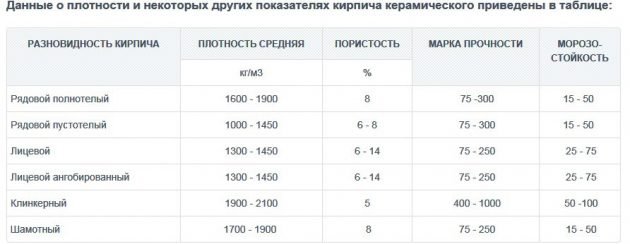

Characteristics affecting quality

The following properties of the product must be taken into account:

- thermal conductivity - is the ability to transfer heat received from indoor air to the outside;

- heat capacity - the amount of heat that allows one kilogram of building material to be heated by one degree Celsius;

- density - determined by the presence of internal pores.

Below will be a description of the different types of products.

Types of bricks

Step-by-step instruction

Determine the location of the stove in the house.

- Do not place flammable objects closer than 38 cm around the oven.

- To avoid moisture condensation or reduced draft, do not place the oven between windows or near outside walls.

- Check that there are no rafters in the place where the chimney passes through the roof, and there are no logs between floors.

- The oven must not impede free movement in the room where it is installed.

- It is best to install it flush with the roof ridge. This will help shorten the length of the chimney.

We lay the foundation correctly.

- Remember that it is best if the foundation of the house and the foundation of the stove are not connected. This will ensure a longer service life for both. After all, temperature differences and loads create different shrinkage.

- For the foundation, we dig a meter-deep hole, cover it with 11 centimeters of sand, fill it with a concrete solution on top.

- Make the foundation 15 cm wider than the stove itself.Make sure that it is perfectly flat and its surface is 19 cm below the floor level.

Let's start laying.

- For those who are building a furnace for the first time, we recommend that you first lay out the brick according to the scheme on a dry one, and then start working with the solution.

- Using a spatula and a trowel, we lay the first row of bricks, using only solid bricks and observing the following rule: vertically located seams do not coincide with each other.

- In the second row, we install the blower door. It is equipped with four hinges that are attached to the stove. We attach a steel wire to the hinges (diameter 1.5 millimeters), brick its ends in the masonry, coat the door with a solution.

- In the third and fourth rows, we install the grate without using mortar and leaving gaps.

- We lay out the furnace firebox using fireclay bricks. Because it is able to withstand increased heat. It is not advisable to mix it with ordinary brick. We install the firebox door according to the same principle as the blower door, but first wrap it with asbestos.

- The rows following the firebox (9 - 12) are laid out according to the usual rules. In this case, it is necessary to control the smoothness of the walls of the firebox.

- Rows 13, 14, 15 form the arch of the firebox.

- In the 16th row, we install a cleaning door.

- From rows 17 to 20 we form a convector with a smooth inner surface.

- Rows 21 and 22 form a web. On the 23rd row, we install another door for cleaning.

- Rows from 24 to 26 are laid out as rows 17 - 19.

- Rows 27 and 28 are used to decorate the overlap of the upper pass and the outlet of the stove. Rows 29 to 31 will close and complete it.

We equip the chimney pipe.

You can create it yourself from silicate bricks or take a ready-made one, but properly insulated. Make sure that there are no chips or irregularities inside the chimney. Sometimes its inner walls are leveled with liquid glass.

At the end of the masonry, dry the oven for 2 weeks.

Ceramic

They are made from clay with the addition of certain substances. After manufacturing, they are heat treated in specialized ovens.The specific heat index is 0.7–0.9 kJ, and the density is about 1300–1500 kg / m3.

Today, many manufacturers produce ceramic products. Such products differ not only in size, but also in their properties. For example, the thermal conductivity of a ceramic block is much lower than that of a conventional block. This is achieved due to the large number of voids inside. There is air in the voids, which does not conduct heat well.

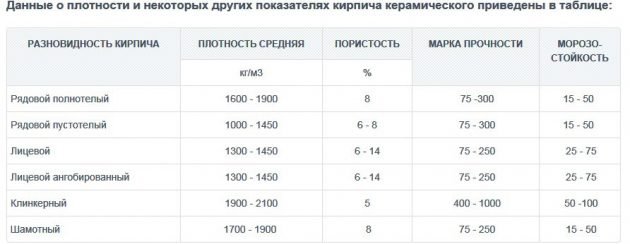

Properties of ceramic bricks

How to prepare the solution?

The mortar for laying fireclay bricks is mainly used sandy-clayey (or not used at all). The connection itself is made by hand or chamotte mortar is used - a fine powder, which, when added with water, forms the necessary consistency of the mixture (the sand should contain grains up to 2.5 mm in size).

The powder, with the gradual addition of pure water, is knocked down to a medium (sour cream-like) consistency with a construction mixer or an alternative tool. Then the solution must be infused for about an hour, after which the composition is mixed again. The main indicator of quality is considered to be the similarity of the refractory characteristics of the mixture with the brick for laying. To ensure the strength of the mixture, you can add Portland cement (1/6 of the total mass of the mixture) or 100-150 grams of salt to a bucket of mortar.

How to prepare the mixture yourself?

- water;

- fireclay sand;

- ground refractory clay.

Clay must be soaked in water in advance for up to 3 days, stirring at times. When the material is ready, it is rubbed through a sieve (with 3 × 3 mm divisions). Further, sand, sifted through a fine sieve, gradually interferes with the clay. It is added in a 6: 1 ratio (3 buckets of solution are used per 100 blocks, or 40 kg of dry mixture). Laying quartz sand, granite or marble chips is not recommended. It is best to use special sand (refractory block crumbled into crumb). The components are mixed dry and only then water is added.

Silicate

Silicate bricks are in high demand in construction, their popularity is due to their strength, availability and low cost. The specific heat index is 0.75 - 0.85 kJ, and its density is from 1000 to 2200 kg / m3.

The product has good sound insulation properties. A wall made of silicate products will insulate the structure from the penetration of various kinds of noise. It is most often used for the construction of partitions. The product is widely used as an intermediate layer in masonry, which acts as a sound insulator.

Silicate brick scheme

How to properly lay refractory bricks?

The first and most important step in the masonry process is accurate markings. You must also observe the following rules:

- Each brick in the masonry process is knocked out and then leveled.

- In each new row of bricks, the stretched cord is fastened with nails in fresh seams.

- The solution should be evenly distributed over the surface, this should be monitored, since the density of the masonry and its strength, respectively, depend on this.

- The brick should be wetted constantly, because when a dry block comes into contact with a solution, the brick actively absorbs its moisture, and this leads to a loss of the properties of the mixture. Moisten the blocks by immersing them in water for a few seconds.

Correct jointing of masonry joints will protect the bricks from premature destruction.

It must be borne in mind that the jointing should be of the highest quality. In a too deep or unsealed seam, water can enter, moisture can be deposited, which, under the influence of temperatures, destroys the masonry. To ensure strong and high-quality horizontal masonry and to ensure the preservation of the thickness of the seams, ordering slats are used to which the cord is attached (they are guided by it when laying the first layer of brick).

Laying in 2 products is performed in spoon rows, in 1 block - with butt rows, in one and a half - alternately with both.Stoves, chimneys and other structures made of refractory material, vertically transverse seams are tied in the nearest spoon rows to the floor, and in butt rows - to a quarter of a block. The ligation of the vertical-longitudinal suture lines is carried out by alternating rows along the laying height.

Facing

Cladding blocks are widely used in the decoration of external walls of buildings, not only because of their attractive appearance. The specific heat capacity of a brick is 900 J, and the density value is within 2700 kg / m3. This value makes it possible for the material to resist well the penetration of moisture through the masonry.

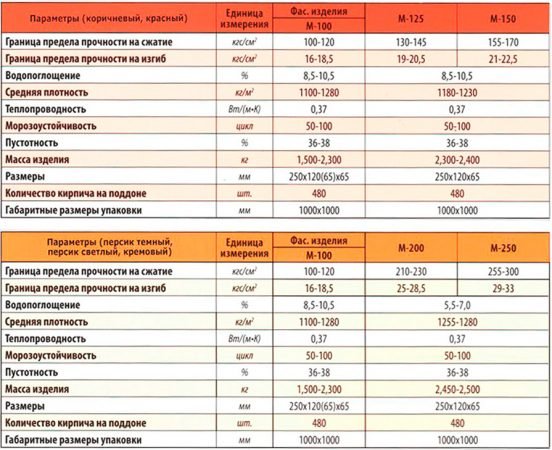

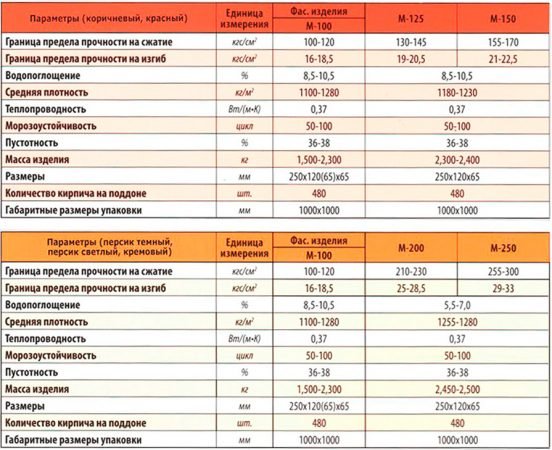

Characteristics of facing bricks

How to fold the firebox with your own hands

The furnace firebox consists of blowing (ash pan) with a door, grate and combustion chamber (firebox) with a door.

Dimensions (edit) are determined based on the volume of firewood for simultaneous loading. The width of the combustion chamber is equal to its door or slightly wider on both sides.

Height the firebox should facilitate complete combustion of the fuel, which is achieved by the presence of free space in the chamber after loading the firewood. Recommended height 80-100 cm.

Reference. The depth of the furnace must be able to accommodate the length of the combustible material, there are no other restrictions.

The combustion chamber is connected to the ash pan by means of a grate... The latter is designed to supply air during combustion and collect ash. When installing the grate, it is necessary to deepen it below the level of the furnace door in order to prevent burning coals from falling onto the floor.

The firebox must have slopes in the direction of the grate to move the ash into the ashtray. Gap between masonry and grate it should be not less than 5 mmto prevent the brick from breaking as a result of the difference in the expansion of the brick material and the metal at high temperature.

The choice of materials for masonry and floors, than to process the structure

The structure is manufactured from clay red bricks with cladding (lining) refractory material. When choosing a brick material, you must pay attention to the fact that it is not burnt or cracked. High-quality bricks suitable for stove masonry have smooth edges, sharp edges and a uniform color, a clear, almost metallic sound is heard when tapped.

Attention! Silicate brick is not suitable for the construction of the device.

The following materials will be required:

- Red brick - for walls;

- refractory and wedge-shaped (fireclay) bricks - for lining and overlap formation;

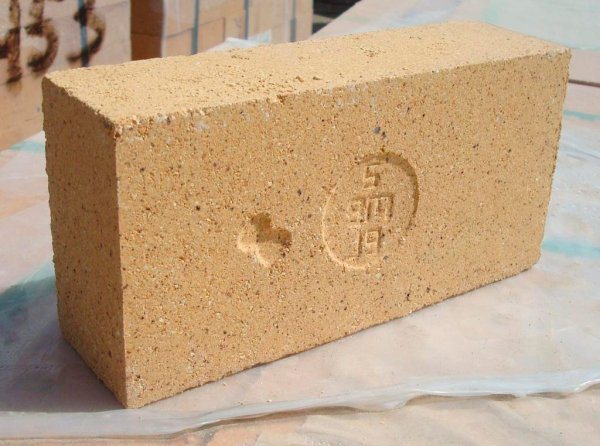

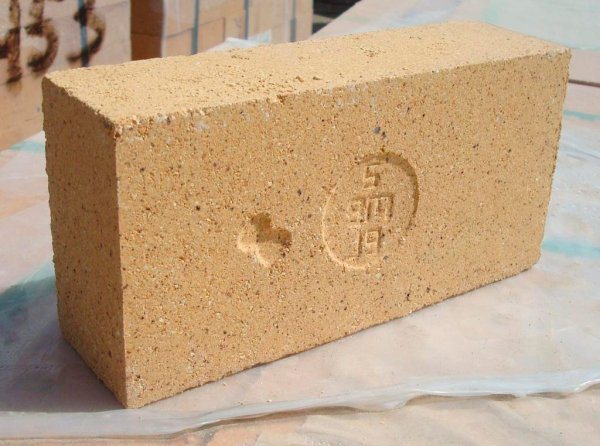

Photo 1. Refractory bricks used for laying the furnace firebox. Before using the material, you must ensure its integrity.

- clay, sand, water - for the solution;

- cast iron grate;

- doors combustion chamber and blower;

- steel strips or wires - for fastening the doors;

- asbestos sheet - for a fireproof gasket between masonry and doors.

For joining oven masonry you can buy a ready-made mixture or prepare the solution yourself. In the high temperature zone, compositions are used exclusively from red clay, sand and clean water. The quality of the solution depends on the viscosity, plasticity and fat content of the clay. The sand for the building must be free of dirt and impurities.

Instrument preparation

Making a structure with your own hands will allow required set of tools:

- oven hammer;

- Master OK - for applying the solution;

- large capacity - for solution preparation;

- building level - to control the correctness of the masonry;

- measuring instruments - ruler, tape measure, square;

- plumb lines - to define the outer contour.

How to properly cover the firebox and make the roof of a brick oven

For the construction of the firebox, it must be determined exact diagram the future oven and laid foundation with a layer of waterproofing.

Before laying on the mortar, you need to assemble the structure without it - for accurate adjustment of the bricks to size.

The construction looks like this in stages:

- Prepare a solution.

- First row laid on the foundation without gaps and formed under the furnace.

- On the second row the formation of the ash pan and the fastening of its door begin. To do this, mark the center of the future firebox and place the blower strictly under it. A flexible wire is passed through the holes in the door frame and its ends are twisted with a bundle. Wire harnesses are fixed in the masonry layer.

- Form a contour blower and the place of laying the grate.

- Fix the fire door with a wire. The door frame is insulated with a non-flammable gasket.

- Form the walls a firebox and a vault with a hole for connecting a chimney.

- Carry out lining the combustion chamber with refractory bricks.

Important! When building you can not bandage simple brick and fireproof due to the different expansion coefficient. When heated, such masonry will burst.

Refractory

Refractory blocks can be divided into several types:

Types of refractory bricks

- carborundum;

- magnesite;

- dinas;

- fireclay.

Fire-resistant products are used for the construction of high-temperature furnaces. Their density is 2700 kg / m3. The heat capacity of each type depends on the manufacturing conditions. Thus, the heat capacity index of a carborundum brick at a temperature of 1000 ° C is 780 J. Fireclay brick at a temperature of 100 ° C has an index of 840 J, and at 1500 ° C this parameter will increase to 1.25 kJ.

Features of the oven masonry

The first row is laid out on dry, that is, the solution is not used for this. It is required to start laying with a corner brick, gradually filling the entire row. Before laying, red brick must be moistened so that it does not draw moisture from the solution. Fireclay bricks should not be soaked. After soaking, it is necessary to apply a thin layer of mortar to the place of the future first row, lay out the prepared red brick.

To eliminate air bubbles, gently tap the surface with the trowel handle.

All excess solution is removed immediately, until it has set. Similarly, strictly following the order, all other rows are stacked. In this case, the vertical seams should not coincide, and if necessary, every 5-6 rows are reinforced with a metal mesh.

If the ordering requires the use of halves or quarters, then they cannot be laid inside the firebox and chimney ducts, since they will quickly crack. Such ends should always be turned inside the masonry. Fireclay bricks are used for laying the firebox. When performing such work, you need to pay attention to the following points:

- The brick should only be placed on its edge.

- A gap of 5 mm should be observed between the walls of the furnace and the firebox.

- For masonry, only fireclay clay mortar is used, this should not be forgotten.

Back to the table of contents

Influence of temperature conditions

The quality is greatly influenced by the temperature regime. So, with an average density of the material, the heat capacity may differ, depending on the ambient temperature.

Comparison table of thermal conductivity of logs with brickwork

From the above, it follows that it is necessary to select a building material based on its characteristics and its further field of application. So it will be possible to build a room that will meet the necessary requirements.

Related video: Types of bricks

Related publications

Pros and cons of ceramic bricks

Standard sizes of one and a half brick

Varieties and area of application of fireclay bricks

Fireclay brick stove: masonry process

Stoves are quite common today, even though there are more modern heating systems. For baths or saunas, for providing additional heating in the house, brick stoves remain indispensable. You can lay out such a furnace from red or fireclay bricks, but fireclay brick itself is too expensive, it is rarely used for furnaces... Most often, the masonry is made from red oven bricks, and fireclay is already taken for the firebox. The result is excellent quality at an optimal financial cost.

Fireclay bricks are frost-resistant and can withstand temperatures up to 1500 degrees.

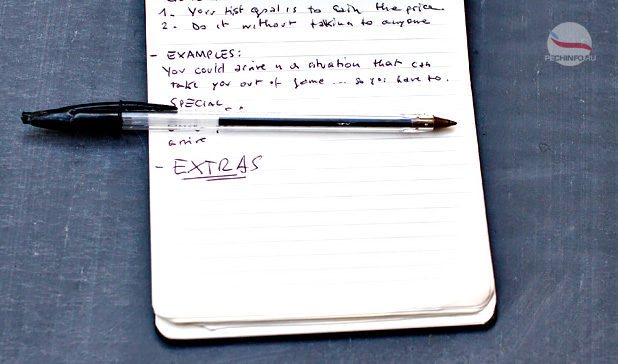

The laying of the furnace itself is carried out in compliance with the order, that is, a special layout for each row. The diagram shows how much material is used and in what order the individual bricks and other elements of the future furnace will be located. To start working on masonry, you must first decide on what the stove structure will be. Today 3 types are used:

- A heating and cooking stove is the best option, which is suitable for ensuring a comfortable temperature in the house and for cooking. Special compartments for baking bread are popular, but bricks should be chosen carefully, fireclay cannot be used, since when heated it releases chemicals, and this is unacceptable when cooking.

- Conventional cooking ovens are intended only for cooking, cooking cabbage, and for drying fruits.

- Heating stoves, fireplaces are designed to heat a certain area or room.

Sauna heaters stand separately; the process of laying them differs from conventional stoves. It is necessary to install a special grate for stones, a container for heating water. The oven itself must be durable, resistant to temperature changes.