General information

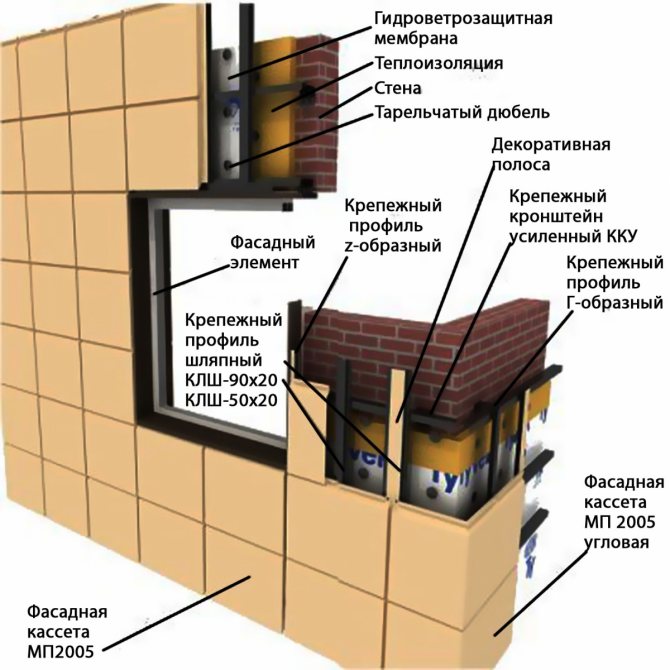

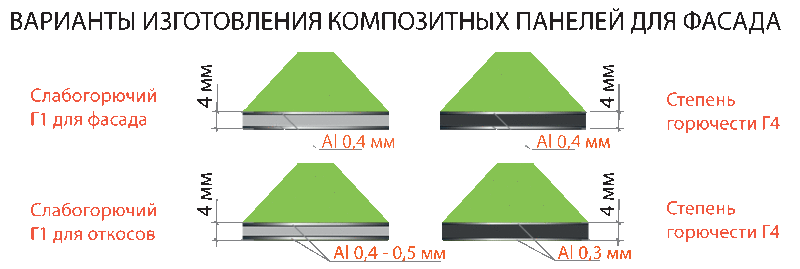

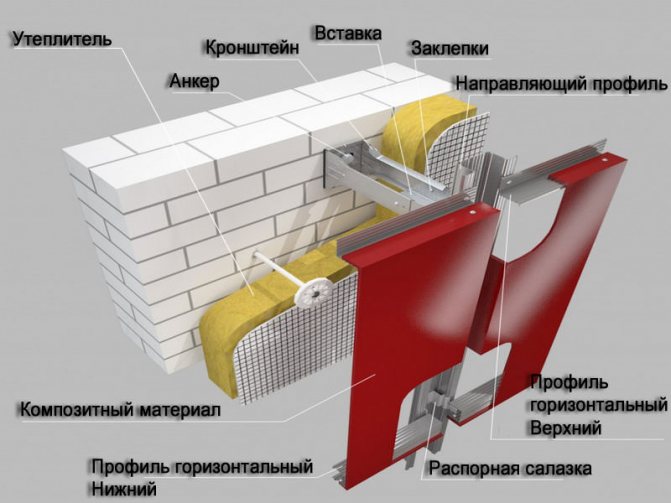

The concept of "hinged ventilated facade" originated in Germany. The structure consists of a protective and decorative coating, a subframe and an insulating layer, which are attached to the load-bearing walls with an air gap between the cladding and the insulation. Thermal insulation is installed in order to additionally insulate the building.

Ventilated facades equalize the temperature fluctuations of the outer walls and reduce their deformation, which is especially undesirable in large-panel housing construction. External thermal insulation significantly increases the thermal insulation capacity of the wall array and reduces the cost of repairing it.

Due to the differential pressure, the air gap works like a chimney. As a result, moisture that condenses under the facade coating is removed from the building envelope into the atmosphere. In addition, heat loss is reduced, since the air in the gap is about three degrees higher than the outside.

A specially designed installation scheme for a ventilated facade absorbs thermal deformations that occur during seasonal and daily temperature changes. Internal stresses in the supporting structure and cladding material are reduced, which can destroy them.

Read our article "Calculation and selection of materials for a curtain ventilated facade".

Ventilated facade.

Price list

Turnkey works

| Turnkey ventilated facade made of aluminum composite panels: | Price |

| - without insulation | 3 415 |

| - mineral wool 50 mm | 3 700 |

| - mineral wool 100 mm | 3 810 |

| - mineral wool 150 mm | 3 920 |

| Registration of a coloristic passport for a building | 155 000 |

| Opening an OATI order | 10 000 |

| Development and approval of the AMP (Road Traffic Organization Project) | 30 000 |

| Heat engineering calculation | Is free |

| Pull-out test of anchors | Is free |

| Facade survey geodetic | 30 |

| Preparation of working documentation for the installation of a ventilated facade | 60 |

| Development of the Project of the Production of Works (PPR) | 30 000 |

| Ventilation facade design project | 30 000 |

| Construction works | |

| Assembling scaffolding | 80 |

| Fastening the banner mesh to scaffolding | 50 |

| Assembly of front elevators, pcs. | 15 000 |

| Rearrangement of front elevators, pcs. | 3 000 |

| Assembling a pedestrian gallery, m. | 2 000 |

| Facade markings for holders | 50 |

| Mounting support brackets | 150 |

| - Paronite gasket | 6 |

| - Bracket | 59 |

| - Facade dowel | 35 |

| Attaching extension cords to brackets | 100 |

| - Extension cord | 63 |

| - Coated self-tapping screw | 7 |

| The device of the first layer of insulation | 200 |

| - Disc dowel | 18 |

| - Basalt heat-insulating plates with a density of 45 kg / m3, m3 | 1 850 |

| - Extruded polystyrene foam (for the base), m3 | 5 020 |

| The device of the second layer of insulation | 100 |

| - Disc dowel | 44 |

| - Basalt heat-insulating plates with a density of 80 kg / m3, m3 | 2 750 |

| Installation of a vertical subsystem | 200 |

| - Z-shaped galvanized profile. colored | 36 |

| - Profile U-shaped galvanized painted | 116 |

| - Coated self-tapping screw | 7 |

| Installation of the starter bar (for concealed mounting) | 100 |

| - Starter bar 1.2 mm galvanized, powder coated | 80 |

| Fastening composite panels | 600 |

| Aluminum Composite Panels | |

| - thickness 4 mm G4 | 950 |

| - thickness 4 mm Г1 (fire-resistant GoldStar FR, S1, A2) | 1050 |

| Installation of the subsystem under the parapet ebb | 500 |

| Installation of the parapet cover, m. | 400 |

| - Parapet ebb, m. | 678 |

| The device of ebb tides, slopes, drippers, m. | 350 |

| - Low tide 250 mm wide, st. 0.6, powder, m.p. | 300 |

| - Slope 250 mm wide, st. 0.6, powder, m. | 400 |

| - Aquilon, art. 0.6, powder, m.p. | 112 |

| Insulation of slopes, m. | 200 |

Ventilated facades made of composite materials

Nowadays, ventilated composite facades are extremely popular.They consist of aluminum composite sandwich panels used for external cladding of buildings using the ventilation facade technology.

Recent data indicate that among all ventilated facades erected in the world, the share of composite is approximately 50%. Composite facades are increasingly being made in the residential sector, on industrial and public buildings, including unique architectural objects. With the advent of aluminum composite panels, a new architectural style has actually been formed.

Composite panels were developed by the German companies Alusuisse and BASF in 1968. A year later, the first composite material of the Alukobond brand appeared on construction sites in Germany, which conquered the European construction market in the 80s. Along with the technology of ventilated facades, composite panels came to Russia in the mid-90s. We got panels made of composite of our own production (ALCOTEK) in 2005. Today, domestically produced composite panels are produced at 15 factories by several companies.

Composite panels.

Construction of houses

67 votes

+

Voice for!

—

Against!

More than 30 companies present aluminum composite panels on the market. Products from all manufacturers have conditionally the same technical characteristics. The general name Alucobond is used for this building material. The word Alucobond is a brand of a Swiss manufacturer that first introduced composite panels to the domestic market. Sometimes the slabs are called sandwich panels due to their design features (layering). The article will focus on alucobond panels.

- ALUCOBOND (Switzerland)

Alucobond panels are widely used by firms engaged in construction and finishing works. This material allows you to transform the exterior of the building, gives architects and builders immense opportunities not only for the design of the facade, but also for the interior space.

Alucobond photo

Alucobond characteristics

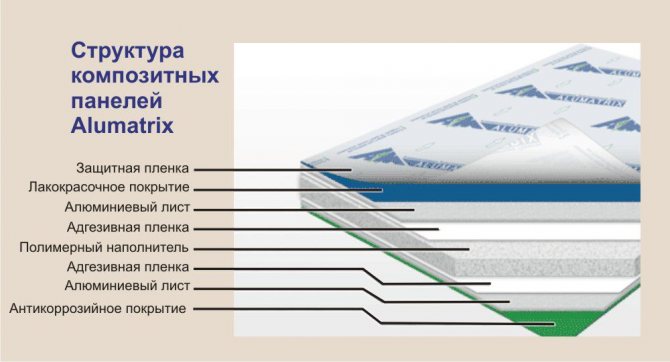

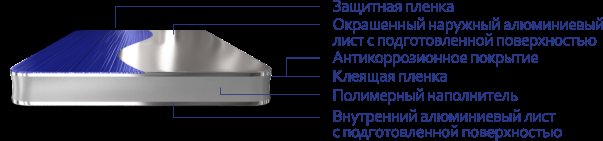

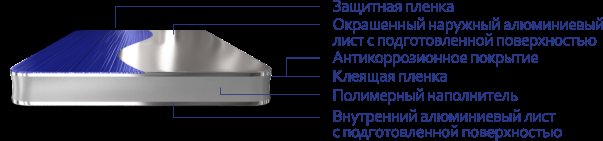

The panels are composed of several layers. Between the sheets of high strength aluminum, there is a filler made of synthetic polymer or expanded polyethylene of high pressure.

- The side of the panel facing the inside of the building is treated with an anti-corrosion coating. The front surface is covered with a layer of polyester (PE) or fluorinated carbon (PVDF) in various shades.

- Polyester paint provides a durable finish with a glossy finish. Products painted with this material are used in almost any climatic conditions.

- PVDF coating is characterized by increased color fastness (practically does not fade) and higher resistance to aggressive environments. Due to their improved performance, the panels are used for cladding in regions with the most severe weather conditions, including coastal areas.

- For ease of installation and protection of the front surface, the painted side is protected with a laminated film, which is removed after the end of the work.

- The rigid and durable construction of the alucobond panels allows them to be used for cladding high-rise buildings using ventilated facades technology. Such a system provides air circulation, thereby facilitating the removal of condensate.

- On a perfectly flat and smooth surface, cracks do not appear during bending and formation of the material. These properties are acquired thanks to a very durable coating. Alucobond can be operated in the most severe climatic conditions.

- In production, a continuous strip of composite material is cut into standard lengths. Also, formed cassette plates are produced, which are completely ready for installation.

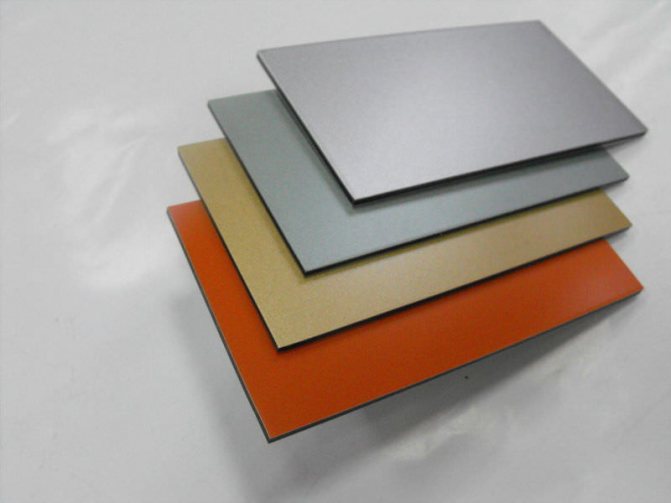

- The panels are available in various colors with a matte finish or a metallic sheen. The widest choice of shades and sizes allows developers and designers to use alucobond for a variety of purposes.

Scope of application of composite panels alucobond

Due to the excellent characteristics of the material, its range of applications is almost limitless. Composite panels are used:

- in the arrangement of facades of any number of storeys, giving buildings a progressive look;

- during the reconstruction of old buildings in order to update the exterior, improve the soundproofing and heat-insulating characteristics of the walls;

- for cladding architectural elements: balconies, canopies, columns, etc.

- in the design of billboards and signboards, light boxes and supports;

- for the manufacture of decorative room partitions, interior finishing material;

- in the automotive industry, from which elements of finishing of cars, buses, car bodies are made;

- in the production of casings, cases, boxes for various equipment.

Plates made of composite do an excellent job with the functions assigned to them. They are not afraid of the effects of adverse climatic conditions, enable construction and assembly teams to bend them to the required degree.

This type of material is widely used for external and internal work with any purpose. It allows you to create real masterpieces, both when arranging the exterior of the building and the interior of the premises.

Advantages and disadvantages of alucobond

Of the advantages of this building material, it can be noted:

- Durability. Manufacturers give a guarantee for panels from 15 to 25 years. This means that the outer cladding can last more than 50 years without the need for repair or replacement of individual sections. The quality of the external coating will retain the attractive appearance of the facade even after decades.

- Simple handling. Composite panels lend themselves to cutting, angular and radial bending, rolling, welding of polymer layers. Corresponding manipulations are performed using conventional wood and metalworking equipment or hand tools.

- Strength and elasticity. Steel sheets give the plates the necessary strength, resistance to mechanical stress. Meanwhile, the material has flexibility that allows it to take almost any shape.

- Weather resistance. The highly durable coating resists harsh weather conditions, so composite panels can be used in extreme temperatures. Special formulations provide protection against corrosion caused by acidic, saline and alkaline solutions.

- Aesthetics. A wide range of colors allows you to embody the bold ideas of architects and designers. The material can "imitate" plaster, marble, chrome, gold, etc. The durable coating will not fade under the influence of ultraviolet rays even after several decades.

- Thermal and sound insulation. The multi-layer structure enhances the soundproofing performance of the building. Thus, the sound absorption coefficient of a 4 mm thick panel is 25 dB. These qualities are especially important for buildings located on busy streets. As for thermal insulation, the filler is more responsible for this property. The polyethylene layer provides thermal insulation equal to 0.01 W / mK.

- Simplicity and cost-effectiveness of installation. The light weight of the panels does not increase the load on the foundation, and the high strength does not allow the use of additional reinforcing elements. The simplified frame design for the ventilation façade makes work easier and saves on budget.

disadvantages

- The negative point can be attributed low refractoriness... Although this indicator is determined depending on the type of filler. The polymer layer is weakly resistant to fire and emits toxic substances during combustion.The mineral layer, made mostly of foamed polyethylene, is treated with fire retardants, which makes it possible to classify such panels as a flame-retardant class. According to international standards, such products are marked with FR.

Today on the market there are panels with an improved "filling", which includes aluminum hydroxide. This substance is resistant to an open flame for 2 hours. But the price of these alucobond panels is significantly higher, so their use is not so popular.

- It is worth noting and complicated repair work... When replacing a damaged panel, sometimes it is necessary to remove several adjacent ones.

Tool for working with alucobond

When installing ventilated facades made of composite panels, a tool is required with which the cassettes will be adjusted to specific dimensions. The most common solutions are milling by means of:

- vertical hand router;

- CNC machine;

- disk milling cutter.

Each method has both advantages and disadvantages. I would especially like to note that the cutting accuracy determines the life of the facade. Poor milling quality leads to the formation of cracks on the panels at temperature extremes.

- Manual frezer... This method is popular due to the mobility and low cost of equipment. This is where all the advantages end. But there are quite a few disadvantages: low performance. The milling speed is significantly lower in comparison with other methods of processing composite panels;

- complexity. The work requires certain knowledge and skills. The tool needs preliminary settings;

- low quality. A finger cutter leaves burrs on the material, as well as a large amount of polymer chips, which makes it difficult to bend the panels;

- unreliability. It is impossible to achieve high accuracy up to tenths with such equipment. In addition, the tool will quickly fail after processing a certain amount of composite (≈ 80 m²).

- simple operation. There is no need to carry out any tuning operations;

It should be noted that the listed advantages do not apply to disc mills of non-original origin. This technique is used for small volumes of work, subject to certain conditions. Accordingly, the warranty period and the cost of the equipment vary greatly.

Alucobond ventilated facade

- Their advantage lies in the ability to carry out the appropriate work in a short time and in almost any climatic conditions. A ventilated façade will provide protection to buildings and a durable façade.

- A special profile system makes it possible to freely circulate air flows between the building wall and the finishing material.Due to this, the water vapor generated during the operation of the building does not linger, but evaporates naturally.

- Insulation allows you to reduce the heat transfer of the walls, thereby minimizing heating costs. At the same time, the heat-insulating layer makes it possible to reduce the thickness of the bearing walls, which means to reduce the load on the foundation.

- The facade panel protects the walls of the building from adverse environmental influences. In addition, it refines the exterior, gives a modern look to buildings that previously needed major repairs.

Alucobond panel mounting technology

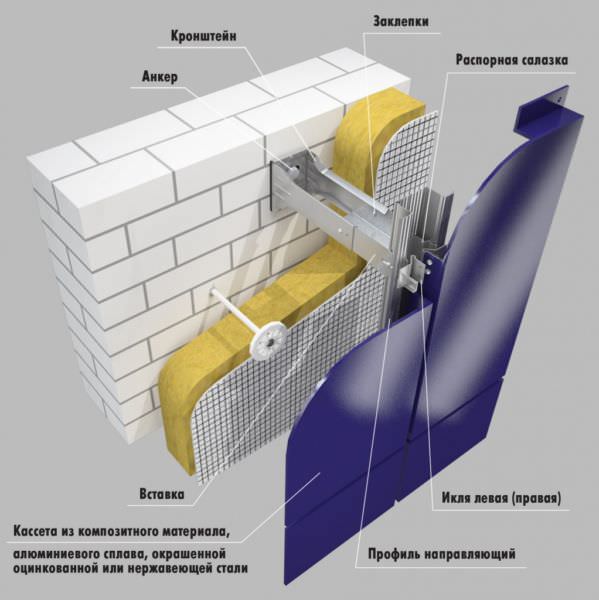

Installation work is not difficult. Here you need to know a few basic points and have experience in construction. The technology is as follows: a frame consisting of a bearing profile and a bracket is attached to the outer walls. Later, the structure is faced with facade panels. The use of thermal break pads will help to significantly reduce the loss of thermal energy.

Stages of work:

- after marking, brackets are attached to the wall, to which the guide profiles will be fixed. The fastening of the brackets themselves is carried out by means of expansion dowels (anchor bolts);

- a layer of insulation of a given thickness is mounted to the wall surface using glue and disc dowels. The thermal insulation material must have a waterproof and windproof membrane on the front side. It is prohibited to use plastic wrap;

- to the installed brackets, the guides are fixed by means of special fasteners;

- further, the installation of decorative panels is carried out.

Alucobond videos

What you need to know when working with Alucobond

Design

When developing a ventilated facade system, it is necessary to know and take into account a number of indicators:

- weight and size of composite panels;

- facade height;

- characteristics of supporting elements;

- wind load;

- corrosion resistance. The supporting structure must be able to withstand the effects of aggressive environments.

Supporting frame

The strength of the structure under the curtain wall is calculated taking into account the following parameters:

- it must withstand the weight of the agro-industrial complex, wind loads, shrinkage of the structure, thermal expansion;

- to make it possible to correct the geometry of the structure (wall irregularities) as much as possible;

- securely and motionlessly fixed to the surfaces of load-bearing walls;

- withstand the adverse effects of climatic conditions without damage to the frame;

- comply with all applicable rules and regulations;

- solve architectural ideas when working with both new buildings and previously built buildings.

Metal parts, including guides, can be made of galvanized metal, aluminum or stainless steel. Of course, the technical parameters of the materials are different, as well as the cost itself. The choice should be made in the direction of strength and quality, and not economy.

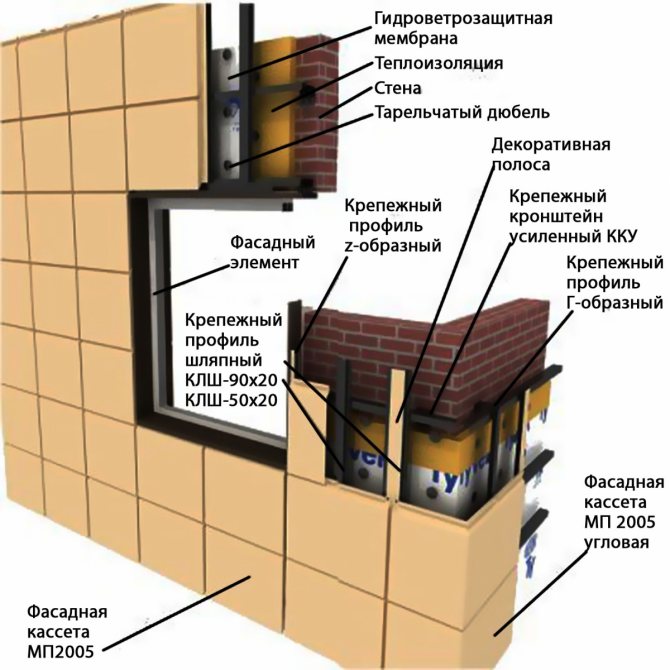

Layers of the cake

High performance in terms of vibration, heat, noise insulation properties can be achieved only by observing the technology. In section, the ventilated facade looks like this:

- sand-cement plaster with a thickness of at least 1.5 cm from the inside of the wall;

- a wall made of foam, aerated concrete or expanded clay. If sand-lime brick is used, then the thickness of the masonry should be 380 cm;

- insulation - mineral wool pressed into slabs, 10-20 cm thick;

- windproof film with a vapor-permeable effect;

- composite panels 4 mm.

The main stages of work with alucobond panels

- Before starting work, drains and antennas are removed from the outer walls, air conditioning units are dismantled. Peeling paint and plaster are removed from the surface. Next, a point is selected from which all subsequent markings will go.

- All points necessary for fastening are marked and working holes for dowels are drilled. The brackets are secured with anchors, where an aluminum washer provides a firm hold.As a rule, the step between the brackets is 60-75 cm, that is, 4 pieces per 3 m.

- Insulation plates are first planted on special glue, for greater reliability they are fixed by means of umbrella dowels. Also, the insulating material is laid between the brackets, after making a cut in the right places. Mineral slabs are covered with a windproof membrane.

- The vertical rails are attached to the brackets with rivets or self-tapping screws. The ventilated gap should not be less than 40 mm, we are talking about the distance between the insulation and the upper surface of the guide.

- Horizontal guides are attached to the vertical guides, where the step must correspond to the size of the cladding. It is worth noting that it is quite permissible to set the profile first horizontally, and then vertically.

- Composite panels are fixed to the rails from the bottom up, fixing is done with screws or rivets. Here it is important to ensure that there are no foreign particles (inclusions) in the gap during installation.

- In the process of work, the location of both vertical and horizontal profiles is necessarily checked. Geometric inconsistencies will distort the entire facade.

Composite panel manufacturers

Although this material is widely represented on the modern market, only 4 companies have gained great popularity. Manufacturers offer a range of panels made of composite, high quality.

ALUCOBOND (Switzerland)

- This is the first company that introduced a new building material to the domestic consumer. Thanks to this, the brand of the factory has become a household name, today all panels are called alucobond, regardless of the manufacturer.

- AKP has been produced under this brand for almost half a century, which from the very beginning and still holds the bar in terms of the quality of products. Today the factories of the concern are located in Germany, the USA and Singapore.

- Besides the unsurpassed quality, the panels feature a wide range of colors. Thanks to the tireless development of technologists, it was possible to achieve the production of panels with shiny surfaces that imitate various natural materials.

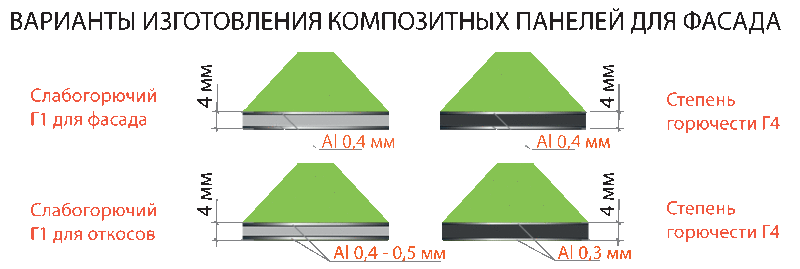

The products are offered with 2 types of filler (polyethylene and mineral). Also, panels are classified according to the type of flammability:

- flammability group G4;

- flammability group G1;

- flammability group G1, but with a higher resistance to flame.

REYNOBOND (multinational corporation)

- The European origin also gives the corresponding quality. Factories are located in the United States and France. Composite panels have high rigidity, physical and mechanical properties ensure the reliability and durability of facades.

- The products are painted in standard colors, but the Chameleon coating is also available. The length of the panels can be up to 6.5 m, which in turn allows you to reduce waste from cutting, thereby optimizing the costs of the set budget.

The consumer is offered 2 modifications of this building material:

- with PE filler (not flame retardant);

- with mineral filler Fr (fire-resistant version).

DIBOND (Germany)

- Multilayer panels are manufactured in Germany using modern technology. German quality speaks for itself. Due to its high technical characteristics, the products of this manufacturer are in the top 5.

- The improved properties of the material significantly expand its use, make it possible to expand the framework when developing projects. The correct shape and rigidity of the AIC greatly simplifies installation work

- The décor range, in addition to monochromatic colors, includes panels with glossy surfaces, chrome, gold, silver, and bronze plating. The originality of colors and textures will allow to embody non-standard solutions for finishing works of the facade, as well as to embody a progressive idea in the interior spaces.

ALPOLIC (Japan)

- The famous corporation Mitsubishi Group has been producing composite panels for 44 years. Products of 2 types are presented here: low-combustible and fire-resistant version of class A2. Such high performance has been achieved by using a filler made of mineralized and highly mineralized materials.

- The factories of the concern are located in Japan and the USA, additional warehouses are organized in Turkey and Holland.

- A feature of the ACP is the use of wear-resistant coatings for the front sides. In addition to resistance to aggressive influences, the coating also has excellent decorative properties.

- The manufacturer confirms the high quality of its products by providing a 20-year warranty. The actual service life of the panels, even in harsh conditions, is at least half a century.

One cannot fail to mention the appearance on the market of automatic transmissions of Chinese and Korean production. Oddly enough, but panels of this origin are not inferior to many products from eminent factories. But the difference in price for products with similar characteristics is quite significant. Among the companies are GOLDSTAR (China) and NTV (joint German-Chinese plant).

Manufacturers have managed to combine the advantages of old materials and the improved properties of modern developments in composite panels. The latest technologies allow you to quickly give facades an aesthetic appearance, at the same time improve the heat and sound insulation properties of the building.

Composition of composite panels

A composite aluminum panel (ACP) is a structure consisting of two sheets of aluminum alloy, between which a non-combustible mineral or plastic layer (polymer alloy) is pressed. The thickness of aluminum sheets is from 0.2 to 0.5 mm, and the total plate thickness is 2 to 6 mm. The polymer layer pressed between the plates can be a mixture of aluminum hydroxide and resin or low pressure polyethylene. In the first case, the fire resistance of the panels is high, in the second, it is low.

The aluminum sheets are coated. The side facing the inside of the building is covered with an anti-corrosion coating, and the outside side is covered with a special protective coating made of PVDF or polyester.

Polyester is considered an inexpensive coating, has a glossy finish and is suitable for all climates. It consists mainly of polyester paint, which has good color fastness. The material has a high level of flexibility, which allows you to make a product of any shape.

PVDF - This is a coating with a glossy surface, which contains polyvinylidene fluoride (70%) and acrylic (30%). The material has increased resistance to fading and the destructive effects of an aggressive environment. Possesses such properties as self-washing and high mechanical resistance. It is considered the most durable coating, practically does not fade. PVDF better tolerates the negative effects of sea salt, has a minimum bending radius.

The chemical-mechanical connection of composite aluminum panels makes them virtually homogeneous material, and special coatings reliably protect against abrasion, corrosion and acidic environment. The panels are resistant to impacts, various mechanical damage, external pressure.

Aluminum composite panels.

Basic requirements for outer shells of LFS on composite panels

Relative and ventilated facade systems must be durable, fire-resistant, resistant to mechanical stress, atmospheric corrosion and erosion, solar radiation, have a low specific weight, provide the required level of insulation of the load-bearing wall from heat loss, airborne and structural noise, as well as aesthetics the appearance of the house, building.In addition, preference is given to quickly deployable and repairable, economical in terms of investment of funds and labor NFS.

Most of the performance properties of the LFR depend on the outer shell, which directly identifies with the environment and, in fact, acts as a protective shield for the entire structure of the curtain facade. Based on simple logic, the responsibility for fulfilling these properties lies with the composite panel in full if it serves as an LFS shell, or partially in the case of a multi-layer cladding with a composite panel.

AKP manufacturing technology

Aluminum composite panels are produced in a continuous strip, which allows, at the request of the customer, to produce panels of various lengths.

The ACP manufacturing technology can be divided into several stages. First, the surface of the aluminum rolls is chemically cleaned and the paint is applied to them by continuous painting. The composite panel is then continuously laminated. The process consists in extruding a mineral filler and combining it at high temperature and using a special technology with aluminum sheets.

At the final stage, cassettes are milled from ACP sheets, from which subsequently the ventilated facade will be installed on the prepared substructure. ACP sheets are made in different sizes. A sheet with a size of 1220 x 2440 mm is considered standard.

Composite panel structure.

Panel types

In fact, there are many types of hinged facades, and they can be produced using various technologies.

They also differ in characteristics, but, despite all the differences, they are united by one goal - to improve the appearance of the building.

Consider some popular types, and then talk in more detail about the installation of composite panels.

Types of hinged facades:

- porcelain stoneware,

- glass,

- siding,

- aluminum,

- fiber cement,

- sandwich panel.

Advantages and Disadvantages of Aluminum Composite Panels

ACP panels are the main cladding material in ventilated facade systems. Using milling and bending, cassettes are made from them, which are hung on the façade substructure. The material has a number of advantages. Among the positive aspects of using composite on ventilated facades are the following:

- Ease. Depending on the thickness of the composite used, the weight of one square. meters can be 3 - 8 kg. With the same rigidity, the panel is 3.4 times lighter than steel sheet, and 1.6 times lighter than a solid aluminum alloy sheet.

- Strength and rigidity. Due to these qualities, large-size cassettes are made from composite for curtain facades, which allows mounting large areas in a minimum time.

- Flexibility. A flat sheet of aluminum composite can be easily transformed. Any curvilinear shape is obtained from it, you can make rounded or sharp corners.

- Increased sound insulation. Composite panels, unlike solid metal sheets, significantly improve the sound insulation of a building.

- Ease of processing. Composite allows you to form the most complex geometric structures directly on the object. The panels can be easily bent, drilled, cut and milled to create unusual architectural shapes.

- Resistant to UV radiation and aggressive environments.

- Corrosion resistance. High-quality anti-corrosion coatings for ACP panels increase the maintenance-free service life of ventilated composite facades by tens of years.

- Various colors. Different color options for the panels allow different elements of the facade architecture to be individually designed.

- Resistant to dirt. The panels are covered with PVDF material and polyester. This guarantees the preservation of the color of the facade under the influence of sulfur compounds, salt suspensions, atmospheric dust.It will not fade from exposure to sunlight. Plain water will easily clean the facade from aggressive deposits and settled dust.

- Durability. The warranty for ventilated facades with ACP panels is 25 years, but practice shows that high-quality ventilated composite facades can easily overcome a 50-year service life without major repairs.

Disadvantages:

- Fire safety. ACP panels are difficult to distinguish in appearance, which is used by unscrupulous sellers and contractors of construction projects. Trying to save money, they offer and use cheaper fireproof panels, which can lead to tragedy. Combustible panels should be used in the construction of buildings up to 10 meters high, which is often ignored.

- The coefficients of thermal expansion of aluminum and the inner polymer layer differ from each other, therefore, in low-quality ACPs, due to the low adhesion of the core to aluminum, bubble formation or complete delamination of the panels is possible on the facade elements.

- Low maintainability. If the composite panels are damaged, it is extremely difficult to repair them, and when replacing the cassette, you have to change the adjacent ones.

- High price. One sq. a meter of a turnkey composite ventilated facade made of a composite of the G4 flammability group (highly combustible material) costs from 3800 rubles, while a square of a ventilated facade made of porcelain stoneware can cost 3200 rubles.

From the above, it becomes clear that the advantages of ventilated facades made of composite clearly outweigh its individual disadvantages, especially since they are determined mainly by human factors.

Installation of composite suspended ventilation facades.

Porcelain stoneware slabs and panels

Porcelain stoneware is a finishing material of artificial origin. It is made from a special powder by the strongest pressure, after which it is fired at temperatures above 1200 ° C.

This allows to give excellent characteristics to porcelain stoneware slabs:

- High strength ensuring safety even under heavy loads.

- They are presented in a rich assortment - the plates differ in shape, size, texture and color, which allows you to choose the best option.

- They have high frost resistance, which is especially important in the difficult climate of our country.

- They are not afraid of high humidity.

With all these advantages, porcelain stoneware panels have only one drawback, but a very important one - they are extremely expensive. This material is one of the most expensive materials used in the construction of curtain walls. But the significant costs are partly offset by the significant service life. More about porcelain stoneware?

Features of installation of composite ventilation facades

Today, aluminum composite panels are presented on the market by many foreign and domestic manufacturers, such as ALUCOBOND (Germany), REYNOBOND (France), ALPOLIC (Japan), GOLDSTAR and ALUCOBEST (China), as well as domestic brands ALCOTEK, ALUCOM, KRASPAN, etc. for their installation, supporting structures made of aluminum alloy, stainless and galvanized steel are used. Most of these systems are certified, have similar characteristics, and are adapted for mounting automatic transmission cassettes.

Facade design for facing with composite panels.

Aluminum composite panels have a variety of options. They are used for revetting columns, making external suspended ceilings with different sharpness, making decorative cornices of various shapes, capitals, belts, etc. The light weight of the composite allows any fresh idea of the designer to be brought to life.

The technology for assembling ventilated composite facades is as follows:

- From top to bottom they mark the facade using a laser, measuring sticks and a tape measure;

- Do the mounting of brackets, consisting of a fixed carrier and an adjustable counterpart.A dowel with a heat-insulating gasket is inserted into the groove of the bracket, placed in a hole drilled in the wall, and fixed;

- Install thermal insulation by attaching insulation plates and a protective film to the wall with special dowels;

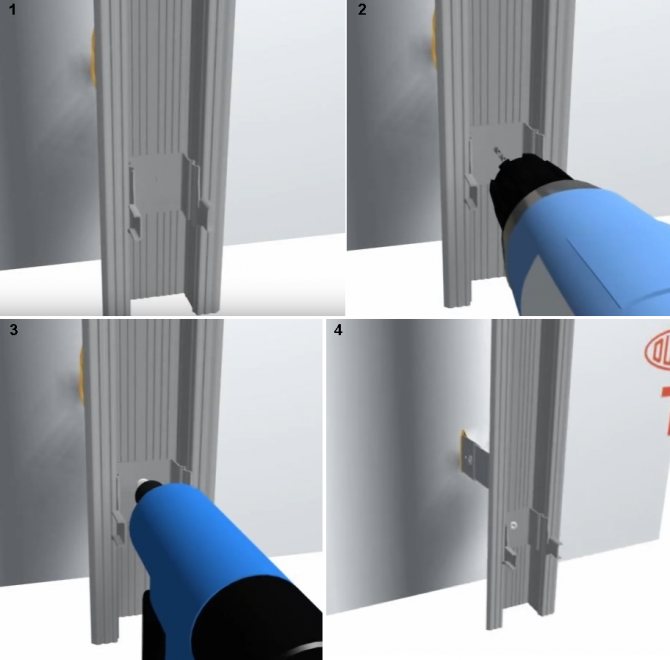

- Self-tapping screws and rivets make the installation of bearing guides of the ventilated facade substructure;

- Prepared composite panels are attached to the frame.

Aluminum composite panels on the entrance canopy of an office building.

There are several ways to fix ACP panels:

- Concealed fixing with prefabricated cassettes. Although the most common method, even good cutting optimization results in up to 40% waste. This is due to a mismatch in the direction of coloring on the finished cassettes, which is clearly visible during installation;

- Open fastening of both individual ACP sheets and cassettes. The disadvantage of this method is that up to a height of 10 - 12 m, rivets or clamping strips for attaching the panels to the ventilation façade subsystem are visible. Advantages - savings on material cutting and the use of large-sized composite elements;

- Concealed attachment with a special adhesive. The method was not widely used due to fire safety restrictions. Other disadvantages are the high price and lack of certification.

A palette of colors for any design solution.

The advantage of composite materials is that they can be processed not only in the factory, but also on site. ACP panels can be processed in a variety of ways:

- to make flaring, getting a different or the same bending radius of the sheet;

- you can mill or drill sheets of ACP, cut out different shapes, which is often used in outdoor advertising;

- panels are bent at any angle with a perfectly straight fold line;

- panels with any degree of processing fit perfectly together.

Features of the creation of materials used in composite panels

Simplified, all composites in the construction industry are mixtures, which are divided into 2 large groups according to their phase (aggregate) state:

- with an established or artificially created porous structure.

With a porous structure, it can be:

- a filler, which is deeply impregnated with a liquid binder with physicochemical reactions between them, and then formed into a multilayer structure to obtain the required package of properties. A typical example is laminated-sheet composites such as plywood, where peeled wood veneer is impregnated with resins and glued into sheets;

- a matrix, into the pores of which a liquid filler is introduced, and physicochemical reactions between it and the matrix determine new properties in the composite. Simple examples are water-repellent or fire-resistant materials deeply impregnated with a hydrophobic filler and fire retardants, respectively; conglomerates obtained by mixing a filler and a binder matrix.

The most famous conglomerates are concrete and reinforced concrete, polymer concrete, aerated concrete, cement-fiber, cement-bonded, wood-polymer materials, foamed polymers, etc.

Those. Both in deep impregnation and in conglomerate structures, the bonds between the matrix and the filler are distributed "over the mass" of the composites, which determines their main difference from laminated materials, "bonded" to each other only due to the adhesion of the thinnest layer of binder along the layer separation boundary. Therefore, composites are more stable under loads, changes in temperature and humidity conditions of operation, durable, and they are recommended as a priority in choosing a material for construction.

However, today trading companies, and often manufacturers, offer to buy a composite panel, which is de facto not a composite. As a rule, these are metal sheets with multi-layer protective and decorative coatings, three-layer "sandwich" panels, package solutions in the form of several bonded layers in a metal case, etc.Of course, pseudo-composites have their own advantages and have found application in construction, however, with a similar intended use and the same requirements for operational properties, it is better to choose a real composite panel.