Principle of operation

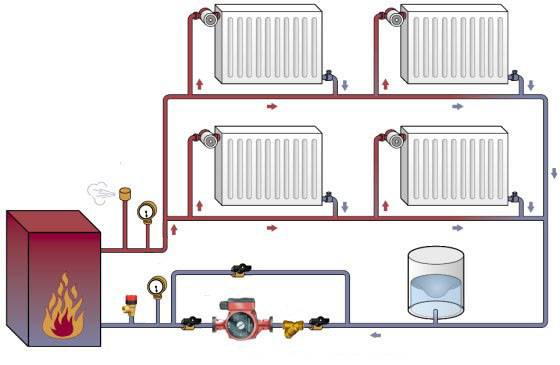

The central element of the entire system is the water heating boiler, from which the hot coolant flows into the radiators installed throughout the house. When moving through pipes and batteries, the heated water gradually cools down and in this state returns to the boiler through the return pipe.

In the boiler, it heats up again to the desired temperature and starts a new cycle through the pipes. The cycles are constantly repeated while the thermogenerator is running.

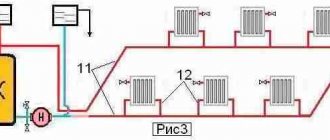

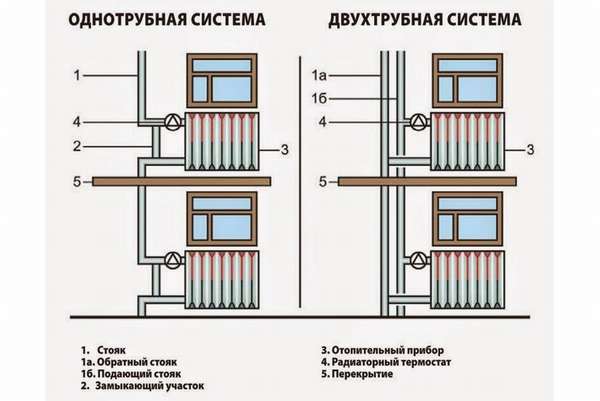

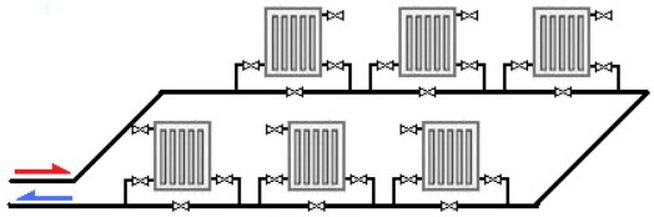

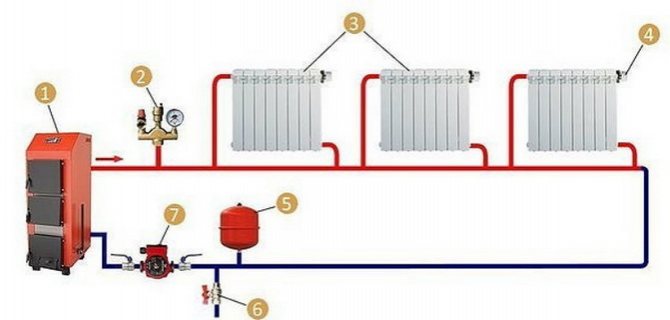

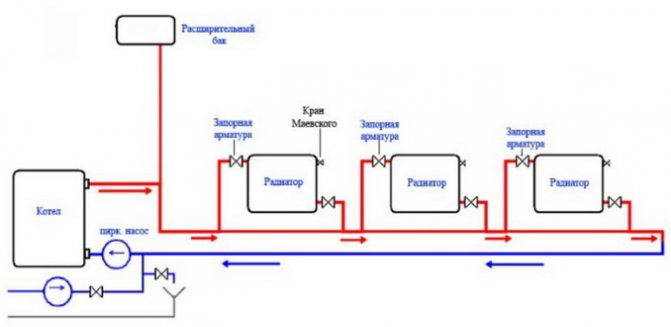

Single-pipe system diagram

This scheme has its own nuances. So, the lowest temperature of the coolant (40-50 ° C) before its return to the boiler is recorded on the most distant (last in the chain) radiator. This is not enough for normal room heating.

In order to prevent an undesirable drop in temperature on the last radiators, it is necessary either to increase the heat capacity of the batteries, or to heat the water in the boiler even more. Both of these options are too expensive.

You can resort to another method of supplying hot water - to install a circulation pump in the pipe circuit, accelerating the coolant through the system. The effectiveness of such a technology, of course, will be higher than the two above options. But in suburban conditions, the technology using a pump may be of little use due to possible problems with the power supply.

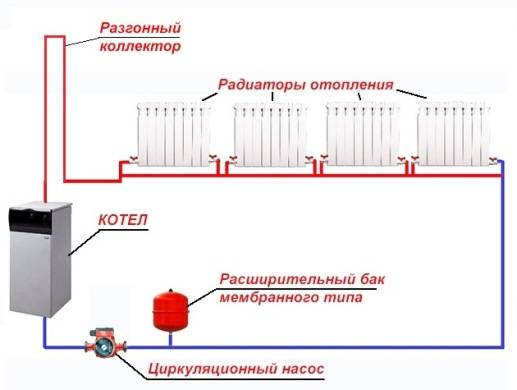

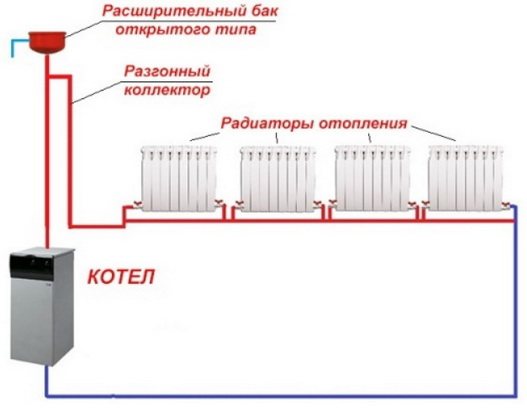

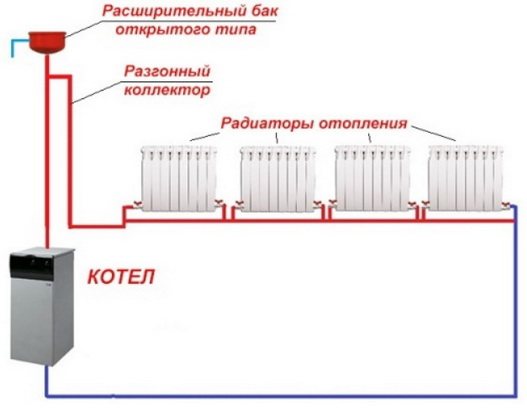

In such cases, the best option that solves the problem of delivering hot water to all radiators may be the installation of a boost manifold. This element is a straight high pipe through which the heated water leaving the boiler accelerates to such an extent that it does not have time to cool down in the intermediate radiators on the way to the last battery.

Boost manifold application

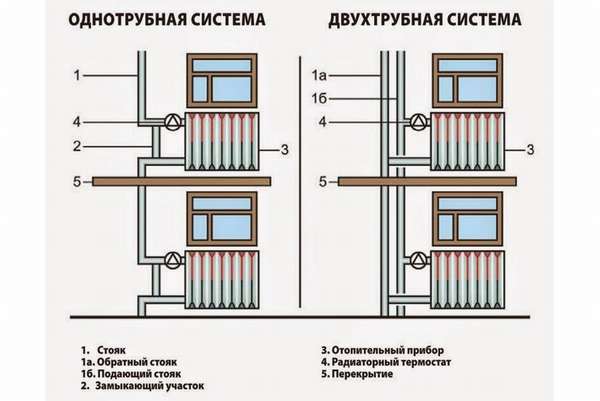

Thus, a feature of a one-pipe system is the absence of a return pipe in it, which serves to return cooled water from the radiators to the boiler. The reverse acting pipe in this case is the second half of the only main pipe.

When choosing a heating scheme, it should be borne in mind that one-pipe technology does not work when the final radiator is located below 2.2 meters. It can be used in two-story houses, and the more the straight collector rises above the boiler, the faster the water will flow in it, and the system itself will be less noisy.

Features and compensation for deficiencies

Heating pipes are laid along the perimeter of the room from below: at floor level, under the floor, in the basement or basement. Hence the first advantages of a one-pipe system with lower wiring follow:

- Economical and easy to install. Less material and less time is required for installation than in other cases.

- Aesthetics. The pipes can be hidden under the floor or in the basement, leaving only the radiators in sight.

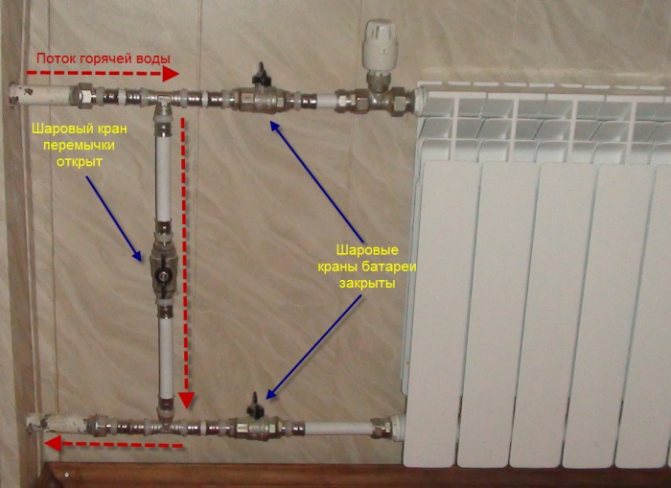

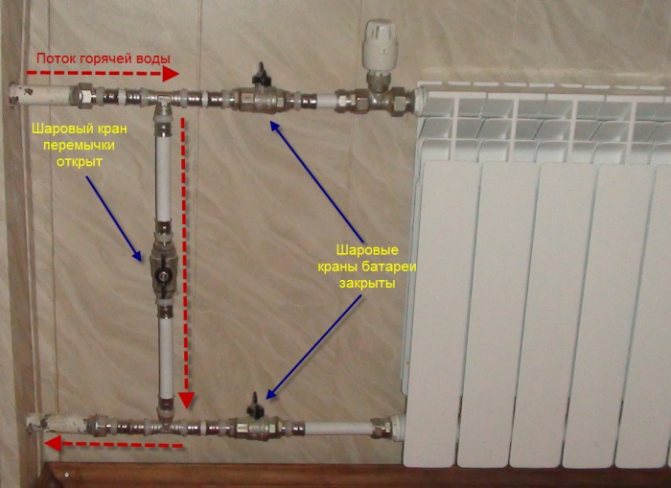

The batteries either cut into the pipe in series, or are connected in parallel to it, while the section of the pipe between the taps to the radiator acts as a bypass. The first option has a significant disadvantage - all radiators work simultaneously, you cannot turn off or adjust any of them without turning off the entire heating main. Also, in the event of a breakdown or leaks, you will have to drain the entire coolant in order to carry out repairs and / or replacement. The heating is uneven, the upper part of the radiator is warmer than the lower one.

This is solved by adding a bypass. The circulation of the coolant is closed. Due to the thermostat, valves and control valves, it becomes possible to regulate the heating temperature of each radiator and, if necessary, shut off any of them without affecting the heating operation.For the bypass to be effective, the diameter of the pipes used for it must be one size less than that of the main circuit.

In a one-pipe system with a bottom wiring, forced circulation is used. Minus - noisy work. The natural flow of the coolant (and, accordingly, a less noisy system) is achieved only by organizing a booster manifold, but this is possible only in houses with ceilings above 2.2 meters.

Advantages and disadvantages

Advantages of a one-pipe system:

- A single circuit can be mounted not only in the room, but also under the walls.

- The specified heating scheme allows to reduce the cost of the project.

- Due to the possibility of the phased connection of room heating devices, it is possible to connect all components of the heating circuit to the distribution pipe.

- The degree of heating of the radiators is regulated by serial or parallel connection of these elements to the system.

- When using the option with one main pipe, you can install a solid fuel, gas or electric boiler.

- The use of this scheme allows you to direct the flow of heated water wherever the owner of the house wants.

Some disadvantages:

- If the heating network is not used for a long time, it will take a long time to start it up.

- It is difficult to adjust the uniform distribution of heat between floors in a house consisting of two or more floors. To compensate for the drop in water temperature in the lower half of the pipe, it is possible to install more radiators on the lower floor, but this method makes the project more expensive.

- It is impossible to turn off one of the levels of a multi-level system if, for example, repairs are required on one of the floors of a building.

- Air pockets can appear in the chain if the slope is not maintained in it. Plugs, in turn, reduce heat transfer.

What is a one-pipe heating system and how is it different from a two-pipe

A single-pipe heating system for a private house, like a two-pipe one. includes:

- a boiler that generates thermal energy, which can use various fuels and can be of a variety of designs;

- radiators that directly heat the premises of the house;

- a pipeline through which a heat-transfer fluid circulates, which ensures the transfer of heat energy from the boiler to the radiators;

- additional equipment that ensures circulation and efficient operation (expansion tank, shut-off and control valves, connecting elements, circulation pump (one or more), safety block, etc.).

- Saving pipes and fittings;

- Less time and labor for installation work;

- With open piping, the main pipeline is less noticeable in the interior of the rooms.

But if you decide to use a one-pipe system, when installing water heating yourself in your home, then you must also take into account its disadvantages:

- Less uniform heating of radiators - as you move away from the boiler, a colder coolant will enter the radiators;

- It may be difficult to control the temperature of individual radiators;

- It is more difficult to ensure good natural circulation of the coolant, especially with a long circuit length.

In order for the disadvantages of a one-pipe system not to affect the efficiency of its work, or at least to minimize them, it is necessary to choose the most suitable type of it.

Installation of one-pipe heating

The correct design of a single-pipe heating system requires knowledge of a number of process features.

The first step is to install a heating boiler. The pipes must be installed so that a slope of at least 0.5 cm per one running meter of the pipe is maintained along the entire line.If this is not done, then air will concentrate on the raised area, creating plugs that are difficult to pass through for the coolant.

However, their occurrence cannot be completely ruled out. Therefore, when designing, it is necessary to plan the installation of special Mayevsky cranes in the system, designed to remove these obstacles.

In front of the heating elements that are connected to the circuit, shut-off valves must be installed. If they are present, it will not be necessary to drain the water from the system in case of repair.

The drain valve must be installed at the lowest point in the system. At the same time, an expansion tank must be connected to the uppermost point of the boost manifold to control and stabilize the volume of water when the coolant overheats.

The collector should rise 1.5 meters or more above the floor level. In this case, the pipe should be securely attached to the wall, avoiding unnecessary bends.

The system can be wired both horizontally and vertically. In the first case, the smallest number of pipes is used, and the devices are connected in series. True, with horizontal wiring, air locks can occur, and the heat flow cannot be adjusted.

In the case of vertical wiring, the pipe is laid in the attic. At the same time, pipes extending from the central pipe lead to the radiators.

www.domskotlom.com

Installation methods

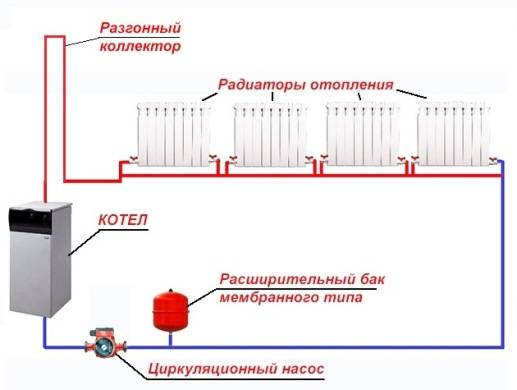

Single-pipe heating in a private house can be open or closed, vertical or horizontal, with lower or upper wiring, natural or artificial circulation of the coolant.

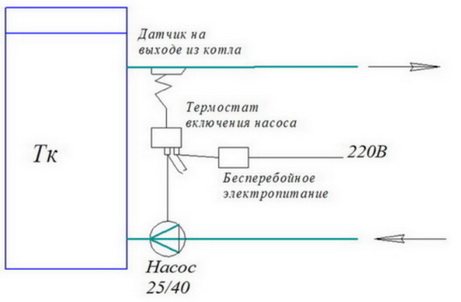

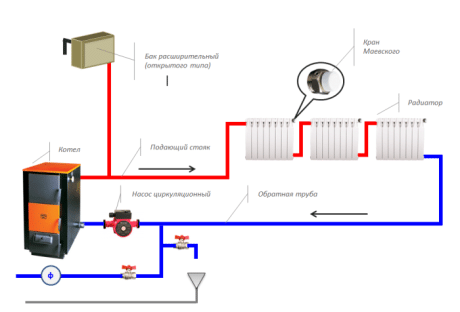

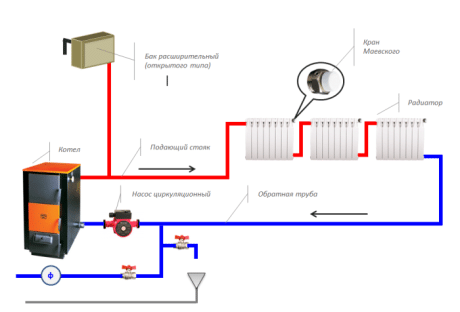

Natural and forced circulation systems

Natural circulation, in which the tank is at the highest point of the room, creating pressure, there is no pump

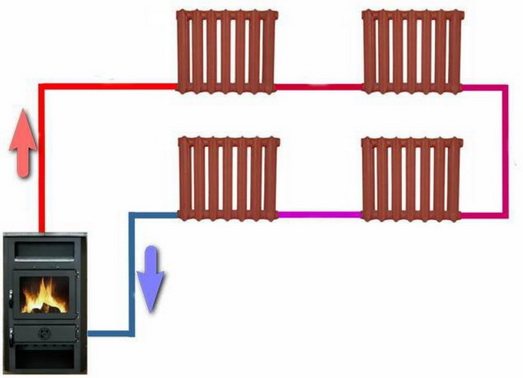

The natural circulation system is considered the most common. Previously, one-pipe standard heating of this type was installed in all one-story buildings, including those with stove heating. Her plan includes an expansion tank under the ceiling that receives water from a boiler. Then it flows by gravity into gas or automatic radiators through pipes.

Now in most multi-storey and private houses, automatic boilers with built-in circulation pumps are installed.

If you need to install a boiler with complex automation, the pump is installed for it separately to avoid overheating when the fuel flares up to extreme temperatures. Forced circulation schemes make it possible to implement projects of increased complexity, they are often used for the installation and connection of underfloor heating. Forced circulation is relevant for multi-storey buildings or houses with attic structures.

Open or closed heating system

The tank in an open system communicates with air, you need to top up with water as it evaporates

In widespread open systems, the water level inside the tank rises after overheating and decreases as it cools. They are supplemented with tanks with branch pipes for venting excess steam and atmospheric pressure. Automated devices operating on gas, pellets or fuel oil are complemented by compact expansion vessels that compensate for the minimum expansion of pressure.

Since the pressure itself will depend on the temperature, in the absence of malfunctions, the boiler turns off on its own, the pressure in it drops. If the boiler runs on peat fuel, coal or wood, the combustion process in it cannot be stopped quickly, which can provoke overheating of the water.

An open or closed system design must necessarily include an expansion tank, a polypropylene pump, a valve for steam release and a circuit for automatic water make-up. For solid fuel boilers, closed systems are more often used.

Horizontal and vertical layout

The vertical system is designed for multi-storey buildings

The choice of an option for a single-pipe, single-circuit view completely depends on the type of building, the number of floors in the building, and other factors. For small houses, horizontal piping of the required diameter is considered ideal. In buildings with an area of more than 60 sq.m. and with more than three rooms, it is recommended to use a horizontal scheme when it comes to a building with one floor, and a vertical one for a two-story building. In the second case, the wiring is installed on the second floor, then stretched from the top to the bottom, and then supplied to the boiler.

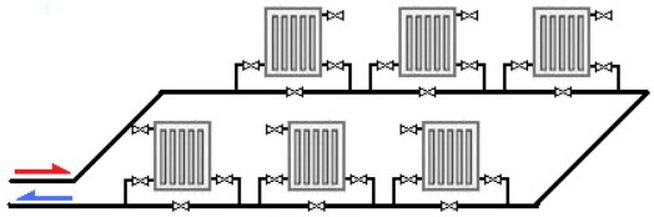

The vertical circuit in a one-pipe system for heating is mainly used in multi-storey buildings, where water goes to the attic or to the upper floor and pours down through separate risers, after which it passes through the radiators. This scheme is called Leningrad.

With a horizontal connection, the pipes are located horizontally, and the heating devices are connected one after the other. This method is relevant for one-story buildings, since it is much less complicated.

Pros and cons of the system

A single-pipe heating system has its positive and negative sides. Knowing about these features, you can accurately answer which one-pipe or two-pipe system is better. So let's start with the pros:

- The biggest advantage is savings. With a one-pipe system, there is no need for jumpers at the batteries, return risers and other elements. This gives an almost two-fold reduction in pipe consumption compared to a two-pipe heating system.

- It is possible to regulate the supply of coolant to each heating device without significantly affecting the operation of the entire system. This is achieved by installing modern devices such as balancers, ball valves and bypasses, thermostatic valves, etc.

- Another plus is the aesthetics of the entire system. Since the number of pipes here is small, it is convenient to hide them behind false walls or panels.

All this makes the one-pipe system popular. But it is also worth remembering that the scheme of all communications will be quite simple. This makes it possible to install the heating yourself without much effort.

But even here there were some drawbacks and there are quite a few of them. Disadvantages of the system:

- In order for all heaters to work efficiently, it is necessary to ensure sufficient pressure in the system. This circumstance leads to the need to install more powerful pumps, which entails an increase in operating costs.

- The installation of the circulation pump itself may also be a disadvantage. The two-pipe system does not need such additional equipment, it is installed only to increase efficiency.

- When developing a diagram of a one-pipe heating system, it is necessary to provide for the location of the pipes so that the gravity of the coolant is ensured. In practice, this feature implies the installation of an expansion tank at the highest point of the system. As a rule, this additional detail is mounted in the attic.

But, despite such disadvantages, cheapness prevails, and one-pipe heating systems are most often found in private houses, especially with a small living space.

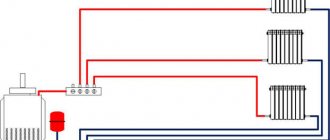

The difference between one-pipe and two-pipe heating systems

The main structural difference between one- and two-pipe heating systems:

- With one-pipe heating devices are linked together by one pipe, the coolant is supplied to the radiators in series.

- With a two-pipe system - with two pipes (supply and return) - the coolant is supplied to each radiator through the supply pipe, and is directed back to the heating boiler through the return.

Varieties of one-pipe systems

Despite its simplicity, a single pipe heating system has variations. In private homes, two types can be used:

- Sequential or unregulated system. In this case, the coolant enters each device in turn, the output is water with a lower temperature, which enters the next radiator.

- Regulated system, popularly nicknamed "Leningrad". This option allows you to regulate the flow of coolant into each radiator. The devices are connected to the line in parallel.

The first option is considered the simplest and cheapest to perform. But it does not allow regulating the supply of the coolant, so the batteries that are located farther from the boiler will have a lower temperature. For this reason, the sequential one-pipe system is used only for heating small houses or individual rooms.

The "Leningrad" system is better in terms of regulation and uniform heating of all devices. Here it is possible to regulate the flow of coolant into each device using shut-off valves. It is these systems that can be installed in houses with a large area.

In addition to the aforementioned principle, one-pipe systems are subdivided according to the method of circulation of the coolant. There are three types of it:

- With natural circulation. In this case, the coolant passes from one radiator to another under the influence of gravity.

- Forced circulation. Such systems are considered to be more efficient than the first option. For forced circulation of the coolant, a special pump is used.

- Combined option. Installation is carried out according to the scheme of a system with natural circulation, and to increase efficiency, a circulation pump is installed in it (through a bypass).

The first of the listed types of system works effectively only with a short route length, for this reason it is used only in houses with a small heated area. To improve circulation, it is advisable to install an acceleration collector immediately after the boiler. This design involves raising the supply pipe by a meter or one and a half above the level of the first radiator. It should also be possible to install an open-type expansion tank located at the highest point of the system.

Despite its lower efficiency, the system with natural circulation of the coolant is quite popular. This is due to non-volatility. If an electrically independent floor-standing boiler is installed in the house, then the power outage will not affect the operation of the heating system in any way.

Note! More efficient, but at the same time dependent on electricity, a structure with forced circulation of the coolant is considered. Such systems can have a long circuit and more than one. In the latter case, several circulation pumps are installed, separate for each circuit.

If in your area there are frequent cases of power outages, and an electrically independent floor-standing boiler is installed, then it is advisable to install a combined one-pipe system. In this case, in the absence of electricity, your house will not freeze.

Single-pipe routing options

With a one-pipe system, upper and lower heating distribution can be used. When connected to the bottom of the radiators, the pipes do not spoil the interior of the room and can be hidden behind the decoration. This option is more often used in forced circulation circuits.

Purpose and principle of operation of the hydraulic arrow for heating

The upper piping of the heating system is laid under the ceiling. This option is convenient in that when the coolant moves from top to bottom, it is convenient to bleed air from the devices using Mayevsky taps. Top routing is more suitable for natural flow systems.

Schemes with gravitational and forced circulation

The scheme of one-pipe heating of a private house with a gas boiler or other heating equipment can be with gravitational and forced current of the heat carrier.The peculiarity of systems with natural movement of the coolant is that they do not use pumping equipment. The liquid moves through the pipes due to the difference in volume and density of heated and cooled water (antifreeze).

Important! In circuits with gravity, a vertical booster riser must be made after the boiler, and the return pipeline is laid with a slope towards the heating equipment.

An expansion tank must be installed in gravity networks. It is mounted at the top of the system - in the attic or high under the ceiling. The heating equipment is installed at the lowest point of the network so that the water itself can drain through the pipeline into the boiler. That is why boiler equipment is installed in the basement or basement. If this is not possible, then the floor in the boiler room is specially lowered.

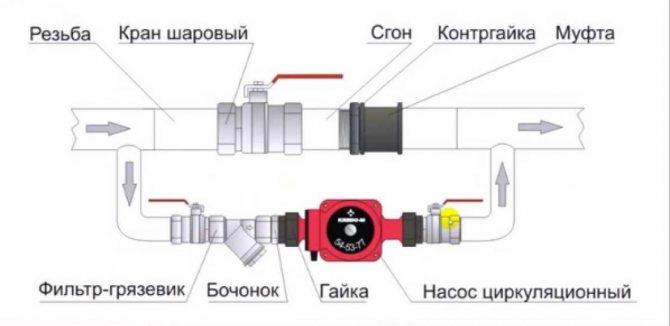

Forced circulation circuits are necessarily equipped with pumping equipment, which is responsible for the transportation of the coolant. The pump is installed in the return pipe before the pump. At this point, the liquid in the pipes has the lowest temperature, which is important for pumping equipment that is sensitive to hot media. In this case, it is not necessary to slope the return towards the boiler.

Important! Modern boiler models are already equipped with pumps, expansion tanks and a safety group.

Circuits with gravitational current are used in small one-story houses. Forced circulation networks can be used to heat a large house or multi-storey building. The main condition is that the greatest distance of the radiator from the pump should not exceed 30 m, because the device will not be able to supply water to a greater distance.

Open and closed systems

The difference between open and closed systems lies in the design of the expansion tank. This capacity is needed to compensate for the expansion of the heated coolant. Without a tank, this would lead to a critical increase in pressure in the network. When the coolant expands, excess fluid enters the tank. When it cools down, the water returns to the pipelines.

The difference between open and closed tanks:

- An open-type expansion tank can be independently made from scrap materials. This is a regular tank with or without a lid. The main disadvantage of open-type networks is that oxygen enters the circuit through an open container, which becomes the culprit for corrosion of radiators and pipelines. This also leads to airing of the system, therefore, Mayevsky taps must be installed on all radiators.

- Closed tanks consist of two chambers - air and water. The two chambers are separated by an elastic membrane. The necessary pressure is necessarily created in the gas chamber. When an excess of expanded liquid enters the chamber, the membrane is pushed into the gas compartment, which increases the pressure there. After the coolant has cooled, the pressure in the gas chamber squeezes the liquid back into the pipelines.

The disadvantages of open containers are that the water from the tank constantly evaporates, so it has to be topped up. Antifreeze must not be used in open circuits. Closed systems are reliably protected from corrosion and air intrusion. Antifreeze can be used in them.

Air-to-air heat pumps for heating a private house

Important! Closed tanks are equipped with pressure gauges, safety valves and air vents.

System installation

If you decide to make a one-pipe heating system in your house from scratch, then the primary task will be to draw up a diagram. It is necessary to clearly determine the place of installation of the boiler, expansion tank, circulation pump, radiators and other devices and devices.

The installation sequence for a one-pipe heating system will look like this:

- First, the boiler is mounted. It is better to install it at the bottom of the building, but not in the basement. At the same time, do not forget about fire safety measures (around the device, walls, floors and ceilings are trimmed with non-combustible material). Together with the boiler, a chimney is equipped.

- Next, we mount the branch pipe from the boiler. For this, it is better to use pipes with a diameter of at least 25 mm. A highway is pre-laid throughout the house, and heating radiators, valves and other devices are installed. When installing, do not forget about the required slope of the pipes. The coolant must move by gravity from the boiler, pass through all the batteries and return to the boiler again. This is very important if your system with natural circulation or combined type. If there is a pump, the slope can be omitted.

- When connecting the main pipe to the boiler, it is necessary to install an expansion tank, the type of which depends on the selected heating system.

- It is advisable to install filters on the return line before entering the boiler. This is to protect all equipment from debris and impurities.

If you are installing a combined type system or with forced circulation of the coolant, then you need to install the pump using a bypass. In the first option, such a combination is required, and in the second it is desirable. Installing the pump through the bypass will make it possible to turn it off in the event of repair or power failure, while the heating system will continue to work.

Before starting operation, it is necessary to carry out a pressure test. This process is done using a special pump that raises the pressure in the system. If the pressure in the system is maintained during the pressure test, then there is no leakage and the heating season can begin.

One-pipe heating scheme: what should be considered?

In one- and two-story houses, it is possible to use both vertical and horizontal one-pipe heating systems.

At the same time, an attic space is needed for the upper wiring, which is far from always convenient. As a rule, the movement of the coolant in the heating system is natural. In order to increase the rate of circulation of the coolant, it is envisaged to include a pump in the system.

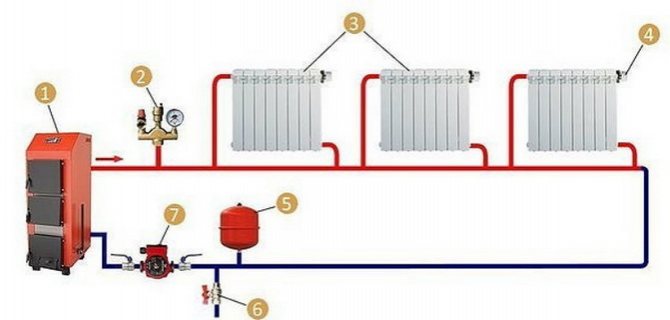

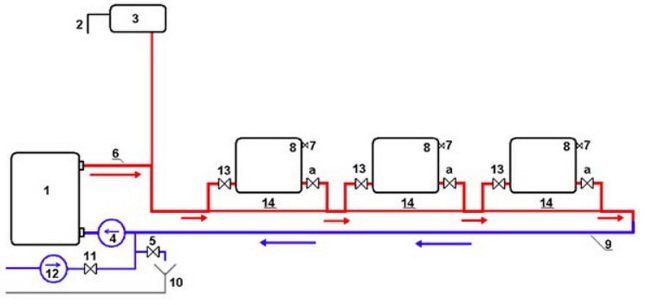

Simple one-pipe heating scheme: 1 - boiler; 2 - the main riser; 3 - expansion pipe; 4 - reverse risers; 5 - top wiring; 6 - air collector; 7 - expansion tank; 8 - circulation pump; 9 - return line.

Regulating and shut-off valves are needed to shut off the emergency section when performing preventive and repair work, redistributing the coolant flow, replacing a broken element. It is practical, fast and very convenient. Mandatory conditions, without which it will not be possible to make the correct one-pipe heating system: the layout of the system elements for a particular room, the location of the pipe junction, connection to the heating boiler; the location of the expansion tank, installation of radiators, valves and pumps; drain taps, etc.

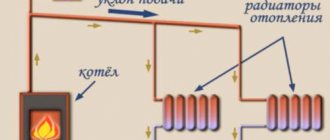

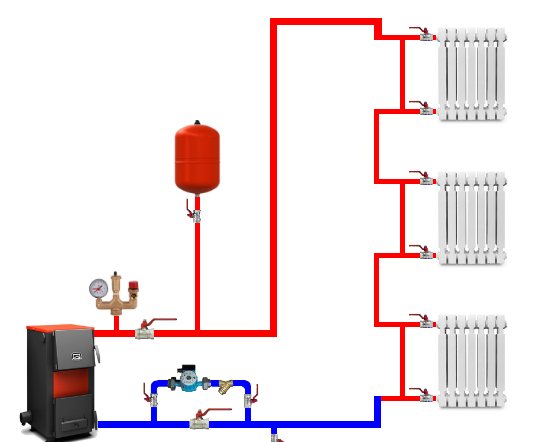

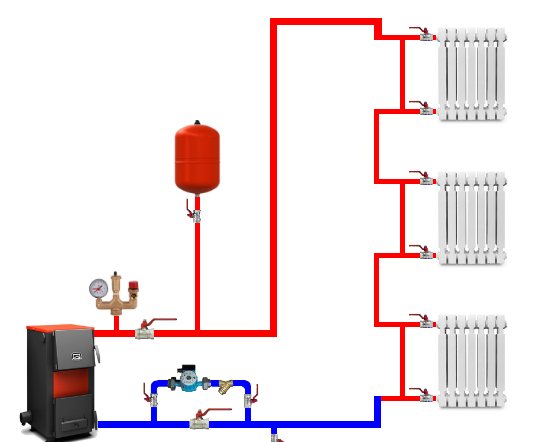

In accordance with the area of the house, various options for the device of the heating system are selected. For private houses with an area of up to 150 m², a heating system will be sufficient, the circulation of antifreeze or water in which occurs naturally. Due to the difference in the density of the coolant in different parts of the batteries, such a system, the diagram of which is shown in IMAGE 2, will work in a balanced way.

If the area of the house exceeds 150 m², then a forced circulation system must be used. For this, a water pump of suitable power is installed.

In any case, the radiators must be additionally equipped with taps (valves), the installation of which will make it possible to shut off the water supply at the required time at a specific section of the highway.This is necessary to isolate a certain area when performing repair work and to maintain heating in other rooms. At the same time, the rest of the premises in the building will be heated normally.

What is a one-pipe system with a bottom wiring

From the name it is clear that all the batteries are connected to one pipe laid from below along the perimeter of the heated premises. The batteries are connected to the pipe in series, the input / output in the batteries can be bottom or diagonal (the second option has the best performance in terms of heating efficiency). All batteries can only work at the same time.

To expand the possibilities of regulating the temperature in each room, a bypass system is used - the batteries are connected in parallel to one pipe, they can work separately and simultaneously, the heating temperature of each battery is additionally regulated.

By the type of the circuit, the one-pipe system is open and closed.

- In the open one there is an expansion tank for receiving an increased volume of water and draining excess water. The cistern is associated with the atmosphere, which gave the system the name open.

- In a closed system, the expansion tank is closed, the whole system is under pressure. To prevent emergencies in a closed version, a safety group is mounted on the system: a pressure gauge, an air vent and a safety valve.

A single-pipe system with a bottom wiring can only work with forced movement of the coolant (with a pump), and even then the length of the circuit is limited. Rather, not so much the length of the circuit as the number of connected batteries and their actual heat transfer.

This knowledge is needed in order to understand the principle of the system and know what can be achieved with its help. Such knowledge makes it possible to make installation more consciously, it will be clear why each pipe and each crane is needed. A bypass system significantly improves the characteristics of one-pipe heating, but it is more difficult to install, more expensive in terms of the number of components and cost. In addition, it can only be installed over floor coverings, otherwise the adjusting needle valves will be inaccessible.

Video - "Leningradka" - heating system

Advantages and disadvantages of a one-pipe system

Disadvantages of a one-pipe system

It is generally accepted that a one-pipe system is cheaper than a two-pipe system. This opinion was formed as a result of the use of this scheme when heating apartment buildings in the Soviet Union. But when such a scheme is implemented in a private house, especially a rather large one, a one-pipe system is no cheaper than a two-pipe system.

A two-pipe system requires an increase in the number of radiator sections along the heating system, thermostatic valves are required to adjust the temperature, pipes of a sufficiently large diameter are required for normal operation - all this together does not contribute to a reduction in the cost of the system.

The second major drawback is the difficulty of adjusting the temperature in each room. To do this, use thermal valves or radiator regulators.

For normal operation of the system, it is necessary to create a sufficiently large pressure and install a sufficiently powerful pump and an expansion tank at the highest point of the system - in a two-story house, the coolant must flow from above. In addition, such a system is quite difficult to adjust.

If the house is large, then the requirement to increase the number of sections of the next radiator in can lead to significant lengthening of radiators and difficulties with their placement.

Dignity

Modern technologies and installation procedures make it easier to balance the system: shut-off valves, thermo valves, balancing valves allow you to balance the system well and ensure uniform heating in all rooms.

The use of taps when connecting a radiator allows you to disconnect and remove a single radiator without shutting down the heating system.

With a single-pipe wiring, only one pipe is laid, which looks more aesthetically pleasing than two.

A single-pipe system warms up very quickly - faster than a two-pipe system.

If the house is small, then there are savings in materials. With a large house, the cost of materials is almost equal to the cost of installing a two-pipe system.

How to calculate the optimal number of radiator sections

The climatic indicators in the premises must meet the requirements of SNiP 41-01-2003, the calculation method is also given there. These are rather complex calculations; it is impossible to do them without serious knowledge of heat engineering. We list only a few initial data that are taken into account during calculations.

File for download - SNiP 41-01-2003

SNiP 41-01-2003 (Heating, ventilation and air conditioning)

- On the premises. Volume, thermal conductivity of walls, ceiling and floor, climatic zone of location, maximum temperature values, number and characteristics of window and door openings, frequency of air exchange by ventilation systems, spatial arrangement of the room, etc.

- Heating systems. The temperature of the heating medium at the inlet and outlet, the speed and type of the heating medium, the physical characteristics of the heat exchangers, the total power of the heating boiler, etc.

This means that you cannot do the exact calculations yourself. For such cases, there are general recommendations of practitioners, which are quite enough for the installation of heating. Moreover, today on each battery it is possible to adjust the heat transfer power, taking into account the actual conditions.

Although the volume of air heats the battery, for simplicity of calculations, square meters of the room are used, while the standard height of the rooms is taken. For buildings, the heat loss coefficient of which does not go beyond the requirements of existing regulatory enactments, it can be assumed that 100 watts is enough for heating 1 m2.

Taking into account the specific architectural characteristics of the premises, you can more accurately find out the costs of thermal energy by the formula

KT (amount of heat) = 100 W / m2 × P × K1 × K2 × K3 × K4 × K5 × K6 × K7where

- P is the area of the room in square meters;

- K1 - coefficient of glazing of window openings, can be in the range of 1.27 ÷ 0.85, depending on the characteristics of glass units. For single - 1.27, for double - 1.0, for triple - 0.85;

- K2 - coefficient of thermal insulation of external walls. From 1.27 for walls one and a half bricks thick to 0.85 with high thermal insulation. Determined "by eye";

- K3 is the ratio of the area of the windows to the area of the floor.

Further, the minimum temperature (K4), the quality of the outer walls (K5), the type of attic (K6) and the ceiling height coefficient (K7) are taken into account. The total heat demand must correspond to the power of the boiler, so that the boiler does not work constantly in critical modes - it is better to make a power reserve of approximately 20%.

Of course, none of the "amateurs" does such simplified calculations, and this is not necessary. Our advice - take about 120 W / m2, take into account the heat transfer of one section of the battery (given by the manufacturer), count the total number of sections for each room and correlate it with the power of the boiler. Do not be alarmed that the temperature will be too high and there will be large payments for heating fluids - each battery can be separately regulated.

Features of a one-pipe heating system

The single-pipe heating system has gained wide popularity in private construction due to the following advantages:

- Hydraulic stability - replacing the radiator, building up sections, disconnecting individual circuits does not change the heat transfer of other elements of the system;

- The minimum number of pipes;

- A smaller amount of coolant in the system reduces its inertia and the warm-up time of the room;

- Aesthetic appearance, especially when installing a hidden highway;

- Simple installation;

- When using modern shut-off valves, it is possible to accurately control the operating mode of the entire system and individual elements;

- Serial connection of heating devices allows you to arrange a water heated floor, mount heated towel rails, etc.

- Inexpensive installation and operation.

The thermostat on the radiator unit allows you to regulate the heating temperature of the battery

The main disadvantage of one-pipe heat supply is the imbalance in heating devices along the length of the pipeline. The further the radiator is from the boiler, the less it heats up. Under the action of the pump, the heating of the radiators is carried out more evenly, however, the cooling of the coolant is still observed, especially with a sufficient length of the pipeline. The negative effect of this phenomenon is reduced in two ways:

- The number of sections of the last radiators is increased, due to which their power and the amount of heat supplied to the room are increased - uniform heating of the rooms is achieved;

- Rationally design the passage of the highway through the rooms - starting with bedrooms, children's and "cold" rooms (corner, with windows to the north), then there is a living room, kitchen, bathroom, toilet and end with utility rooms.

Installation of a one-pipe heating system

To carry out installation work, in addition to ordinary tools, you also need to have a special apparatus for welding propylene pipes, it is not very expensive, it will not be difficult to learn how to work with it. The standard set includes scissors for cutting pipes - it is very convenient to use them, the cut is smooth.

How to install the heating system? The work should be divided into several stages.

Stage 1

You need to make a sketch of the heating system, think over the location of the boiler on it, where and how the pipes will lie, how many, where and which radiators need to be installed.

Do not expect that the sketch will work the first time, after the first attempts to markup, there is a high probability that you will have to make changes. It may be necessary to create several circuits for the removal of cold water, and this will require the purchase of additional plumbing fixtures and fittings. When sketching, take into account the power requirements of the boiler and the optimal physical characteristics of the heat exchangers.

Stage 2

Purchase of materials. Count the number of all turns, tees and transitions, couplings, ordinary ball and needle valves, control and management systems, the length of polypropylene pipes.

An important note - if you have an open-type heating system, then you can buy ordinary pipes, if the heating system is closed (operates under a pressure of 1.5 atm.), Then the pipes must be reinforced with foil. If the contour is located under the floor, you need to purchase insulation.

When all calculations are made, increase the total number of pipes and fittings by 10%, this will cover non-productive waste and possible errors. In the end, it will be much cheaper to increase the amount of materials than the need to “freeze” them during the work and once again go to the store to buy the missing one.

Recommended pipe diameters depending on the expected capacity of the heating system.

| Nominal diameter in inches | Maximum throughput of the coolant | Maximum heat load |

| ½ | 5.7 l / min | 5.5kw |

| ¾ | 15 l / min | 14.6 kW |

| 1 | 30 l / min | 29.3 kW |

If the calculated pipe diameter is larger than the standard diameter on the radiator, purchase the appropriate adapters.

Stage 3

Make markings in place, stretch pipes, arrange batteries, fittings and taps, re-check all components. Do the markings carefully, use a level.

Everything has been prepared, checked and recalculated, a plan for the heating system has been drawn up, the ultimate goals are clear, you can proceed with installation.If you are installing a heating system during the construction of a building, it is better to lay pipes under the floor, if the building is already standing, you will have to fix them at the bottom of the wall. Pipes under the floor should be insulated, for this there are special insulators, they are very effective and easy to install.

One more thing - are you going to make an ordinary one-pipe insulation system or a bypass one? The second is somewhat more complicated and requires more reinforcement. But it allows you to adjust the temperature of each battery and, if necessary, repair or replace them without completely shutting down the system.

Our advice - for a small country bath with one or two rooms, you can use an ordinary system, for buildings with three or four rooms, it is better to mount a bypass.

Start with the boiler, and when choosing the installation site, take into account the free space and the possibility of flue gas discharge. There is no single algorithm for installing boilers, much depends on its type and design features. Boilers can be floor-standing or wall-mounted, with different technical characteristics, dimensions, etc. The main rule is to strictly follow the recommendations of manufacturers for installation and discharge of exhaust gases, take into account the requirements of SNiP II-35-76 and SNiP 2.04.05-91.

BOILER ROOMS. Updated edition of SNiP II-35-76. BOILER PLANTS. Official edition

Updated edition of SNiP II-35-76

Single-pipe heating in the house

The idea of creating a one-pipe heating system in a private house may seem tempting at first glance. It is likely that one pipe instead of two is much cheaper. Probably, such a system is easier to mount…. You can even put a single pipe under the baseboard - it's not difficult to hide, it's not two pipes ...

Let's figure it out in order, is it really cheaper? Is it easier to do? But the most important thing is how the one-pipe system will behave in operation? Will the heating in the house be simply of poor quality? Will the shortcomings of the system turn out to be too significant. And therefore one-pipe (Leningrad) will not be applicable at all ...

How many radiators and how to connect them

How many radiators are there more often in the house? Today, an ordinary house will be a building with an attic floor and a heated area of 200 sq. M. At the same time, there are about a dozen radiators at the bottom and 5 pieces in the attic. If you consider a one-story house of 100 square meters, you will need from 8 heating devices.

If they are connected with one pipe in series one after the other, then the latter will turn out to be cold, with the usual parameters of the heating network.

If they are connected in parallel to one pipe - the same last will be "ice", if the heating characteristics are ordinary ... But what is meant by the word "ordinary"?

Normal specifications

When creating heating, everything tends to minimize, simplify, and reduce the cost.

For the movement of the coolant, circulation pumps are used, noiseless and low-power. The maximum motor power is usually up to 100 W. The newest computer-controlled models are able to choose the most economical operating mode themselves, and users are happy when the display shows a power consumption of 12 W with a house area of 150 square meters.

Pipes are used with an inner diameter of 16 mm for one or two radiators and 20 mm for a group of up to 6 pcs., 25 mm can already be the main line from the boiler for the whole house. What will happen to a one-tube if all this is applied to it?

Savings in creation and operation

If a one-pipe system is created with progressive (economical) heating parameters, then it will not work on the scale of a house (5 or more radiators in a ring), because the last radiators will be cold.

A conventional circulation pump will not provide the rate of heat exchange (supply of the necessary energy for sequential switching).And the usual pipe diameter will create too much hydraulic resistance when trying to increase the flow rate.

To heat the last device in the ring, a powerful pump and a large-diameter annular pipe are needed.

What is the temperature of radiators in Leningrad

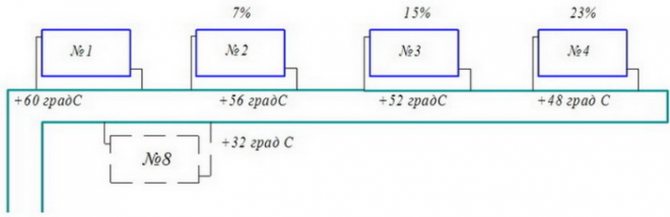

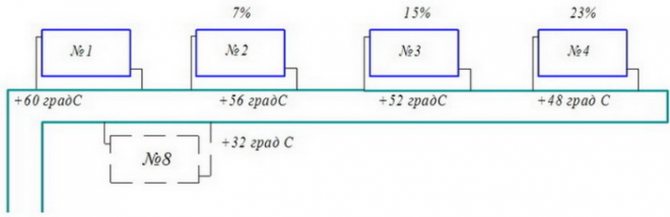

With sequential switching on for one pipe, the radiators will take some of the energy and gradually cool the coolant. If the supply temperature is +60 degrees, then on each radiator the loss during normal circulation of the coolant (up to 30W per pump) will be approximately 7% or 4 degrees. Then at the exit from the 4th radiator there will be plus 48 degrees C. But the 5th in the ring will already be of little use for heating. And for example, on the eighth radiator in the ring - there will be 32 degrees - just cold.

Equalization of temperature between supply and return is possible only with a large diameter of pipes and a powerful pump that creates a sufficient flow rate of the coolant.

Wasteful single tube for large houses

In large houses, with several dozen radiators, where operational losses are not too high, you can consider the option of a one-pipe heating system.

- A steel pipe of large diameter (from 50 mm) is used according to the design calculation, with a special pump that creates a significant speed of fluid movement, up to the limit of noise in the pipe. The pipe is placed along the outer wall ring in the floor space.

- A pair of taps for radiators or floor convectors under high windows are connected to the pipe. The pressure difference is created not only due to the cooling of the liquid in the instruments, but mainly due to the installation in the sail pipe on the supply pipe.

- Significant construction costs and operating losses are leveled by the large heating power, and are not significant when considering the entire costly part of building such a house. With a decrease in the heating area, the role of these costs will increase and they will turn out to be unacceptable.

Why is it so wasteful

Is it possible to squander resources and make such an economical heating system during creation and especially during operation? Where 20 W can be used for circulation, 200 W will be spent. (?), How much exactly - only calculations for a specific hydraulic network will show, but in any case - many times more.

It remains unclear why the necessary expensive operation is needed, because only a kilowatt or two of energy accumulates in the difference in a day, and over the years of operation - a decent heap of money thrown into the wind.

Other methods of temperature equalization - deep balancing of the first radiators makes the whole system even more expensive and unstable in operation. It is recommended as a way out to increase the area of the radiators to compensate for the temperature loss. But then already the 8th in the ring should be twice as large as the first - too wasteful method of heating.

When the diameter of the pipe is doubled, its cost rises faster. The cost of its fittings and taps increases several times. Any installer will say that a workable one-pipe with a diameter of 32 mm for 10 radiators will cost more than a two-pipe laid with a pipe of 20 and 16 mm (two dead ends, 5 pieces each).

In addition, the installer will add (most likely) that such large fittings and pipes are more difficult to install. A single tube with a large diameter tube will cost more to build.

Where and how are single tubes used

In production facilities, it happens that you need to heat large workshops. Then it turns out that the local boiler house will be more rational with a one-pipe system a kilometer long, with hundreds of connected heating devices and a powerful pump.

Single pipes can be found everywhere in centralized networks of multi-storey buildings, because the heating riser is this system with a high circulation rate.

When a Leningrad woman is more rational in a private household

A one-pipe system will clearly be rational when creating heating in some small room, up to 4 radiators in a maximum of one ring, but up to 3 pieces is better. They can even be connected in series one after the other with a polypropylene pipe with an outer diameter of 25 mm, so as not to overload the circulation pump of the minimum size 25/40.

How to create a one-pipe heating system

One of the options for creating a one-pipe heating system in a small private house is to create 2 or 3 rings with 2 - 3 radiators in each. Theoretically, this is possible if the boiler is located in the central part of the building and the heating rings can be laid from its piping in different directions. For example, in one wing of the house there are 4 radiators, in the other - 3 pcs., On the attic floor - 3 pcs. An approximate diagram of a two-pipe for one heating ring for 3 devices.

The house will have a one-pipe heating system of acceptable quality for uniform heating 10 pcs. radiators, simpler, more economical, and cheaper in comparison if these devices were connected with two pipes.

But the problem is that such an arrangement of the boiler, with the ability to close the rings of 3 radiators with one pipe, is a rarity. Most often, the boiler is taken to a utility room in the outer part of the house. And then it is necessary to lay either long dead ends - 5 devices each, or one ring along the perimeter with the inclusion of all consumers in it - it is necessarily created from two pipes, a passing connection scheme is used - how to create a ride ....

Installation of a gravity pipe - heating for a garden house

When there is a problem with electricity somewhere in a remote house, a gravity system becomes optimal - 3 - 4 radiators in one ring. Pipes with a diameter of 30 mm (internal) are used. It is advisable to use steel pipes 40 - 50 mm in diameter. The boiler is installed in a sump - the heating line is below the cooling line, i.e. the midpoint of the radiators, only then will there be circulation.

As an option for creation - from the supply of a metal pipeline to a raised open-type expansion tank. It is located under the ceiling, heats the air at the top, - raising the cooling line. From it, wiring around the house with one pipe, you can also use plastic options, through 3 radiators, and back to the boiler. The system turns out to be expensive, but irreplaceable where there is no electricity.

Radiator connections

There are several options for turning on radiators in a one-pipe heating system.

- Sequential switching is the most economical to create. Applicable up to 3 pcs. heating devices.

- Parallel connection with top supply connection - can be used both on gravity and in the largest rings with a pump. Here, the movement of liquid through the device proceeds both along a parallel branch, as well as due to thermal convection of water when it cools down in the device.

- Parallel bottom connection. Here one principle of "parallel branch" is not enough, a valve or an insert is switched on on the main pipe - narrowing the cross-sectional area by two or more times. A barrier is often simply welded into a steel pipe.

With parallel connections, it is possible to balance the first radiators in large rings in order to equalize the temperature along the entire chain. But as recommended, this method is not life-saving if the network parameters are normal, and experts recommend only increasing the cost of the network even more by increasing the size of the last batteries.

Applied materials and equipment

A solid fuel boiler is mainly used, since automated options, in small buildings (with a single tube) for 3 - 4 radiators in the heating ring, are rarely used. A 25/40 circulation pump is selected, for which the maximum heating area is up to 150 m2. in an insulated house. Recommended piping using a 3-way cold return valve.As well as electrical protection against overheating and cooling through the boiler after the end of combustion.

Polypropylene pipes 25 mm (outer), or metal-plastic pipes 20 mm. Connection taps - 20 mm (16 mm). Balancing valve on the first radiator instead of the shut-off valve.

Also, the boiler is equipped with a safety group and a return filter in front of the pump.

Heating boiler installation

Step 1. Choose a location. The boiler must be located as close as possible to the existing water supply system, problems with the chimney must be solved. Mount the boiler on the wall or place it on the floor, keeping it horizontal. When installing the chimney, follow basic fire safety rules.

STEEL GAS HEATING BOILERS "DANKO" TYPE. MANUAL

Boiler manual

Installation and service manual for VIESMANN specialists

VIESMANN - gas boiler installation instructions

Step 2. If the heating system is open, you need to make an expansion tank with a drain. It can be an ordinary metal square container for about ten liters. It is connected to the boiler at the hot water outlet, and the tank must be located above the boiler and batteries.

The system has forced circulation of water, so it makes no sense to put the tank very high. The tank must have a constantly open drain pipe to drain excess water during heating and to prevent the formation of a vacuum during cooling of the coolant. The closed expander is mounted in the same way.

Video - Expansion tank of membrane type

Video - Connecting a membrane expansion tank to polypropylene

Step 3. Installing the security unit. It is installed only for closed-type heating systems in an accessible place, in most cases near the boiler. The control and safety unit consists of a pressure gauge (shows the actual pressure in the system), an air release valve and a safety valve. The safety valve automatically opens when the maximum permissible pressure values are exceeded.

Video - Security Group

Step 4. Pump installation.

Pumps are sold together with boilers, in all modern gas and electric boilers they are mounted in the body, no additional action is needed. If the installed model does not have a built-in pump or you have a solid fuel boiler, you will have to purchase it separately. Installed in any convenient place at the cold water inlet from the heating system to the boiler.

Video - Installation of a GRUNDFOS circulation pump in a heating system

Step 5. Filter installation. There are nuances here. The fact is that many heating boilers have two hot water circuits, one is used for heating, and the second is used for domestic needs: shower, washing dishes. If water is taken from the boiler frequently, then the likelihood of various mechanical impurities entering the boiler increases, it is recommended to install a filter. If the boiler works only for heating, then it is not necessary to install a filter, water is not taken from the system anywhere, no impurities will get into it. There is an option - water in the country is supplied by floating pumps from wells. In this case, a filter must be installed during the installation of the pumps. If this has not been done, put a filter at the water inlet to the boiler.

There is an axiom in mechanics - the more different equipment is installed, the more vulnerable the system, the greater the likelihood that any device will fail. Experienced engineers try to install only critical mechanisms and equipment, all others are not used. This also applies to the filter - there are no such in another place or the probability of impurities entering tends to zero - there is no need to install filters. These are extra connections, extra housings and filling, and each connection can leak.Keep this rule in mind when installing any system.

Practical advice. All existing filters (except for very expensive ones with molecular filters, the so-called osmosis filters) purify water only from mechanical impurities. This is good, but they do not exist in the water from the pipeline. The boiler is afraid of deposits on the walls of calcium salts - heat transfer is significantly reduced, efficiency decreases. To prevent such phenomena, we recommend using ordinary liquid Calgon (used during washing). Pour it into the closed heating system during filling at the rate of about 1 liter per 100 liters of water - problems with calcium will be solved.

One-pipe system options

The hot water heating line is necessarily equipped with an expansion tank that equalizes the pressure. It accepts excess coolant during expansion and returns it to the pipeline during cooling, preventing pressure surges. There are two fundamentally different types of expansion tanks - open and closed. The type of heating system will also depend on which of them will be built into the line.

Open heating system

An open heating system assumes direct contact of the coolant with the atmosphere. It is used for the device of non-volatile or combined heating. An open expansion tank is a cylindrical or rectangular vessel, partially or completely open. At a certain level, a drain is performed to drain excess liquid into the street or into the sewer.

In the scheme of an open heating system with forced circulation, the expansion tank is connected directly after the boiler, the outlet is arranged at the highest point of the line. The container itself should be located above all connected devices, therefore, the tank is often taken out to the attic. In this case, it must be insulated at low temperatures.

Due to the contact of the coolant and air in the tank, the hot water is saturated with oxygen and naturally evaporates. Hence the limitations and disadvantages of such a scheme:

- It is required to constantly monitor the level of the coolant in the tank and replenish it on time;

- It is necessary to observe the slopes of the pipeline (5-7 degrees) so that the air released in the pipeline is vented into the expansion tank and the atmosphere;

- Antifreeze should not be used instead of water, as it emits toxic substances when it evaporates;

- The presence of oxygen in the coolant reduces the service life of heaters with steel parts.

Attention! The absence of slopes during the installation of the pipeline of an open heating system will lead to airing of the line. However, open heating has its advantages:

However, open heating has its advantages:

- It is not required to monitor the line pressure;

- The coolant can be replenished even with a bucket, simply by refilling it into the expansion tank to the required level;

- Even in the presence of small leaks, the system will function properly - as long as there is a sufficient amount of water in the pipeline.

Diagram of an open-type heating system with forced circulation

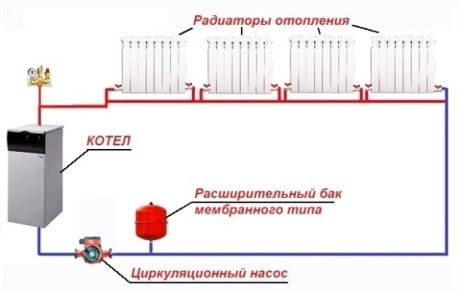

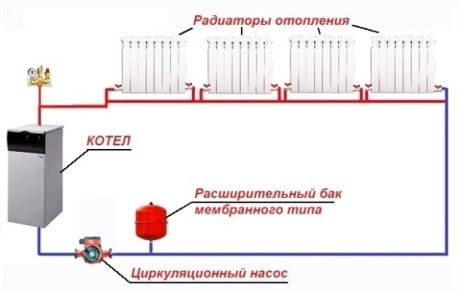

Closed heating system

The scheme of a closed heating system with forced circulation is currently the most widespread. It is a closed hydraulic line, completely closed from air access.

A closed water heating system involves the use of a membrane-type expansion tank. It is a sealed cylindrical metal body, the inner cavity of which is divided by a membrane. One part is filled with air, and in the second, water is squeezed out of the line, the volume of which increases when heated.

The membrane expansion tank can be installed anywhere in the line, but for ease of maintenance it is connected to the "return" - next to the boiler.

A feature of the closed circuit is the presence of a slight overpressure in the line. Therefore, a closed trunk must contain a security group. This unit is installed on the pipeline leaving the boiler (supply) without shut-off valves. Contains pressure gauge, air vent and safety valve for emergency water discharge.

Important! A security group must be included in the scheme of a closed system.

- The coolant under pressure warms up faster;

- The probability of airing the heating main is practically excluded;

- Filling with antifreeze is possible, since the coolant does not evaporate and is not saturated with oxygen (relevant for periodical buildings);

- Ease of service - all devices that ensure the functioning, control and security of the system are installed in one place;

- Using modern equipment, you can make a closed heating system fully automated and integrate it with smart home programs.

The disadvantage is volatility. Solved by purchasing an autonomous generator.

Diagram of a closed-type heating system with forced circulation

Installation of heating pipes and markings for the installation of radiators

| Step, no. | Illustration | Description or explanation |

| Step 1. Drill holes for clips (pipe fasteners) and holes for pipes to pass through ceilings or walls. | Depending on the material for making the walls and floors, you need to use an ordinary drill or perforator. | |

| Step 2. Pull the pipes through the holes. | It is very important - while pulling pipes, you need to close their holes, otherwise there is a possibility of foreign objects getting inside. It is impossible to remove objects from the pipe later, and they can create many problems. Is the pipe very long and difficult to pull? Consider where you can install the couplings, measure the distance and cut the pipe into several pieces. Cut off the pipe with a margin, you will never be able to measure the optimal length of the pipes right away, then you will make a fit on the spot. | |

| Step. 3. Marking the place of installation of radiators. | All radiators should be located at the same height, carry out work on a level. Each type of radiator has its own differences, to make it easier and faster to mark, make a simple template from a piece of board or plywood. Mark the position of the upper and lower mounting brackets on it, drill holes in these places. Then just put the template on the floor, lean it against the wall and mark the attachment points for the brackets. Do all the marking work very carefully, the quality and speed of further work on the installation of the heating system largely depends on this. | |

| Step 4. Prepare radiators. | Nowadays they do not use cast-iron radiators, aluminum or bimetallic ones are in high esteem. Their advantage is that with a smaller size, a much larger heat exchange area. The same advantage is also a disadvantage that the manufacturers do not indicate. Aluminum radiators have a lot of different jumpers (to increase the area), which are located in hard-to-reach places. It is impossible to remove dust from there. If the thickness of the dust reaches one millimeter, then the heat transfer efficiency is halved. Where has dignity gone? A rhetorical question, but the high price remains. Advertising is often used by manufacturers in order to sell products more expensive and faster, and not to do something useful for the consumer. This applies not only to radiators, remember this. Unscrew the factory fittings (some types of radiators may have plugs), seal the threads with sealant, tow or a modern tape seal. Attach valves and tees in the same way, if necessary according to the technological scheme. |

How to work with polypropylene pipes

We have already mentioned that these pipes have excellent characteristics and quite a reasonable price, it is these qualities that have become the reason for their high popularity. Soldering of pipes is carried out with a special soldering iron, the melting temperature of polypropylene is + 270 ° C, this temperature should be set on the thermostat of the device. The heating time of pipes depends on their diameter. The table shows the approximate values of the parameters.

Pipe heating time

| Diameter of the word passage of the pipe, mm | Approximate heating time, sec. |

| 20 | 5 |

| 25 | 7 |

| 32 | 8 |

| 40 | 12 |

| 50 | 18 |

| 63 | 24 |

| 75 | 30 |

The soldering iron has two nozzles, with the help of one the inner surface of the pipe is heated, with the help of the other the outer surface of the pipe is heated. You need to heat both surfaces at the same time, as soon as the specified time has passed, the pipe sections are removed and inserted into each other with little effort. It is very important - it is forbidden to rotate the pipe during joining, the efforts should be only axial. After connecting, you need to hold the connections for some time (ten seconds) to cool down.

With the acquisition of experience, a neat edging will be obtained. In terms of strength, the joints almost do not differ from the strength of solid pipes, leakage and depressurization during operation are excluded. Do not forget to add one centimeter on each side when cutting pipes, this length will go to the connection. We do not get tired of repeating - any work requires intelligence and attentiveness.

Do not rush to glue everything in a row, think, foresee your actions a few steps ahead. There are times when you need to skip the area to be treated and glue the pipes in front, and then return to the original place. This is due to the fact that then it will not be possible to get to the workplace with a soldering iron. In a word, think over the soldering technology a few steps ahead - how which segment needs to be rotated for soldering, will there be such an opportunity later, etc.

Installation of radiators

One of the most difficult types of work when installing a heating system. We have already made markings on the wall, now we need to hang the batteries.

Step 1. Drill the holes for the dowels according to the marking. For drilling, you need to use a drill with victorious surfacing (for bricks and concrete). The drill should be set to perforation mode. Choose the diameter and length of the dowels taking into account the dimensions and weight of the batteries.

Step 2. Screw the Mayevsky tap, drain and plugs to the battery.

Please note that the plugs can be installed in different places, depending on where you installed them, the flow of the heating medium can be diagonal or horizontal. If you have a bypass heating system, then you need to solder the tees in the right place, make a branch for attaching a jumper, which allows you to completely disconnect the battery during repair or replacement.

One more thing - in order to be able to adjust the temperature of each battery in the bypass heating system, it is necessary to install a needle valve near each radiator, with the help of which the flow rate of the coolant will be regulated (in this way the temperature of the battery changes). Why exactly a needle faucet? Because it provides smooth and precise regulation of the flow rate of the heating medium.

When brazing, observe the direction of the tee with the direction of the radiator taps. In order not to be mistaken, before starting work, make special marks for yourself with a pencil, check their correctness and only after that start soldering. If you make a mistake, it’s unpleasant, but not fatal. Cut off the wrong section and repeat the operations in the correct order, it is for such situations that you bought all the elements with a margin.

Step 3.Bundle the batteries for the bypass sections. We have already mentioned that they increase the versatility of the system. This operation only applies to the bypass system.

System start

For your information, industrial heating projects for commissioning provide up to 10% of the total budget. This means that commissioning is very important and complex. To insure you against making mistakes, here are some practical tips.

- Open all valves and air vents before filling the system with water. Please note - not after filling, but before. Let the water spill a little on the floor, that's okay. Close them only after the appearance of water.

- Fill the system slowly, do not open the water tap completely. The fact is that fast filling can cause air jams to form in places from which they cannot be removed - you have to drain the water and start all over again. This does not always happen, it all depends on the correct installation of the system, but such an embarrassment happens for beginners.

Video - Starting and filling the heating system with a coolant

It is advisable to install a single-pipe heating system with lower wiring in small buildings, the further the battery is from the boiler, the lower its heating temperature. If permanent residence is not planned in the country house, then in winter, during the absence, the water must be drained, and refilled upon arrival. Not everyone wants to do such things. The way out is to use antifreeze as a coolant, but this is expensive.

If desired, you can mount a one-pipe heating system in the bath. But why? The steam room does not need to be heated, the batteries are installed only in the dressing room. One or two radiators are enough for this room. The system will be used for several hours a week. Is it worth it to waste so much time and money? Perhaps, for a small bath, it is worth buying an ordinary heater. It is advisable and economically viable to install a heating system in a large bath complex or a bathhouse combined with a residential building.

banya-expert.com

Device and principle of operation

Heat supply based on water heat carrier is divided into 2 types. It can be horizontal and vertical. Which type of pipe laying to choose depends on the architectural structure of the building.

A single-pipe heating system with natural circulation works according to the following principle: a heat carrier consisting of water, brine and antifreeze moves through the pipe and heats the residential building. The movement of the liquid occurs in a closed loop. The circulation of the coolant comes from the heat generator, then returns. All technical equipment required for the construction is connected to a single line.