Most insulation materials have a porous or fibrous structure. Basically, this means that inside the material there are many small voids filled with air. Due to this, such materials have a high coefficient of resistance to heat transfer. With improper installation, builders' mistakes, it happens that the insulation gets wet, and the voids inside it are filled with water. If this happens, the thermal insulation material loses its properties, because its resistance to heat transfer is seriously reduced.

Roof insulation got wet, what should I do? With a decrease in temperature and frost, instead of a heater, there is just a layer of ice. This leads to a strong increase in the heat loss of the room. If the building has an autonomous heating system, fuel consumption and money costs increase significantly. With centralized heating and the inability to increase the heating power, the temperature in the building drops significantly. Excess moisture in the roof space creates dampness, the wooden elements of the roof suffer, and the metal parts of the structure corrode. As a result, wet insulation turns out to be the cause of a whole heap of related problems.

Possible causes of moisture accumulation in thermal insulation

The problem when the thermal insulation material under the roof gets wet requires an immediate solution. This can happen for many reasons. Here are the main ones:

- During installation, the waterproofing material between the roof and the insulation was damaged. This is usually a film or superdiffusion membrane. The workers may have punched it when they were assembling the roof. This often happens when the waterproofing is attached by over-stretching, which is a mistake. Installation must be carried out so that the waterproofing sags a little and does not create excessive stress on the material. Also, moisture from possible condensation can collect and drain in places where the film sags.

- The joints of the waterproofing sheet were not carefully glued. In this case, condensate moisture can penetrate through the cracks in the joints.

- Poor installation of waterproofing in places of passage of a chimney or ventilation shafts. Here it is necessary to bend the edges of the waterproofing upwards and fix them to the pipe walls with a clamping bar or a clamp.

- A low-quality waterproofing material was used, a cheap superdiffusion membrane is moisture permeable.

Expert opinion

Konstantin Alexandrovich

In addition to possible reasons with waterproofing, moisture can penetrate into the insulation due to improper installation of the vapor barrier layer, which should protect the insulation from vapors from the interior. Even with good ventilation, steam is always present and with warm air accumulates at the top of the roof. Therefore, a vapor barrier is always installed in front of the insulation layer. If it is installed incorrectly or damaged, moisture will penetrate into the insulation.

What if the insulation is already wet?

First, it is necessary to determine the degree of wetting of the thermal insulation, regardless of whether the insulation in the floor or roof has suffered. If it is saturated with moisture through and through, then the only thing that remains is to throw it away, since it will not work to dry the insulation in the roof. However, many modern thermal insulation materials are made with protection from getting wet, for example, mineral wool fibers are impregnated with special hydrophobic substances that prevent the fibers from being impregnated with water.And if the insulation is not very wet, then you can try to dry it. How to do it? It is necessary to create a draft so that the moisture gradually evaporates from the insulation layer. To do this, you can use a heat gun. If the weather permits, it is better to remove the roof or facade coating material and dry the thermal insulation.

If the insulation gets wet, then, most likely, the weather is not ideal, and there may be a problem with the drying of the insulation. After all, the speed of its drying under the material of the roof or facade will in any case be low, even if you manage to create a good draft.

The best solution would still be to remove the wet thermal insulation and install a new one instead, avoiding mistakes during installation again. After all, not completely dried heat-insulating material definitely has the worst coefficient of resistance to heat transfer, which entails increased heat loss and heating costs. In addition, high humidity has a bad effect on wooden supporting structures, which threatens the need for their early repair. And these are costs of a different order than just replacing the insulation, and the savings can go sideways.

Wet business: how to deal with wet insulation

Finding that the insulation is soaked, there are two options for the development of events. If the fibers are wet only on the top and in a small area, it is possible to dry this area. This requires two conditions: a draft and clear warm weather.

URSA experts recommend replacing the insulation that is wet through and through. The main thing is to avoid the same mistakes when editing new material.

How to fix the problem and keep the insulation dry

To protect your newly insulated roof from getting wet, consider our professional advice:

- it is advisable to carry out installation in dry weather;

- before installing the mineral wool, cut the waterproofing film into layers of the required length;

- after fixing the insulation, immediately cover it with a protective membrane;

- glue the joints of the film, fix it on the rafters with a construction stapler;

- only walk on the boardwalk to avoid tearing the waterproofing.

You can choose a special insulation material for pitched roofs and waterproofing for it at https://www.ursa.ru/construction-solutions/skatnie-krishi/.

Proven materials, competent installation and the roof will remain dry in any weather!

Insulation ventilation

Poor ventilation of the under-roof space is a common cause of high humidity in the thermal insulation layer. Ideally, with good ventilation, air always circulates between the roof covering and the insulation, which prevents condensation from collecting. That is why it is so important to have proper ventilation not only in living quarters, but also under the roof.

Important! When installing roof ventilation, it is important to ensure air exchange in the space between the roof covering and thermal insulation. To do this, you can install special aerators in the ridge or directly in the cover. If you do not have any, it will not be superfluous to install them.

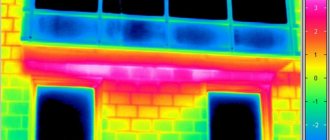

With insufficient thermal insulation between the living quarters and the attic on the roof from the inside, there is an increased formation of condensation. This can be dealt with by regular ventilation, then the condensation will dry quickly and no drops will form. But this is called dealing with the consequences. does not correct the cause or solve the problem. In such cases, it is better to invite specialists with a thermal imager to inspect the building and identify the places of greatest heat loss.

Condensation in wood floor insulation

Question:

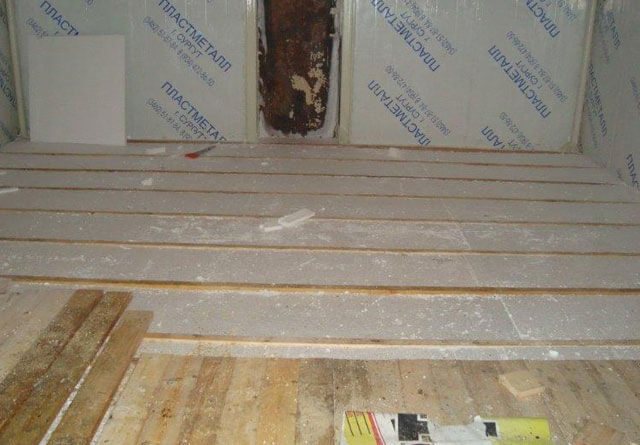

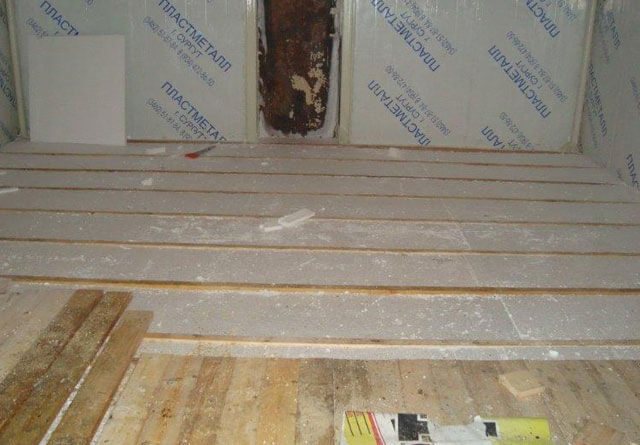

Good day! There is a log house 6 * 9. Attic - gable roof. It will be insulated in the future. The foundation is a tape of concrete, on it is a brick base 60 cm high, 1.5 bricks. The house is planned to be used for seasonal living, with occasional visits in winter. There were vents in the plinth, two on the short side and three each with a 120mm long pipe.After detecting condensate, I was forced to urgently add a similar amount of air vents to the first crown of the bar. The size of the vents is 10 * 30cm. I covered all the air vents with a metal mesh. I did not close the air in winter. Metal roofing. There is no interfloor overlap yet. The contour is closed, the windows and doors are standing. The soil is not isolated from moisture. Pie of the floor in the basement from below: to the logs the roughing board is 0.25 solid, then the mineral wool insulation in the "trough" without any membrane or waterproofing from the bottom, then the vapor barrier "***", (they write the analogue of isospan) with the smooth side to the insulation, - counter rail 2 cm, and floor board 40 mm. I didn't sew the board, I just laid it down.

Result: As early as the beginning of winter and then until April, a crust of ice forms on the inside of the vapor barrier. In the spring I opened it - on the mineral wool over the entire area of the house there is a layer of water of 10 mm. I threw out the vapor barrier, the mineral wool dried out. I do not know what to do. Give advice. The construction is at a standstill, there are no competent recommendations yet. Nobody takes into account the factor that the house is a seasonal residence. Maybe not use films at all and leave the mineral wool between the lags, or remove the mineral wool in general, do not insulate the floor, but insulate the basement? What should be the cake in the basement and under the same operating conditions of the house in the overlap of the first floor and attic, if the roof is insulated. And even in winter, when he saw condensation in the insulation, he added air vents, but in 1 crown of a bar, and not in a brick base! How critical is this for a bar?

Oleg, Nizhny Novgorod.

Answer:

Hello Oleg from Nizhny Novgorod!

Cold enters the house from three sides - from under the floor through the ground, and from the side of the walls and from the roof, that is, from the street.

In houses of permanent residence, when the temperature in the premises is stable above zero, the heating of the soil under the floor is more or less sufficient and, accordingly, the flow of cold from here decreases sharply. Insulation of the foundation and, above all, its basement part, also reduces the flow of cold from the bottom of the house.

But the fact that the house is seasonal residence immediately increases the likelihood of freezing its bottom. Due to lack of heating. And, as a result, the presence of condensation on the floor elements.

What to do? There may be many options, but, in my opinion, it is more optimal to proceed as follows. The first is to lay the simplest waterproofing on the entire surface of the soil under the house, at least in the form of an ordinary plastic film. Press it down in several places so that it does not move underground from drafts. Then evaporation of moisture from the soil and its ingress on the lower surfaces of the floor elements will be minimized.

It is not advisable to remove the existing insulation from the subfloor. It really should be dried to the maximum, if this is still possible. And put it back on the rough floor. And so that moisture does not penetrate into it, overlay both the top and bottom with a moisture-proof film. Brand-type does not play a special role. The main thing is that the smooth, moisture-proof side of the film would not be to the insulation, but to the outside of it. That is, the point is that water neither from below nor from above would get into the insulation, especially the mineral one. If you used solid brands of insulation such as penoplex, then films as such are not needed at all, this insulation does not absorb moisture.

About kotrreeks, etc. - no comments. An air gap is the right solution.

That is, all the insulation of the floor is preserved with the addition of another layer of film to it along the bottom of the insulation. Your type of insulation will be damp without the film. If the insulation is completely thrown out, then the notorious dew point will be located along the border of any element of the floor, with the presence, of course, of condensation.

Warming of the basement can additionally be done both from the outside and from the inside, by installing the already mentioned foam plates.Interior installation is less effective, since the base will freeze to a greater extent. Outside it is better, but then in addition, at least a decorative closure must be applied (flat slate or DSP is cheaper, basement siding is more expensive).

The pie is like a closure, lathing, ventilation gap, insulation. The ventilation gap may not be in front of the insulation, but after it - between the stone of the basement and it.

Regarding the vents already done in the lower crown, see for yourself - they most likely should be strengthened so that during the operation of your house it would not deform.

And so the air vents are arranged only in the stone basement of the house. In the lower beam it is extremely rare for the reason that the lower flange should not have cuts along its entire section, as this sharply reduces the structural strength of the house.

All wooden floor elements must be antiseptic in two or three layers with impregnation compounds intended for this purpose.

The ceiling is insulated, and at the same time it is also soundproofed in about the same way as your floor on the first floor. Namely, a film is attached to the lags-beams of the floor from below.In your case, no matter which side, but personally I prefer smooth down, then either a lining board or edged board is attached from below, and then a lining is attached to it (other options with plywood are also possible . panels, etc.)

Insulation is placed on top of the film. Here it is already possible to use the usual mineral basalt type. On top of it there is a film (with the moisture-proof side up! From possible water leaks when washing the floors of the second floor (attic). An air gap of at least 2 centimeters is desirable, but not necessary. Then the finishing floors.

Roof. With insulation of about 10 cm layer. With a film both above and below it, if it is mineral. In compliance with the installation technology. (Air gap, counter grill, etc.) Without insulation, you risk getting a steam room in the summer. With a metal roof (metal tile or metal profile), condensation will necessarily form on its lower side as a result of temperature changes above and below it. Therefore, the moisture-proof film, again with the smooth moisture-proof side up (!), Will receive trickles of water on itself and it will need to be drained away. Therefore, a minimum of deflections of the film and at the bottom of the eaves-cornices a gap for drainage from this film of moisture should be provided.

Approximately and in general terms so.

Once again, there are other variations.

Good luck!

Construction in Moscow and Moscow region

We work with a guarantee! A wide range of construction services. Foundation, walls, floors, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Other questions about condensation in rooms:

- Condensation in the garage from the roof how to get rid of

- Condensation inside the house above the well

- Condensation between the heated and no floor of the log house

- Mushrooms on a log house

- Humidity in aerated concrete house

- Condensation in the attic floor after insulation

- The wall in the adobe house is damp

- The wall in a log house in winter gets wet

- The walls in the house are damp

- Condensation under the floor of the extension

- The corners of a brick house are wet

- Condensation in ventilation pipes of an apartment building

- Condensation from the profiled sheet roof

- Will the insulation get damp in winter in an unheated house?

- Mold in a new log house

- Home mushroom what to do

- Condensation in wood floor insulation

- High humidity in a brick house

- Dampness in an old house without a foundation

- Condensation on the ceiling of a one-story thermal house

- How to get rid of dampness underground

- How to clean a vegetable pit on the first floor loggia

- Mold on hardwood floors in a brick house

- Condensation from inside the roof of a plastic balcony

- Condensation on plastic windows

- How to dry a basement

- The wall of the kitchen in a new building gets wet

- Condensation from the roof in the shed extension

- The bottom bar of the house is sweating

- Condensation on the extension to the house

- Wet walls in a log house

- Dampness after installing plastic windows

- Why is the floor damp in the corner of a frame house

- Condensation from bathroom ventilation

- The floors in the country house are constantly rotting

- Moisture in an unfinished house

- Condensation in the greenhouse

- Condensation in the insulation of partitions in the house

- Condensation in the bathroom vent

- Condensation in an irregularly heated house

- Condensation in roof insulation

- Condensate in the chimney of a gas boiler

- Condensation in window frames

- Dampness in the house what to do

Condensation in the house

All questions to Semyonich about construction

Semyonich (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topic of lumber, building materials and works, the author's opinion and knowledge of a real shabashnik with more than 15 years of experience is given. There is a section - funny stories of shabashniki. If you would like to receive information about this, subscribe to the newsletter of our website. It is guaranteed that your address will not be passed on to third parties.

Apartment renovation in Moscow and Moscow region

We work with a guarantee! A wide range of renovation works. Professional craftsmen.

+7 (905) 797-20-34

luxurykomfort.ru

| Dacha | Bath |

| For giving | Tool |

| Materials (edit) | Bikes |

| Foundation | Log cabins |

| Roofs | Warming |

| Walls | Siding |

| Floors | Cellars |

| Attic | Window doors |

| Stairs | Outbuildings |

| Wells | Toilets |

| Balconies | Loggias |

| Condensate | Flooding |

| Fences | Kennels |

| Sidewalk | Birdhouse |

| Adobe | Carts |

| Garages | Barn |

| Greenhouses | Bath |

| Swing | Brazier |

| Shower |

| Horizontal bar |

Thermal insulation using penoizol

An alternative to expanded polystyrene and polyurethane foam is penoizol, which is a "liquid" foam. Due to the fact that it contains special additives, it does not have the disadvantages that are present in its solid counterparts - flammability and the presence of rodents.

Penoizol has a drawback: to apply it, you must use the services of a team of craftsmen with special equipment. This kind of work is quite expensive. Insulation with penoizol involves laying a vapor barrier and filling the space between the attic beams with a layer of liquid material 20-30 centimeters thick. A layer of roofing material is additionally placed on top and a plank floor is laid.

Why does mineral wool get wet

The thermal conductivity coefficient of mineral fibers is 0.031-0.042 W / m 2 * K. This means that a 5 cm thick layer of glass wool is equal to the thermal effect of a meter-long brick wall. But the insulating properties are lost when moisture penetrates into the fibers.

Reasons for getting wet:

- Damaged the waterproofing membrane when laying the insulation. They pulled the canvas too tight, accidentally pierced it with a nail or self-tapping screw.

- The joints of the film were not glued. As a result, condensate penetrates into the fibers of the mineral wool.

- The waterproofing was not fixed tightly enough near the ventilation and chimneys.

- A low-quality diffuse membrane was used.

The risk of getting wet: what is the danger of raw insulation

Wait to get wet roof insulation

dries up on its own - a dangerous delusion. Wet mineral wool does not retain heat. In addition, it becomes a source of unpleasant odors, the spread of mold and bacteria. Well, the "cherry" is in the troubles of the roofing pie: wooden rafters are destroyed, metal structural elements rust at an accelerated pace. The result is a major overhaul of the roof.

To avoid problems, check the condition of the insulation:

- if streaks or drops appear on the walls of the attic;

- cracks appeared on the roof, the roofing elements do not fit tightly;

- in places of accumulation of snow, the roof caved in.

Preparing walls for insulation

If you think that mineral wool, the characteristics of which are suitable for your home, is a good insulation, then you must first prepare the walls for finishing. If the walls have plaster, it is necessary to remove it to brick, wood, concrete or stone, depending on what the walls of the house are made of.

If there are level differences on the walls by more than two centimeters, then they must be eliminated. After cleaning the walls from dust and dirt, you can cover the prepared walls with a primer.

You will need two types of mineral wool, which will differ in density. The soft board is placed against the wall, as such wool can fill all the unevenness of the wall. Place a hard board on a soft board, so you will form a smooth surface of the walls outside. The total width of the insulation should not be more than 10 centimeters.

Insulation work begins from the bottom, the plates are glued with a special glue.

When insulating a wall, you will have to adhere to the following sequence: wall, insulation, reinforcing mesh on dowels and facade plaster.

You can also insulate your house by making a ventilated facade. This will help prevent the formation of wet condensation, which is harmful to the mineral wool. Even in spite of their high moisture resistance, they let water vapor pass through themselves through their thickness, which can spoil both mineral wool, deforming and stratifying it, and the walls of the house.

Ceiling insulation with foam

In second place in popularity after mineral wool is foam. This is the name of a polymer material that consists of cells filled with gas. Due to their presence, the foam has thermal insulation characteristics. For household needs, polyurethane foam and expanded polystyrene are most often used.

The average value of the coefficient of thermal conductivity of foam is 0.041 W / (mK), which is similar in terms of thermal insulation properties to glass wool. Polyurethane foam (PPU) and polystyrene foam have an affordable cost and low weight. Such quality as lightness makes transportation, storage and installation of foam on the ceiling convenient.

But these heaters have a number of disadvantages, and this circumstance makes them not the best choice when arranging thermal insulation inside a residential building. Polyfoam is highly flammable and, during combustion, releases substances hazardous to human health. In addition, they appear even in the case of a slight heating of the material.

In the layer of this heat insulator, mice often start, but for insects and fungi, the foam does not become a breeding ground. When making a choice of how to insulate the ceiling inside the house, its owner must remember that a "greenhouse effect" can occur in the room where this material is laid.

There are two options for installing polystyrene foam:

- on glue;

- on the frame.

There is a certain technology on how to properly insulate ceilings in a private house using an adhesive:

- The surface on which the insulation is to be mounted is washed and protected from irregularities. If necessary, it is primed.

- Glue is applied to the sheet of material, it is desirable to use a tile, and after three minutes it is pressed against the insulated surface.

- The above procedure is repeated with all foam boards.

- A layer of reinforcing plaster is applied to the sheets and a fiberglass mesh is laid.

- After drying, it is covered with plaster again.

The installation of expanded polystyrene on the frame is similar to the process of installing mineral wool, but by laying sheets of this material between the slats, "liquid nails" are applied to their sides.

The most high-tech modern heat insulator is polyurethane foam. It is a polymer applied to any surface using special equipment. After mixing with air, foam forms on the ceiling, which creates a single layer of insulation.

PPU is characterized by environmental friendliness, long service life, does not form seams, prevents the penetration of street noise into the room.

see also

Comments 133

but there is no photo where the crate was stuffed during construction? this is how i garage wings, 50mm bar c-a.d-cd.net/e0bce06s-960.jpg

It was the same with me, only I beat 30 bar.Between the crate and the metal tile, everything is in order for me, the whole problem is insufficient insulation in the summer, I will add 10 cm

Relevant for me as well. Now with a thaw, then with frost. Every time it rains differently in the attic ... The builders shrug their shoulders. Cattle! The warranty for the house has long expired, it will probably be necessary in the summer like that myself ...

yes, I will also wait for summer now, there is no way to definitely additionally insulate

The problem is that your crate is not properly mounted (the absence of a counter crate is often neglected), warm air still penetrates through a loose connection (insulation with a rafter) and condenses at the junction of the crate and a hydro-windproof membrane. Membranes are different, which can be laid on the insulation and which must provide for a vent gap. Returning to the insulation, I can say that in our strip it is advisable to use the thickness of the insulation overlap of at least 20 cm, and you have only 15. And yet, lay it not only between the rafter beams but also crosswise horizontally, to exclude cold bridges between the insulation plate and rafter leg. What can be done now is hard to say, you can try to give an additional layer of insulation though…. What you need to do in the spring is to do the counter crate, but how to decide for you. I will try to throw off the crate scheme in a personal. Yes, the scheme that you attached - there is no outline of a piece of wood on it, the very counter lathing.

I fully support it. There is nothing to add. Ideally, just dismantle the roof and make a counter crate.

The problem is that your crate is not properly mounted (the absence of a counter crate is often neglected), warm air still penetrates through a loose connection (insulation with a rafter) and condenses at the junction of the crate and a hydro-windproof membrane. Membranes are different, which can be laid on the insulation and which must provide for a vent gap. Returning to the insulation, I can say that in our strip it is advisable to use the thickness of the insulation overlap of at least 20 cm, and you have only 15. And yet, lay it not only between the rafter beams but also crosswise horizontally, to exclude cold bridges between the insulation plate and rafter leg. What can be done now is hard to say, you can try to give an additional layer of insulation though…. What you need to do in the spring is to do the counter crate, but how to decide for you. I will try to throw off the crate scheme in a personal. Yes, the scheme that you attached - there is no outline of a piece of wood on it, the very counter lathing.

here is the link the membrane fits without a gap (declared by the manufacturer) I'm waiting for comments on what's wrong www.drive2.ru/c/1988136/

The problem is that your crate is not properly mounted (the absence of a counter crate is often neglected), warm air still penetrates through a loose connection (insulation with a rafter) and condenses at the junction of the crate and a hydro-windproof membrane. Membranes are different, which can be laid on the insulation and which must provide for a vent gap. Returning to the insulation, I can say that in our strip it is advisable to use the thickness of the insulation overlap of at least 20 cm, and you have only 15. And yet, lay it not only between the rafter beams but also crosswise horizontally, to exclude cold bridges between the insulation plate and rafter leg. What can be done now is hard to say, you can try to give an additional layer of insulation though…. What you need to do in the spring is to do the counter crate, but how to decide for you. I will try to throw off the crate scheme in a personal. Yes, the scheme that you attached - there is no outline of a piece of wood on it, the very counter lathing.

ventilate the under-roof space ... cut the film under the conkem.your warm air passes through the insulation (a little) and all this economy precipitates. everything is simple. the roof is a very serious construction ... I myself have dealt with this dense topic. I have thoroughly studied ... not many people understand and builders what is needed and for what purpose ...

During the construction of the house there was the same problem 1 in 1 ... What did they find out - no or a small gap between the insulation and the vapor barrier, as a result, insufficient ventilation and condensation - as they decided - they removed the insulation, I have it double - closer to the roof of cotton wool, then the type of foam , only modern material, I don't remember the name. So they opened the cotton wool, lowered it 5 cm lower and the plates were also redone - this winter showed that the problem had disappeared.

A strange topic ... If you did everything according to the picture, then the condensate should be blown out through the ventilation gaps. If there is no ventilation gap, then this is just an option for condensate. First, what is the distance between roofing and waterproofing? Is the insulation placed close to the film? Take apart the binder and insulation for now. Warm up everything with a cannon to dry it.

metal tile counter-lattice 25mm lathing 30mm memrana then insulation then vapor barrier

Well, minus only the thickness of the counter-lattice. Otherwise, everything is correct. Is the ridge ventilated?

the upper membrane is tightly stretched where the ridge is not cut

But it should be. How is it written in the instructions?

The same problem (((the day before yesterday there was “rain” on the second floor. Tomorrow builders will arrive, we will sort it out.

On the first drawing, if you take it literally, there is an error! And if this is repeated verbatim, the result will not be good!

Is this a picture from the net?

How do I dry the attic? And in order to additionally cover the logs with insulation, you need to dry the wet insulation correctly, after all!

This is a more difficult question! Unless, of course, take advantage of the thaw and try to warm it up with cannons in combination with airing! can work! If in frost it is already more difficult!

Alexander, a huge human THANKS to you, I will stick to your experience and thank you for your active participation

Sergei, not at all for that! It is always hard to help remotely. Now, if there was a possibility of visual inspection, then the conclusions would be more unambiguous! But you are far from me! ;))

How do I dry the attic? And in order to additionally cover the logs with insulation, you need to dry the wet insulation correctly, after all!

Once again I will add that when laying an additional layer, ventilate the previous ones for staggered laying and the density of adjoining to the attic lags. So I saw that some kind of cable comes out of the insulation. You also need to pay close attention to such places! And I also forgot to ask if chimneys go through the attic?

And ventilation of the outer walls

We must take care of the ventilation of the space inside the wall simply because the theory differs from practice and we cannot make a 100 percent reliable vapor barrier.

Now let's get back to the problem under consideration.

If the inside of the exterior finish gets wet in the built house, then this means that the vapor barrier is made very badly, ventilation is not done at all, and it also means. that the wall is not sufficiently insulated. I would like to comment specifically on the last statement.

I am humid air

Suppose I am warm room air. There is steam in me. Somehow I got inside the frame wall and started moving towards the cold. Why am I moving from warm to cold? These are the laws of physics. Density difference and all that. So I move myself and reach the layer of insulation. I need to get over it. Overcoming the insulation, I notice that the temperature around decreases and for this reason I lose my steam. It is deposited on the fibers of the cotton wool directly in its thickness. It is clear that losing moisture I become drier. But I still move on.Somewhere in the middle of the cotton wool layer, the temperature exceeded zero. At the same time, I already lost a lot of steam and left it behind right in the cotton wool, on its fibers. And when I had not yet come out of the cotton wool, but already somewhere very close to its outer edge, I felt that there was almost no steam left in me. And now I come out of the cotton wool and bump my forehead into a serious obstacle in the form of some awful film or OSB sheets. Then I feel like a sperm in a condom (sorry for the hooligan example), and I start to beat against this film. BUT THE STEAM IN ME ALREADY HAS ALREADY NOT REMAIN, and on this film or OSB plates I leave some last and completely microscopic molecules of frost, which can be seen only through a microscope.

And we have rivers flowing within our walls! What kind of insulation is this if warm air comes out of it?

Results and conclusions

Anything can be in an unfinished frame wall - we do not pay attention.

If the house is built and has a vapor barrier, the cotton wool may be slightly damp to the touch. THERE SHOULD NOT BE ANY RIVERS AND FLOWS OF CONDENSATE IN PRINCIPLE!

If there are rivers, then the vapor barrier is bad, and the insulation is also bad.

For a comfortable home and the longevity of your home, there should be small vents in the outside wall. Such that air can enter and exit, but very slowly and there is no wind inside the wall. Otherwise, all the heat will go away with the steam. It seems clear about durability, but what does comfort have to do with it? Despite the fact that wet and frozen cotton wool loses its properties in many respects and the house becomes even colder, and the moisture inside the walls is even greater, and so on to the point of absurdity. The ventilation holes should not be in the middle of the wall and not staggered along the entire wall, but only at the top and bottom and not a lot!

When vapor barrier is needed

It is unambiguously enough to simply formulate the condition of whether a vapor barrier is needed. When insulating with mineral wool, protection against water vapor will be needed when there is a possibility of contact with air coming from the side of the room.

To ensure efficient operation, each layer of the insulating “cake” must be more or less air permeable. This ability should increase from room to street.

Thus, warm air from the room very slowly seeps between the fibers, displacing the cold air from there.

These can be vertical frame racks, floor joists or rafters. On the outside (outside) side, a wind-waterproofing barrier is arranged, which protects against the effects of precipitation and strong direct wind.

This scheme is valid when making frame walls, floors, attic roof, residential floor ceiling in the presence of a cold attic on top.

Internal partitions and floors between living quarters require a slightly different approach. In this case, humid air can penetrate the mineral wool from any side. To maintain the thermal performance of the structure, a vapor barrier is installed on both sides.

Excess moisture is removed through the ventilation gap left under the external decorative facade.

Thermal insulation with ecowool

The name of this insulation has the prefix "eco", which means that it is an environmentally friendly material. 80% of ecowool for the ceiling consists of natural cellulose, and the remaining 20% are various additives. For example, lingin gives the structure of a heat insulator stickiness, and antiseptics and boric acid protect against rodents, fungus and decay.

The composition of ecowool contains fire retardants that prevent the combustion of the material; it only smolders under the influence of flame and high temperature. The thermal conductivity of this insulation is 0.038 W / (mK).

There are two ways to insulate the ceiling with ecowool - dry and wet.The first option involves laying the material in pre-prepared cells on the ceiling surface, but in this case its thermal insulation qualities do not exceed 60-70% of the possibilities.

When using the second method, special equipment is used - it moistens ecowool and then sprays it under high pressure. As a result of contact with water, the insulation acquires stickiness, as a result of which it adheres tightly to the ceiling surface. For wet application, special equipment and the services of craftsmen will be required.

Step-by-step instructions on how to insulate the ceiling with glass wool externally:

- The ceiling surface is protected and leveled in order to get rid of the remnants of construction debris and dirt.

- A crate is assembled from a wooden bar, similar to that intended for the installation of mineral wool. This stage can be omitted, but in this case it will be impossible to use the attic.

- Lay the vapor barrier film in one layer. If necessary, it is used to protect the elements of the crate.

- With the help of a blowing machine, the material is filled in the space between the slats, paying special attention to hard-to-reach places and crevices. The minimum thermal insulation layer of ecowool is 25 centimeters, but in regions with very low temperatures in winter, it should be 40 to 50 centimeters.

- A waterproofing film is overlapped over the insulation, fastening the seams with special tape.

We insulate the ceiling in a private house with our own hands: penoplex - quickly and reliably:

A relative of foam is a porous but harder material. The structure of the penoplex is not ball, but perforated. The sheet does not consist of interconnected round granules. It is a homogeneous, foamed, pumice-like mass. The inner capsules are completely isolated from each other - the material completely retains water.

Extruded polystyrene is excellent for insulating window slopes and ceilings. Thanks to its rigid structure and low thermal conductivity, penoplex saves space: sheets of a thinner section retain the same amount of heat as thicker foam.

The end of each slab is selected by a quarter: the slabs are easy to join, there are no through gaps left between them, the surface is perfectly flat. Penkplex panels are fixed to the ceiling with adhesive foam. All work is easy to do with your own hands. For greater strength, the connection can be planted on fungi, but, according to experts, this is an unnecessary measure: the penoplex planted on the foam will disappear at the same time when the interior doors fall out - in 75-100 years.

Penoplex is excellent for insulating ceilings in rooms with high humidity: it simultaneously performs the functions of thermal insulation, vapor barrier and decoration. The foam ceiling will save on drywall: a smooth hard surface after putty acquires sufficient hardness and strength. For a private house, penoplex is an ideal material for insulating both the basement and the attic under a cold roof.

Types of mineral wool

If you need, then you need to buy facade wool, since for external and internal insulation of mineral wool, its characteristics are different.

One of the main features of facade wool is its moisture resistance, that is, it has a high degree of hydrophobicity.

The density level of facade mineral wool is very high and the ability to repel moisture makes it stand out from a number of similar heaters.

Types of mineral wool:

- fiberglass;

- basalt;

- stone.

Also, a great advantage of mineral wool is fire resistance. Manufacturers produce insulation in the form of mats or slabs of various thicknesses: 5, 10 or 15 cm.

What affects the life of the insulation?

As with everything, it is believed that the life of the insulation depends on its cost and quality.Manufacturers of the inexpensive substance claim that it can last at least 50 years. In practice, this figure is not confirmed by anything, therefore, in the footnotes, they write that today there is no standard operating time for heaters.

In addition, what matters is what the material is made of. Experts confirm that man-made fibers cannot be guaranteed for more than 35 years. During this time, they dry out and collapse. But most importantly, they lose half of their heat-saving properties. While natural fibers do not lose their original qualities and can serve for a longer period.

Regulatory guidelines require every home to undergo an energy audit after construction is completed. Such inspections should be carried out every 25 years in order to be able to assess the level of heat-saving properties at the moment. But since we are unable to find out the exact figures due to the verification, we use the data that come to us from Europe.

Protection of basalt insulation after installation

And, of course, immediately after the installation of a section of basalt insulation on the wall, this section is closed. This protects the already installed cotton wool on the walls from slanting rain.

The membrane itself does not tolerate ultraviolet light very well, so you must not hesitate with the subsequent decorative coating - siding or whatever you have chosen.

If you are not doing a ventilation facade, but, then you shouldn't worry too much here. The plaster layer will calmly cover the cotton wool, it will still get a little wet during the installation process.

- The question is asked by Andrey Sukhorukov, Perm: Hello, dear colleagues! Would you like to clarify how you can protect vinyl siding from the sun and frost? I look at the neighbors ...

- Do you personally think that the rising prices for electricity and gas make you think about saving energy resources? Try to answer this question honestly. If yes, then this material ...

Ceiling in a private house: choosing insulation for rooms, verandas, outbuildings

The market today offers two classes of insulation: mineral wool and foam.

- The first category includes many fibrous mats obtained from molten slags, rocks, glass.

- The second group includes polymer panels obtained by foaming and gas filling.

- Among them there are heat insulators invented by folk architects. The most popular and most time-tested is sawdust.

Heaters of both types have common advantages:

- they are easy to lay - the work can be done with your own hands;

- low cost - due to the budget price, fibrous and gas-filled materials are used in construction as insulation.

The disadvantages of each material are also known:

- polystyrene - low-melting, combustible, toxic with strong heating;

- mineral wool is hygroscopic, the insulation can completely lose its user properties in water.

We insulate ceilings under a cold roof: a universal mineral wool material

Minvata - stone insulation has its own advantages. Among them:

- fire and heat resistance,

- plasticity - flexible mats can be used to cover curved surfaces;

- biological resistance;

- vapor permeability - for insulation of the ceiling in a wooden house - a unique quality.

In favor of stone wool is the fact that it easily restores its heat-insulating characteristics - you just need to dry it. Mineral wool is successfully used for external insulation of facades and ceilings. It's hard to imagine a more humid environment, but cotton wool can handle it. Both facades and ceilings are made using a special technology - they provide for air vents in order to remove moisture outside the warming cake.

Ventilation gaps are arranged from bottom to top. The channels have two functions: they serve for dew drainage and for ventilation. In such conditions, cotton wool is protected from condensation, so it is eternal.

Mineral wool and polystyrene are deprived of the advantages that a unique natural primordially traditional material - sawdust has.