The expansion tank is a very important element in the heating system. It prevents pressure build-up in the heating system when it heats up. Tanks can be open and closed. Open tanks have a number of disadvantages that membrane tanks do not. They are bulky, have a lot of heat loss, and do not work under high pressure. Diaphragm tanks are more perfect, and they do not have the same drawbacks that open ones have.

- 2 Advantages of diaphragm expansion vessels

- 3 Construction of the expansion membrane tank

- 4 Selection of the diaphragm tank

- 5 Calculation of the volume of the diaphragm expansion vessel

- 6 Installation of the diaphragm expansion vessel

- 7 Possible breakdowns

What is a diaphragm expansion tank

An expansion tank is an important element in heating, because it prevents the coolant from boiling, which can lead to bad consequences.

Such tanks can used in different systems:

- with heat pumps and solar collectors;

- with an autonomous heat source;

- connected to the central heating network according to an independent scheme;

- with closed contours.

Diaphragm tanks regulate the pressure in the heating system in case of its increase and with pressure drops, which prevents emergency dangerous situations and times of malfunction of heating systems.

The expansion diaphragm tank can be with fixed and replaceable baffle. The first ones are made with an internal cavity divided into two parts by a securely fixed membrane, which is located along the perimeter of the section.

Tanks with a replaceable partition differ from fixed ones in that the coolant is in the membrane tank and does not come into contact with the steel surface. Membrane assembly and disassembly simple enough through a bolted flange.

Advice... When installing the membrane tank, it is necessary to securely attach it, because during operation, the mass of the tank increases.

What is an expansion tank for closed heating systems

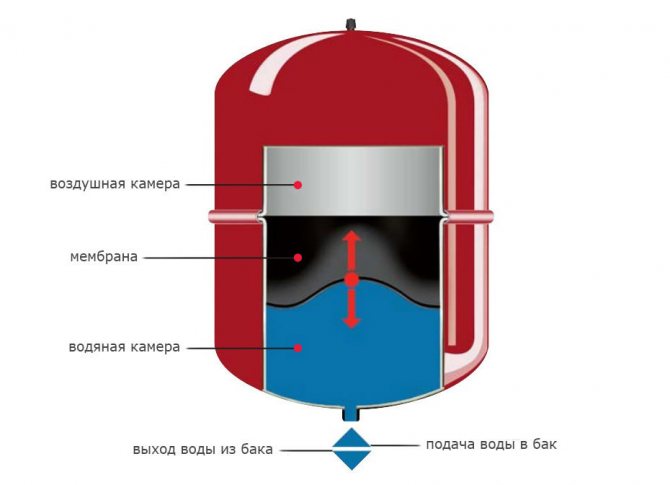

In closed heating systems where the operation of pumps is provided, closed expansion tanks must be installed. This is a vessel of a certain size, inside which there is air.

When water expands in the heating system, the excess part formed as a result of this thermal expansion enters this reservoir, in which the air located there is compressed. As soon as the liquid begins to cool down and decrease in volume, part of the water from the reservoir enters the pipes again for further circulation.

Tanks for expansion of the heating medium can be classified as follows:

- Membrane. In such variants, there is a mechanical partition between the gas and the liquid in the tank. Depending on the shape of the membrane, all membrane tanks can be divided into two subspecies:

- With poppet diaphragm.Such a membrane is attached to the inner wall of the tank in the middle part, and can take different shapes depending on the temperature of the coolant. So, if the temperature of the coolant is quite high, then it will press on this membrane with greater force, as a result of which it acquires a convex shape.

- With a pear-shaped membrane. Such a membrane follows the shape of the tank itself. There is a small air-filled space between the membrane wall and the tank wall. In this case, the liquid does not come into contact with the walls of the structure, which determines a long service life.

- Membraneless. In this version, there are no separators between the liquid and gaseous phases, so the coolant is in contact with gas or air. The main disadvantage of such structures is that additional compressors will have to be installed outside, which will automatically pump air into the tank.

Today, the most common are membrane tanks.

Benefits of diaphragm expansion tanks

Expansion tanks have a huge number of advantages:

- do not pollute water;

- low costs during operation;

- easy installation;

- safety, reliability;

- installation in any part houses;

- impossibility of pouring water out of the tank;

- no heat loss;

- minimum air supply;

- membranes made of natural rubber and butyl can be used in drinking water supply;

- used for any type of water;

- convenient to use;

- radiator and boiler due to lack of contact between water and air last longer, than usual.

Expansion membrane tanks are used in closed heating systems and ensure reliable boiler operation.

Advice... When choosing a membrane tank, you should give preference to closed-type tanks, which are much better than open ones.

The purpose of the expansion tank

An expansion tank is needed to compensate for the pressure of the coolant in the heating system. The pressure difference arises due to a change in its temperature during the heating process, since its volume changes depending on the temperature.

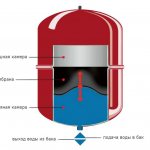

IN closed heating systems an expansion tank of a closed sealed design is used. Inside the tank there is elastic membranewhich divides it into two parts. One of the parts of the tank contains air under pressure, the second part is penetrated by the coolant.

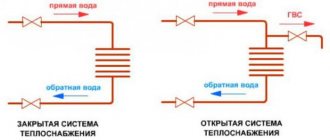

The circulation of the coolant in a closed heating system is provided by a circulation pump. IN open heating system the pump is not needed, and therefore any container can act as a tank, the coolant into which will be drained directly from the heating pipes.

Expansion vessel in a closed heating system

Diaphragm expansion tank design

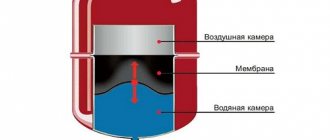

Diaphragm expansion vessel - flat or balloon metal bodyseparated by a rubber membrane inside. One part contains air or gas, which is compressed to a certain required level. The air compression level can be found in the passport. The other part of the tank in working order will be filled with water and due to this the level of gas compression will be the same as in the entire heating system. Compressor in tank maintains the pressure in the air chamber.

One of the most important elements of a diaphragm expansion vessel is the diaphragm, which can be two types:

- balloon;

- diaphragm.

Diaphragm valves are used in tanks with a small volume and cannot be replaced. Balloon can easy to replace if necessary, this type of expansion tank is also more reliable due to the fact that the water is in the membrane and does not touch the tank body.

Advice... When choosing a diaphragm expansion tank, you need to pay attention to the material from which the diaphragm is made.

Why is the initial pressure in the expansion vessel important?

I will not bother you with calculations here, but I will immediately give you the main numbers. But first I will explain why it is important to know the initial pressure in the expansion vessel. Here's why:

- after filling the system with a coolant, the expansion tank itself must be filled to 25% (0.25 of the tank volume), under this condition there is still 75% of the tank volume that can be compressed, and, conversely, there is 25% of water that can leave the tank. This condition must be ensured by the initial pressure in the tank.

Why is the latter also important and what happens if the tank is completely empty? With any drop in temperature or a slight leakage of the coolant, the pressure in the system immediately drops to zero. It is unacceptable!

In another extreme case, the tank is full. If the temperature in the system rises further, the coolant has no place to go. The pressure will increase until either the safety valve is triggered or a rupture occurs in the system.

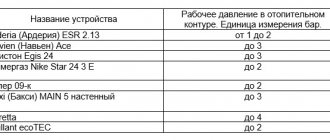

Therefore, it is necessary that when filling the system at room temperature, the pressure in it is set (usually 1.5 atm., Since most wall-mounted boilers are designed specifically for it to start working). If this pressure is not created, the wall-mounted boiler simply will not start. In general, at this initial system pressure, the tank should be 25% full.

Diaphragm tank selection

In heating systems, the membrane load, like the expansion of water, does not change very much, but the temperature of heating the liquid can be about 90 ° C.

When choosing an expansion membrane tank, special attention should be paid give to the material from which the membrane is made. The material must be of high quality, reliable and resistant to high temperatures and extremes.

You should also pay attention to the following characteristics of the membrane:

- range working temperatures;

- long life time;

- sanitary and hygienic requirements;

- resistance to impact high temperatures;

- dynamism.

Advice... When choosing an expansion membrane tank, it is necessary to select tanks with a strong and reliable body so that it lasts longer.

Expansion element installation

Unlike an open-type system, in which the level of the liquid in the expander must be higher than the level of the entire system, the use of a sealed tank does not require this condition to be met. However, there are rules governing its location.

For example, it should be taken into account that when the pump is turned on, excess pressure is created at its outlet, and some vacuum at the inlet. Installing an expander after the pump will compensate for the lack of fluid, and this will facilitate its operation. On some gas boilers, the tank is usually already installed. Other interesting moments with a different way of connecting the expander can be seen from this video.

The pump is installed at the boiler inlet, which makes it easier to work: it heats up less, the seals work at a lower temperature than if the pump was at the boiler outlet. If a double-circuit boiler is used, expanders are installed on both circuits, and on the first one is used an expander for heating, and on the second for a water supply.

Dual-circuit system

According to the method of installation, the tanks are:

- horizontal;

- vertical.

In horizontal designs, mounts are provided on the case, they will allow you to fix the device on the wall. This arrangement makes it possible to save space and has an aesthetic appearance. Tanks with a large volume are made only of vertical design, installed on the floor or on stands.

To check the pressure in the system, dial gauges are installed. Depending on the complexity of heating, there may be several of them. The tank itself is cut off from the system using a shut-off valve, equipped with a safety valve, a nipple through which air is pumped in with a conventional bicycle or car pump. In complex heating systems, a safety group is used. It consists of a pressure gauge and an emergency valve; it is separated from the system by a shut-off valve and a device that prevents accidental closing of the valve.

Tank and safety group

During operation, it is necessary to carry out a periodic inspection, it takes place every six months.During a routine check, the following actions are performed:

- the tank is examined in order to determine visible damage, violation of sealing, peeling of paint, smudges;

- the pressure on the tank is measured when the boiler is not working, it must correspond to the calculated one;

- the membrane is examined.

If a malfunction is found, it should be repaired immediately. When replacing components, use original or compatible ones. If the expansion tank is not used for a long time, it must be disconnected from the system, drained, cleaned and dried.

Calculation of the volume of the expansion membrane tank

In order to determine the volume of the expansion membrane tank, it is necessary to determine the total volume of the heating system, which consists of several volumes:

- pipeline;

- heating device;

- boiler.

The easiest way to determine the required volume of the tank is calculate 10% of the total volume of the heating system. If it is 500 liters, then you need a tank with a volume of 50 liters.

If the volume of the expansion membrane tank is less than necessary, this will lead to bad consequences. Cracks will begin to appear, hot water will leak through the threads, and the tank itself can deteriorate very quickly and it will have to be changed.

The membrane tank is selected individually for each heating system.

Advice... If safety valves are installed in a closed heating system, pressure build-up can be avoided and the entire system protected.

Installation of a diaphragm expansion tank

You will need skill and knowledge to install and connect a membrane tank to a heating system. You should not undertake the installation of the tank yourself if you are not sure that everything will be done correctly.

To install you will need:

- step key;

- gas wrench;

- plastic pipes;

- adjustable wrench.

When installing a membrane expansion tank in a heating system, you need to be very careful and careful check the tightness connections.

The expansion tank must be sealed, it cannot be disassembled, opened, it just connects to the pipelinewhich is closest to the boiler. It is also necessary to install safety devices to prevent pressure build-up.

When installing the tank, it is necessary take into account a few rules:

- install a membrane tank before branching;

- the room should be constantly temperature above 0;

- the tank attachment point can receive a huge load, so it must be carrier;

- recheck calculations before installation;

- If the volume of the tank more than 30 liters, then it is not attached to the wall, but placed on its legs;

- At the outlet of the tank, install pressure gauge, and at the inlet - a check valve, if there is no pump.

Advice... In order to extend the service life of heating systems, it is not necessary to use oxygen-containing water and corrosive gases.

Expansion tank installation

The accumulator can be installed anywhere in the heating system. The main condition for its installation is availability when carrying out maintenance work. The tank can be installed in pipelines of both direct heating agent supply and return. The fact is that the pressure in these pipelines is the same, so the membrane tank for heating will work identically in both cases.

It is not recommended to install it near the circulating pump.so that swirls of the liquid do not affect the operation of the tank. There must be shut-off valves in the system around the accumulator. Usually ball valves are used for this. This is done so that during repair work, the tank can be cut off from the general structure.Usually, additional pressure gauges are installed next to the membrane expanders to make it easier to control the pressure and to bleed off excess pressure in time. When installing the equipment, it is very important that the pressure in the air circuit of the tank is 0.2 bar less than in the heating system. In this case, the coolant will always be pressed against the membrane, and its operation will be more efficient.