Mineral wool for wall insulation and its dimensions: 11 options

When choosing a heater, carefully study the characteristics of mineral wool so that it fits all requirements You can insulate a house yourself. This can be done easily and simply if you decide on the type of heat-insulating material and familiarize yourself with the nuances for laying it. When choosing a heater, special attention should be paid to the properties of the material. Minvata dimensions are an important issue that must be resolved before laying the material. Mineral wool of various lengths, thicknesses and widths is suitable for a specific type of work.

Standard sizes of insulation

The leader in the market of thermal insulation materials is. It is engaged in the production of plates, mats, rolls and cylinders. Varieties of mineral wool are used to insulate a specific type of structure. To insulate the frame structure, mineral wool is usually used, in which the thickness is 46-213 mm, the width is presented in the size from 566 to 612 mm, and the length is 1175 mm.

For thermal insulation of walls, roofs, facades and other parts of buildings, as well as for insulation of equipment, mineral wool with a thickness of 50 to 150 mm is used

For high-quality sound insulation of multilayer walls, mineral wool of the following dimensions is used: thickness - from 51-101 to 205 mm, width - from 613 mm, length - from 1175 mm.

Flat roofs are usually insulated with wool, which has the following dimensions: thickness - from 55 to 175 mm. Width - from 1195 mm, length - from 1280 mm. All sizes of mineral wool can be found in special catalogs. The most common way to insulate outside and inside is to lay mineral wool mats on frame structures.

Cotton wool sizes:

- ISOVER М34 - 40 mm by 200 mm, 610 mm by 1220 mm. 3000 mm by 9000 mm;

- Frame-M37 - 42 mm by 203 mm, 610 mm by 1220 mm, 3000 mm by 22000 mm;

- ISOVER M40 - 50 mm by 200 mm, 610 mm by 1220 mm. 3000 mm by 9000 mm;

- Frame-M40 - 50 mm by 200 mm, 50 mm by 1200 mm, 7000 mm by 14000 mm.

To insulate the piping, mineral wool cylinders must be used. Usually, Knauf mineral wool is used for insulating roofs, facades, walls and other parts of the building, which is presented in the following variation: thickness - 55-155 mm, while its length and width may vary. The latter characteristics should be selected based on ease of use.

Mineral wool for insulation of the facade, walls outside and inside the house

Ursa Geo Light insulation in a roll

Roll insulation Ursa Geo Light is produced on the basis of fiberglass mineral wool and belongs to the category of universal thermal insulation materials. It can be used for thermal insulation of walls, roofs, attic floors and floors. This insulation, according to domestic standards, belongs to the category of completely non-combustible materials, therefore it recommended for thermal insulation of buildings with strict fire safety requirements.

Insulation Ursa Geo Light is produced using a technology that does not involve the use of a large number of additives and plasticizers in order to give the final product the necessary characteristics. Studies show that Ursa Geo mineral wool contains 10-12 times less volatile substances than European safety standards require. Price - from 550 rubles per roll.

Pros:

- minimum coefficient of thermal conductivity;

- minimal water absorption;

- excellent sound insulation properties;

- resistance to fungal attack;

- environmental friendliness;

- increased fire resistance;

- chemical resistance;

- long service life.

There are no downsides.

Mineral wool in ISOVER rolls Isover Classic-Twin 50 mm thick

Isover Classic-Twin-50 is a roll insulation made of mineral wool, made on the basis of high-quality fiberglass, obtained using the patented TEL fiber-forming technology from natural materials. The insulation has a low thermal conductivity and fairly high sound insulation characteristics.... Its use provides a reduction in noise levels of up to twenty percent.

Isover Classic belongs to non-combustible materials, therefore its use as a heat insulator also provides structures with additional protection against fire. Isover Classic-Twin-50 can be used in the form of a mat with a thickness of 50 mm or 100 mm depending on the thickness of the insulation required for the project.

Insulation is recommended for insulating ceilings over cold basements, suspended ceilings, interfloor ceilings, cold attic ceilings. Due to the elasticity, resilience and one hundred percent restoration of the declared dimensions, the laid insulation does not require additional fastening. It fits as tightly as possible to the base and to the frame, leaving no gaps or gaps. Price - from 650 rubles per package.

Pros:

- perfectly retains heat;

- can be used as a sound insulator;

- has good elasticity, therefore it is securely held in the frame without additional fasteners;

- the insulation is safe for the environment and human health.

Mineral wool for Ecorol insulation. TR 044 Knauf density 10 kg / m3

This material is produced in the form of a roll of insulation. It is made on the basis of mineral wool obtained using the modern ECOSE technology. Due to this technology the insulation contains only natural ingredientsand acrylic and phenol-formaldehyde resins are absent. Thanks to this composition, Ecorol is completely safe for human health.

Mineral wool insulation Ecorol is used for internal and external thermal insulation of building envelopes of buildings and structures of all types, as well as for external thermal insulation of pipelines and industrial equipment for various purposes. Environmental friendliness, ease of installation, excellent performance make Ecorol an ideal insulating material. Price - from 1500 rubles per package.

Pros:

- low coefficient of thermal conductivity. Properly carried out thermal insulation of the building with the help of this insulation will reduce heating costs by half;

- high level of sound absorption;

- good fire resistance. This insulation belongs to the category of non-combustible materials;

- good biostability. Mineral wool insulation cannot become food for rodents or a breeding ground for fungi and mold;

- simple installation of insulation.

Of the minuses, a somewhat overpriced can be noted.

Minvata in rolls: types and sizes

There is a wide variety of all kinds of innovative thermal insulation materials on the modern market. This is a liquid thermal insulator, polyurethane foam, and silica mats. However, mineral wool is still the most popular of them.

Today thermal insulation with mineral wool is one of the most demanded construction services.

Mineral wool has a low thermal conductivity, a wide temperature range, high fire safety and absolute environmental friendliness.

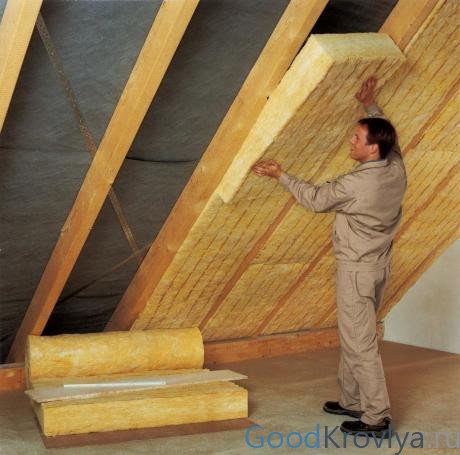

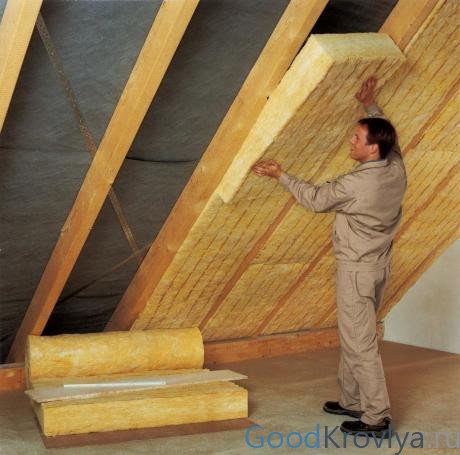

Rock wool rolls are commonly used to insulate horizontal surfaces. This installation involves careful handling and avoiding too much stress on the surface. With the help of rolls, overlaps between floors, floors, attics, roofs with a slight slope are insulated.They are also used to insulate pipes, mantels and home stoves.

Roll sizes (width, thickness, length in mm):

- Ursa M-11 - 1150 x 53 x 9000;

- Isover Classic - 1220 x 50 x 8200;

- Isover Sauna - 1200 x 50 x 8200;

- Heat Knauf Dacha - 1220 to 50 to 7380.

Bulk mineral wool is inconvenient to roll up, so usually its thickness does not exceed 50 mm. Mineral wool in rolls can be used to insulate rooms with a large area, in which the surface is subjected to significant stress. For laying rolls, logs, rafters and other building elements are usually used.

Properties and advantages of mineral wool slabs

Factors such as thermal conductivity, vapor permeability, moisture resistance and density are decisive in the choice of material for a particular structure. Mineral wool insulation has the best performance among thermal insulation for roofs, attics, attics. At the same time, it should be noted that their variety allows you to design the surface as budget and accurately as possible, in accordance with the requirements and needs of the building owners.

Mineral wool slabs

Before buying a heat insulator, you need to understand its main types, applications and design features.

The indisputable advantages of heaters ↑

The advantages of using mineral wool slabs include:

- durability, since their service life is at least 50 years;

- excellent performance of noise and heat protection;

- high vapor permeability;

- affordable cost;

- ease of marking, cutting, laying;

- low specific weight, allowing to remove the load on the overall structure;

- powerful indicators of density and strength;

- fire and biological resistance;

- unattractiveness for arranging nests with rodents and other pests.

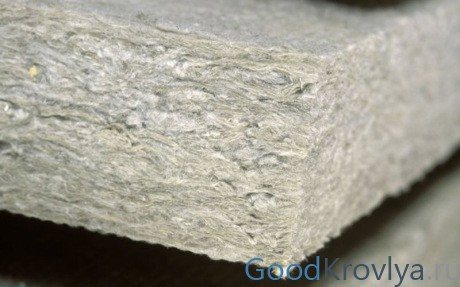

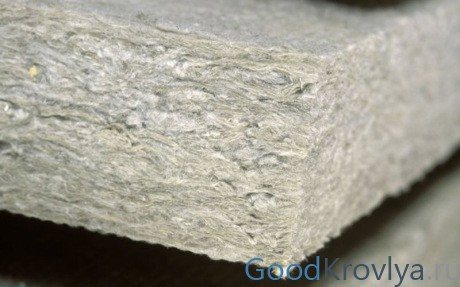

The fibrous structure allows the boards to minimize heat loss

Indicators of thermal conductivity and fire resistance ↑

Protection of the ceiling space from the penetration of cold is the main purpose of the blocks. The permissible value of their thermal conductivity is regulated by GOST 4640-2011. Average values range from 0.032 to 0.039 W / (m ° C), which is several times superior to many other insulators in terms of the ability to retain heat. This property is due to the peculiarities of the porous, fibrous structure of the material.

The incombustibility of mineral slab insulation is one of the main advantages over other insulators. A short circuit in the wiring or other common causes of ignition of the under-roof space is often aggravated by the use of fire hazardous materials.

Comparison with Styrofoam

The use of cotton blocks is permissible when covering surfaces, the heating of which reaches + 400 ° and at an air temperature of up to + 750 °. Basalt mineral slabs can withstand up to two hours of exposure to a 1000 ° directed flame. However, this property is applicable only to those products that do not contain combustible synthetic fillers.

Permissible density loads and coefficients of moisture permeability and vapor permeability ↑

The distribution load capacity is determined by the density of the mineral wool boards. The higher it is, the more resistant the blocks are to deformation stresses. This indicator for roofing mats ranges from 125 to 200 kg / m3 and characterizes the purpose of the material for a particular structure, in order to maintain its low thermal conductivity and durability.

When purchasing thermal insulation boards made of mineral wool, you should pay attention to their resistance to moisture. The material easily absorbs water, as a result of which it reduces its thermal insulation capacity. To increase resistance to the effects of a liquid medium, manufacturers impregnate the material with water repellents.The level of water resistance is determined by GOST standards, the average should be no more than 4-7 pH.

Thermal insulation scheme with mineral wool plates and a moisture-proof membrane

In comparison with other insulators, mineral wool insulation has the highest vapor permeability - 480 * 10-6 g / (m * hour * Pa). This property allows the roof to "breathe" freely when using blocks of stone, basalt or glass wool, even with a significant thickness of the material. As a result, the roofing structure remains dry, fully protecting the structure from mold, rot, and fungus.

Suitable sizes of mineral wool in slabs

The mass of advantages of mineral wool contributes to its widespread use in the construction process. To accurately calculate the amount of material needed, you need to be informed about the dimensions of the slabs. If, when choosing heat-insulating materials, you need to know the number of squares, then when choosing cotton wool you need to pay attention to the dimensions of the plates.

Mineral wool slabs are used for exterior and interior construction work.

Standard slabs have the following dimensions: 1000 x 500 mm. In each case, you can choose the appropriate thickness of the slabs. The number of slabs is determined by the size of the finished building.

Slab sizes:

- Isover Frame P-32 - 1170x610, while the thickness can vary from 40 to 150 mm.

- Isover Frame P-34 - 1170x565, while the thickness can vary from 40 to 200 mm.

- Rigid plate Izover - 1550x1180, while the minimum thickness is 30 mm.

You can calculate the required number of plates already in the hardware store, having previously measured the area of the room. You can calculate the number of mineral wool sheets in advance. Having previously found out how many sheets are in one package or bundle. If the sheets do not fit, they can be cut neatly. Scraps of cotton wool can be used to insulate cracks and joints. The density of the sheets is selected depending on the required quality of thermal insulation.

Advantages of fiber insulation

Mineral wool slabs are characterized by

:

- low specific gravity - insulation with this material will not overload the structure;

- high strength (this indicator depends on the density of the slab);

- fire resistance;

- biostability (the material is resistant to decay, unattractive to pests and rodents);

- durability (the operational period, subject to correct installation, exceeds 50 years).

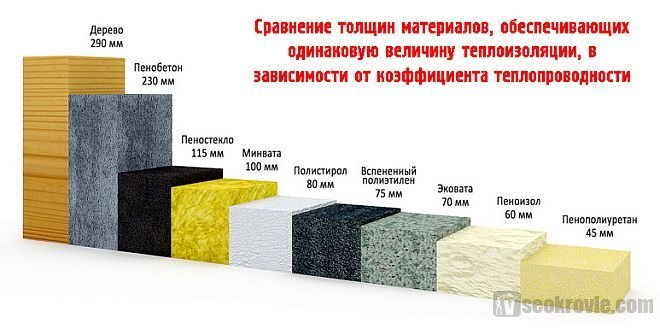

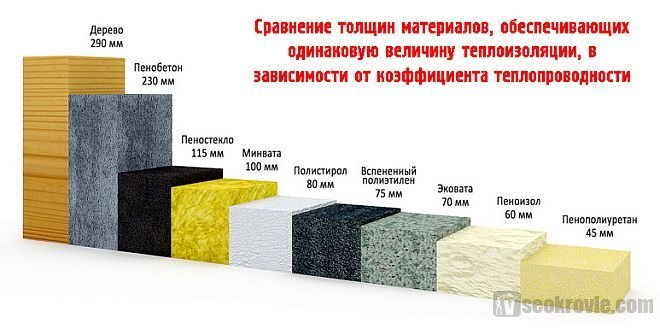

Comparison of thicknesses of materials for thermal insulation

High technical characteristics make the material the market leader in thermal insulators

.

Thermal conductivity

Mineral wool slab insulation due to its fibrous structure provides good protection against heat leakage. Thermal conductivity indices depend on the type and purpose of the slabs - they are in the range of 0.036-0.042 W / (m • K) at temperatures from 10 ° C to 25 ° C in accordance with GOST 4640-2011.

Fire resistance

Mineral wool belongs to materials with a high degree of fire resistance - such insulation does not ignite from accidental sparks and does not contribute to the spread of fire. Fiber boards withstand contact with surfaces heated to + 400 ° C and air heated to 750 ° C.

Non-combustible basalt fiber slabs withstand contact with an open flame (1000 ° C) for two hours, provided that the material is made without the use of fillers from combustible synthetic substances.

Density

The higher the density of a block, the stiffer it is and the better it withstands deformation stresses under load. The following types of mineral wool boards are distinguished

:

- soft plate (40-55 kg / m3, grade PM-40 and PM-50);

- semi-rigid plate (60-90 kg / m3, grade PP-60, PP-70, PP-80);

- rigid slabs (100-150 kg / m3, grade ПЖ-100, ПЖ-120, ПЖ-140);

- plates of increased rigidity (160-210 kg / m3, grade ППЖ-160, ППЖ-180, ППЖ-200);

- solid plate (220-300 kg / m3, grade PT-220, PT-250, PT-300).

Laying slabs with your own hands in the attic

Moisture proof

Mineral wool slabs are prone to moisture build-up. At the same time, the strength and other properties of the fiber do not suffer, but the replacement of air with moisture in the structure of the material leads to a sharp increase in the thermal conductivity coefficient, that is, to a deterioration in operational properties. The use of certain fillers makes it possible to hydrophobize the material. According to GOST, the level of water resistance of the insulation should be on average 4-7 pH.

Vapor permeability

Mineral wool is characterized by the highest vapor permeability in comparison with heat insulators from other materials. The indicator is 480 * 10-6 g / (m * hour * Pa). In insulation structures, where an impervious vapor barrier is not provided (for example, external insulation of walls under plaster), or a gas-permeable membrane is used, insulation with mineral wool makes it possible to maintain gas exchange through the structures, which ensures a favorable microclimate in the room.

Using a vapor barrier to protect against moisture

Features of mineral wool for insulation

Modern construction cannot be imagined without the use of mineral wool as an insulating material. It has a wide range of uses, which makes it particularly popular with builders. The most common use of mineral wool is to insulate building structures.

Manufacturers produce products of different types and purposes: plates, mats, rolls, cylinders

Usually, roofs, floors, walls and ceilings are insulated with mineral wool: the size of the materials depends on the area of the room and the type of insulation.

Mineral wool is often used to lay the middle layer. At the same time, loads on the insulation of various types of surfaces in any buildings, houses and structures are avoided. Vertical laying of mineral wool is used to insulate facades and walls. The inclined and horizontal laying method is chosen for insulation of the ceiling, roof and roof.

What is mineral wool used for:

- For equipping ventilated façade systems and for installation in curtain walls.

- Mineral wool is used to insulate building sandwiches of panels and blocks, which are used to build multi-layer walls with different types of cladding. They can be metal, concrete, particle board, fiberboard and OSB.

- To insulate various industrial structures, equipment and pipelines.

Related article: Wall mounted spice rack

Modern manufacturers offer consumers different types of general construction insulation. Cotton wool can be presented as a lightweight heat and sound insulating material that does not have a coating. Another option is cotton wool with one-way caching using aluminum foil. Cotton wool can be equipped with special sound-absorbing material.

Mineral wool insulation for the roof: 3 types to choose from

Mineral insulation for roofs and roofs, the price per m2 of which is available to both a private owner and a construction organization, is divided into three types: basalt wool, fiberglass and slag wool.

-

Basalt (stone).This is an environmentally friendly insulation made from natural raw materials - basalt rocks. Differs in a long service life, fire safety, durability, stability of parameters, biostability, inertness, hydrophobicity, breathable properties.

- Staple fiberglass mineral wool

produced on the basis of quartz sand and glass breakage. It has an excellent level of heat and sound insulation, light weight, convenient dimensions and low cost in Moscow per m2 and cubic meter, which is up to 3 times lower than the basalt analogue.

- Slag

- budget material made from metallurgical waste. Differs in toxicity, instability to water, aggressive media and vibrations. The only advantages of the insulator are incombustibility, good thermal insulation and low price.It is highly discouraged to use such material for insulating living quarters.

Attention!

If you are offered to order stone wool for a roof at a fantastically low cost per m2, there is a 99% chance that they are trying to slip dyed fiberglass or a harmful slag wool on you. Purchase materials from an authorized dealer and ask for a quality certificate.

Mineral wool. Types, properties. (video)

The use of basalt insulation is a fairly popular way of insulating premises. The service life of mineral wool is very high, so industrial buildings and residential buildings are insulated with it. Construction foil and stone wool is designed for different types of insulation. The amount of materials used depends on the area of the room to be insulated. Cotton wool is used to insulate walls, ceilings, floors and other surfaces. For each of them, it is better to use cotton of a certain quality and composition.

Minplate: types and technical parameters

Mineral fiber mats vary in technical performance as it depends on the following factors

:

- used raw materials;

- arrangement of fibers;

- density.

When choosing a material for insulation, it is necessary to take into account the scope of use of a heat insulator with certain properties

.

Varieties of slab insulation

There are three types of thermal insulation mats - glass wool, slag wool and stone wool.

Glass wool is the cheapest insulation option. For manufacturing, the same components are used as for glass - dolomite, limestone, borax, sand, soda. The fiber is 5-15 microns thick and 15-50 mm long. Operating temperature range from -60 ° С to +450 ° С. Glass wool cakes over time and its heat-shielding properties decrease. During installation, fragile fibers break easily, therefore, during operation, it is imperative to use protective equipment

.

It is also important to properly close the insulation with a vapor barrier so that glass dust does not penetrate into the room.

.

Slag wool is characterized by low environmental safety, since blast-furnace slag serves as a raw material for its production. For this reason, the material is not recommended for indoor insulation of residential premises. Fiber thickness is 4-12 microns, length - 16 mm. Slag wool easily absorbs water, therefore it is not suitable for external insulation of structures

.

Roll of slag

Stone wool (basalt insulation) is the most effective and safe heat insulator, since it practically does not crumble during the installation process, its particles do not enter the air as a suspension. Stone fiber material is durable and fire-resistant, environmentally friendly if phenol-formaldehyde resin is not used in its manufacture. But the product has a high cost.

According to the structure of fibrousness, the minelite is

:

- with a chaotic arrangement of fibers;

- with a lamellar (perpendicular) arrangement of fibers.

With a lamellar arrangement, the breaking strength of the material is higher.

Features of the

The main property of any heat-insulating material is its thermal conductivity. In order to achieve the optimal temperature in the house, it is necessary either to reflect heat from the surface, or to prevent transmission along the wall of the building. According to this criterion, all heaters are divided into two categories:

- preventing type - in these products the thermal conductivity is very low;

- reflective type - here the level of infrared radiation is reduced several times.

Dimensions of mineral wool: release form and dimensions

The volume of production of the Russian mineral wool market is steadily increasing. The highest figures for 2013 are admirable, with a 52.5% increase over 2009.

The share of use of mineral wool in construction has increased from 46% in 2010 to 60% by now. Starting from mid-2017 and in subsequent years, growth in the production of mineral wool products is forecasted.

This success is attributed to many factors.This is an increase in apartment building, and the growing popularity of suburban housing, and an increase in industry in general. However, an important factor is a thoughtful study of the needs of the construction market by product manufacturers.

Knowledge of the required technical and operational characteristics, dimensions and dimensions of mineral wool, understanding what a builder needs to build quality housing, allows the manufacturer to produce the products that will be in demand.

How the purpose of mineral wool affects its size

Insulation is necessary for any building in order to:

- reduce heat loss in winter;

- protect from overheating in summer;

- to preserve the elements of the supporting structure of the building from the effects of negative environmental factors;

- increase the service life of the structure.

These tasks are quite within the power of inorganic insulation. From a solid list of materials of this kind, mineral wool is in special demand. Mineral wool has long been successfully used in construction.

Related article: DIY wall shelf ideas

By giving preference to this type of insulation, the consumer receives the following advantages:

- thermal conductivity index 0.035 W / mk, one of the best;

- quality dielectric properties;

- high rates of vapor permeability;

- the best parameters of fire resistance;

- low hygroscopicity;

- high resistance to aggressive environments.

This material can be used for wall insulation, both inside and outside. It is used for roofs, attics and basements, and interior partitions. Its dimensions are of the same standards as the distance between the guides where the mineral wool is laid. If there are violations of standards in construction, it becomes necessary to adjust the size of the insulation.

Basalt mineral wool

Basalt mineral wool GreenGuard UNIVERSAL TechnoNIKOL facade

Basalt wool GreenGuard UNIVERSAL is a unique new thermal insulation material from the company TECHNONICOL, which consists entirely of natural ingredients... This insulation is produced using the innovative GEOlife technology. The main advantage of this technology is the absence of chemical compounds in the composition of the insulation that are dangerous to human health and the environment. Insulation meets the highest environmental safety standards.

GreenGuard UNIVERSAL is a versatile insulation material. It can be used for thermal insulation of vertical structures (walls, partitions, facades lined with siding and other materials), horizontal structures (cold attic floors, log floors), as well as sloped roofs, including heated mansards. Price - from 460 rubles per package.

Pros:

- low thermal conductivity values ensure high efficiency of the heating system and air conditioning of the building;

- the strength and elasticity of the insulation allows you to install it in different positions. Throughout the entire service life, the material will retain its original characteristics without swelling or shrinking;

- good fire resistance. The material is non-combustible and becomes a significant fire barrier during a fire;

- environmental friendliness.

No significant drawbacks were found.

Mineral wool basalt stone TIB water-repellent

TIB is a stitched-through mats made of super-thin basalt staple fiber without lining. Basalt fiber does not absorb moisture well, but pierced TIB mats are additionally impregnated with a water-repellent compoundtherefore they have high vapor permeability and do not accumulate condensate.

Insulation materials TIB can be used to insulate objects of any kind and type.TIB broaching mats are also used for thermal insulation of pipelines, various industrial, power, ship equipment and nuclear power plants. Basalt heaters are not afraid of fire, rain and severe frost. Price - from 2400 rubles per cubic meter.

Pros:

- excellent thermal insulation properties. In terms of thermal insulation, a 100 mm thick basalt mat is able to replace a wall made of silicate bricks with a thickness of 1400 mm;

- high fire resistance. Basalt mats do not burn. They are able to withstand temperatures up to 1000 degrees without changing their structure;

- the insulation does not absorb moisture, but allows it to pass through itself. Therefore, thermal insulation made of basalt wool helps to maintain the required level of humidity in the room, and is not susceptible to damage by fungi and other microorganisms;

- durability and reliability. Basalt wool has a high tensile and compressive strength, so pierced mats are capable of performing their functions for a hundred years;

- chemical resistance;

- environmental friendliness.

An overview of the types of mineral wool and tips from the pros for choosing it are shown in the video:

Application

Insulation is produced in rolls or slabs. For example, rolls are best for roof insulation, slabs are good for walls.

There are also mats that are necessary for floor insulation.

Often, stone wool is produced in the form of granules, as well as in the form of cords and bundles. These forms of packaging are used in industrial construction.

For effective house insulation, the following thickness of mineral wool is used:

- outer wall - 100mm;

- ceiling, attic - 150 mm;

- roof and attic - 300 mm.

The width of the mineral wool in rolls and slabs is the same - from 565 cm to 620 cm, length - from 1117 cm to 1380 cm. The data are given for the example of isover mineral wool.

Another similar insulation, for example ursa, is also versatile in use. Ursa is produced in slabs and mats with a thickness of 30mm to 100mm, a length from 1250 to 10000mm, a width of 610mm-1200mm.

As you can see, the differences in dimensions of different brands are insignificant. The price is also approximately equal.

And yet, specialists at different sites use different brands of mineral wool insulation.

No matter how similar different types of insulation are in terms of their technical and operational characteristics, dimensions and other indicators, the advice of a professional on their use will be extremely useful!

Mineral wool which is better

Mineral wool is an effective insulation material, without which no construction can do today. This material is safe for humans and the environment. It does not burn, does not emit harmful substances and has excellent performance in noise and heat insulation.

Types of mineral wool for insulation

Mineral wool, depending on the composition, is divided into:

- glass wool;

- basalt or stone wool.

Glass wool is essentially foamed glass as it is made from silica sand and glass waste. Its main advantages are elasticity and vibration resistance. They are due to the large length and thickness of the fibers. Exactly this allows you to squeeze and tilt rolls and mats of mineral wool almost as you like - then they will still straighten out.

Basalt wool is made, as the name implies, from basalt and similar rocks. Basalt mineral wool keeps warm well and is an absolutely natural material. It consists of short, twisted fibers, which make it an excellent sound insulator. Facade basalt mineral wool is quite dense, therefore it can be used under load. It practically does not shrink... Its dimensions remain unchanged at any temperature and at any time of the year.

Mineral wool is available in rolls, mats and slabs. Plates of mineral wool 1000 * 600 * 100 mm and other sizes are usually pasted over with aluminum foil, fiberglass or non-woven material during the production process. Each of these options has a specific purpose and is used for a well-defined situation.

For example, 0.24 m3 mineral wool slabs in a package, covered with fiberglass, are used in the installation of ventilated curtain walls in order to obtain maximum wind protection as a result. Mineral wool for insulation in a roll, covered with foil, is excellent for insulation of horizontal surfaces.

Parameters of mineral wool for insulation of walls, ceilings, roofs

Each type of insulation has its own scope of application, where it performs its functions as efficiently as possible. Thermal insulation of a building of excellent quality can be created only if each structural element is insulated with an appropriate insulation. Fiberglass insulation is preferable for internal works, and basalt for external ones.

Mineral wool slabs and mats with a thickness of 50 mm are best suited for thermal insulation of pitched roofs, mats and slabs of high density stone wool - for flat roofs. For facades of the so-called "wet" type, water-repellent basalt mineral wool is used, and for hinged ventilated facades - compressible mineral wool mats.

Our review will consider the products of the following manufacturers:

- Izovol - a domestic company that develops and manufactures thermal insulation materials that are unique in their composition and manufacturing technologies. The products of this manufacturer are used in the construction of new buildings and the reconstruction of old structures, both civil and industrial;

- ROCKWOOL - the world leader in the production of sound and heat insulation materials from stone wool, designed for buildings and structures of all types. The products of this company are not dangerous for the ecology of our planet and contribute to solving the problem of global climate change;

- TechnoNIKOL Is one of the largest international manufacturers of efficient and reliable building materials. This company offers the consumer the latest technologies, in which world experience is combined with the developments of its own research centers;

- Ursa Is a German company that has been present on the building materials market for over a hundred years. Today it is part of the Uralita Grout concern and produces high quality thermal insulation materials;

- ISOVER Is a French manufacturer of heat and sound insulation materials based on glass and stone fibers. The products of this brand are produced in more than forty factories around the world;

- Knauf Is a German manufacturer whose mineral wool is famous for its high quality and absolute safety for human health. This is due to the fact that the composition of the materials of this brand does not include phenol-formaldehyde resins containing harmful substances;

- Izomin Is a Russian manufacturer that specializes in the production of heat-insulating materials based on basalt fiber. All heaters from this manufacturer contain water-repellent additives and are classified as non-combustible materials. They are of high quality and attractive prices.

Let's calculate the required amount of insulation

It is useful to consult with a professional on any questions. For example, which wool is better for a particular object - stone wool, the one in which basalt rocks are used, the so-called basalt wool, or another.

Will you need foil wool, what mineral wool materials will be needed in general, and is it possible to optimize costs.

For example, let's calculate the required amount of insulation for the roof.

Stage one:

- we calculate the roof area;

- add the area of attic walls and partitions;

- add 3% to the total.

Stage two. We choose the insulation, the roll area of which most closely matches the area of the insulation. We consider the material and sheet, and in rolls, and in mats.

Stage three. We divide the roof area by the area of the insulation squares and multiply the unplanned number of layers. The amount received will determine how many sheets, rolls to buy, how much panel material will be required in pieces.

In order not to waste money on the insulation bleed, carefully calculate the size of the room, carefully analyze everything that is written on the packaging of this or that insulation. However, even if the minelite or roll tape was cut, there is nothing wrong. Waste will come in handy for insulating house buildings.

Mineral wool is considered almost the best insulation in the country's construction market. The sizes of different brands of these products are almost the same.

The dimensions are dictated by building codes, this standard approach optimizes the construction process in many ways.

When choosing a heater, it is important to take into account technical characteristics, professional advice on the purpose of a particular material, length, width, thickness and other important indicators.

Density is a significant characteristic. Usually it is 11-350 kg / m2 kW. The highest density cotton wool is used for internal partitions and has dimensions similar to other types of insulation.

Watch the video, which explains the nuances of counting and laying insulation:

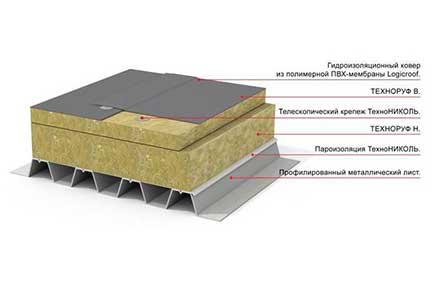

TechnoNIKOL for roofing

TechnoNIKOL for roofing

The use of roof insulation carries two main tasks - to prevent the penetration of cold air in the cold season, and to prevent excessive heating of the premises from the sun in summer. Materials successfully cope with this task. TechnoNICOL for roofing... The widest range of TechnoNICOL heat-insulating building materials for roof insulation will allow you to make a choice in favor of the most optimal option. But when choosing, it is necessary to take into account that insulation materials that meet certain requirements are used for various types of roofs. So, when installing thermal insulation for flat roofs of industrial or civil buildings from mastic or fused materials, one type of thermal insulation is used, and for the insulation of a pitched roof of a country house, it is possible to use a different type. Another type of roofing is a sandwich panel roof, which is performed mainly on rapidly erected buildings. For the manufacture of these panels, you will need insulation with completely different characteristics.

|

|

Necessary thickness of roof insulation TechnoNICOL determined by calculation. In this case, several factors are taken into account, where the main ones are the thermal conductivity of a single insulation and the climatic zone of construction.

Heaters for pitched roofs

Carry out insulation with the above materials TechnoNICOL for roof installation, having a pitched system is quite acceptable, but impractical. The insulation located between the roof rafters does not take on any external loads, except for its own weight, which can be neglected. The main task during the installation of this thermal insulation is a tight fit to the rafters at the design thickness and the smallest number of joints. In this regard, the most suitable insulation materials TechnoNICOL there will be rolled varieties with a low density. For example, the heat-insulating material "Teploroll", which is extremely lightweight due to its low density. This is an absolutely non-combustible building material, which is very important when constructing a pitched roof, where all the supporting structures are wooden.

Thanks to a large selection of geometric dimensions, you can easily choose the right option to reduce waste and multiple sections. From insulation made in the form of separate plates, you can about. This is an absolutely universal insulation for any unloaded surfaces. Very lightweight and easy to install.It is advisable to lay in several layers to achieve the required thickness of insulation, without overlapping joints.

Thermal insulation roofing materials for flat roofs

Certain types of external loads act on flat roofs. The main factor that can, over time, affect not only the thermal conductivity, but also all the quality characteristics of the roofing, is the weight of the snow cover in winter. When choosing a heater TechnoNICOL for roofing, it should be borne in mind that its compressive strength must be sufficiently high. Otherwise, depressions will appear on the surface of the flat roof, where rain and melt water will accumulate. Subsequently, this will lead to damage to the upper layers of the roofing carpet and external moisture leaks. An excellent choice for a flat roof insulation device will be PIR TechnoNICOL thermal insulation boards, which are distinguished by extremely low thermal conductivity, high compression resistance and low specific gravity. TechnoNICOL XPS Extruded Polystyrene foam has also proven itself excellently, which does not give shrinkage deformations and is absolutely not subject to decay. Its service life is more than 100 years. You can also make roof insulation with TechnoNICOL materials in the form of basalt wool slabs. This type of insulation is quite budgetary and is widely used in industrial construction. The main thing is that the density of the slabs is at least 100 kg / m3.

Insulation is laid in several layers, in a checkerboard pattern, to exclude "cold bridges". A good example is roof insulation TechnoNICOL "Technoruf B", which is used as an upper heat-insulating layer. But it should be borne in mind that due to the ability of basalt wool to absorb condensate moisture, so-called "breathing holes" should be provided in the roof structure.

Insulation for roof sandwich panels

To reduce the cost of roofing sandwich panels, in addition to polymer insulation, basalt wool insulation is used as additional layers. Such material must meet the following requirements:

- have a very high density, about 130-170 kg / m3;

- be non-flammable;

- compression strain must be zero.

Insulation materials meet these conditions. TechnoNICOL for roofing from three-layer sandwich panels "Basalit Sandwich K" and "TECHNOSANDWICH". Both of these insulation materials are successfully used in the construction of any rapidly erected buildings and structures, as well as in the production of sandwich panels.

General characteristics

The product is sold in two forms: slabs and rolls. The dimensions of the sheets are established by GOSTs. In the twisted version, the length of the mat can reach 10 meters, the width - from 1 to 1.5 meters. Slab parameters: 1250 * 610 mm. Thickness varies from 2 to 15 cm. Density is another important indicator, which indicates the number of fibers per 1 m³. On the packaging it is indicated by the letter P. For working with walls, values from 35-150 are suitable. The higher the value, the greater the load on the base.

Differences between mineral wool

As we have already said, there are three types of mineral wool insulation. Each of them is made from different raw materials and has its own properties.

Glass wool

A material consisting of molten glass broken, dolomite, sand, soda, or limestone.

Benefits:

- Air permeability.

- Fire resistance.

- Elasticity, vibration resistance.

- Withstands low temperatures.

- Lower cost than other mineral wool.

Minuses:

- Short shelf life - 5-10 years.

- Shrinkage 80%.

- Strongly absorbs moisture.

- Causes itching or even an allergic reaction on contact with the skin.

As for the scope of application, usually it is mineral wool for insulating walls inside the house.

Slag

Produced from metallurgical waste. It is inferior in characteristics to other types of insulation.

- Does not provide adequate sound insulation.

- Cannot withstand strong heat. Does not burn, but cakes and loses its thermal insulation qualities.

- Does not tolerate temperature extremes.

- Protective clothing and a respirator are also required for mounting.

- Do not insulate damp rooms with metal fasteners, since under the influence of humid air, slags will contribute to corrosion.

- High hygroscopicity.

Related article: What tool is needed for plastering walls

Plus - such a layer in the wall does not attract rodents and insects. Most often used on dry surfaces of temporary buildings or non-residential buildings.

Stone

Most expensive material. It is he who is usually chosen for outdoor work in private, including frame wooden houses. The production uses rocks. Thanks to this, the final product has a lot of advantages:

- High density, and hence strength.

- Fire resistance. Does not ignite at any temperature.

- Minimum shrinkage (5%).

- Long service life (up to 50 years).

- Provides excellent sound insulation.

- Almost does not break in the process of work, which happens with other types of products.

- Water vapor permeability. The fibers repel moisture.

The downside is the high cost. Despite all the advantages, it is not always rational to insulate with these particular plates.

Types and technical characteristics of mineral wool slab insulation ↑

Depending on the form of release, raw material and configuration, the mats have different technical characteristics. Having understood them, you can easily choose the most suitable option for a qualitative reduction in the thermal conductivity of the roofing structure of a building for any purpose. The main distinguishing features of each:

- material of manufacture;

- density;

- structure of the arrangement of fibers.

A well-chosen insulation will help to avoid heat loss

The main types of plates ↑

The three types of thermal insulation boards made of mineral wool blocks are glass wool, stone wool and slag wool. Each of them has a certain thickness, fiber length and technical characteristics that determine the relevance of the application on a particular surface.

Glass wool is a budget insulation with a sufficiently high density and elasticity, with a thermal conductivity coefficient of 0.03-0.052 W / mK. It is made from the same raw materials as ordinary glass - sand, borax, soda, dolomite, and limestone. The thickness of the fibers is 5-15 microns, the length is 15-50 mm. Temperature range of application from +450 degrees to -60.

Glass wool mineral wool slabs

The advantages of glass wool include low cost. The disadvantages are lower technical indicators than those of analogues, as well as an increased danger to the respiratory tract, mucous membranes, skin, which forces not only to close it as tightly as possible with a finishing material, but also to use overalls and respiratory masks during installation.

Slag wool is made from blast-furnace slag, has a fiber thickness of 4-12 microns and a length of 16 mm. Thermal conductivity is equal to 0.46-0.48 W / mK, hygroscopicity is high. However, this variety is hydrophobic and the least resistant to dampness, which will not allow its use with external roofing insulation, and its low environmental friendliness, excludes its use in attic and mansard rooms.

Mineral wool slag wool slabs

Stone wool is one of the best insulation materials in terms of thermal conductivity equal to 0.077, the highest strength, a wide range of density 30-220 kg / m3 and fire resistance. In addition, the material is the safest for the health of the respiratory tract and skin, since cotton wool practically does not crumble and is much less volatile than glass. The only drawback is the high cost of the product, but the technical characteristics often justify the money spent.

Mineral wool stone slabs

How to read density markings correctly ↑

According to existing norms and standards, insulation blocks for roofing work are marked as follows:

- P-125 - semi-rigid mineral wool slabs. Mainly used to insulate attic spaces as well as pitched roofs. Density - 125 kg / m3, thermal conductivity - 0.049 W / mK, compression ratio - 12%.

- P-150 - used as fire, heat and sound insulation of roofing systems. Density - 150 kg / m3, average thermal conductivity - 0.04 W / mK, strength - from 0.01 MPa, compression rating - 2%.

- ПЖ-175 and ППЖ-200 are rigid mineral wool slabs capable of withstanding a load of 175 and 200 kg / m3, as a result of which they are often mounted in flat roof structures subject to high deformation deflections. Thermal conductivity - 0.042 W / mK and 0.052 W / (m K), respectively.

Insulation of a pitched roof from the inside

Insulation of a flat roof

At the same time, according to the structure of fiber, they are distinguished:

- Random placement of fibers, with a density of 120-180kg / m3 and breaking strength from 10kPa.

- Lamellar (perpendicular), with a density of 80-120 kg / m3 and a strength of 80 kPa.

The choice of insulation for ease of installation ↑

Laying any heat-shielding layer implies a structure with additional steam, moisture, windproof membranes. For ease of installation on complex surfaces, you can purchase a multi-layer insulation.

To protect the fibers from being blown out by the wind and exposure to moisture - laminated with fiberglass or polymer film. To enhance vapor barrier and reduce thermal conductivity - foil mats. There are also slabs with a bonding bitumen layer, which are widely used in the arrangement of external rough layers of roofing structures.

Foil mineral wool boards

Manufacturers of mineral insulation boards

Buying thermal insulation boards made of mineral wool, you will not always be able to determine their quality by mere appearance. Demand quality certificates from the seller indicating that the material is made in accordance with GOST or TU. A competent choice of the manufacturer can also serve as a guarantor of a good insulation. The most famous and well-established domestic and foreign brands in the building materials market that produce slabs:

- Concern Rockwool;

- Technonikol;

- Ecover;

- ISOVER;

- KNAUF;

Plates are delivered in packages

Advantages and disadvantages of mineral wool for wall insulation

Let's summarize a little. The advantages of almost all types of mineral wool include several qualities:

- Non-flammability.

- Easy handling. Plates and rolls are cut with a knife or saw.

- Good noise and heat insulation.

- Simple installation.

- Long service life (5 to 50 years, excluding slag material).

- The need to work in protective clothing and a respirator.

- Additional vapor barrier may be required for fiberglass.

It is also believed that when heated, the insulation emits vapors that are harmful to health. Manufacturers say this is a myth. In addition, after installation, the layer with thermal insulation is closed with plasterboard, boards or other finishes.

Particles that enter the air when cutting products can be harmful. To do this, it is recommended to close the airways, and if the fibers get on the skin, wash them off only with cool or cold water. This is to prevent the pores from expanding and cutting dust from getting into them.

Overall, it is a modern, easy-to-use, effective material for protecting your home from high and low temperatures.

How to choose mineral wool products

First, you need to pay attention to several characteristics:

- Thickness of mineral wool for wall insulation. The thicker the insulating layer, the higher its fire safety, sound insulation and strength. For internal partitions and frame structures, 5 cm mats are suitable.For facades - from 5 to 10 cm.

- Density (P). We wrote about it above. The rigidity of the structure and its ability to withstand loads depend on it.For facades, the indicator should be in the range of 100-125 kg / m³. If plaster is chosen as finishing, then 150 kg / m³. For interior partitions - 75-90 kg / m³.

- Thermal conductivity. The smaller it is, the better. In this regard, basalt and fiberglass products have proven themselves well.

- Water vapor permeability. The coefficient suitable for private buildings is that of stone wool. It is designated MU1. The larger it is, the better the product.

- Fire resistance. The level of fire resistance of fiberglass is 600 ° C, material from mountain alloys - 1000 ° C.

What else to pay attention to

If you plan to work outside the building, choose basalt slabs. When insulating from the inside is required, a fiberglass coating is also suitable. When purchasing, look at the storage conditions.

- If the product is even a little wet, it makes no sense to purchase it. Check that the packaging is free of gaps.

- Blocks and rolls should be under a canopy and not outdoors.

The most famous manufacturers of mineral insulation are Isover, URSA, Rockwool, Knauf. Their products are certified and quality tested.

Density marking

The density of the mineral wool is chosen depending on the intended purpose

The density indicator helps to quickly determine the purpose of the product. The marking includes a letter indicating the degree of hardness, and numbers - the density of the mineral wool. The following categories are distinguished:

- PM-40 and 50 - very soft, does not withstand the load. Suitable for insulating frame structures.

- P-60, 70, 80 - due to low density, the material is easily deformed, therefore it is used in lightly loaded structures: pitched roof, pipe thermal insulation.

- ПЖ-100, 120, 140 - mineral wool semi-rigid and rigid insulation is used for thermal insulation of walls, floors, roofs in low-rise buildings. It is part of panel structures.

- ППЖ-160, 180, 200 - withstands high loads. Suitable for insulation of flat roofs, concrete screeds, building facades.

- PT-220, 250, 300 is a rigid and solid heat insulator. They are used for finishing and insulating works in difficult areas: reinforcing screeds, insulation of ceilings.

The complete labeling contains more information. It indicates the dimensions of the product, the flammability class, the level of moisture absorption, and the tensile strength.

How to properly insulate walls with mineral wool

Let's talk first about what can put all your work down the drain.

Mounting errors of mineral wool boards

- Lack of surface preparation. It should be flat, clean and treated with an antiseptic (if it is a tree).

- Carrying out work during precipitation or leaving finished work without rain protection.

- Insufficient adhesive application. Correct when it is distributed over the entire surface, including the perimeter. The most suitable adhesive is polyurethane foam or dry mix. The first products are easier and faster to work with, but slightly more expensive. Both products are resistant to external influences and guarantee good adhesion.

- Unfilled seams between insulation parts. They can only be closed with inserts of the same material. The maximum clearance is 2 mm.

- Intersection of slabs in window and door corners. There should be no joint in these places.

- Lack of mechanical fasteners. Anchors and dowels are used as additional connections for heavy sheets. The optimal amount is 3-4 pieces per piece (two at the corners, 1 or 2 in the center).

- Smooth mounting, joint to joint. Masters advise to install the elements in a checkerboard pattern - this way it is easier to avoid cracks in the structure.

These are the main mistakes people make when doing thermal insulation at home on their own.

Instructions for insulating the walls of the house with mineral wool outside

You will need a metal profile or timber to create the lathing, accompanying tools for building the frame, a knife or saw, fasteners and a membrane film for vapor barrier. There are two methods.Let's consider one of them. The work is carried out in several stages.

- Surface preparation. It is necessary to remove all old layers of plaster and other finishes from it, clean off dirt and mold, carry out processing and remove all irregularities with a primer.

- Installation of the frame. After the primer has dried, mount the guides at a short distance from the facade - about 10-15 cm in 60-100 cm increments, 1-2 cm less than the width of the block or roll.

- A film is placed under the first layer - the smooth side to the plate and the vapor-absorbing one inside. It is attached with double-sided tape or a stapler.

- The first layer of cotton wool is attached on top. Usually a softer one is chosen so that it hides depressions or bulges if they remain after alignment. Plates are laid from bottom to top, and rolls - from top to bottom.

- Further, more rigid elements are mounted. For reliability, they can be fixed with a construction stapler or mushroom dowels.

- Another layer of vapor barrier is placed on top (the film is not stretched), lathing and cladding.

In the case of fastening under the frame, it is important to know in advance the size of the mineral wool insulation for the walls in order to correctly calculate the distance between the profiles.

Wall insulation with Penoplex

For thermal insulation of the walls from the inside of the house, the Comfort brand is used. The thickness of the product varies from 20 mm to 150 mm. In each specific case, it is necessary to choose this indicator depending on the room. In living rooms, experts recommend using 40, 50 or 60 mm. At the same time, other dimensions of the slab are standard - 600x1200 mm.

Penoplex insulation is a dense material that is not afraid of moisture. He does not need a frame for installation. There is no need to carry out hydro and vapor barrier. The most important thing is that the surface to be insulated is even, without large differences (up to 3 mm).

Fixation with glue

Penoplex company recommends using Penoplex FASTFIX glue specially made for this purpose for fixing thermal insulation boards. It is sold in a 750 ml can.

The adhesive is applied to the board along the entire perimeter (1-2 cm from the edge), as well as in one strip in the middle. After that, you need to stand for 2-3 minutes, then apply insulation at the destination. Within 5 minutes, the slab can be moved, adjusting the location.

There are several guidelines. It is best to moisten the surface of the walls to be insulated before installing the plates. If the work is carried out at subzero temperatures, then the glue container must be heated, but not higher than +30 ° C. In this case, you can use warm air or water.

Fixing with dowels

More recently, Penoplex slabs were attached to the walls using special mushroom-shaped plastic dowels. For this, through holes were made simultaneously with a drill in the slab and in the wall. The dowel was inserted into this hole. Two such holes were made for each slab. Fastening could also be carried out with the installation of dowels in the joints of two panels.

If thermal insulation of facades is carried out, then it is better to use a combined method using glue and dowels.