The knowledge of how to glue a sewer plastic pipe when the necessary equipment is not at hand will be useful to every home craftsman. Frequent leakage must be eliminated urgently when it is not possible to replace the damaged element. You can completely assemble the plastic piping system using special adhesives.

Sealing PVC pipes

The composition and principle of action of adhesive materials

Plastic products are glued using specialized chemical compounds that dissolve the outer surface of the material. The active component in most variants is methyl ethyl ketone, cyclohexane or tetrahydrofuran. Adhesive for sewer pipes made of PVC or polypropylene is made on the basis of the same substance as the parts of the pipeline themselves. In addition, various additives are mixed into the adhesive materials, which allow to influence the viscosity of the mixture and its setting time, as well as improve adhesion.

In the process of glue hardening, plastic pipes are rigidly connected due to the interweaving of molecular polymer chains on the outer surfaces of the parts to be joined. The solvent is then evaporated and a compound is obtained that has the same characteristics as a new one-piece product.

Sealant and epoxy adhesive

There can be many reasons for the appearance of cracks or leaks on plastic pipes. This may be a violation of the installation rules, improper operation or a simple defect in production. If the crack is small, then you can not replace it, but try to glue the pipe.

The first way to carry out repair work is to use a silicone sealant. This method is suitable when the crack is blind. As a rule, this method is used when repairing sewer pipes. The work progress will be as follows:

- The crack is cleared and expanded as far as possible. This is necessary for the sealant to penetrate as deeply as possible.

- Further, it is necessary to degrease and dry the place of repair work.

- A layer of sealant is then applied and allowed to dry.

And how to repair a through hole, for example, in the same sewer pipe? In this case, it is better to use a two-component epoxy adhesive. The work is carried out in the following sequence:

- The cracked area is cleaned, degreased and dried.

- Then we prepare a suitable bandage. A piece of fiberglass or other dense and flexible material is best for this.

- The repaired section along the entire length of the crack is wrapped with a bandage with a margin, while the number of revolutions should be at least five.

- The last step is to apply a layer of epoxy adhesive.

How to choose a glue?

When choosing how to glue the sewer pipe, you need to pay attention to the following factors:

- bonding material;

- setting duration;

- technology of use;

- temperature conditions;

- time and storage conditions after opening the package.

All the necessary information is described in detail in the instructions, which should be carefully studied.

There are 2 main groups of adhesive materials for gluing plastic pipes:

- One-component formulations. Such products are sold ready-made and do not require preliminary mixing of the components. Adhesives are packaged in glass, plastic or metal containers and are used to join different types of plastic. They consist of dissolving, softening and joint-forming chemically active substances.But they do not have additives or additives that can change the duration of the course of a chemical reaction and enhance the strength of the abutting place. A typical example of such materials is sealant for PVC and polypropylene (Moment).

- Two-component formulations. They are produced in 2 separate components, which are in different packages. They are mixed immediately before use. Chemically more complex compounds, since they include elements that improve adhesion and reduce the evaporation time of solvent components. The addition of additives promotes the acceleration of the formation of stable polymer chains, due to which bonds of the atomic level are obtained stronger. Higher quality of the joint is provided.

A convenient and effective way to quickly glue all types of pipelines is to use a special sealing tape.

Popular insulating agents and features of their use

In construction and repair shops there is a wide range of insulating materials that are designed to seal the fittings of the plumbing and sewer systems. Each type of sealant has an individual composition and is designed for a specific purpose. We will tell you more about which of them is better to choose for repairing plastic pipes.

Polymer (silicone) sealants

This is the most common material for securing sewer pipe fittings. It is also used to repair cracks.

Sealants are sold in different tube sizes.

Silicone products are distinguished by their composition into acidic and neutral substances. It is important to take this into account. Each species has its own advantages and disadvantages.

- Acid sealants cheaper, but suitable for a limited number of materials. The presence of acid can destroy the plastic.

- Neutral remedies - more expensive, but they can be used without restrictions.

Both, after drying, form a strong elastic film with waterproofing properties. In appearance and quality characteristics, they are similar to rubber.

Before applying the composition to the cracks, they must be thoroughly dried, cleaned with fine sandpaper and degreased.

The drying time is indicated on the packaging. Most often it is 4-6 hours.

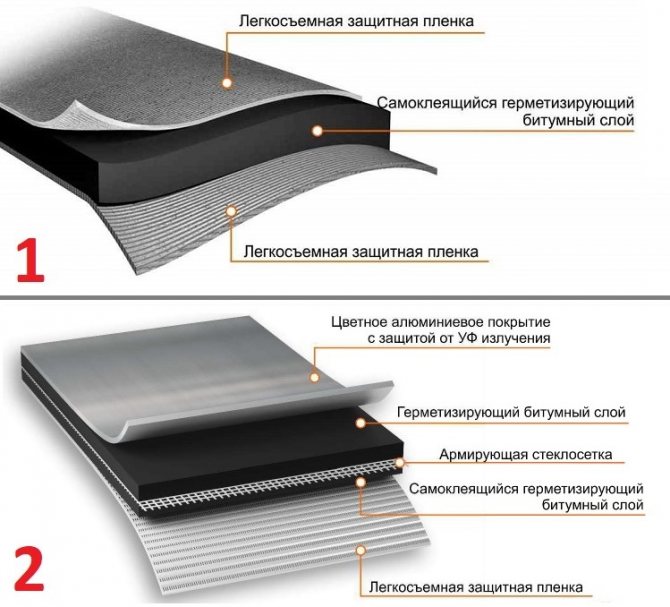

Sealing tape

It is a self-adhesive material of two types - with and without foil. They are made of polymer-bitumen materials that provide reliable waterproofing.

The foil-free sealing tape is used in closed rooms, while with an aluminum coating and UV protection, it is intended for outdoor pipes.

When choosing a tape for repairing sewage in an apartment, it is worth considering the types of tapes. They differ in the following markings:

- "Z" - winter. Retains properties at temperatures from minus 2000 to +1000.

- "L" - summer. Withstands up to +3000.

- "T" - heat-resistant. It is used to insulate a heat pipe for pumping liquid up to +15000. This type is considered industrial.

For repairing pipes in an apartment, summer or winter tapes are used.

Repair of cracks in sewer pipes is carried out in the following order:

- The place of sealing is dried with a hair dryer.

- The tape is separated from the protective layer and applied to the pipe with a mastic layer inward, at a distance of at least 5 cm from the crack.

- The winding is carried out with an overlap, avoiding wrinkles and bubbles. The surface must remain perfectly smooth, without the slightest error.

When applied correctly, the material provides reliable waterproofing and heat resistance. Does not lose elasticity and strength throughout the entire service life. It is so durable that it is successfully used in the construction of oil pipelines. So, you can not worry about the reliability of the apartment sewage system, repaired with a sealing tape.

The disadvantages include the high cost of the material.

How to prepare and glue plastic piping elements?

Since the pipe adhesive contains toxic volatile components, all work should be carried out in a well-ventilated area. The temperature should be within + 5 ... + 35 ° С. It is recommended to protect hands with rubber gloves to avoid causing an allergic reaction or irritation.

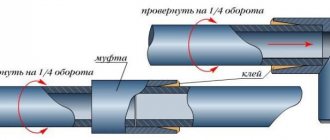

The sequence of actions is as follows:

- Cut pipe sections of the required length using special scissors (pipe cutter) or a fine-toothed saw. The edges of the cut are cleaned with a file and sandpaper to remove chips and burrs.

- Then the bonded area of the surface must be well cleaned of dirt and dried thoroughly.

- The preliminary assembly of the pipeline structure and the final adjustment of all elements are carried out.

- Before gluing the damage or gluing all the parts together, the gluing points must be degreased with a special solution or an alcohol-containing liquid.

- The adhesive is thoroughly mixed. When using the repair method with two-component glue, measure the required amount of material and knead it with your hands until it is ready (plasticine consistency).

- Using a brush or applicator, the glue is evenly distributed over the prepared surface. The parts are joined and fixed in a stationary state for several minutes (the exact time is indicated in the instructions). Reapplication is sometimes required. A thick mastic is applied to the repaired area and strongly pressed with a tourniquet.

- Excess glue protruding along the edges of the joint is removed with a paper towel or rag.

- The connected parts are left alone until the adhesive is completely dry.

The general tightness of the joints and the reliability of the entire structure are checked no earlier than after 24 hours. When sealing the leak, the repair mass hardens in an hour.

How and how to seal a hole in a plastic pipe - methods tested by masters

Modern household communications are increasingly equipped with plastic pipes: this is especially true for sewer and water supply systems, mostly consisting of polypropylene or PVC products. Like any other plumbing, these systems need periodic repairs.

Priority actions when a leak is detected

If a leak appears on the heating or high pressure pipe, you must immediately shut off the system with shut-off valves. To solve the problem of how to close a hole in a plastic pipe, you can use a clamp. Such designs are characterized by very simple use, which consists in putting on the damaged area and tightening the bolts.

The older way is to use rubber: this is how heating and water pipes are often repaired. This involves wrapping a piece of rubber around the damaged area, for which you can use an old car tire.

For clamping, a clamp, thin wire or strong cord is used. Ordinary oil paint is also used, which is spread on a cloth previously wound over the leak (read also: "How to eliminate a leak in a plastic pipe - options for sealing a leak"). All these methods have only a temporary effect, since the leak later will certainly make itself felt. The best way to repair a crack in a plastic pipe is to completely replace the problem area, especially since in the case of plastic pipes this is not difficult to do.

Using sealant and epoxy adhesive for plastic pipe

A number of factors can contribute to the appearance of cracks or leaks in plastic piping. This is what mistakes were made at the stage of installation of the system, and the violation of operation. And the plastic parts themselves may be defective.

If the size of the formed crack is small, then it is not necessary to change the entire pipe. You can try to seal it with silicone sealant first, especially when it comes to blind damage. Most often, sewer systems are repaired in this way.

In this case, you need to act like this:

- Clean up and expand the damage. This is done for deeper penetration of the sealant.

- Carry out degreasing and drying of the repaired area.

- Apply the sealant as needed and let it dry well.

However, it happens that the pipe gets through damage. How to glue a sewer plastic pipe in this case?

This is done using a two-component epoxy composition, in compliance with the following sequence of works:

- The place where the damage has appeared must be cleaned, degreased and dried.

- To prepare the bandage, you will need fiberglass or other dense and flexible material.

- The prepared bandage is wrapped around the crack itself and the place around it, with a good margin. Wrap the material around the pipe at least 5 times.

- At the final stage, epoxy glue is applied.

In addition to sewerage systems, in this way you can repair water pipes and heated towel rails.

How to seal a hole with sealing tape

With the help of this modern material, it is possible to qualitatively eliminate small leaks on the pipes located in the bathrooms. Outwardly, it is an adhesive fabric impregnated with special substances. Most often, joints and connecting elements are sealed with a sealing tape. As for straight sections, they can also be repaired in this way.

When using a sealing tape, it is important to follow this sequence of work:

- The place of damage must be well cleaned and dried.

- After stretching a small piece of tape, it is wrapped around the pipe. It is important that this procedure is accompanied by constant tension in the tape, otherwise wrinkles will occur.

- When winding, each new turn should be laid on half of the previous one. It is best to pack the pipe with two layers of sealing tape.

The main disadvantage of this method is the insufficient resistance of the repair material to sunlight. To achieve a good durability, the wound tape is covered with additional protection.

Repair of cracks by cold welding

Specialty stores currently offer special cold welding for sewer pipes. It is made specifically for the repair of plastic products used in the organization of water supply systems, cooling systems, heating communications.

Damage of almost any degree of difficulty can be repaired by cold welding. In this case, thermal action is not required, since a chemical reaction is used to bring the constituent components into working condition.

The work itself to repair a damaged plastic pipe has the following sequence:

- It all starts with surface preparation, for which the entire problem area is treated with an emery cloth. This is followed by degreasing the base with alcohol-containing liquids. If you neglect this procedure, the applied patch will serve several times less.

- It is necessary to calculate exactly how much material is required for a high-quality embedding. For this, a simple visual inspection is usually enough: the main thing here is that the repair mass can cover the entire problem area.

- The substance must be taken in hands, on which protective rubber gloves are previously put on, and begin to knead. This procedure is continued until the material is colored in a specific brown shade. Another sign of the readiness of the material is that the mass has reached the state of plasticine.

- With the finished plastic material, you need to close up the damage well by pressing it with a tourniquet.Then there is a pause in work, for about an hour: during this time, the repair mass solidifies. It must be made so strong and dense that any drilling, cutting and other impacts on its surface are completely safe.

It is important to take into account the presence of components harmful to the human body in the composition of cold welding. For safety reasons, it is recommended that you obtain protective gloves and goggles in advance. To speed up the process of solidification of the plastic mass, some experts recommend exposing it to warm air using a construction or ordinary hair dryer.

Cold welding for sewer pipes is suitable for repairing damaged plumbing. For example, if a piece of material breaks off from a sink or toilet bowl, cold welding will help to glue it back with good quality. When buying this universal remedy, you should check its expiration date, compositional features and the availability of a quality certificate.

Source: https://trubaspec.com/montazh-i-remont/chem-i-kak-zadelat-dyrku-v-plastikovoy-trube-proverennye-masterami-sposoby.html

What to do first of all if a leak occurs

If there is a leak in the high-pressure pipes, heating system or other communication in an apartment or house, then first of all, you need to close the shut-off valves. This truth is familiar to everyone. But what to do next?

The emerging leak can be "plugged" with clamps. Such structures are in the required area and are tightened with bolts.

It is possible to use a dilapidated method - use rubber. In this way, I often repair a heating or water supply pipe. The problem area is wrapped with a piece of rubber (for example, from car tires) and clamped with a clamp or pulled over with a narrow wire or strong cord.

Advice! It is possible to use a simple paint. The place where a crack or leak appears is wrapped with a cloth and painted over with oil paint.

But all of the above methods can be considered a temporary solution. If such patches are left for a long time, the leak will appear again. Just on this basis, many masters advise replacing the problem area, especially since it is quite easy to do this using plastic pipes.

Causes of defects when gluing PVC pipes

Sometimes, some time after sealing a crack in a PVC pipe or gluing the entire structure, fluid leakage is observed at the joints. Most often, the reasons are the following technological violations that were made during the work:

- Poor surface preparation on old pipe and severe irregularities. In case of poor processing of the cut edges, when roughness remains on the material, the adhesive dissolves and softens the material unevenly.

- Contamination remained on the treated areas. Unfatted surfaces also cannot be well impregnated with glue.

- Uneven application of the adhesive leads to non-gluing in some places of the joint.

- The seam is not completely glued if a thin surface film has formed on the adhesive layer due to its overdrying. All work must be done quickly.

- A soft and loose glue layer instead of a good strong joint is formed at low ambient temperatures during work. In this case, the solvent does not completely evaporate and the composition does not harden.

- A porous adhesive layer may remain if the components are poorly mixed prior to application. Remaining air bubbles weaken the seam severely.

- Insufficient compression force or lack of holding time, as a result of which there is a distortion and displacement of the parts to be glued during the curing of the composition.

- Incorrectly selected brand of glue.

In order not to have to take additional measures to eliminate the leakage due to poor-quality gluing, it is necessary to correctly select the adhesive composition and strictly observe the technology of the work.

Priority actions when a leak is detected

If a leak appears on the heating or high pressure pipe, you must immediately shut off the system with shut-off valves. To solve the problem of how to close a hole in a plastic pipe, you can use a clamp.Such designs are characterized by very simple use, which consists in putting on the damaged area and tightening the bolts.

The older way is to use rubber: this is how heating and water pipes are often repaired. This involves wrapping a piece of rubber around the damaged area, for which you can use an old car tire.

For clamping, a clamp, thin wire or strong cord is used. Ordinary oil paint is also used, which is spread on a cloth previously wound over the leak (read also: "How to eliminate a leak in a plastic pipe - options for sealing a leak"). All these methods have only a temporary effect, since the leak later will certainly make itself felt. The best way to repair a crack in a plastic pipe is to completely replace the problem area, especially since in the case of plastic pipes this is not difficult to do.