Rules for crimping SNiP

The norms for crimping the heating system are described in documents such as SNiP 41-01-2003, and also 05.03.01-85.

Air conditioning, ventilation and heating - SNiP 41-01-2003

It is possible to carry out hydraulic checks of water heating systems only at positive temperatures in the premises of the house. In addition, they must withstand a water pressure of at least 0.6 MPa without damage to the tightness and destruction.

During the test, the pressure value should not be higher than the limit for the heating devices, pipelines and fittings installed in the system.

Internal sanitary systems - 3.05.01–85

According to this SNiP rule, it is necessary to check the water heat supply and heating systems with disconnected expansion vessels and boilers by hydrostatic pressureequal to 1.5 working, but not less than 0.2 MPa in the lower part of the system.

The heating network is considered to have passed the test if it holds for 5 minutes under test pressure and does not fall by more than 0.02 MPa. In addition, there should be no leaks in heating equipment, welds, fittings, threaded connections and pipes.

Purpose of hydrotesting of the heating system

Since there is an increased pressure in centralized heating systems, closed-type networks are installed. Leaks may appear in areas of leaking connection of heating devices or in areas of poorly tightened threaded connections. This causes flooding of premises, leads to damage and destruction of various building structures.

If the depressurization occurs during the cold season, then in order to repair the network, it will be necessary to stop the operation of the entire heating system, which is fraught with freezing.

To avoid unwanted leaks and check the tightness of the network, hydraulic tests are carried out. They are mandatory before the commissioning of a new construction site with a centralized heating system. Also, hydrotesting is carried out before the start of the heating season.

They include the following list of works:

- pressure testing of heat supply communications;

- flushing of pipes.

On a note! The heat supplying organization has the right to refuse to supply heat to the house if there is no certificate of the tests carried out.

Housing offices are specially notified of the preparation of heating networks. In addition, the housing offices should have specially trained workers who can carry out pressure testing and flushing of the network. In the contract for centralized heating of any object, a clause on hydrotesting the heating system must be prescribed.

Conditions for performing crimping

Test work is correctly performed if all the necessary requirements are met. For example, it is impossible to carry out third-party work on the test object, and testing must be supervised by the shift supervisor.

Pressure testing is carried out only according to the program approved by the chief engineer of the company. It defines:

the procedure for employees and the technological sequence of verification... They also outline safety measures for ongoing and ongoing work performed at adjacent facilities.

There should be no unauthorized people during pressure testing of the heating system, switching on or off the testing devices, only employees who take part in the test remain in place.

When work is carried out in adjacent areas, it is imperative to provide for reliable fencing and disconnection of test equipment.

Inspection of heaters and pipes may only be carried out at operating pressures. When the heating system is pressurized, the certificates are filled out to confirm the tightness.

Services conducting hydraulic tests

If the heating system is installed by a contractor at the stage of construction of new housing, then the responsibility for pressure testing of pipelines lies entirely with the contractor.

In the case when the heating system is already functioning, regardless of whether it is a residential building, a municipal institution, a shopping or office complex, the pressure testing is performed by an organization that serves all the building systems. In housing construction, the law stipulates the obligations of the management company to maintain the heating systems in working order, and, consequently, to carry out measures to prepare for the heating season.

For administrative and other complexes, systems are tested either by the operating organization or by a contractor who owns all the necessary permits to carry out a set of works.

Before commissioning the heating system, a number of certain measures are mandatory. The system is flushed and pressurized, the result of the work performed is an act that confirms that the installation work was performed correctly. This document and other necessary documents are filled out by specialists who are authorized to carry out these events. In order to independently carry out testing work, it is important to understand what it means to pressurize the heating system.

Crimping procedure

This method of checking the heating system involves the implementation of hydraulic tests:

- Heat exchangers;

- Boilers;

- Pipes.

Thus, it is possible to identify leaks, which indicate a depressurization of the network.

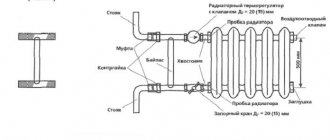

Before testing the heating system with plugs, isolate the heating system from the water supply, visually assess the reliability of all connections, and also check the functionality and condition of the shut-off valves.

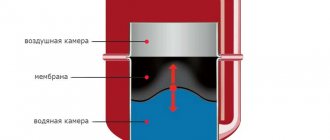

After that, the expansion tank and the boiler are turned off for flushing radiators, pipelines from various deposits, debris and dust.

During the hydraulic test, the heating system is filled with water, but when performing air tests, this is not done, but simply the compressor is connected to the drain valve. Then the pressure is increased to the required value, and its indicators are monitored with a pressure gauge. If there are no changes, the tightness is good, therefore, the system can be put into operation.

When the pressure begins to decrease beyond the allowable value, means there are defects... It is not difficult to find leaks in a filled system. But in order to identify damage during the air test, a soap solution should be applied to all joints and joints.

The air pressure test takes at least 20 hours, and the hydraulic test takes 1 hour.

Having corrected the identified defects, the procedure is repeated anew, and this has to be done until there is good tightness achieved... After carrying out these works, the certificates of pressure testing of heating systems are filled out.

Checking the heating network with air, as a rule, is carried out if it is impossible to fill it with water, or when working at low temperatures, because the liquid can simply freeze.

Tests in apartment buildings

In apartment buildings, air pressure testing of the heating system can also be carried out. We will now consider the necessary conditions for carrying out the work. In the event that you find water leaks, they need to be repaired.But often, without high pressure in the system, it is quite difficult to find thin cracks in the seams. In apartment buildings, it is necessary to carry out pressure testing of both individual apartments and all highways.

You need to complete the preparation:

- Inspect all locking fittings. If the valves are made of cast iron, then be sure to replace the glands on them. Replace gaskets on flange connections. All bolts that have lost their original appearance must also be replaced. Be sure to install new pressure gauges, it is recommended to send the old ones for verification in order to decide whether they can be further used for measurements.

- Visually inspect all pipes and fittings to identify even minor defects and damage. If you find problem areas, you need to quickly repair them.

- Check the condition of the thermal insulation material on the highways laid in the basement and between floors.

After preparation, you can proceed to directly pressure testing:

- Fill the entire circuit with water of low hardness (to prevent limescale build-up). It is better to pump it into the system, of course, with an electric pump. Pressure - 6-10 bar. In a container with liquid, you need to lower the hoses - drain and supply. Next, connect the pump to the heating network and turn on the pressure operator. It is necessary to set the pressure in advance.

- Timed half an hour - during this period, the pressure should remain almost at the same level. In the event that the pressure does not drop, the test can be considered completed. You can fill the system with working fluid and start active operation.

- If the pressure drops, then there are defects in the heating system. The procedure for pressure testing the heating system with air is about the same, but you will have to use a soap solution - without it, it is difficult to find a leak. As soon as you find defects, you can proceed with the evacuation of the system and repair. After that, you carry out repeated diagnostics of all heating.

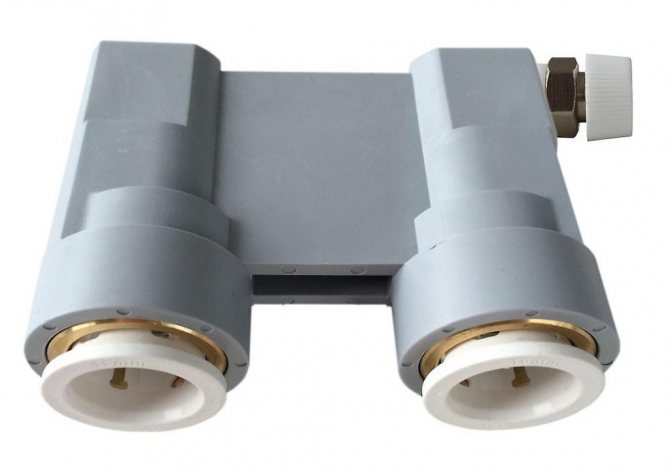

The inlet assembly is carried out in a similar way - the pressure in this case should be about 10 bar.

Heating system pressure test

This document displays the following information:

- What kind of crimping method was used;

- The project according to which the circuit was installed;

- The date of the check, the address of its carrying out, as well as the names of the citizens who sign the act. This is mainly the owner of the house, representatives of the repair and maintenance organization and heating networks;

- How the identified malfunctions were eliminated;

- Check results;

- Are there any signs of leakage or reliability of threaded and welded joints. In addition, it is indicated whether there are drops on the surface of the fittings and pipes.

Flushing the system

At the stage of preparing heating networks for the heating season, their mandatory hydropneumatic flushing is carried out. This is necessary because the coolant circulating in the network during the heating season causes scale deposits on the walls of devices and pipelines. Because of this, the cross-section of the line decreases, and the hydraulic resistance increases. For the same reason, the heat transfer of radiators worsens, fistulas appear and local overheating of heating devices is observed.

Important! Due to a 0.1 cm thick layer of limescale, the heat dissipation of the batteries is impaired by a maximum of 20%. Flushing increases the efficiency of the heating network.

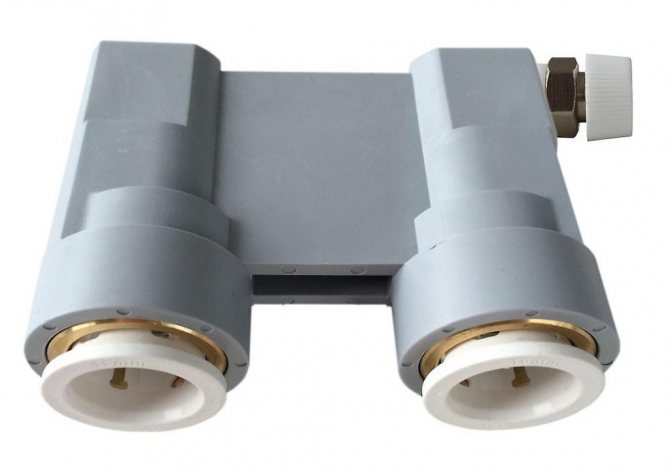

For flushing, the circuit is filled with water. An air compressor is connected to it. This promotes rapid circulation of the coolant and causes the appearance of turbulent flows. As a result, various deposits are easily detached from the walls of pipelines and batteries.

To protect the compressor from the return flow of the coolant, a check valve is installed. Be sure to close the valves of the automatic air vents.To improve the decomposition of scale, instead of water for rinsing, special solutions are used.

Permissible test pressure during pressure testing of hot water heating

Many developers are interested in the pressure under which the heating system should be checked. In accordance with the requirements of SNiP presented above, during pressure testing, pressure is allowed 1.5 times higher than the working one, but should not be less than 0.6 MPa.

There is also another figure specified in the "Rules for the technical operation of thermal power plants". Of course, this method is "softer", the pressure in it exceeds the working pressure by 1.25 times.

In private houses equipped with autonomous heating, it does not rise above 2 atmospheres, and it is adjusted artificially: if excessive pressure appears, then the relief valve immediately turns on. Whereas in public and multi-apartment buildings, the working pressure is much higher than these values: five-storey buildings - about 3-6 atmospheres, and tall buildings - about 7-10.

Pneumatic tests

Hydraulic tests are permissible only at air temperatures above zero. That is why it is more difficult to carry out such work in a building that has not been commissioned. Due to the low temperature in the new building, pressure testing is carried out using air.

For pneumatic pressure testing, a compressor is connected to the Mayevsky tap or an ordinary drain pipe. Moreover, the unit can be connected at any point in the heating network. The device then pumps air, causing the pressure to rise. It is important that the indicator does not decrease in the line for a given period of time.