x605x1125 |

| Chimney diameter | mm | 130 |

| Rated power | kw | 40 |

| Mounting method | Floor | |

| Heat exchanger | Cast iron | |

| Combustion chamber type | Open | |

| Price | Thousand. rub. | 122 |

Kiturami Turbo HIFIN - 17

The installation is a double-circuit oil heating boiler that provides effective heating of a room of 190 m2 and installation of a DHW circuit. The unit is equipped with separate heat exchangers.

Specifications:

| Options | Units | Value |

| Dimensions (edit) | mm | 705x330x605 |

| The weight | Kg | 40 |

| Efficiency | % | 89,7 |

| Chimney diameter | mm | 80 |

| Rated power | kw | 19,9 |

| Fuel consumption | kg / h | 2,15 |

| Price | Thousand. rub. | 34 |

Navien LST 21K

An economical heating system designed to heat a dwelling up to 210 m2 and provide hot water supply. The device is characterized by high performance and reliability, however, the electronic control system is very sensitive to voltage surges; during installation, it is recommended to connect to the network through a stabilizing device.

Specifications:

| Options | Units | Value |

| dimensions | mm | 754x320x520 |

| Weight | Kg | 51 |

| Efficiency | % | 90 |

| Chimney diameter | mm | 75 |

| Thermal power | kw | 21 |

| Fuel consumption | kg / h | 2,52 |

| Price | Thousand. rub. | 34 |

In addition to the official rating data, compiled on the basis of data provided by the sales departments of various sales representatives, when choosing a boiler for organizing diesel heating in a house, it will not be superfluous to read the reviews of the owners of such equipment.

Reviews of diesel heating boilers for private houses

1. We decided to purchase a diesel heat generator for heating the country house, since there is no gas supply in the village and is not expected in the near future. The price of a diesel boiler at the time of purchase was about 35 thousand rubles, which is quite commensurate with our budget. I installed the boiler myself and there were no significant difficulties. Now, for two years now, the house is warm and cozy, we are very pleased with the purchase.

2. Since there is no centralized gas supply in our village, we had to look for alternative options. Electric boilers disappeared immediately, since power outages are not uncommon in our country. Of the remaining options, we settled on a Navien LFA 21K double-circuit diesel boiler. As time has shown, the choice was absolutely correct, for 4 years now there have been no problems with heat and hot water.

3. It is very good that when installing a diesel boiler in a house it is not necessary to equip a special chimney! We installed the unit in a separate annex next to the house, and we brought a sandwich pipe through the wall to the street.The turbine copes well with the removal of gases and we do not feel any unpleasant odors. In terms of performance, the unit provides enough heat and besides, there is no hot water interruption.

4. The year before last, a diesel boiler ACVNmini was installed. In general, there are no significant complaints, unless it makes noise. This year I will make soundproofing from plasterboard with mineral wool lining and then it will be very good.

The use of units operating on liquid fuel as a heat generator is quite justified in the absence of centralized gas supply. In addition, unlike solid fuel boilers, the duration of a diesel boiler in autonomous mode is limited exclusively by the capacity of the fuel tank.