Panel houses are quickly built and have a low cost. Typical panel structures: sections of walls and ceilings, sanitary modules - are manufactured at the factory, and only assembled at the construction site. At the same time, it is extremely important to carry out high-quality insulation of interpanel seams. Otherwise, cold, dampness and drafts will penetrate into the home. There are several insulation materials and methods of their application. Seams can also be damaged by natural shrinkage of the house caused by soil mobility.

What is Vilatherm?

Vilatherm is an elastic porous molded product based on polyethylene foam. The material is produced by direct extrusion and physical foaming. Due to the peculiarities of the technology, the finished tourniquet receives certain physical and mechanical characteristics, which set the main list of its positive qualities.

Save photo

You need to log into your account

To add a photo to yourself, log in or register.

The manufacturer introduces to the market a wide range of round elastic cords with and without a hole, that is, tubular type - a hollow cord, as well as a one-piece bundle.

With the purchase of material, you can receive accompanying documents attached to the batch - certificates of quality and conformity, certificates from SanEpidNadzor, which issue an opinion on environmentally friendly products.

Wood sealants

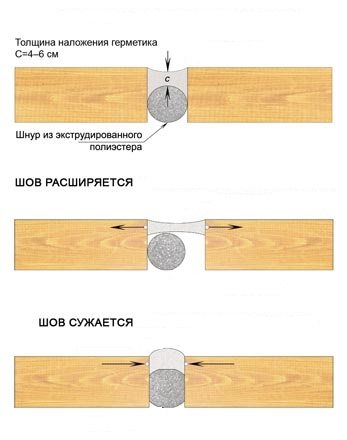

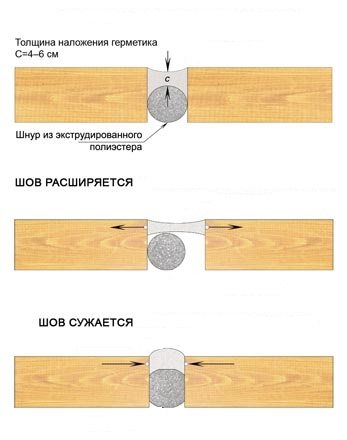

For the warm seam technology, special wood sealants are used, which, as a rule, are made on an acrylic base. The main feature of sealants is their elasticity, due to which permanent sealing occurs, even when the dimensions of the joints and cracks change.

We will not advertise companies in the article. The choice is yours.

Characteristics of Vilaterma

- Flexible elastic cord with a porous closed cell structure. Material of various densities, hollow and solid for selection according to the requirements of certain applications;

- The material is malleable for a wide variety of manipulations - it bends, twists, tied in a knot. Continuous laying in a seam of any shape and thickness is possible, with a change in its parameters linearly or depending on geometric indicators;

- Moisture-permeable material, strong enough for mechanical damage and tear. Shrinks, crumples, stretches and straightens out when the bookmark is removed from the preform;

- It is realized in skeins, in separate cut pieces of 3 meters, of any other size. Vilaterma color - white;

- Possesses chemical resistance, is a sound insulator and heat insulator!

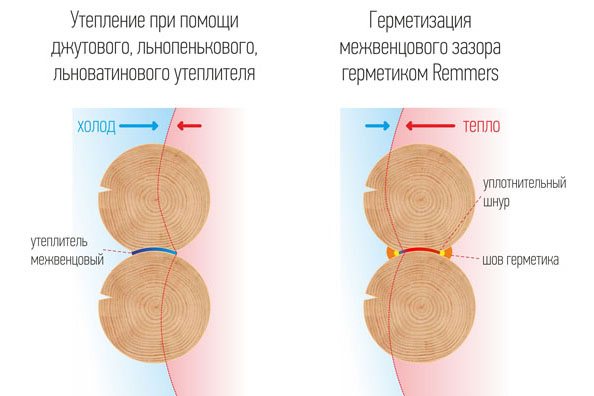

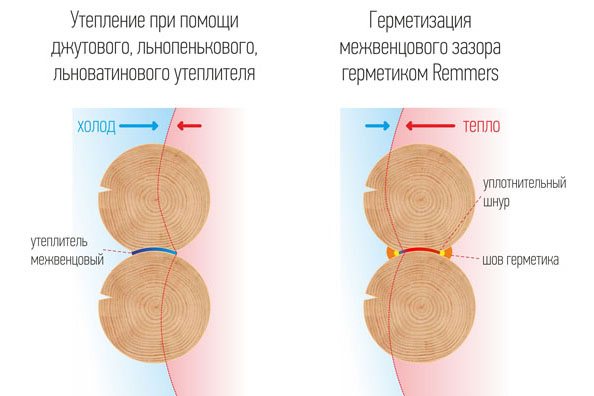

Traditional ways of insulating a wooden house

Our ancestors used natural aggregates that could relatively easily fill voids, while being good insulation materials. The fillers were "nailed" into the cracks, thereby filling the voids. This method was called caulk. For caulking, moss, linseed tow, wool were used.

These materials had flaws. Various insects were introduced into them, which attracted birds. Birds, trying to get insects, pulled out the insulation. A number of birds took out insulation for the sake of building material for their nests. In addition, the insulation dried out over time, as a result, voids formed again. As a result, I had to caulk every year or two. Outside, the cracks could be covered with clay. This temporarily protected the insulation.

Main advantages

When choosing a material for certain jobs, it is important to take into account not only the characteristics, but also the advantages over other materials used in this area, or direct competitive analogs. This will allow the most accurate comparison to select the product that suits your requirements!

Among the main advantages of Vilaterm are the following:

- It is very convenient to work with the material. Cutting with an improvised tool, the use of cuts and residues is practically waste-free. The ability to replace the material with another one with different characteristics;

- Ease of purchase. Large assortment of standard sizes: diameter of heat-insulating bundle from 6 to 80 mm, length - any;

- Convenience of delivery. Light weight, so you can deliver the cord in a package, bag, trunk, and in small quantities, even in your hands, giving it a comfortable shape and fastening it with tape;

- Choice by structure and type of material - a hollow tube and a one-piece, more compression-tight cord;

- Density of Vilaterma - 25-40 kg / m3, choice for different requirements and working conditions;

- Working temperature of the material from -60 ° С to + 80 ° С;

- Elasticity - 0.26-0.36 MPa;

- Thermal conductivity of Vilaterm - 0.04 W / m ° С;

- Water vapor permeability about 0.002 mg / MhPa;

- Water absorption within 3% by weight!

You can compare the data with other materials, because there are really a lot of analogues, and even earlier, few people used a porous elastic tourniquet in their work. Today, advertising campaigns for it are strong, and thanks to this, the products overwhelm the market!

Types of materials for insulation of interpanel seams

For sealing and insulating joints of abutments, expansion joints, it is recommended to use materials that withstand deformation well, have a service life of at least 15 years, and a wide range of operating temperatures.

Professional polyurethane foam

Sealing of interpanel seams with polyurethane foam without sealing tapes or bundles is used for economical and partial repairs without complete opening of the joint. It fills all the voids, freezes in 12-24 hours. The remains are easily cut off with a construction knife to a flat surface, which is covered with a sealing mastic.

It is not recommended to use foam without additional sealant for moving joints. Thermal deformations will gradually lead to the appearance of cracks that will allow moisture and cold to pass through.

Pros:

- quick and convenient seam insertion using a nozzle pistol;

- good adhesion to concrete;

- even distribution at the joint;

- effective heat and waterproofing with external protection with mastic;

- heat resistance of the seam - from +90 to -50C.

Minuses:

- high total cost of sealing, based on the price of one cylinder and the required amount per building;

- foaming at a temperature not lower than -10C;

- freezing of frozen foam in case of violation of the temperature regime of operation.

Guernite cords

Elastic sealing cords based on foam rubber. Due to the structure with superficially closed pores, they are practically air- and water-tight, and they can successfully solve the problems of insulation and waterproofing. The material has a long service life, but is little used in modern construction, which is associated with the large weight of the coils.

Pros:

- low water absorption - 3% by weight;

- operating temperature range - from +70 to -60C;

- affordable price.

Minuses:

- inconvenience in work due to severity - a running meter of a cord with a diameter of 50 mm weighs 1.5 kg;

- compaction at a temperature not lower than -20C, the need for holding in heat before laying;

- decrease in properties in case of damage to the surface film that closes the pores.

Foamed polyethylene harnesses

Foamed polyethylene cords or bundles are used for heat and waterproofing of interpanel seams. Elastic material with closed cells minimally deforms during compression, retains its shape well.It is characterized by stable properties during the service life, low thermal conductivity and water absorption, lack of adhesion to sealant mastics.

Advantages of expanded polyethylene harness:

- light weight, easy installation;

- minimum water absorption - no more than 2% by weight;

- operating temperature range - from +10 to -60C;

- thermal conductivity - 0.035 W / m * K.

Assigning material

- Construction - log houses, log cabins, panel residential and technical, industrial facilities;

- Finishing works: sealing expansion and heat shrink joints, joints inside the premises. Work with ceilings, floors, installation of damping lines, laying in shrinkage joints, for soundproofing partitions by limiting vibration transmission;

- Outdoor work: sealing of seams and joints of wall panels in low-rise and high-rise construction, seams of blind areas, garden paths, preliminary laying of concrete sites in the seams;

- Thermal insulation works with roofs, walls, floors - reducing heat loss and limiting the access of cold air;

- Application as a sealant in almost any related field;

- Insulation of doors and windows, slopes and junctions of frame structures and the main walls of the building;

- Sealing of structural joints of various parts and their bases in refrigeration units, ventilation ducts and equipment;

- Use as a shell, a shell for water supply and sewerage pipes for protection, as well as limiting heat loss, eliminating condensation!

In practice, Vilatherm cord can be applied many more places on demand and compliance. But it is worth starting from the main directions!

Why do you need to insulate the log house

What is wrong with the seams in the traditional laying of logs, inherited by modern architects from many generations of ancestors? Why is the caulking of a log house still an indispensable stage in the construction of wooden houses?

The thing is that wood is a living material provided to man by nature. No matter how perfect the woodworking is, and the perfect fit of the logs cannot be achieved, especially when it comes to chopped logs. For many years, the tree, still alive, reacts to temperature changes, humidity: it dries out, cracks, then it bursts. Therefore, cracks are inevitable through which cold air enters the room, and warm air leaves.

Cracks in a wooden house

It turns out that the choice of wood for building a house initially presupposes mandatory thermal insulation. The owner can only decide whether it will be a new technology - a warm seam for a wooden house - or traditional caulking.

Application of Vilaterm: myths and refutation

It would be possible to give only a dry list of the scope of Vilaterm, but it is more interesting to touch upon the advertising description from many sellers on the Internet and building stores, wholesale bases. Often, they are seriously exaggerated, pointing out non-existent advantages and qualities of the material. Therefore, it is worthwhile to additionally study the main advertising theses on the application and positive properties, as well as give them a true assessment, perhaps a refutation, comment on each separate point!

- Wide application in construction, renovation and finishing works as a heat insulator, sealant and sound insulator. Yes, this is a perfectly true statement;

- The material is used to exclude leaks from the outside into the interior through cracks and interpanel joints. In fact, Vilatherm only seals the seam, and therefore, as a waterproofing material, it works only partially. To ensure high-quality protection, a whole range of works will be required, using additional materials, for example, waterproofing mastic;

- Crevices and cracks filled with Vilatherm become hydrophobic. The concept is rather vague, since it should be indicated, as in the previous paragraph, that only in complex application.Independently, the material, if it is not provided with additional protection with mastic, due to the influence of the atmospheric environment, will lose its properties - crumple and shrink, while passing more and more water;

- Vilatherm removes mold and mildew, dampness from the walls. The material certainly does not have such properties. But as a warning of these problems, it works;

- Thermal insulation of facades and walls. Vilatherm has certain thermal insulation properties. But it will not make the wall warmer when laid in interpanel seams. You can use it, but only for its intended purpose;

- High-quality insulation and sealing of joints between reinforced concrete slabs in construction. This is indeed the case. One of the best modern sealing materials and representatives of insulation systems;

- Noise isolation of the room. Minimal noise reduction from the outside when laying in a seam. But for high-quality sound insulation of a separate room or object, work is carried out with all structural planes - walls, floors, ceilings. Also, it is necessary to choose the right doors and windows;

- Thermal insulation of pipes in private housing construction. If the combination of characteristics is permissible, then this type of work can also be applied by completing the external finishing of water supply or sewage pipes;

- Vilatherm is suitable for sealing joints when installing window systems and doors. Correct statement, the foamed elastic tourniquet does an excellent job with such tasks;

- Vilatherm in work with floating floors, dry screed device. Yes, the material is suitable for the installation of a damper zone around the perimeter, sealing. But more often a foam tape of a similar structure is used. It all depends on the choice of craftsmen at the place of work;

- Furniture production - as form-building elements. Perhaps, but the application is not widely developed;

- Insulation of old wooden windows, doors, any structural openings. Maybe! And in this area, the material has long proven itself well;

- Car repair - noise insulation of car and truck bodies. True statement!

In fact, as mentioned earlier, in the construction industry and related areas, due to the characteristics and features of this product, it will be quite easy to find an application for it!

What is a wooden house

Before we start talking about insulation of a log house of a wooden house, it is necessary to clearly define what will relate to the concept of "wooden house". It would seem that to understand! But thanks to marketers trying to sell us even what we don't need.

As a result, frame houses, SIP houses, double beams, insulated beams and other technologies are all trying to be classified under the concept of a wooden house. After all, there is a tree in them. Yes, there is a tree. But it is also present in the wooden floor of a brick house, and in the wood concrete block. These are not wooden houses!

We can talk about a wooden house only when the tree acts not only as a structural part, as a frame, but also as the main heat-insulating part (and there is no need to bring frame houses with ecowool made of paper here).

Thus, only houses that are built of rounded or chopped logs, planed, profiled or glued beams can be classified as wooden houses. These are houses where the tree is a monolith, serves as both a frame and a heat insulator.

In my article, I will call wooden houses made of logs and beams a log house. Maybe someone will argue with me, but I do it for a reason. Yes, indeed, such houses were not cut down, but, firstly, they are a modern development of the construction of houses using the technology of manual felling. In examples, what is the difference between a Norwegian log house from a gun carriage and a house built from a profiled beam. In both cases, both manual felling and machining can be present.

Secondly, the blockhouse is not just cut down with an ax, it is assembled by means of locking joints of solid wood parts (logs, beams). And there is no concept to characterize this phenomenon in wooden architecture. Who knows, tell me. Well, not a castle!

So, I think we agreed. We will talk about the insulation of a log house as a generalizing structure from a log or a bar.

How to work with Vilatherm

Internal work. When laying the sealant in the seams during internal work, its further protection is optional. Requirements for dry processes are minimal. It is enough to firmly press the cord into the cavity, trying to lay it straight, without twisting along the length. Such a device is allowed when sealing windows and doors, interpanel seams before plastering and finishing, when pouring floors. Bonding of material is possible!

Outdoor work. When sealing external seams with Vilatherm, additional foam and waterproofing materials are used. This requirement works in the field of sealing interpanel vertical and horizontal seams. On a loaded plane, as well as when installing a blind area, platforms and paths, the material is installed without mounting foam, on an adhesive base or liquid sealant, with additional mastic waterproofing!

Step-by-step instruction on technology:

- The cord fits into the seam based on its dimensions. It is not recommended to stretch or compress the material along its length, as this will violate its density, leading to the material protruding from the seam;

- For sealing joints of static structures, cracks in sites, heat-shrinkable seams of the pavement, material is used with a diameter tolerance of up to 40-50% greater than the width of the cavity. It should fit snugly into the mold;

- Cutting the cord is done with a knife or scissors. Tearing the seal is not worth it, as it has good tensile strength. By making an effort to break, you break the structure of the material;

- It is possible to work with seams of any shape and length. Sealing at the joints of individual Vilaterm sections up to 10-20 mm;

- After installing the cord in the mold, additional protection from moisture and ultraviolet radiation is mandatory!

The main stages of work

The list of works for thermal insulation of seams is almost always the same. It begins with the fact that all cavities in the seams are filled with polyurethane foam, which, due to its properties, fills large empty spaces. After that, a special insulation is installed in the seam, as a rule, this is a Vilatherm cord, the diameter of which depends on the width of the seam between the panels. On top of the insulation, either polyurethane foam or a special solution is applied. From above, the seam is treated with a special sealant, which can also be bituminous mastic.

If, during the restoration or overhaul of the joints, it is found that the condition of the insulation is within the standard indicators, then it will be possible to significantly reduce the cost of work, since it will only be enough to update the outer layer of the sealant. The sequence of installation of various types of insulation with subsequent treatment of interpanel seams with a sealant is the most common technology for performing repair, restoration or insulation of multi-storey buildings.

Vilatherm and polyurethane foam: the difference in insulation and sealing of seams

In this comparison, you can work without tabular data, because there is a standard experience of masters, which shows that in almost any region, polyurethane foam, which is not protected by painting, plaster or mastic from the influence of the external environment, becomes unusable at the junction of the first and second seasons. Finally deteriorates and spills out after 2 years, in more suitable conditions - after 3 years.

Vilatherm and similar materials based on foamed polyethylene show more serious service lives in an unprotected environment - about 8-10 years.At the same time, there is minimal shrinkage, primary damage to the external structure, drying out of the material.

Using polyurethane foam or foamed polyethylene cord, the materials should be additionally waterproofed. But in the event of a violation of the protective layer, Vilatherm minimally absorbs moisture and temperature fluctuations, when the polyurethane foam begins to actively accumulate and pass water through itself into the interior. It remains to add here the conditions of a negative temperature, and the sealing material is almost completely damaged, although the mastic protective layer is still more or less suitable externally!

With foam, internal damage is more likely. And the problem is that even when inspecting the building before possible maintenance work, only an experienced master will notice minimal damage and start working with the seams. If such a moment is missed, moisture will begin to accumulate inside, complementing the necessary conditions for the development of a pathogenic environment. And according to the first opinion, the insulated and sealed seam will already cause dampness and mold on the inner walls!

Working with Vilatherm is pleasant and simple, but most importantly, it is convenient and inexpensive. The sealing harness is available in different sizes, is on sale in almost any outlet, and costs from 3 rubles per running meter. Decent option at an affordable price!

Functions of sealing materials

Materials for sealing interpanel seams, junctions of window blocks, balconies, loggias to openings perform several functions and help maintain the required temperature and humidity conditions in the building.

Key tasks:

- Additional thermal insulation

... Insulation of interpanel seams increases the energy efficiency of the building, reduces heating costs, and eliminates drafts. - Waterproofing

... Tight sealing of joints prevents the formation of condensation, the appearance of mold and mildew on constantly damp areas of the wall from the side of the room.

Competent termination involves complex work. To solve the problems of heat and waterproofing, insulation is used - a special sealing gasket and hardening mastic, which plays the role of a sealant.

Sealing of interpanel seams of apartments - price per meter "by key" for PRIVATE PERSONS (with materials):

1) Secondary sealing,

price (lubrication of joints) - from 350 - 400 rubles / r.m. with materials (restore sealant without insulation). 2)

Primary sealing,

price with insulation (for example, in new buildings) - 600 rubles / r.m. with materials. 3)

Repair of interpanel seams

and sealing of joints (repair of a closed seam: filling the interpanel space with polyurethane foam through technological holes and sealing mastic) - 650 rubles / r.m. with materials. four)

Overhaul of interpanel seams

(complete opening of the seam, removal of the old filler of the seam, high-quality filling with good seals and sealing of the joints) - 650 - 900 rubles / m. including materials, the price depends on the type of seam to be opened. In 90% of cases, the rate for sealing the seams will be 600 rubles. per running meter. If the interpanel seams of the house are not typical, for example, they are concreted, then the cost of opening the interpanel seam increases. five)

Sealing of loggias and windows

with insulation - 600 - 650 rubles / r.m. materials are included.

* Prices for the repair of interpanel seams of apartments include the cost of consumables. We will not "calculate" the final price from small components, and even add on the object. Our price per meter is final and below the market average.* Insulation is carried out with high quality, taking into account the fact that the apartment needs to be "cut off" from the cold bridges that penetrate through neighboring apartments along the entire thickness of the panel.* Warranty service throughout the year (included in the price). You will check your seams for all seasons, if everything is in order, the sealing will last at least 10-15 years.

UP

The minimum volume of sealing interpanel seams with insulation

for Moscow - 25 running meters. For the Moscow region - 30 running meters. Just greasing the seams (restoration of the sealant in the absence of problems with insulation), the minimum volume is 40 meters for Moscow and 50 meters for Moscow Oblast. This means that less volume will cost the same. In fact, it is better to make 25 meters of high quality and close the problem than to “fake” the interpanel seams meter by meter every year, and the problems will remain - blowing and freezing, leaks and mold. Moreover, there is no less than 9 meters. Judge for yourself: if the corner gets damp, you need to make a vertical seam (3.3 meters with plates), plus you need to make a meter up and down a meter (another 2 meters) to put plugs blocking the cold from the neighbors. Horizontally one meter to the right and left at the top and bottom also, this is another 4 running meters. Although horizontally towards your apartment, it is better to make the entire seam to the next vertical seam.

A superficial view of the problem is interpreted as follows: an angle of 2 meters damp, which means you need to seal 2 meters. This is exactly what the dilettantes from the managers do, it is not clear than 2 meters at the request of the tenant. And the problem doesn't go away. And it will not go away, since you need to eliminate the cause, and not just the visible result. For example, if a corner leaks during rain, it is advisable to seal not only your entire vertical seam, but also at least the floor above. Sometimes, upon opening, water flows like a waterfall from the vertical seam, which has accumulated there all summer. You need to eliminate the cause!

To find out the exact cost of repairing the seams of your apartment,

you need to calculate the running meters of the seams and multiply by the price per running meter. All prices per meter are final and include materials. Some sites offer a calculator for calculating the cost of repairing the joints of your apartment according to the house series. But the fact is that the sizes of the slabs in the houses are different, despite the same series, the running meters of the interpanel seams of apartments in the same house are also different depending on the layout. Therefore, the information about the price obtained with the help of such a calculator has a large error and unpleasant surprises for the customer at the end of the work. It is very simple to calculate running meters of interpanel seams, it is enough to measure the length of the horizontal seam outside the house and multiply by 2 (lower seam and upper seam). Then count the number of vertical seams and multiply by 4 meters (despite the fact that the ceiling height in the apartment is 2.7 meters, you need to count the thickness of the panel plates from the bottom and from the top, plus we seal with a margin, going into the adjacent seams by 0.5-1m to isolate your apartment from cold air and leaks from the seams of neighboring apartments.

UP

The role of the Vilatherm sealing cord in the "Warm seam" technology

- The cord fills the seam, which saves sealant;

- Additionally insulates the building;

- Serves as a gasket between wood and sealant. In the absence of a cord, if the tree begins to lead, the entire seam will become unusable. And in the presence of a Vilatherm cord, the sealant will be attached to the cord and touch the logs only at two points.

If we compare the classic caulking and sealing "Warm seam", then the second method, of course, demonstrates the best results.

Calculate the cost of a warm seam

Features of application technology

The Energoflex cord for sealing seams between logs has a low weight and simple installation technology. To use it, you do not need to have a special tool or have special skills in the construction business. However, there are some features of laying technology, which should be taken into account when working with insulation. The cord itself is a kind of cushioning material between the wooden base and special sealants.

The technology of using a cord with further sealing has several stages:

- preparation of the base.For this, dust, dirt, shavings and other contaminants are removed from the wooden surface. When working in winter, it is also necessary to clear the logs of snow or ice. When working in hot weather, it is recommended to slightly moisten the seams. Cleaning is carried out using a grinder with an appropriate attachment, spatulas, scrapers or a wire brush. Large cracks are additionally treated with special acrylic primers and allowed to dry (about 8 hours);

- laying the cord. After preparing the surface, proceed directly to the laying of the Energoflex insulation. All cracks, joints and cracks in the log structure are evenly and tightly filled with a cord so that the material does not protrude beyond the boundaries of adjacent logs;

- applying sealant. After installing the sealant, the inter-seam space is evenly poured with a special compound. Before purchasing a sealant, you should clarify its degree of interaction with the seal material in order to avoid the destruction of the cord.

Subject to the simple rules for installing the Energoflex sealant and the recommendations of the sealant manufacturer, the log structure will be reliably protected from heat loss in winter.

You can read an article about the technology of work on insulating the facade with expanded polystyrene at this link.

Sealing of loggias and balconies.

In all panel houses, loggias and balconies very often leak and are blown through. The main problems of loggias and balconies of panel houses:

- Leaky and leaky connections and joints of double-glazed windows in glazed balconies. - Leaky and leaky connections and joints around the loggia or balcony. - Ebbs are missing or incorrectly installed. - Worn out soft roof of the loggia.

Leaky seams and joints of double-glazed windows and walls in glazed loggias are sealed in the same way as in the joints of window frames with panels. Sealing of a loggia or balcony is carried out according to standard technologies for sealing joints between panels. And the replacement of the soft roof of the loggia is carried out according to the standard technology of installing a soft roof from waterproofing materials.

UP

Sealing joints of windows and panels.

A common problem with windows in panel houses is that there is no tightness of the joints between the glass units of the windows and the panels of the building.

When building a house, the joints between window frames and panels are plastered, or the panel comes to the construction site with windows. In any case, the joints are plastered, putty and painted. Water and cold do not explicitly penetrate, but the frames are almost always cold, since the cement mortar is not a heater, but over time it also allows moisture to pass through.

If old window frames are replaced with plastic double-glazed windows, window companies seal the joint between the frame and the panel with polyurethane foam without protective sealing of the joint. Polyurethane foam is a heater and at first it is warm in the apartment. But the polyurethane foam is afraid of the effects of the external environment, solar ultraviolet radiation and moisture. Within a short time, it gets wet and crumbles, therefore cracks appear in the joints, into which wind and moisture penetrate. In order to eliminate all these problems, it is necessary to cover the foam with a layer of sealing mastic.

On top of the sealant, you can put galvanized, painted platbands. Above the window slope, mount a wide ebb to drain water, and not a narrow cast over the frame, as window companies put it, which, on the contrary, facilitates water flow into the upper joint between the frame and the panel.

See more: Insulation and sealing of windows and abutments:

In order to get rid of mold around the windows, the windows are sealed - the joints and abutments of glass units and panels are sealed, the abutments of the ebb and the panel are insulated. Read more.

UP

Insulation of a panel house - briefly about the main thing

Faced with the need to reduce the heat loss of an apartment in a panel house, you need to consider the issue in the following sequence:

- sealing joints between panels;

- insulation of external walls with foam plastic using the wet facade method.

Sealing the joints may be enough to keep things warm. This will cost significantly less than the insulation of the end walls of panel houses. If you are not satisfied with the result, then you will have to be insulated with foam, naturally, the effect of wall insulation in tandem with sealing the seams will be higher. Styrofoam is attached to the wall using a universal dry glue that is diluted with water, or glue-foam. Additionally, fixation is carried out with dowels. Foam is better than ordinary glue, it is more reliable, it is more convenient to work with it. At the same time, it will be more profitable to buy glue-foam at a price if it is used as the manufacturer recommends.