Reasons for the appearance of cracks in pipes

A long-operated cast-iron sewage drain in an apartment usually flows for one of the following reasons:

- there was an impact mechanical effect on the metal;

- decrease in wall thickness as a result of prolonged exposure to corrosion;

- destruction of pipeline fasteners and change in the direction of the static weight load;

- a simultaneous combination of two or three of the above consequences.

Longitudinal cracks in plastic sewer materials appear only as a result of the lack of compensation for thermal expansion or there was an external shock of great force.

How to get rid of an unpleasant odor

A specific smell from the sewage system in the house can appear not only with a leak, but also due to clogging, the formation of plugs from organic waste. There may also be a malfunction in the operation of the water seal - a siphon connecting the plumbing with a sewer pipe (although the siphon is just designed to protect against unpleasant odors of domestic waste water).

We recommend that you familiarize yourself with: Technology and features of laying sewer pipes in the ground

Another reason for the appearance of an unpleasant odor is the process of depressurizing the joints in the room, which can be overlooked if the water is released drop by drop and flows down the pipes through the hole in the ceiling.

You can get rid of the smell by removing the blockage in the sewer, replacing the siphon that connects the sink in the bathroom, the sink in the kitchen or the bathroom in the bathroom with a sewer pipe.

If an insufficient tight fit of the pipe leading from the siphon to the tee is found, you must use a special sealant (sold in hardware stores).

If the integrity of pipes and connections in the sewerage system is not violated, and an unpleasant odor is present, it is necessary to clean the pipes with the help of special powerful reagents such as "Mole", which dissolve plugs from organic residues.

If, after use, an unpleasant odor still remains, and the water from the drain drains more slowly or is delayed, the help of a plumber is needed.

The cleaning specialist uses a flexible cable with a brush nozzle, which is inserted through the drain into the sewer pipe and mechanically pushes the blockage.

How to repair a crack in a cast iron sewer pipe with your own hands

In order to eliminate the leak, it is necessary to accurately determine the cause of its occurrence and find the place where it leaks. Depending on this, choose a possible repair method and carry out work. There are several ways to fix a sewer leak. They differ in the level of reliability, the appearance of the pipe after repair, and the complexity of execution.

Method 1. Installing clamps with a rubber gasket

This method of performing repairs requires access to the pipeline with a margin of at least 50 mm from the walls. This condition is very often not met, especially when the pipe is angled in the toilet.

To install the clamp, it is necessary to clean the surface to metal using metal brushes. After that, install a clamp with a rubber gasket.

Method 2. Cement bandage

This is a reliable way to repair longitudinal cracks in non-pressure pipelines. It consists in applying a gauze soaked in cement mortar to the site of damage.

The place to be repaired must be thoroughly cleaned of old paint and rust. Prepare a slurry with the addition of sand in a 1: 1 ratio. Dip the cheesecloth into the solution and make sure it is well saturated with the fabric. Apply the cement bandage to the surface in several layers and tie it with a rubber band or copper wire.

It is recommended to cover the cement surface with liquid glass (silicate glue). This will speed up the setting of the mixture and prevent it from eroding.

Method 3. Application of chemicals

One of the best sealants for sealing cracks and holes in cast iron is a mixture of phosphoric acid and copper oxide powder in a 2: 3 ratio. The prepared solution hardens very quickly and therefore it must be done before the very application to the site of damage.

Before covering the crack, the cleaned surface must be degreased with acetone or gasoline.

A solution based on orthophosphoric acid can be replaced with epoxy resin, but its curing time is longer and after application, a surface winding of dense impregnated fabric is required.

How to seal a sewer pipe is the easiest

Very often, homeowners are interested in how to cover up a cast-iron sewer pipe if it flows at a stamped joint. Again, silicone sealant will come to the rescue. Before sealing the sewer pipe joint, clean the socket of the old putty, remove the remaining debris and dry the pipe.

Note that the following phenomenon is often encountered: the compound does not flow, but emits an unpleasant odor. In this case, the sealing of the sewer pipes can be done with ordinary cement. In order to make the joint more durable and speed up the setting, before covering the joint, add a small amount of sodium silicate (water glass) to the solution.

It is very simple to repair sewer pipes with your own hands in an apartment with Cold Welding glue. To properly seal the hole, before starting work, empty the cavity of the sewage system from the remaining liquid and mark the place of leakage with chalk. Then clean the pipe surface and degrease it. Apply a small “cold weld” patch to the damaged area, then apply a rubber seal to it. By the way, this method is also the answer to the question of how to eliminate a leak in a plastic sewer pipe.

In conclusion, it should be noted that if a sewer pipe is leaking at the junction, it can be sealed using a tape consisting of an aluminum or copper layer on a bitumen-rubber base. The tape is very effective, strong and durable. And the sealing of sewer pipes is very simple with it.

How to replace a damaged pipe section

The sewerage system of the apartment consists of a riser and drainage from plumbing and household appliances.

Replacing only the riser in the toilet or individual sections of the horizontal pipe is technically possible, not rational from the point of view of further operation.

Required tools and materials

To complete the work, you will need to purchase a set of parts, which will necessarily include:

- socket pipes with a diameter of 110 mm, lengths of 2000 and 1000 mm;

- transition pipe "cast iron-plastic" 110 × 127 mm;

- compensating coupling (sliding) 110 mm;

- tee or cross, depending on the wiring configuration;

- rubber sealing cuffs 110 × 127 mm;

- three fasteners in the form of clamps;

- assembly grease or sanitary silicone.

From the tool you need to prepare:

- grinder (angle grinder) with a cutting wheel for metal;

- hammer 300-500 grams;

- mount;

- perforator with drilling.

Progress

After the preparatory stage, you can proceed to the direct implementation of the work. First of all, you should ensure that there is no fecal waste in the riser.

The cast iron riser is cut in stages. First, a window is cut out on the outside with a depth of at least half the pipe diameter. After that, the back wall is cut and the riser can be disassembled.

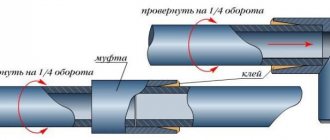

A cast iron-plastic adapter is put on the upper cut of the cast-iron pipe. The bell of a two-meter plastic pipe is pushed onto it, on the lower end of which the compensating sleeve must be pushed to the limit.

A rubber sealing collar is inserted into the lower cast-iron socket and a tee or a cross is installed, into which a meter-long pipe is then inserted. Its axis should coincide with the axis of the upper pipe. The movable expansion joint goes down and connects the two parts of the riser. The horizontal lines are routed to the desired sides from the tee or cross.

Repair methods

You can repair a leaking sewer pipe in different ways, the choice of which depends on the place of the leak, the size of the hole or crack.

We recommend that you familiarize yourself with: HDPE pipe for laying cables in the ground

Plumbing professionals use several standard methods to seal pipes in the event of a leak:

- at the junction where there are threaded or flange connections, winding from linen strands is used, which are tamped tightly into the gap between the pipes and filled with a special solution;

- the resulting hole or crack in the body of the cast-iron pipe is sealed with a rubber seal and a metal clamp;

- small holes and fistulas in pipes are wrapped with a bandage, pre-impregnated with epoxy resin;

- small cracks are sealed with a special quickly hardening sealant, then wrapped with reinforcing tape.

If it is quite simple to eliminate a leak at a pipe joint with a sealing material, then in a straight section where a crack or fistula has formed, it is necessary to properly prepare the pipe for repair.

Clamp overlay

The most reliable way to seal the pipeline in case of violation of integrity (crack or hole up to 2 cm) is to apply a special clamp.

To do this, the place of the future patch is cleaned with sandpaper or a special metal brush.

Further, the treated area is degreased using any solvent (acetone can be used).

The section of the damaged pipe is wrapped with a special rubber gasket or rubber bandage, on which a metal clamp is put on.

The product is fixed very tightly with bolts and nuts. This method allows you to eliminate the leak and immediately return the pipeline to working condition.

Winding

Another proven method for sealing leaks is to wrap with an epoxy-impregnated bandage. To do this, you must take the preparatory measures described above (cleaning and degreasing).

For wrapping, a regular gauze bandage is suitable, which must be lowered into a container with epoxy resin (sold in hardware stores in the paint and varnish department). The pipe is wrapped in several layers, if necessary, it is additionally fixed with wire.

Repair with sealants

The use of liquid sealants is the third way to seal pipes in the event of a leak. It is suitable for small holes and cracks up to 1 cm.

We recommend that you familiarize yourself with: Making a greenhouse from a profile pipe and polycarbonate with your own hands

For this, special semi-liquid polymer compositions are used, which are applied with a brush to a previously cleaned and degreased metal surface with a brush. The substance hardens on contact with air and provides reliable crack sealing. But this method is only suitable for small longitudinal cracks.

Holes of irregular shape more than 1 cm are not sealed with sealants.

Important! Before patching a cast iron pipe, assess the general condition of the pipeline.If the pipe is significantly outdated, covered with rust, and its internal clearance is greatly reduced due to deposits, it is more advisable to replace the entire pipeline with a new one using polypropylene or polyethylene pipes.

What to do if a leak occurs at the joints

Repairing a leak at a pipe joint is a relatively simple task. If all the elements of the pipeline in the area with a leak are not damaged, and the leak was formed due to a leaky gland, you can use plumbing flax and seal the joint yourself. To do this, you will need to prepare in advance a solution of PVA glue, water and polycement.

The algorithm of actions is as follows:

- The pipeline is closed.

- The area of joint depressurization is dried with a rag and a hair dryer.

- Any sharp instrument is used to remove the rest of the binder cement.

- The linen winding is compacted with a stamping or other flat tool.

- The gap between the two sections of the pipeline is filled with a prepared solution of PVA glue and polycement.

- The joint is additionally lubricated with a brush soaked in the resulting solution.

It is not recommended to use the sewage system within 24 hours after the repair

Expert advice

Eliminating the leak by installing a clamp, bandage or using sealants, it should be understood that if such damage already exists on the pipe, this means that its service life has come to an end and any repair will only be a temporary solution to the issue.

Therefore, immediately after repairing the leak, begin preparations for replacing the entire pipeline as a whole.

Features of the repair of plastic pipes

Unlike cast iron, plastic sewer drains have a smooth outer surface. Therefore, the easiest way to fix a leak on a flat area is to use a special sealed tape, which can be purchased at a building materials store.

The tape is applied over the hole in such a way that half of its width constantly overlaps the previous strip. Laying is carried out with the maximum possible tension of the material used. The damaged area of plastic pipes should be covered with tape in two layers when winding it in the opposite direction.

For repairs, you can also use a clamping strap and sealants of various compositions.

The cement bandage, due to the low adhesion of the plastic surface, will not adhere to the pipeline.

Nuances of repairing PVC pipes

Since all polymer pipes for internal sewage are made of polyvinyl chloride, the nuances of repairing PVC pipes are no different from the features of repairing plastic pipes, which are described in the previous paragraph.

What to do if there is a leak at the junction of the fitting and the pipe itself

It is necessary to remove the old sealing compound between the inner surface of the socket and the outer wall of the pipe. Then fill the joint with new sealant.

Sealing fistulas in a pipe

Fistulas are formed as a result of corrosive effects on the metal and their sealing is completely analogous to repairing when cracks form, which you can read about above.

How to get rid of an unpleasant smell in a pipe

There will always be an unpleasant smell inside the sewer pipe. This is the nature of fecal effluent.

But in order to prevent the smell from entering the room, it is necessary to ensure the complete tightness of the system, install siphons on all connection points and make sure that they are constantly filled with water.

Cast iron pipe sealing materials

Sealant tape

In the sewer system, the joints are the most vulnerable point, so they require increased attention. To seal them, it is customary to use not only linen winding or plaster bandage. There are many more modern and effective materials.

Self-adhesive tape

The material is widely used in plumbing work due to its simplicity, efficiency, resistance to corrosion, and low price. Self-adhesive tape should not be used only in open areas as it is not UV resistant.

Before sealing, be sure to thoroughly prepare the surface of the pipes. They are cleaned of dirt, dust, dried, primed. The tape is wrapped around the desired area with a half overlap. The material is applied in two layers to increase reliability.

Silicone sealants

The material is presented in the form of a special mixture that hardens upon contact with air. Silicone sealants are made from rubber, there are additives to increase the strength and adhesion properties. To increase the polymerization of the mixture, manufacturers add vulcanizing admixtures to the composition.

Silicone sealants are distinguished by high resistance to various temperature conditions, sufficient mechanical strength, moisture resistance, and a long service life.

Other methods of sealing

To increase the reliability of units in the sewer system from cast-iron plumbing pipes, special mixtures are used:

- epoxy resin;

- asphalt mastic;

- technical sulfur;

- cement with asbestos fiber (in a ratio of 2: 1);

- resin strands.

At home, epoxy is most often used. For its hardening, polyethylene polyamine (cold method) or maleic anhydride (hot method) is used. Technical sulfur is suitable for sealing the drainage system. It is pre-crushed, heated and poured into the gap between the pipes.

Features of the repair of sewer pipes on the top floor

If it is planned to repair hot water supply pipes, then it is imperative to turn off the water supply. This should also be done if the leak is serious.

If there is a slight crack on the pipe, then you can do with a clamp and a small piece of rubber. If they were not at hand, then you can use a simple or copper wire. To carry out repairs, work must be performed in two stages. First, you need to cut the required piece of rubber from any suitable element, be it a car tire or a tube. Next, the prepared piece of material is applied to the crack and fixed to the pipe using a clamp.

During the process, you need to make sure that the rubber layer completely covers the crack. In the worst case, gases will flow into the room. This repair method is more suitable for apartments located on the upper floors, since in these places there is an air area of the pipeline. As a result, faecal waste will remain on the lower floors, and gases will go upstairs.

If the apartment is located on the ground floor, then it is recommended to choose another repair option, which is more reliable and efficient.

How to glue a plastic sewer pipe

If fistulas are characteristic of cast iron, then no pipe, including plastic, is insured against cracks. If a hole has formed in the flat part, the same clamps come to the rescue.

Just as with a cast iron pipe, the clamp can be replaced with a piece of rubber (for a short time!) And wire.

A small crack can be repaired with silicone sealant. Act in stages:

- the crack is expanded (if possible) so that the composition penetrates as deeply as possible;

- the surface is thoroughly cleaned and degreased;

- dry the repaired area with a construction hairdryer;

- apply a sealant.

A two-component epoxy is used to repair the through hole. The procedure is slightly different:

- the surface is cleaned and degreased;

- the damaged area is wrapped with a bandage (it is prepared in advance from a flexible dense material) - along the entire length, with a margin, overlapping, at least 5 turns;

- epoxy glue is applied.

Sealing tape

The method is very convenient and inexpensive. The tape is an impregnated adhesive fabric.

It is indispensable in the repair of hard-to-reach areas and is so convenient that it is used to seal cracks on straight sections of a sewer pipe. As with other materials, the surface is thoroughly cleaned and degreased, then the tape is stretched and wound around the pipe section (the tape tension must be constant to avoid wrinkling). They are wound with an overlap - the next layer should cover half of the previous one, so that in the end the material becomes two-layer.

Cold welding for the repair of plastic pipes seals cracks reliably and permanently. Surface preparation should be approached with great care - for better adhesion of the XC to the pipe. The site is not only cleaned and degreased, but also treated with sandpaper (do not forget to dust off after processing).

Procedure (work with gloves and goggles!):

- CS is kneaded with hands until ready - they write that it is determined by color (the material will turn brown) and consistency (plasticine), but this is optional and depends on the components (follow the manufacturer's recommendations);

- apply a mass to the repaired area in such a way as to close the crack with a margin;

- press the cholesterol with a tourniquet.

After complete drying (at least an hour), the patch can be drilled, cut, sanded. Drying is accelerated with a construction hairdryer. They also dry the surface before repairing.

Replacing a pipe or fitting is the best way out. Let's say this is somewhat more complicated in the case of cast iron parts, but when it comes to plastic, there are no obstacles. Plastic pipes and fittings are inexpensive, always available in a wide range. They won't take a lot of money for the replacement either. Fumbling with pipe patching not with the aim of temporarily blocking the leak and calling the master, but with the desire to completely fix everything, is justified only as a hobby.

Once the leak has been repaired, it may seem like a temporary patch will last for centuries. This is often true (especially with the use of cold welding), but no less often the case ends with a serious breakthrough and the subsequent flooding of all the neighbors living below with sewage. Having taken urgent measures to eliminate the leak, contact the specialists for a full repair / replacement of the damaged section of the sewer network - in order to avoid serious consequences.

The old multi-storey buildings are laid. This material wears out over time. Holes or cracks appear in the pipes and cause leaks. To solve this problem, you will have to resort to a thorough inspection of the sewer line, followed by the elimination of the defect.

Ru209..ru209..ru209-300 × 200..ru209-768 × 512.jpg 768w "sizes =" (max-width: 1024px) 100vw, 1024px ">

Cast iron pipe repair

If a cast-iron pipe leaks in the toilet, repairs are immediately made. This process depends on many factors, the main of which are:

- the strength of the pipeline;

- the size of the defect;

- the presence of longitudinal chips and cracks.

The fact that the pipe has burst may be evidenced by:

- the appearance of an unpleasant odor in the sewer system;

- the presence of smudges on the outside and pipe joints.

If a leak is detected at the point of entry into the pipe (as a result of a poor-quality connection at the transition point of the siphon or drain hole), then the problem is solved by:

- replacement of the gasket;

- pulling up the connection elements;

- sealing the inlet structure.

And how to repair a cast iron pipe when a leak is found on the structure itself? In this case, you should carefully examine it for the size of the defect. If there are small holes or cracks in the pipe, then you do not need to dismantle it to carry out repairs. Otherwise, the damaged area will have to be removed.

An easy way to reanimate cast iron pipes

It is possible to repair the sewer system in this way in two stages, but remember that it is not recommended to use the water supply system until the cement has dried (about 24 hours). At the preparatory stage, it is necessary to cut the bandage into pieces of 40 cm and dilute the cement with water. Instead of water, you can take liquid glass. The consistency of your mortar should not be too thick. If you do not have a bandage, then you can take unnecessary women's tights.

We pass to the main stage: we lower one piece of the bandage into the solution and leave it to soak, and then we wrap the damaged area on the pipe. The finished layer can be sprinkled with a little dry cement. Then we do the same with other pieces of bandage, until there is a cocoon at the crack site. We process the top layer with silicate glue to reduce the setting time.

1pokanalizacii.ru

Why do cracks appear in a cast iron pipeline

When a cast iron pipe begins to leak, it is imperative to establish the cause of the leak. On this basis, a specific repair technology is selected.

First, you need to determine where the crack has appeared. Often, a leak is formed at the joints of the pipes or from mechanical stress, which caused the appearance of external defects.

External damage can be caused by a variety of reasons:

- The installation of the sewer pipes was done with mistakes.

- During the assembly of the pipeline, the manufacturers did not check its tightness.

- The neighbors connected a ground wire to the riser. Such actions are prohibited by law.

- Natural wear and tear. Old pipes are useless to repair, they need to be replaced immediately.

A crack that appears at the junction of the fittings indicates a poorly performed work by the plumbing technicians when installing the sewage system.

vseprotruby.ru

How to fix a leak in a cast iron sewer pipe?

There are several ways to help fix this problem. The choice of a method for repairing the system is influenced by the size of the defect, the strength of the pipeline and the presence of longitudinal cracks, as well as spalling.

If you have leaking pipe joints, follow these steps:

- turn off the sewage system during repair work;

- dry the pipeline joints with a rag or hair dryer;

- remove cement from joints;

- stamp the gap between the nozzles with a linen plumbing roll;

- make a solution of polycement and PVA glue;

- coat the crack at the joint with a solution, there should be several layers;

- do not use the sewer for 24 hours.

Advice!

Instead of a solution of polycement and PVA glue, you can use a special silicone sealant, then you will have to not use the sewage system for only three hours. You can also use baby clay, epoxy, wet rubber, or waterproof glue to lubricate the joints.

If there is a crack in the cast-iron sewer pipe, then it is imperative to talk with neighbors in order to implement a comprehensive repair and avoid further breakdowns in the sewage system.

You can seal the crack with:

- plug for sewer pipes - eliminates leaks in small holes (important: use only short wooden wedges, as long ones will create obstacles inside the fittings), drive in this chop in the place of breakage, then wrap the pipeline with gauze and soak with epoxy;

- several layers of gauze - wrap the pipeline with gauze, if the leak is small, soak the gauze with epoxy resin or cement, apply gauze on the problem area, completely wrapping it to a cocoon state, wait a day until the cement dries;

- use a rubber bandage to temporarily eliminate the breakage; over the bandage, be sure to make 20 tight turns using copper or aluminum wire;

- a special clamp to eliminate any leaks (note: for pipes with a diameter of 5 cm, you will need a clamp, which will cost up to $ 8), wrap the hole with a gasket, cover the rubber with a clamp and tighten it;

- repair sleeve for sewage - it helps if the hole is very large, cut the rubber gasket to the size of the sleeve, put it on and tighten.

If a longitudinal crack or small chip has formed, then it will be more difficult to repair them.

If the breakdown is in the chimney of the riser, then the reason for this situation is the icing of the inside of the branch pipe during the cold season. Simply put, the pipeline is frozen inside due to the expansion of the frozen water. Use a sealant to fix this problem. You will need:

- Extend the crack by making a groove for the sealant.

- Degrease the place of breakage.

- Dry the place of breakdown.

- Apply silicone sealant.

- Insulate the pipeline in order to avoid further breakdowns, longitudinal cracks and chips.

If there is a strong unpleasant smell in your home, then more decisive action will be required. In order to remove the chips, use a special two-component adhesive ("cold welding"). Smear the leak with this glue, let it cure well, then sand it.

vivoz-gbo.ru

Heating systems

For interconnecting heating radiators most often. If you notice water on the floor, then you need to immediately find out where the leak formed. How to repair a crack or other hole in a heating pipe?

The most common ways to repair a leak are:

- To temporarily solve the problem, it is enough to take soft rubber (for example, from an old bicycle tube), wrap the damaged area tightly, put a clamp on top or wrap with wire.

- With a bandage. To do this, you need to buy a factory-made bandage, which is completed with a sealing rubber band, as well as a clamp, and mount it in a problem area.

- When water drips or flows at the connection of the heating pipe, then this is a more complicated option, since it is possible that there are different diameters of the risers. In this case, you can also use the factory bandage, only you should replace the sealing gum with a piece of soft rubber. The main thing is to properly wind it around the pipe, as well as to smooth out the difference in diameters. After that, apply a clamp.

- Heating pipes can also be repaired using electric or gas welding. Although, in most cases, a crack in a pipe is closed at home without welding. But these are temporary measures.

In some cases, urgent repairs to cast iron pipes can be done independently. Suppose that the riser in the bathroom or toilet begins to leak. If the crack or fistula is insignificant, and the flow from the riser does not threaten to flood either you or your neighbors, you can try to solve the problem without resorting to such drastic measures as a complete replacement of the riser. We want to talk with you about the technology for performing such repairs in this article.

Cast iron for water supply and sewerage

First, consider how you can repair a leak if a cast-iron sewer or water pipe is cracked.

Two cases are possible:

- flows at the pipe joint;

- there is a crack or fistula in the riser.

The breakdown of the 1st type can be eliminated by means of a new capping of the socket.

To eliminate this type of leak, you need to perform the following set of actions:

- shutdown the sewage or water supply system;

- use a hair dryer or rags to dry the joint;

- remove the remnants of the old cement mortar, packing;

- using a linen plumbing reel, stamp the gap between the pipes;

- from polycement and PVA glue, make 200-300 ml of an aqueous solution, which several times, with an interval of 8-10 minutes, anoint the place of minting;

- do not use the sewer throughout the day.

In the second case, you can repair the riser in several ways:

- Chemical method

This requires:

- using a metal brush or coarse-grained sandpaper, it is good to clean up the place of future repairs;

- thoroughly degrease the problem area with acetone or other solvent;

- take copper oxide and phosphoric acid, prepare the mixture necessary for work in a ratio of 3: 2;

- using the resulting composition, carefully cover the joint. The procedure should be carried out with a freshly prepared mixture, since it hardens for several tens of seconds. Therefore, it will be possible to use the sewage system in 2-3 hours.

- "Cold welding" For reliable sealing of the hole, you should buy "Cold welding" - this is the name of a special glue. So, before sealing the hole, you need to clean the right place from dirt, water, rust, mark the place for repair with chalk. After that, you should well grind the desired place on the surface of the collector with coarse sandpaper and degrease it. Then apply a small patch of glue to the hole, apply a rubber sealing patch on top. In a similar way, the hole in the plastic pipe is eliminated.

- Reliable In order to give a complete answer to the question of how to repair a crack in a cast-iron sewer or water pipe, you need to remember one more, the most reliable, method. For its implementation, it is necessary to take in approximately equal proportions sulfur, iron filings, and also powdered ammonia.

Mix all the ingredients thoroughly, while adding the required amount of water to form a homogeneous mass, which in its consistency would resemble thick sour cream. Seal joints and other holes with this solution. As practitioners say, there is no better way to seal cracks and holes.

- With a clamp Plumbing and sewerage systems have been repaired with a special clamp for decades. It is very effective at filling holes. Before starting work, you need to purchase a clamp or, in extreme cases, make it yourself, given the diameter of the pipe. First, the pipe is very tightly wrapped in the place where the hole is with a rubber winding. Then they put a clamp on this place and securely tighten the bolts on it. In this way, you can get rid of any leak, even a large one.

Plastic or PVC

If a small crack or hole has formed in, then you can. If there are too large holes, it is impossible to eliminate the leak by soldering. So how do you practically repair a crack in a water pipe?

We carry out this procedure with the help that can be bought at a hardware store. So, first you need to turn on the device, wait until it warms up. At this time, you need to completely get rid of the water in the pipe cavity, dry it. After that, it is necessary to tightly fill ordinary bread (without a crust) into the end of the riser and solder with a hot device. The whole procedure is carried out very quickly - within 10 seconds.

In this case, a special nozzle is used, on the one hand it is thinner, on the other - wider. In this case, they use special polypropylene rods. Such a tool is intended for welding small holes. This can be a cut with a knife, accidental drilling with a drill during construction work, etc.

First it is necessary to drill the resulting hole with a larger diameter drill.

For example, if the pipe was damaged with a drill with a diameter of 6 mm, and you have polypropylene rods with a diameter of 9 mm, then drill a hole with an 8.5 mm drill. After that, take a heated welding machine, thoroughly heat the place of future welding, insert a rod into it, wait a few seconds and remove the machine.After cooling down, after 5-8 seconds, carefully cut off the excess part of the rod. The pressure of the water will easily knock out the remains of the bread.

Cold welding is often used to seal a crack or hole in a PVC pipe. Before eliminating the leak with this special glue, it is necessary to prepare the right place: clean the pipe section from dirt, wash, dry. Then apply glue to the surface, put a patch of rubber of the required size, straighten it well, making sure that not a single bubble appears.

When patching a crack in, it is best to use a bandage.

This requires:

- buy a bandage together with clamps, taking into account that its width should be 4-5 cm larger than the size of the crack;

- with the help of soft but strong rubber, tightly cover the damaged area, apply and secure the bandage.

In order to seal the crack in the Korsis pipe, use a polyethylene repair plate with an electric heater mounted in it. Interestingly, if such a pipe is in the ground, then the damaged section of the pipeline is not excavated. Special technology makes it possible to carry out repairs underground.

Working with plastic pipes

Installation of couplings

Sewers made of plastic pipes are very popular due to their ease of installation and operation. Plastic is a malleable material, working with it is not particularly difficult.

After a crack is found, the damaged section of the pipe is disconnected from the system and dried. Direct elimination of the leak can be performed in several ways. One of the safest is to install a coupling, but this method only repairs small cracks.

- The coupling is installed in the following way:

- The section of the structure is cut out with scissors. The incision lines are at a distance of 2-4 cm from the damage.

- A new pipe is prepared, which will be installed after dismantling the old one.

- A thread is cut on both pipes so that it is half the length of the coupling.

- Pipes are assembled using couplings and fittings.

Sealing with sealed tape

You can make repairs using a special sealing tape. It is excellent for small cracks and can also be placed at the pipe joint if the problem is due to poor connection of the pipeline elements.

Photo: pipe sealing tape

The benefits of sealing tape include ease of use and versatility. It allows you to quickly complete repairs without much effort. The tape is glued in such a way that half of it overlaps the previous layer, and the tension is maximum. It is important to avoid wrinkling. The place that leaks is wrapped in a double layer.

If it is necessary to close up an open section of the pipeline, the tape is additionally equipped with a protective coating. This will provide additional strength to the plastic pipes and prevent future breakdowns. The most important advantage of the tape is the ability to close a through crack - however, in the presence of such complex damage, it is better to replace the pipeline section using fittings.

Silicone sealant

Another way is to seal the damage. This approach has been proven to work well for long cracks. In order to cover the pipe, a sealant is usually applied, which is applied to a clean, well-dried and degreased surface. The sealing material consists of a silicone known for its high adhesion properties. Depending on the type of hardener used, there are two types of sealant:

- neutral - universal, suitable for applying to the surface of all types of materials;

- acidic - recommended for use only with those types of materials that are not associated with acids.

Photo: sealing the damaged pipe with a sealant