Advantages and disadvantages

Clinker tiles have a number of properties that distinguish them from other finishing materials:

- The wear resistance of the material is a huge advantage. The strength of a tile can be compared to that of clay brick, since in fact it consists of well-fired clay.

- Due to its composition, clinker tiles are considered an environmentally friendly material, fungi do not form on them, they are not exposed to ultraviolet radiation.

- It has a low water absorption rate. This makes the tiles frost-resistant.

- It is very easy to take care of this cladding. A simple wash as it gets dirty is enough without the use of additional agents.

- Assortment of material. There are many clinker tiles of various colors, shapes, patterns and surface reliefs. The front side of the tile is possibly glossy.

- Depending on the type of clinker tiles, it can be used for paving, facing, construction of hydraulic structures.

But clinker tiles also have disadvantages:

- This is a rather fragile material.

- The price of the tiles is above average.

Step by step instructions for work

Clay floors can be made using several technologies, using different mixtures. Clay in the floor can be supplemented with straw, lime, cement and other materials. Consider the principle of such a foundation using the example of its main options: an adobe floor and a cast adobe.

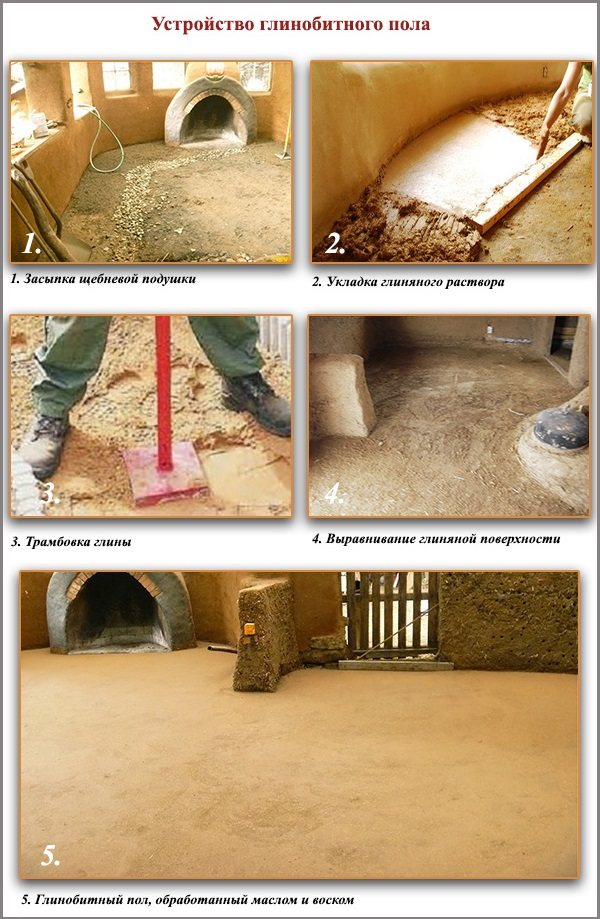

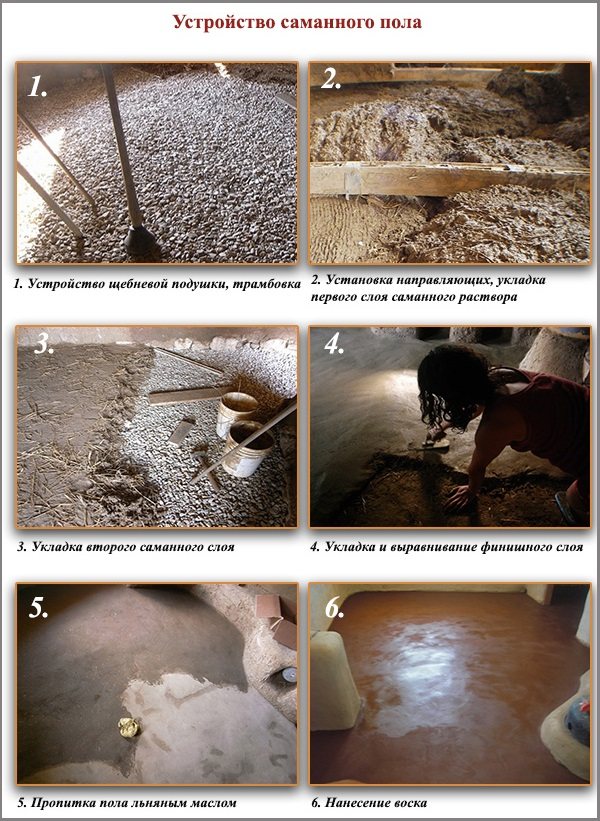

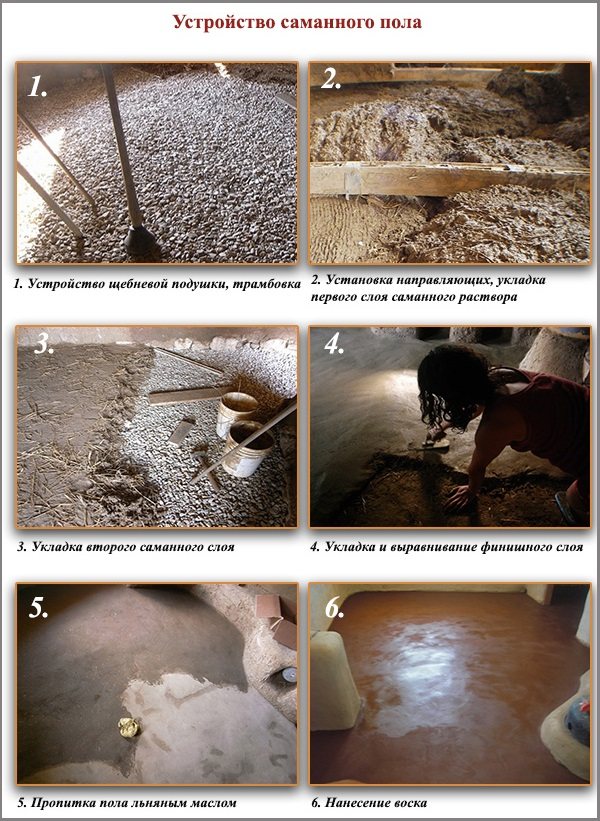

Option # 1 - adobe floor

This option is the easiest. It is more suitable for arranging the base in sheds, storage rooms and other outbuildings. Although it can be used in summer cottages, in houses of temporary (summer) residence.

The adobe floor is a clay-sandy, densely compacted layer. It is laid out directly on the ground. For the installation of such a floor, you will need oily clay, sand and tamping.

Progress:

- A layer of soil with a depth of 50-60 cm is removed.

- A layer of sand, about 10-15 cm thick, is laid on the bottom of the resulting pit. It is leveled and compacted. For this, a manual rammer is often used, made of a piece of a log or a bar about 100 cm long, with a diameter (section) of 10 cm. A grip is nailed to the upper end, with which you can hold the thrombus. A board with dimensions of 20x20 cm is attached to the bottom end.

- On top of the compacted sand, a layer of crushed stone is poured, 10-15 cm thick. It is also leveled and compacted.

- A thick, heavy solution is prepared from clay and sand (the amount of water is minimal).

- The solution is spread on a layer of crushed stone, leveling it with a trowel or spatula.

- The clay layer is compacted with a rammer. Places where pits form are leveled with an additional portion of the solution. The ramming continues until the ram starts to bounce off the surface.

- Sprinkle the surface with coarse sand and try to tamp it into the thickness of the clay floor. The remains of sand remaining on the surface are swept away with a broom.

After such a floor has dried, it is treated with oil and wax.

Option # 2 - adobe floor

Saman is a composite material made by mixing clay, sand and straw with water. The finished adobe is laid on a drainage layer of crushed stone or gravel, leveled along the guides. Usually laying takes place in several layers. The first 1-2 layers are basic and play the role of a base. The last layer is the finishing layer, traditionally coated with oils and wax.

When making an adobe floor, rubble (for drainage), sand, clay and straw are used.First, sand and clay are mixed, then water is added. The straw is mixed in at the last stage, trampling it into the mixture. Typically, the ratio of clay to sand in adobe varies from 1: 1 to 1: 3. The amount of water is 0.25% of the clay volume. The amount of straw is 10-15% of the volume of the mixture. You can mix clay, sand and water manually (using a shovel, trowel) or in a concrete mixer.

Consider the order of work:

Removal of the fertile layer (30-40 cm)... The upper fertile layer is removed along the soil, be sure to select the roots of the plants. Deepen by 30-40 cm, then tamp the base.

Drainage from gravel (10-20 cm)... The tamped base is covered with a layer of gravel, 10-20 cm thick. In areas with a harsh climate, it is possible, in addition to gravel, to use heat-insulating bulk materials. Perlite, which has low thermal conductivity, is well suited for these purposes.

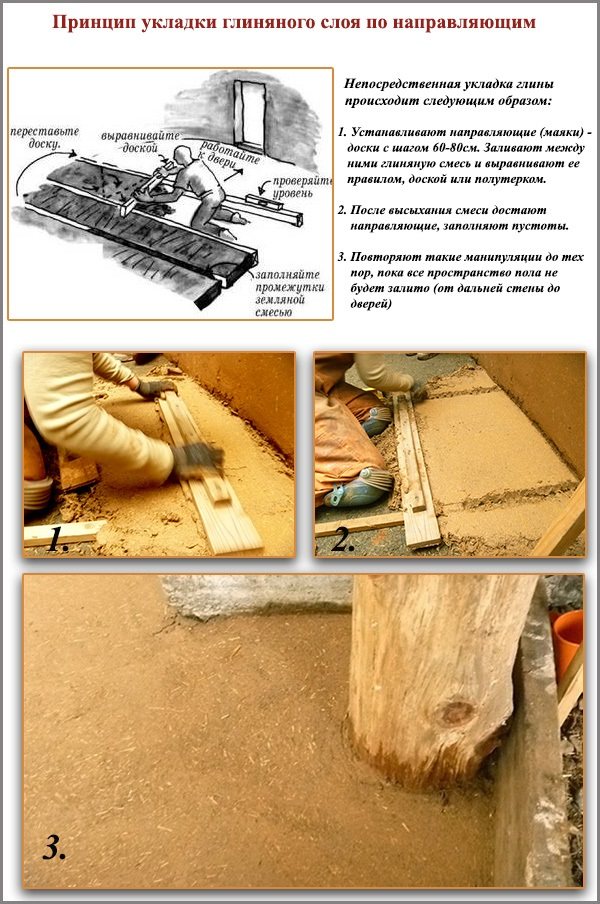

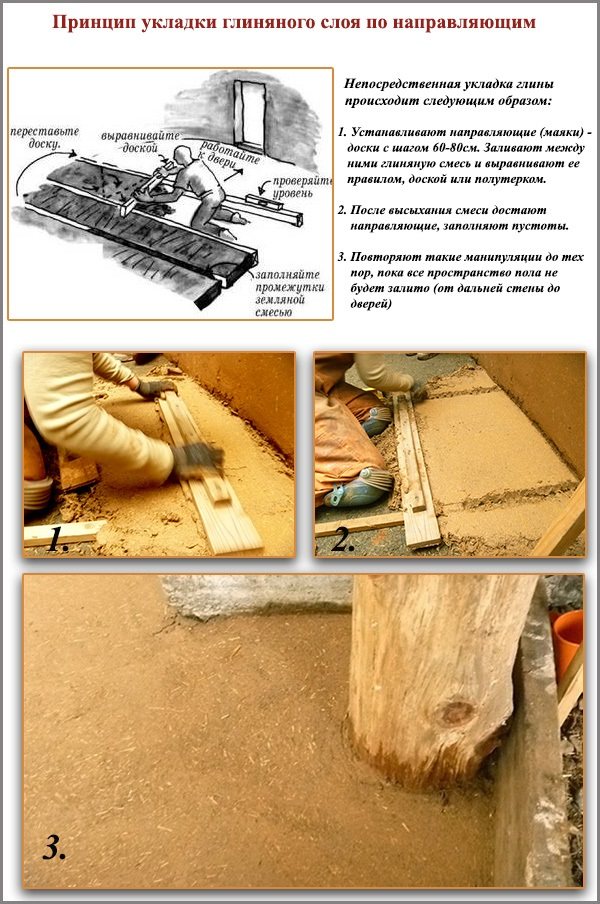

Laying the main clay layer (4-10 cm)... Laying is carried out using guides - flat, straight boards, 4-10 cm wide. They are installed on the edge, secured with sticky pieces of adobe. The step between the guides is 60-80 cm (at this distance it is convenient to "pull" the mixture as a rule alone). The location of the guides is parallel to the wall along which you plan to start work. Usually, this is the wall opposite the front door.

The adobe mixture is laid out between the guides, leveling it with a trowel. To achieve a flat surface, the mixture is "pulled" along the guides with a wooden or metal rule (you can use a flat board, a long scraper). You should get a continuous and even, but rough surface. There is no need to overwrite this layer.

After 1-2 days, when the adobe mixture grasps, the guides are carefully taken out of it. However, they can be left thicker if there is no need for reuse. The voids remaining from the guides are filled with an adobe mixture. In order for the wet portion of the mixture to properly adhere to the already dried layer, the edges of the grooves are moistened and loosened with a sharp tool.

The main layer, depending on its thickness, temperature and humidity, dries for 1-2 weeks. Only after that it will be possible to move freely on it. If it is necessary to speed up the process, a fan heater is installed in the room. Simply raising the temperature (using radiators, for example) is not enough. For uniform drying of adobe, air movement, blowing is necessary.

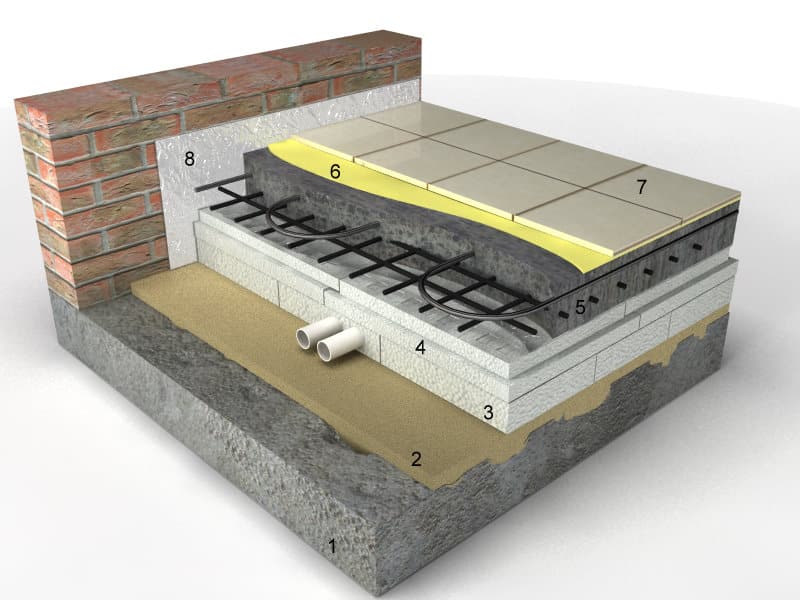

Laying the second (intermediate) layer (2.5-4 cm)... This layer is optional, but allows you to increase the thickness of the clay layer and increase the heat-saving properties of the surface. Underfloor heating cables can be laid in the thickness of this layer.

Lay this layer in the same way as the first, using guides. This time, boards (slats), 2.5-4 cm thick, are used. Saman is laid out between the boards fixed on the edge, on the pre-moistened surface of the main layer - for better adhesion. The surface is leveled with a trowel and "pulled" along the guides. To reduce the likelihood of cracking on this layer, it is recommended to lay the guides at right angles to the guides of the first layer. Then two layers of adobe will be laid perpendicular to each other, which will increase the strength and strength of the finished clay floor.

The last, finishing layer (1-2 cm)... The last layer of adobe will bring the floor level to the required level. This layer is the thinnest, so there is a high probability of cracking on it. For this reason, this layer should not be made less than 1-2 cm.

If the clay floor will be the front floor surface, thinner and shorter straw stalks are introduced into the adobe mixture for the finishing layer.

Thin slats or metal guides (profiles), 1-2 cm thick, are used as guides.Also, the finishing layer can be applied without guides, carefully laying out each portion of adobe and controlling its horizontal level. The clay mixture is spread with a spatula, smearing and pressing carefully against the previously moistened surface of the second layer. The finishing layer is carefully leveled by rubbing the clay, “polishing” it with a float, spatula or trowel.

When the adobe floor is completely dry (it will take several weeks), you can start finishing it.

Preliminary stages

It is completely pointless to start facing work on an unprepared wall. Some novice home craftsmen naively believe that a layer of ceramic tiles will reliably hide all the "ugliness" of the surface, and the result will be a straight, beautiful wall. They are cruelly mistaken!

What does the preparation process involve?

- It is imperative to get rid of the old wall decoration. It won't, for example, keep the adhesive on the tile on the painted surface. Old wallpapers or even small fragments of them are completely excluded. If previously there was a tile on the wall, then after dismantling it, all flows and drops of frozen glue should be removed.

No old finish should remain on the walls

- The quality of the plaster layer, if any, is necessarily checked. All problematic, crumbling areas are removed immediately. It is necessary to tap the entire area, to identify the places of instability, which must also be removed. And most often it happens that if an exfoliating area is found in one area, then everything else will be pulled from it, that is, the plaster has to be knocked down completely.

Unstable plaster fates are removed without regret. And more often it ends with a complete removal of the old plaster layer.

- In no case is it ignored if traces of their biological damage are found on the walls - mold spots, fungal colonies, etc. Antiseptic priming is carried out on all surfaces without exception, but if this microflora has already settled, then you will have to carry out preliminary "treatment" of the wall with special compounds.

It is completely unacceptable to start finishing in such or similar conditions. We'll first have to deal with the "treatment" of the walls.

- There should be no cracks or cracks on the surfaces. If they are identified, appropriate repair work is carried out to ensure their high-quality termination.

Cracks and crevices must not be left under the finish - all identified defects of this type must be sealed

- The wall should be flat, that is, it should be a plane, not a twisted, collapsed, protruding or concave surface. Tiles can be installed on aligned walls without any problems. Yes, there are techniques for leveling walls precisely by installing ceramic cladding. But, believe me, not even all experienced craftsmen like to do this, since this task is extremely difficult. And if a newcomer is about to "debut", but there is nothing to even think about. It will be much easier to align - and the finish will definitely turn out to be of high quality.

There are many ways of leveling, and some of them, for example, using moisture-resistant drywall or gypsum fiber boards, are not so difficult and do not take much time.

moisture resistant drywall

- Ceramic tiles are most often installed in rooms with high humidity, so you should also think about reliable waterproofing. To a greater extent, this applies, of course, to the floor, but on the walls it makes sense to provide a waterproof "belt" at least 100 ÷ 200 mm high from the floor along the entire perimeter. In addition, it is advisable to reinforce with waterproofing the sections of passage through the walls of water supply and sewer pipes, the area around water outlets.

Waterproofing wall surfaces - with a belt along the floor and around pipe penetrations.

- Finally, the wall should be carefully primed with a deep penetration compound.This measure will completely remove dust from the surface, eliminate the phenomenon of moisture absorption. That is, the wall material will not take water from the tile glue, allowing it to harden in optimal conditions. The best adhesion performance is achieved. In addition, many primers also have antiseptic properties, and such a preventive treatment will never be superfluous.

The wall must be primed with a deep penetration compound.

If the absorbent qualities of the material are high, then the primer treatment is performed twice, necessarily waiting for the first layer to dry completely. As a rule, the primer is applied immediately after the completion of the preparatory work. But if, for some reason, there is a significant gap in time between this stage and finishing, it will be advisable to apply the primer again - a day before the installation of the tiles. So a quality result will be guaranteed.

Now the surfaces of the walls can be considered ready for finishing with ceramic tiles.

primer for walls

It is clear that these two issues are closely intertwined. In this publication, we will not analyze design approaches to choosing the interior of a room - we will dwell only on some practical aspects.

Let's make a few remarks at once. Below we will consider not the most difficult way of laying tiles on the wall. It is impossible to grasp with attention and all possible cases. Some points of the work will be deliberately removed from the presentation - simply because these stages are discussed in more detail in individual articles of our portal.

But in general, the basic technological methods will be shown, and a novice home craftsman should form a stable understanding of the procedure and rules for performing wall cladding with tiles.

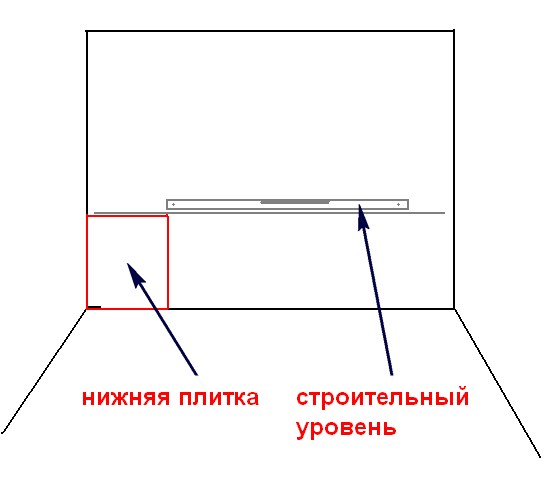

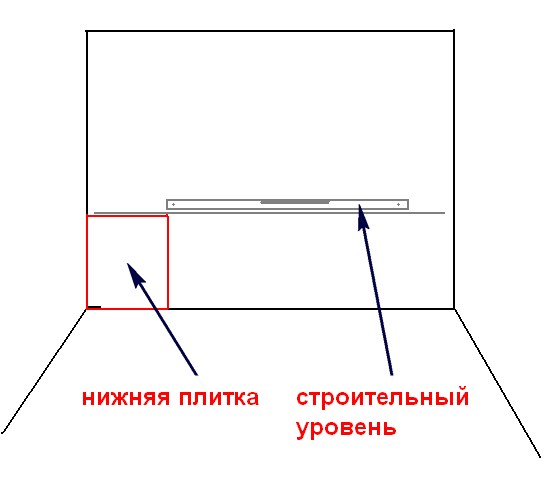

Above, it was already mentioned in passing that it is best to start laying tiles on walls not from the very bottom, but from the second row, at whatever height it is located according to the developed scheme. This way you can achieve perfect horizontal rows, without really looking back at the evenness of the floor. Well, then, when the flooring is laid, it remains only to precisely fit the tiles of the first row - and everything will turn out very neatly.

This means that at the first stage it is necessary to break through the laying line of the second row, and place some kind of base on it - a support for the tiles.

| Illustration | Brief description of the operations performed |

| It is necessary to implement such a project - for each of the walls a pile is provided with a detailed scheme, which the master will adhere to when laying. The bottom row begins with a whole tile, the top is also whole, but somewhat hidden in height by a stretch ceiling. However, installation will still start from the second row - much easier and more accurate. | |

| If the preparatory work was carried out earlier, and the room was simply "waiting for its turn" for finishing, then it would be useful to perform one more priming of the walls, on which construction dust could have settled, which impairs the adhesion of materials. Normal deep penetration soil is used. It is better to plan the application of the primer one day before the start of the main work. | |

| If priming has already been carried out before, then the composition will not be highly absorbent. And with the help of a roller, this operation can be done very quickly. The next day we start finishing work. | |

| The original view of the bathroom. | |

| As already mentioned, it is best to work (especially in the absence of experience) on flat walls. Here everything seems to be fine with this, but it never hurts to check. Therefore, work begins with control - checking the verticality of the wall. | |

| And the conformity of the plane is checked by applying a long rule. Ideally, it should adhere to the surface along its entire length. But on this wall you can see a gap - there is a slight curvature.This should be noted to yourself - you will have to take a slightly different approach when laying the starting row. If the deviation is no more than 3 ÷ 5 mm, then it is easy to eliminate during finishing. But if the differences are large, it is better to do alignment. | |

| The planes have been checked, the identified areas of small deformations are outlined - you can proceed to skipping the line of the starting, second from the bottom row. Tiles have not yet been laid on the floor in the room, so you cannot vouch for the ideal horizontal floor. Therefore, you need to check and find the highest point - it is from this point that the baseline marking will go. The laser level turns on, which sets a horizontal line in all walls. It is not necessary to place it high - 100 ÷ 150 mm from the floor is enough (optional). | |

| Now with a square, you can walk around the perimeter and check the height of the beam above the floor surface. Measurements - along the corners and along the length of the walls with a step of about one meter. The results can be written in pencil directly on the wall or on the floor. | |

| The point where the minimum height value is obtained is the highest point. From her we will begin to "dance". | |

| You can simply measure the height of the tiles on the wall, but it's easier, so to speak, to simulate the situation. Two cartons are laid on the floor, which imitate the layer of glue under the floor tiles. | |

| We temporarily put floor tiles in a corner. Now from it you can see how the bottom row will rise on the wall. | |

| We put two spacer crosses to imitate the thickness of the seam between the floor and the wall. | |

| Now the tile of the lower row is "in place", and a small line is drawn along its upper edge with a pencil on the wall. | |

| It is at this level that the profile will be attached, which will become a support for laying the second, starting row. | |

| This line must be transferred to all walls around the perimeter of the room. The easiest way to do this is with a laser level. | |

| Pencil marks are made on the beam projection ... | |

| ... which are then connected with a solid line using a rule or a long ruler. It doesn't matter if there is no laser level. All of the above6 operations can be done using the water-based one - the accuracy will be no worse. Simply at first, one "base" horizontal line is very accurately marked on the wall with the help of a water level. And then all measurements are made from it, and it is easy to make a parallel transfer of the horizontal line to any section of the wall. But relying on a bubble, even the highest quality and longest level is undesirable, since an error may well run into. It's good for control, but for room-scale layout, you still need something more precise. | |

| A galvanized guide profile, which is usually used for plasterboard systems, is very well suited as a support for the starting row. There are usually holes in it, but if not, they are drilled with a drill, with a diameter of 6 mm, and with a step of about 500 mm in order to prevent sagging. In principle, other materials can be used instead of a profile, for example, a long strip. The main thing is that it is not heavy and perfectly flat. | |

| After installation, the top edge of the profile must exactly match the marked line. So it is better to call an assistant to control the position during the installation of the fasteners. | |

| The profile is applied exactly along the line, held in this position, and a hole for the dowel-nail is drilled approximately in the center of the wall (6 mm, length up to 35 ÷ 40 mm). Then the dowel-nail is inserted into the hole until it stops and screwed in with a screwdriver to the end (it is better to screw it in so that then there are no problems with dismantling, which happens when driving). | |

| The center is fixed, you can, if necessary, adjust the position of the profile, and then fix it at all other points. | |

| A similar operation is carried out on all other walls. It is clear that the profiles should converge perfectly at the corners, for which it is even better to cut them from the edges at an angle of 45 degrees.During the installation of the profile, regular control is carried out using a level. At this stage, it can be considered complete. |

We suggest that you familiarize yourself with How to make a blind area of concrete around the house

Layout and installation

When the base is completely dry after preparatory work, you can start marking. Bathroom tiles are laid from below. In order for the horizontal to be strictly maintained and the tile not to float down, it is necessary to install a special support.

Layout scheme for laying tiles.

To calculate at what height to install it, you need to measure the height of the wall from ceiling to floor. Based on this size, you can calculate how many solid tiles (including the seams) fit on the wall. It is worthwhile to carry out such calculations very carefully so that in the end there is a solid tile under the ceiling. This arrangement makes it possible to obtain a good appearance. In turn, the notched tiles will be positioned above the floor, where they will hardly be visible.

A wooden lath and a special metal corner can be used as a support. This auxiliary element is attached to the wall to the concrete base, the fastening should be carried out using dowels. If the walls were previously leveled with plasterboard and a metal-profile frame, then it is necessary to fix the support in the profiles. In order to install such a support exactly along a horizontal line, it is worth using a hydro level. An additional element in the marking process will be a vertical line, which is outlined with a plumb line. Thanks to it, you can control the quality of the tiles.

In addition to the floor and walls in the bathroom, you can also tiled the screen under the bath and close the pipes.

How to calculate the number of tiles you need

Calculating the number of tiles required for cladding is quite simple. To do this, you need to measure the width and length of the surface to be faced, whether it be a facade, a staircase or a stove. At the time the measurements are taken, the length is multiplied by the width to give the surface area. The area of the elements located in the calculated surface is subtracted from the taken value, and the area of the required number of tiles is obtained.

Usually the manufacturer himself shows how many tiles are required for facing 1 m2 of surface, and taking into account the tile joints, based on this, it will be very easy to find out how many tiles are needed.

General preparatory work

The preparation of the bathroom, in which it is supposed to lay ceramic tiles on the walls, begins with an inspection of the room. Walls are checked for unevenness and lack of verticality. Bathroom piping must be installed prior to tiling. If the surfaces are uneven or deviated from the vertical, then these shortcomings need to be eliminated with plaster with cement mortar on a sand base. The bathroom walls are measured to calculate the area and calculate the number of tiles. The necessary materials and tools are purchased:

It is recommended to use plastic wedges for gluing tiles.

- sand;

- cement;

- tile adhesive;

- grouting into seams;

- plastic crosses for laying tiles;

- a bucket for mixing glue;

- drill with stirring attachment;

- building level;

- notched trowel;

- simple spatula;

- white rubber spatula;

- rubber sponge;

- grinding block;

- moisture resistant primer;

- tile;

- metal profile or rail for laying the first row;

- diamond core bit for cutting holes;

- plastic wedges;

- roulette;

- tongs for breaking tiles.

What other materials and tools will be needed

For the purpose of carrying out the work, the following tool is useful:

- grinder, in order to cut the tiles to size;

- a drill with a nozzle for mixing the adhesive mixture;

- containers for mixing glue;

- measuring devices (tape measure, level);

- notched trowel;

- pencil;

- Master OK.

In those cases, at a time when the working surface lacks improvement, in other words, it is too embossed, it will also come in handy:

- shovel,

- buckets,

- usually

- mesh for sifting sand.

Tile adhesive

Gone are the days when tiles were laid exclusively on homemade mortars of sand and cement. Nowadays, a wide range of dry building mixtures for the preparation of tile glue is on sale. Such compositions are distinguished by high adhesion, durability, reliable fixation of ceramics to any prepared surfaces, resistance to moisture and mechanical stress, a fairly quick setting period and complete drying.

Popular brands of tile adhesives

Despite the wide choice, it is still better to give preference to proven brands that guarantee product quality. A few examples are shown in the illustration above.

Of course, you should also take into account the features of the room where the decoration is done. So, if a wall is faced on the street or in an unheated room, then it must be glue for external work. For bathrooms, you should look for a composition with increased moisture resistance - usually this is indicated by an understandable pictogram or in text instructions.

We offer you to familiarize yourself with Buy the best sealant for joints in floors at the best price in the construction online store

Most often, the glue is produced in a gray version, but for some light thin tiles or for a marbled finish, it is better to pick a white (or light beige) composition.

| Tile size (for rectangular - on the long side), mm | Recommended comb height of a notched trowel, mm | Approximate consumption of adhesive solution, kg / m2 |

| no more than 50 | 3 | 1.9 |

| from 50 to 100 | 4 | 2.5 |

| from 100 to 300 | 6 | 3.8 |

| from 300 to 400 | 8 | 5 |

| from 400 to 500 | 10 | 6.3 |

| over 500 | 12 | 7.6 |

Based on these data, it is quite possible to make preliminary estimates.

The reader can also use the offered online calculator.

Quality formulations from trusted manufacturers

The success of the installation of a mirror to a tile in a wet room largely depends on the choice of glue. Therefore, you should consider several options and choose the one that is suitable not in terms of cost, but in terms of quality and reliability of fixation. Among the most famous are the following:

- "Loctite" is a high-quality and demanded two-component composition (activator glue). One tube of 300 ml liquid nails is enough to glue two medium-sized mirrors. A more economical option is the Loctite aerosol, which will be enough for more than 10 intended uses.

- Tytan specially designed for bonding mirrors to ceramics. It is resistant to moisture, forms an elastic seam, does not damage the surface of the mirror, quickly adheres, and is easy to use. The composition includes resins and rubber mixtures, thanks to which the reliable fixation of the mirror product with the tile is ensured, even with high humidity in the room.

- "Soudal". The moisture-resistant adhesive provides high-quality adhesion of the mirror to surfaces made of various materials, including ceramic.

We invite you to familiarize yourself with Design of a bathroom with a shower made of tiles

If you follow all the rules for installing a mirror in the bathroom, with a responsible and careful approach to work, you can easily glue a decorative product to a ceramic surface yourself. The main thing is to choose the material for reliable fixation and clearly follow the entire sequence of actions, focusing on the dimensions of the selected mirror and the conditions of the room.

Laying ceramic tiles on the wall - step by step and step by step

An acceptable surface for laying clinker tiles on a wall is considered to be a sufficiently smooth and strong wall. It is not necessary to achieve a perfectly smooth surface.For example, such a roughness, as on a cinder block, does not interfere with installation at all. But a brick wall with deep seams needs to be plastered.

You will also have to plaster the wall if there are falling off elements on it, such as destroyed bricks, dilapidated tiles or plaster. Before plastering, get rid of loose elements: tap the surface, for example with a hammer, and remove the loose fragments.

For plaster, a simple mortar of sifted sand and cement is excellent. Well, the thickness of the plaster layer will depend on the depth of the wall imperfections. Indeed, they are constantly trying to get by with a minimal layer.

Clinker tiles have a lot of weight, therefore it is clear that the perfect floor for laying clinker tiles is a cement base, for example a slab or a cement screed. The screed is useful in cases where the surface is embossed. But do not forget to head that the floor must be free of all kinds of debris and dust before pouring. Otherwise, the tile will not adhere well and will separate from the base over time.

It must be stated that when preparing the floor, pay more attention to the slope. In the case of wall surfaces, this is not too important in principle, but on the floor, especially in rooms with high humidity, this cannot be ignored. Take the bathroom, for example. If you do not pay attention to the slope of the floor, it may turn out that moisture will accumulate in hard-to-reach places. The horizontalness of the floor is a prerequisite.

Choosing a scheme, layout and laying method

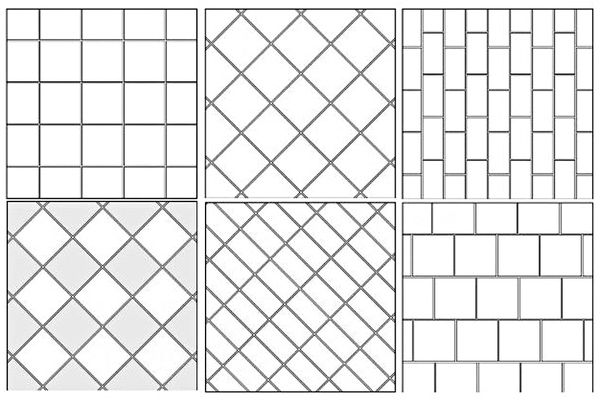

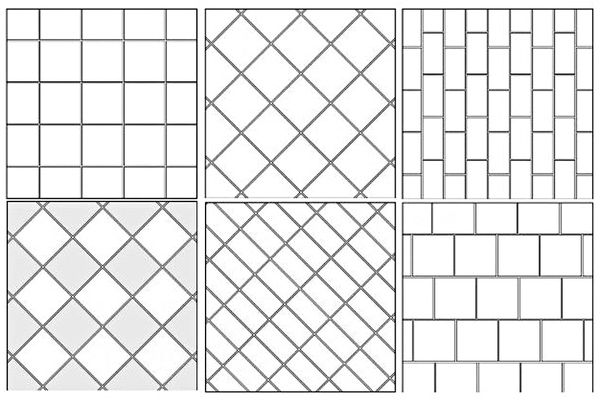

There are several ways to properly lay the tiles on the walls, here are the main ones:

- classic layout or seam in seam;

- at a run;

- diagonal or diamond layout;

- combination of various schemes (modular layout, carpet, offset, etc.).

If you want to lay tiles on the wall with your own hands, and you do not have enough experience with ceramics, then it would be right to dwell on the first two options, since the remaining methods require certain skills in handling the facing material.

Having chosen the scheme according to which the tiles will be laid on the wall, you need to mark the base. So that during the subsequent installation, the tiles lay flat on the wall, with the least amount of trimming, and, accordingly, waste, this must be done very carefully. For this, a laser level is used, which provides the most accurate marking, but if it is absent, you can do with an ordinary tape measure and a construction plumb line.

When facing vertical surfaces, remember to indent from the floor surface.

In order not to mark the wall with a directly laid fragment (which is also allowed), for convenience and speeding up the process, you can prepare a wooden lath, on different sides of which you can draw several dimensions of the length and width of the tile, taking into account the thickness of the seams. The first step is to determine the position of the ceramics horizontally by applying a measuring rail to the wall, find the optimal location of the tile, and the place where the elements will be trimmed, if necessary. This can be both at the floor and at the ceiling, or half of the fragment at the bottom and half at the top.

Then we move on to marking the vertical arrangement of the ceramics. To do this, the measure is installed horizontally on the wall and it is determined in which direction it is better to displace the laid elements in order to obtain an aesthetic appearance of the wall surface to be faced.

Before putting ceramics on the wall, you still need to decide which method is best to put the ceramics:

- From the center. With this method, the trimmed fragments are symmetrically located on both sides of the wall.

- From one of the corners. In this case, tiles should be laid from the most visible angle.

Selection and preparation of the adhesive mixture

Clinker tiles may be glued to the cement mortar. Sand and cement are useful for this. 4 parts of sand and 1 part of cement are poured into a mixing container. It is very comfortable to measure parts with buckets. For example, if you pour 4 buckets of sand and 1 bucket of cement, then there will be an optimal amount of mortar, which does not have time to harden during the laying of the tiles.

It must be stated that the cement mortar does not provide the maximum long term of the coating, and builders give more preference to special adhesive mixtures containing polyurethane. Such compositions can be produced both in finished and in dry form, and any glue is characterized by a certain degree of frost resistance, hardening and scope of application. The most popular brands of adhesive for clinker tiles are Ceresit CM, RKS, Knauf, Extrabond.

Mixes, which are sold dry, are prepared according to the instructions. But, much more often, the instruction is banal - you need water in a certain proportion and whisper to stir with a construction mixer.

So, we come to the consideration of the technology of laying tiles on the floor. First, it is worth mentioning a few more nuances.

Floor tiles are manufactured with a thickness of 14 to 30 mm. When choosing floor tiles, it is necessary to take into account such an indicator as wear resistance. In accordance with this parameter, clinker tiles are divided into four classes of wear resistance, where class 1 is the least wear-resistant tile, and class 5 is the most wear-resistant tile.

In order to achieve a certain design of the floor, it is possible to lay clinker tiles in a certain pattern.

- Simple linear masonry is often used - this is a practical option for most rooms.

- Some people like diagonal laying more, and this option is also likely, but keep in mind that in this case there will be a lot of waste.

- Clinker tiles can be laid with bandaging. This option is appropriate in some interior styles, for example, Provence, English style, loft.

- The combination of clinker tiles with mosaics looks presentable.

- Laying clinker tiles in the form of circles looks very interesting, but this method can only be used when finishing a floor of a large area, since otherwise all beauty will be lost, and in dry rooms - with circular laying, rather wide gaps between the tiles are obtained, from which, when hit the grout is washed out.

We suggest that you familiarize yourself with How to sheathe the ceiling of a bath from the inside

Before laying the tiles, you need to process the floor, check the corners of the tiles. If the corner of the tile does not fit into the corner of the room, then you need to move away from the wall and draw an even straight line from corner to corner, applying the rule in order to level the unevenness. This operation is repeated at each wall to obtain an even rectangle of the largest possible size. If this operation is neglected, then it will be necessary to adjust the tile against the wall. But, when using a skirting board, this may not be relevant.

When laying diagonally, the markings start from the center of the room.

- Laying begins from a corner that is sufficiently well lit. Initially, you need to lay out a row of whole tiles, check the plane with the rule, correct it, if necessary.

- Apply the adhesive on the floor with a notched trowel in a layer of approximately 8-10 mm. It must be stated that the adhesive mixture can be applied not to the floor, but to the tiles themselves, there is no huge difference.

- Then the tiles are laid and pressed a little in order to remove the cavities. The laid tiles are controlled by the level and, if everything is fine, then the second is laid.

- At the end of the laying of each subsequent tile, dividing crosses of a certain size are inserted into the seams. In this matter, it is better to focus on the advice of manufacturers.In most cases, they advise how thick the crosses should be.

It is more profitable to create laying in rows across the width of the room. be directed to emphasize that if a sufficient laying speed is achieved, then smoothing a row of tiles is possible with a long rule. The rule is applied to the side of the row and pressed slightly until the entire tile moves in one line. In order for alignment, it is necessary that the mixture remains uncured. This means that it is possible to correct the position of the tile within about 15 minutes.

At the end of the installation, the seams are rubbed. For this, special grouting is used. It can be furan based grout, epoxy or cement (cannot be used when grouting joints between glossy tiles, since it works like an abrasive). Application is carried out with a rubber spatula, and after drying is complete, the excess is removed with a wet sponge.

Laying tiles

After the support is installed, you can start laying the tiles. First, one-piece elements are laid. A special adhesive solution is used to fix the tile to the base. It can be sold ready-made or as a dry mix that you need to prepare yourself. During preparation, it is very important to respect the proportions, since more water can significantly impair the quality of the mortar and its adhesion.

Tile laying technology.

The adhesive solution is applied to the tiles in an even layer. In order to minimize costs, it is worth using a notched trowel. The size of the teeth can also be completely different. The tiles are laid in rows. Plastic crosses must be installed between each element, which allow you to make all the seams the same.

It is very important to take short breaks between rows. This is necessary in order for the adhesive under the tile to dry a little, thereby fixing the tile. Otherwise, if you cover the entire wall, the tiles may begin to slide out. The result will be broken seam lines. After the solid tiles are laid, you can start filling in the remaining spaces. For this, the necessary elements are cut out and laid on the surface in the same way. The best option for cutting ceramic tiles is an electric diamond wheel machine.

In order to slightly process the edges of the tile after cutting, it is worth using sandpaper.

But you should be careful not to damage the front side of the product.

Clinker cladding

If laying is done indoors, then it must be borne in mind that the walls intended for clinker cladding must be made of durable materials. Materials such as drywall will not support the enormous weight of clinker tiles.

In the event that the laying is carried out on the facade of the building, go to the cladding of the entire perimeter of the basement, and later start laying another surface. Glossy tiles are well suited for the basement, since the dirt from precipitation will be easily washed off from it.

- Before starting work, prime the walls.

- The first row, in most cases, is quite laborious, since you have to adjust the dimensions of the tiles to one level, starting from uneven ground. To do this, perform a horizontal line a row higher from the ground and trim and lay the tiles along this line.

- If masonry is selected with an offset, then the second row is shifted to the floor of the tile to the side, so that a semblance of brickwork appears. So at the corners of the building, it is useful to start every second row with laying tiles, cut in half. be directed to emphasize that for a more rapid laying process, it is necessary to lay out the first row strictly according to the level, later one corner, changing the whole and half of the tile. This procedure will allow you to deal with cladding without the distraction of trimming.But, you should not glue the tiles right away on two corners, since it is difficult to calculate what size of the halves will come in handy for the second corner.

- The seams are closed after the glue has dried and the spacers have been removed. A waterproof and frost-resistant grout must be used for the joints.

How to lay tiles in the bathroom with your own hands

Most often, tiles are laid, of course, in bathrooms and toilets. The cladding process is not much different from those described above. The main thing is to choose the right plaster and adhesives. And also correctly calculate the required number of tiles themselves. So as not to buy it later.

There are several tips for laying the material in this particular room:

- trim elements are best placed at the bottom and in the corners;

- it is worth using a horizontal starting rod;

- the lower edge of the tiles in the initial (bottom) row must be installed along this wooden strip;

- check the evenness of the "sides" in the rows with a laser level.

It should be remembered that ceramic or tile, even when laid on a properly prepared surface, dries for several days.

A specialist tells about the secrets of laying tiles:

(57 voice., middle: 5,00 out of 5)

How to glue baguettes to the ceiling: the choice of glue and the installation process

How to arrange a doorway without a door?

Similar posts

Facing steps

For laying on the steps, choose a tile with an abrasive spraying, so that during the icing the steps are not slippery. be directed to take into account the width and height of the step and select the appropriate tile, this will help to avoid unnecessary trimming and speed up the work.

- First of all, the vertical part of the step is faced. On the surface of the vertical side, a tile is glued so that its upper part lies in the same plane with the horizontal surface of the step. If necessary, trim the tiles.

- Then the tile is laid on the horizontal surface of the step so that the seams coincide with the seams of the vertical tiles. It is necessary to ensure that the tile does not protrude forward more than 2 cm, since such a protrusion will be a good lever when pressure is applied to it. Steps with a huge tile overhang help less.

- Leave the seams empty. If the facing of the porch is carried out, then the width of the seams should be at least 10 mm, since this will reduce the stress on the tiles during frost and prevent destruction. At the end of the complete installation, the seams are sealed with decorative grout. Again, in the case of external cladding, you need to choose a frost-resistant grout.

Wall cladding with tiles: the first row is the most difficult

The tiles are always laid from the bottom up. At the same time, it is not worth laying the first row of tiles on the floor, since the floor very often has a large curvature. If the first row of tiles is laid on such a floor, then the whole finish will most likely end up with a curve.

To solve the problem, a wooden rail or a metal profile is installed at the bottom of the wall. It is fixed to the wall or floor strictly horizontally. This creates an ideal base for cladding. The first row can be glued very evenly, and behind it, the entire finish will be distinguished by excellent evenness.

Furnace cladding

There are no big differences in the lining of the furnace when compared with the lining of the walls. In addition, it is necessary to use limiting crosses for the seams and perform horizontal rows. In addition, it is directed to leave the seams empty in order to fill them in the future with decorative grout. But it is necessary to take into account the huge temperature differences, based on this, the tiles and glue should be directed to choose heat-resistant ones. A simple cement mortar is not suitable for such a lining.

In order for the stove to look more beautiful, it is possible to start work from the contours of the doors and corners, using tiles with a blacker color in relation to the main cladding.The black color will hide rapidly developing smoke pollution. But when working in such a sequence, you will have to use a grinder quite often, since there will be a large number of trimming elements.

As you can see, clinker tiles can be used for finishing very different surfaces, the main thing is to choose all the materials correctly. If you have any questions, you have the opportunity to ask them on the site.

Toilet mounting methods

Installation of the device is carried out after finishing work and laying ceramic or faience tiles. After all, if the plumbing device is installed before finishing, then it is very difficult to cut the tiles on the floor around the plumbing.

The device, when installed in a bathroom, is attached in two ways: by a closed type and an open one.

The closed type of fastening is carried out by means of bolts located inside the plumbing structure. The open method involves bolting the foot.

Open

Experts consider open mounting to be as reliable and simple as possible, since installation is quick and easy. But in terms of aesthetics, this type of fixing the toilet bowl to the tile is inferior to the closed method of fixing. In addition, when cleaning, it is necessary to thoroughly wash the frame of the device in the place of the open attachment to maintain the cleanliness and sanitary condition of the room.

Closed

Having bought a toilet, which is installed in a closed way, it is imperative to mark the installation site, outlining the outline with a pencil and marking the place for the mounting holes.

There are many methods for installing mirrors, choose the one that suits you best, depending on the weight and design of the product itself and the type of base.

Advantage of the method: suitable for installing a product of any shape and weight. Disadvantages: thorough preparation of the base surface for work and the impossibility of dismantling the mirror (if it is necessary to outweigh the product, the old coating is broken and fragments are removed).

Progress:

- mark the mounting of the mirror on the wall;

- remove the cladding along the marked lines;

- clean the base, if necessary, putty or level the surface;

- apply a primer to the base;

- tile the lower border, inserting dividing crosses between the lamellas to obtain even seams;

- fix the profile or rail on the wall along the upper edge of the depression for an emphasis;

- lay the top curb, then the sides;

- remove excess glue with a sponge;

- wait for the composition to solidify completely. In terms of time, it will take at least a day, but more accurate information is contained on the package;

- prepare the glue mixture for work (it is advisable to make a solution of a thick consistency). Using a notched trowel, apply an even thick layer to the wall;

- place the mirror with the bottom edge to the installation site. Immediately insert dividing crosses between the canvas and the border;

- place the accessory flat against the adhesive mixture. Adjust its position so that it is flush with the tiles;

- press the reflective surface with your hands for 10-15 minutes;

- after the glue has dried, remove the support strip and fill the joints with trowel mixture.

We offer you to familiarize yourself with the washing machine hums: why does the machine knock and rattle when washing? What should be the noise level when drawing water?

A simple and convenient way is to fix the web with ready-made holes:

- mark the location of the mirror and drill holes in the wall, the diameter of which should correspond to the size of the dowel, and the depth is 5 mm larger than the screws or self-tapping screws used;

- drive in the dowels;

- fix the canvas by installing rubber gaskets between the metal parts of the fastener and the mirror, cover the caps of the screws with decorative heads.

Laying wall tiles with a batten

It is easier to lay out from below - the new rows are based on the previous ones, but then the top row will be uneven. This is where the vertical guide corners will help. In them, from floor to ceiling, tiles and borders for ceramics and porcelain stoneware are inserted and glued.

Professional finishers lay the tiles on top - this makes the wall look more spectacular, because you don't have to trim the top tiles. The difficulty here is that the tile slides down the glue layer under its own weight.

If there is a gap between the top tile and the ceiling, slide it up until it stops, moving the rest of the tiles along with it. Now the gap remains at the bottom, and so that the tile does not slide, you need to support the bottom row. For example, screw a piece of rail with self-tapping screws.

The hardest part is lay out the tiles in the bathroom... To do this, it is advisable to dismantle taps, heated towel rails, sockets, switches, remove the cabinets, and after the work is completed, put them back.

Removing the bath itself is problematic. Therefore, the guide corner of the lower row is laid on the edge of the bathtub, and upon completion of the work, the seams between the corner, bathtub and tiles are filled with colorless silicone. This is how two corner rows are assembled. A thread is pulled between the two lower opposing tiles without sagging, a line is drawn along it on the wall, and a rail is fixed along this line, which will provide support for the lower row. Do not hesitate, because one vertical row (in the corner where you plan trim tiles for joining with an adjacent wall) will have to be disassembled and cleaned off.

Tiles and walls are greased with glue. The first row is laid out on the rail. There should be no voids under the tile, otherwise it will then come off. To do this, it is gently pressed by hand or tapped with a rubber mallet. To make the seams even, crosses are inserted between them. We check the quality of the styling by a level or rule. We are waiting for the glue to set and the first row will become a reliable support for the next.

We lay out the following rows, checking the quality of the installation vertically, horizontally and diagonally. Remove the excess glue that has come out by wiping the wall with a dry cloth. When the glue between the seams hardens, remove the crosses. We remove the bottom guide rail. Cut to the desired size and glue the tiles in the bottom row.

How to trim tiles

For work, a tile cutter is used (or a glass cutter, which is not desirable).

- Mark the front side with a pencil before cutting.

- Firmly trace along the marked line with the tile cutter

- Place the tile on the edge of a flat surface and press down on the overhanging part.

If a trim tiles you need not in a straight line, it is better to use a grinder with a special disc for tiles or stone. Use a low speed drill and special drills for small holes. Use the crown bit for drilling large holes.

Bonding tiles

Ceiling tile gluing scheme.

Tiles are laid in the bathroom on dry cement glue with a composition intended for walls. The glue is prepared by mixing the structural components with water. In this case, the mixture is poured into water, and not vice versa. Bathroom walls must be treated with a moisture-resistant primer. It will provide the necessary waterproofing and reliable adhesion of the tile to the wall. In the process of pasting, you need to be careful and constantly monitor the evenness of the surface, verticality and coincidence of the edge lines. You need to fix the tiles in small areas, marking out squares with a side of four tiles.

Plastic crosses help maintain tile spacing... A day after gluing, the crosses are removed. The glue is spread on the wall with a notched trowel. This tool is used to cover the tiles with glue. The tile is pressed with small movements parallel to the wall.Some masters advise wetting the tiles, but this is not necessary - the supporting surface of the tiles absorbs the necessary moisture from the adhesive solution. Laying should be done slowly so that after gluing each tile, the glue sets. In a hurry, you can inadvertently move the tile that is not firmly seized, and thereby weaken the reliability of its future fastening. When pressing the tiles against the wall, you do not need excessive force - this way you can squeeze out almost all the adhesive from under the tiles. The part of the composition, squeezed out, is removed with a wooden or plastic spatula to avoid scratching the surface.

If it is necessary to bypass obstacles in the form of pipes, vents or doorways, the necessary cutouts are made in the tile. Some difficult areas can be bypassed during installation times to make cutouts easier and fewer. If possible, it is best to use a tile jigsaw. Such a tool is equipped with a wire or rod, on which an abrasive compound is sprayed. With this method, obstacle avoidance is ideal. If you don't have a jigsaw, use a grinder. In this case, the cutouts are obtained with corners, which should be covered with any details that do not violate the harmony of the tiled coating. If there is a need to drill holes in the wall to accommodate any interior items, it is better to postpone this work until the walls are completely dry after cladding.

After the wall has been glued with tiles, it remains to fill the gaps with grout. This is done with a white rubber trowel, moving the tiles diagonally. A checkerboard style would be an option for straight styling. It uses tiles of different colors, laid in the form of a checkerboard. There can be as many ways of laying tiles as the imagination of the master allows. One of the most common is diagonal. To mark the wall, you need to draw two perpendicular diagonals. They should be positioned at a 45 ° angle to the top edge of the future full cladding. Laying the tiles starts from the middle of the surface, first all whole tiles are attached. It is not necessary to lay the entire diagonal at once, but to glue in sections, as with direct laying. It is better to put the last triangles along the edges of the cladding at the end of the work.