When designing your home, you need to take care of the future heating system. Indeed, comfort, as well as the health of all residents of the house, depends on high-quality heating. In order for the heating system to work effectively, you need to select a suitable heating boiler and install it in the system in compliance with all rules and technologies. If the boiler is installed incorrectly, then various kinds of malfunctions may occur in the future. The most popular problem is the frequent switching on and off of the heating boiler. But not everyone knows the possible causes of this problem. Therefore, in our article we will consider the reasons for the frequent switching on and off of the gas boiler, as well as ways to eliminate them.

Possible reasons

There are times when you purchased a new boiler, installed it and started using it. But it starts to turn on and off randomly. Of course, he must regulate his work himself, but there should not be frequent shutdowns. In this case, you need to understand the reason. After all, this indicates the presence of any problems. If the device is frequently switched off and on, then its service life is significantly reduced due to wear of the working parts. And, consequently, the boiler will fail.

There are several reasons for the frequent shutdown of the heating boiler. But if you do not understand gas boilers, it is better to consult a specialist.

Let's consider the possible reasons:

- The boiler output is designed for a larger area than is available in the room.

- The circulation pump is installed incorrectly.

- The boiler has been selected incorrectly.

- There is no thermostat in the room. The boiler is controlled according to the temperature of the heat carrier.

- The temperature range is incorrect.

The problem is simple, but sometimes it requires replacing the gas boiler.

Why batteries do not warm up well in a private house

Just as in the case of a high-rise building, there may be several reasons for the poor performance of heating batteries in a private house.

Reason 1: problems in the hydraulics of the heating system

The most common reason batteries stay cold is due to the hydraulics in the heating system. In this case, one of the heating branches is working properly, and the other is intermittent. This is typical for a new heating system or when adding radiators to an existing one. If the hydraulics are incorrectly calculated, and in particular the diameters and lengths of the pipes, some of the batteries may simply not heat up. The hydraulics can be adjusted using special taps.

Reason 2: one-pipe heating system

One-pipe heating systems are found in many private houses. In such a system, batteries that are often remote from the boiler heat up much worse than those close to them. This does not mean that there are problems, this is a feature of the operation of a one-pipe system. The only solution here may be only to replace the system with a two-pipe one.

Reason 3: boiler malfunction

The batteries may not warm up due to malfunctions in the operation of boilers with built-in automation, pumps and sensors, which is a typical problem for autonomous heating systems. In this case, it is necessary to contact directly a specialist working with such equipment.

Overpower

In no case should a boiler with a higher power be installed than is required for a particular room. The required power must be calculated accurately. After all, a lack or an overabundance of power can adversely affect the operation of the equipment.Therefore, if you did not succeed in calculating the required power yourself, then you can contact the specialists who will correctly make all the calculations.

But in order to determine the power, it is not enough to know the area of the heated room. The following factors affect the power value:

But there are many resources on the Internet where you can find online power calculations. For a rough calculation, you can use them.

But if you bought a heating boiler and noticed that the power is much higher than the required one, then you need to solve this problem. First you need to find out how often the boiler can turn on during normal operation. In order to ensure normal operation for a boiler with increased output, it is necessary to install a four-way mixing valve in the hydraulic system. This option will show excellent results. But you will also have to spend a considerable part of your funds.

If your appliance has a multi-stage burner, then you can try the method of lowering the burner.

Another way is to connect the boiler to the boiler. In this option, in addition to reducing the power of the gas heating boiler, it will be possible to provide the house with hot water supply. In order to determine the power of a single-circuit and double-circuit heating boiler, it is necessary to use different schemes. It is better to choose boilers with the minimum power required to heat your home.

In order to correct the problem of frequent boiler start-ups and also to reduce fuel consumption, a thermo-hydraulic distributor can be used instead of a mixing valve. Its cost is, of course, much higher, but the result is much more effective.

Local causes of inoperability of the heating system

The last battery is too long.

Why is one battery hot and the other cold. Experts name the following reasons for this situation:

- airing the system;

- low quality of the coolant;

- poor quality of the heating element.

In most cases, the above problems are solved independently by the homeowners. However, the help of a specialist is never superfluous.

Airing the system

... Air can accumulate in individual elements of the heating system. This phenomenon is called contour airing.

Air can enter the wiring:

- from;

- if ordinary tap water was used as a heat carrier. It contains a certain percentage of dissolved air;

- the aggressive medium of the coolant oxidizes the walls. As a result, oxygen is released. It accumulates inside, forming a plug.

It is easy to determine if there is an air lock inside the heating equipment. To do this, turn off the taps on the supply pipe and return at the same time, and then open them in complete silence. If, at the moment of opening the tap, there are extraneous noises and gurgling inside the device, there is an air lock. It is she who is the main reason why one battery is cold, the rest are hot.

How to remove air jams, the video will help:

Debris and rust in the heating circuit can also explain why the last radiator is cold. Foreign objects block the flow of hot water, thereby reducing the heating efficiency of the house.

Thermostat device

Another common reason for frequent switching off and on of a heating boiler is the lack of a thermostat. This means that the device is controlled only by the temperature of the heat carrier. When the water heats up to the desired temperature, the boiler turns off. And after the water began to cool, the boiler turns on again. But the problem is that the air in the room cools down longer than the coolant. With this method of controlling the device, fuel consumption is significantly increased.And the room will have an elevated air temperature, and it will be uncomfortable to be in it. Therefore, it is necessary to install a thermostat. With its help, the gas heating boiler will be automatically controlled. After installing a room thermostat, fuel consumption will decrease and heating will become more comfortable and efficient.

After the air temperature in the room becomes lower than the comfortable one, the gas boiler will turn on. Thus, the air in the room will always be comfortable, and the fuel will not be consumed more than it should be.

There are many thermostat options on the market that have different costs and functions. Mechanical room thermostats would be budget options. But they are reliable and do not require special maintenance during operation. Modern programmers have a more complex structure. They can be assigned different options, set different temperatures.

In order for the heating system to function correctly and not consume excess fuel, it is necessary to correctly install it. If the boiler is controlled by a room thermostat, then you do not need to monitor the switching on and off of the device. Thus, you will save on fuel consumption and the gas boiler will last longer.

What to do if the bottom of the battery is colder than the top

If the battery is hot at the top and cold at the bottom, then it is not functioning properly. In this case, diagnostics is required not only by the battery itself, but also by the entire heating system. The cause of the problem may lie in recent work on the heating system and changing the radiator. As a rule, the problem "hot top - cold bottom" appears due to the occurrence of an air lock (99% of cases), clogging of the radiator valve (a consequence of improper system start-up).

This problem is solved in two ways. You can remove the airlock using a Mayevsky crane or a descender. First of all, shut off the coolant supply to the radiator and leave the return flow open. Open the drain, wait for the air to escape, close the drain and open the coolant supply. This is usually enough.

In the event that this method did not work, and we are talking about an apartment building, it is better to call a specialist. There is another option for private houses. First you need to turn off the heating supply, open the drain at the highest point of the system and squeeze out all the air with back pressure.

Each heating system can have its own characteristics, and therefore the likelihood of atypical problems is high. These include improperly selected pipe diameters, incorrect distribution of the coolant, poor flow capacity, lack of pressure, malfunctions in the circulation pump or expansion tank. In any case, only a specialist can fully understand all the nuances, therefore, in case of difficulties in solving a problem, it is better to seek help.

The efficient operation of the heating system determines how comfortable the temperature will be in the cold season in the house. Sometimes situations arise when hot water is supplied to the system, and the batteries remain cold.

It is important to find the cause and eliminate it. To solve the problem, you need to know the design of the heating system and the reasons for the cold return during hot supply

Why don't the batteries heat up?

You have noticed that the last battery in the heating circuit of the house is cold. What to do? Experts advise to first determine the nature of the breakdown. It can be both global and local. In the first case, you need to pay attention to the correct installation of the bypass and the heating element itself. The breakdown can be eliminated only by redoing the heating wiring in the house.

Local breakdowns include air locks and impurities inside the heating element.They are the main reason why the middle or last battery in the heating system is cold. These problems can be independently eliminated by a person without professional skills. But the help of specialists will not hurt here.

The heating radiator may not function properly and this is not uncommon. To put it simply, it does not heat or heat, but not enough. To begin with, you should determine the cause and, based on it, "prescribe treatment." There are few reasons, but each of them can be solved in several ways.

Heating circuit problems

The pump must be matched to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be looked for in the wiring itself.

A list of the main malfunctions of the heating circuit:

- the filter on the return line or the needle valve (Mayevsky's valve) is clogged;

- insufficient power of the circulation pump;

- the rules for installing the natural circulation heating circuit have not been followed.

Any of the above problems should be resolved before the start of the heating season. Otherwise, the room may remain without heat for several days, since the repair provides for a complete drain of the coolant.

So, why does the boiler not heat up the batteries if everything has been working normally during the previous years? The reason is a mud plug, which has formed on the heating circuit filter and completely blocks the coolant flow. It is solved simply - the water is drained from the pipes or, with the help of bypasses, its circulation is shut off, the filter is cleaned. To prevent a repetition of a similar situation, it is necessary to completely replace the coolant with a parallel one.

In a gravity system, the slope of the pipes is of key importance.

The second reason why the boiler works, and the batteries are cold, is the insufficient power of the circulation pump. The performance of the device is not enough to timely and efficiently pump the entire volume of the coolant. Or, in the house, the heating system has branches that are at a significant distance from the pump. As a result, the circulating pump overheats, the heating equipment operates with excessive consumption of the energy carrier, and the radiators remain cold. The solution is to replace the coolant pumping device with a more powerful one.

If the house has a two-pipe heating circuit with natural circulation of water, and during the heating season it is often noticed that the boiler is on and the batteries are cold, then the reason lies in the failure to comply with the slope of the line. According to regulatory documents, only a pipe slope of 10 mm for each running meter in a natural circulation heating system will ensure the normal movement of the coolant. As a result, the batteries warm up evenly throughout the house. If there is no slope, the coolant stagnates, which negatively affects the temperature of the radiators. You can solve the problem by completely redoing the wiring.

Why are the batteries cold when the boiler is running?

Low efficiency of the heating system can be the result of malfunctions, both of the circuit itself and of the main heating element. In the case of a heater, attention must be paid to the three-way valve, the functionality of the pump and the technical condition of the heat exchanger. Typical problems for heating wiring are a blockage on the filter, insufficient power of the circulation pump and the absence of a slope in the pipes of the circuit with natural water circulation.

The water in the heating boiler can boil due to the fact that the rate of its heating in the boiler exceeds the rate of heat transfer in the heating system of the house. This can happen for several reasons:

- insufficient circulation rate of the coolant or its absence;

- insufficient amount of coolant (water) in the system - most often it happens in open systems with an expansion tank;

- excess of the heating boiler power in comparison with the total power (heat transfer) of the heating radiators of the house, taking into account losses - in the absence of a boiler draft (power) control system;

- incorrect installation of the heating system.

Now let's look at these reasons in more detail.

When insufficient circulation rate

of the heat carrier, the heated water does not have time to transfer the heat received in the boiler into the system and can heat up in the boiler to the boiling point. This can occur in heating systems with natural circulation of the coolant, if the correct slopes of the installation of pipes are not observed or, less often, if their diameter is insufficient. With a forced circulation system, this can occur if the circulation pump is not selected correctly, is faulty, does not work or there is no electric current supply to it.

Also, the water in the boiler can boil if for some reason in the system not enough water (heat carrier)

and air got into it. If the heating system is with natural circulation and with a conventional expansion tank, this sometimes happens and in this case you just need to top up the water. Depending on the design of the heating system, sometimes it is required to bleed air from the system or some part of it (in the absence of an automatic valve).

To increase the circulation of water in the heating system, it is necessary to redo the heating system or, best of all, install a circulation pump. Even if the slopes of the pipes are not quite correct or in the absence of them, the circulation pump will provide the necessary circulation.

The water in the heating system can also boil if the installed the boiler in terms of power is much higher than the heat transfer capacity of the entire system

, especially in the absence or malfunction of the automatic control (traction) system of air supply. In this case, it is necessary to install a semi- or automatic draft control system, replace the boiler (if it is homemade without a draft control system) or increase the number or power of radiators. Also, as an option, you can install an indirect

The reason for the boiling of the boiler is that the water in the heating system does not have enough time to cool down sufficiently. The movement of the coolant (water) must be calculated in such a way that it has time to cool down completely on its way through all the radiators and returns to the boiler already cooled. If this does not happen, then the overheated water at the inlet to the boiler has time to boil while moving along it.

There are a number of factors that lead to overheating of the water in the boiler. Each of them is based on either an incorrect calculation of the heating system, or the failure of its individual elements. A more accurate determination of the sources of failure of the stable operation of the heating system requires a detailed analysis of a specific circuit.

It is solid fuel boilers of long burning that are most susceptible to this problem. When analyzing the origin of the malfunction, first of all, it is necessary to establish at what stage of the heating arrangement the process of water boiling was detected. There can be two options:

- The coolant in the boiler began to boil immediately after the completion of the installation of pipes and the first start-up.

- Water boiling occurred in a system that had previously worked properly for several months or years.

In the first case, you must first carefully examine the performance of each of the devices. The cause of a malfunction can be both an incorrect connection of one or more devices, and mistakes made during the pipe laying process.

Boiling water, which has appeared in an already operating heating system, is less common. This is usually due to the failure of the circulation pump and the ingress of air into the system.If the pump is in order, then there is a possibility of a blockage in the pipeline. The formation of limescale from the inside of the valves or pipes causes them to narrow and slows down the rate of movement of the coolant.

Slow movement of water in the boiler

If the functions of each element of the heating system are normal, then perhaps one or more pipes are not sufficiently large in diameter. Even one short section of pipeline with less than optimal channels can be a source of problems. The fact is that the coolant will not move fast enough along narrow channels. This leads to water retention in the system, and therefore in the boiler.

When water is in a heated boiler for too long, it builds up a higher temperature than necessary. As a result, the liquid boils with all the ensuing consequences. Most heating systems have protection specifically for such cases, sometimes even two or three levels. However, a protection trip is a sign that something went wrong.

It is also important to take into account the diameter of the taps (valves) at the points of connection of pipes to radiators. Often these places are deliberately made too narrow in order to extend the residence time of the water in the battery and to give the radiator sections the opportunity to warm up well. This technique ultimately also inhibits the flow of water through the pipes.

It is especially important to manufacture a pipeline with a correctly calculated diameter (at least 25 mm) in natural circulation systems. That is, if the circulation pump is not included in the circuit. In such a heating system, the movement of water is ensured by the natural laws of hydraulics and gravitational forces.

With the correct arrangement of all elements, the coolant starts to move independently during the heating process. Hotter water has a lower density and weight, while colder water is heavier and denser.

Correction of the water flow rate is available only by decreasing or increasing the clearance of the control valves. And here there is always a limit: when all the valves are fully open, it will no longer be possible to accelerate the movement of the coolant.

The role of the circulation pump

A circulation pump is a device that is installed in a heating system to create forced movement of water in it. It is installed, as a rule, on the return flow circuit of the coolant so that the pump works with already cooled water.

A heating system with a circulation pump is called a forced circulation heating system. If earlier the water moved through the pipeline in a natural way, then the problem of boiling the boiler can be solved by installing such a pump. It will accelerate the movement of the coolant and avoid excessive liquid retention in the boiler, which led to its boiling.

At the same time, such a solution is only a temporary measure. At the first case of a power outage, the pump will stop working and the water in the boiler will immediately begin to boil. It will be impossible to use heating during this period, even if it has boiling protection systems. All measures to prevent boiling of water in a system with a stopped pump are of an emergency nature. They are aimed only at preserving the integrity of the boiler and pipes for a short period until the boiler cools down.

If the water in the boiler boils, and the pump in the system is working properly, then the circulation pump should be calibrated. It can be configured both for insufficiently strong pressure, and for creating excessively high pressure. In both cases, the phenomenon of so-called cavitation occurs, leading to the appearance of air bubbles in the water.

The situation can be corrected by the following methods. First, the pump must be set to its slowest operating mode. If boiling has stopped, it means that the apparatus was creating excessive pressure.The solution is to place a bypass with a balancing valve between the water inlet and outlet.

For loop pumps, there are inlet and outlet pressures. This indicator at the point of water entry is 0.8 bar, and at the outlet - 1 bar. Deviation from standard values inevitably leads to cavitation. Cavitation is harmful because it causes the formation of air bubbles in the water, which harm all elements of the system. It is because of them, among other things, that the coolant in the boiler boils.

Another case that leads to the appearance of cavitation is the installation of a pump in the boiler and a loop pump in counterflow. When the scheme requires the placement of two pumps, then during the installation of each device there is a possibility of their placement in counterflow. If, after inspecting the system, this installation error is found, it should be corrected.

Boiler output too high

A newly installed heating system with a boiling boiler is, most often, an incorrectly selected power of the heating unit. There is an average indicator of the required power for heating 10 m² of the area of a residential building. This figure is 1 kW, provided that the house was not insulated using enhanced heat-shielding technologies.

Thus, we can say that for a small house with an area of up to 100 sq. m is enough for a boiler with a capacity of 10 kW. Of course, the installation of a unit with a small margin of up to 12-13 kW is also possible, but the inclusion of a boiler with a capacity of 20 kW or more in such a scheme is unacceptable.

The coolant simply does not have time to cool in the radiators and will return to the boiler still hot. Additional heating of not fully cooled water will sooner or later cause it to boil.

The boiler is boiling. What to do?

Boiling water in a boiler is an unusual situation. The design provides for the possibility of boiling of the coolant, but it will not be able to work for a long time in this mode. Therefore, the first thing to do is to set the thermostat to zero and wait until the combustion process in the firebox stops.

Attention! If your solid fuel boiler does not provide measures to protect against boiling, and the heating system is sealed, then boiling of the coolant can cause an accident. There are even cases when long-burning boilers explode under the pressure of the steam formed inside.

In closed heating systems without automatic protective ducts for releasing pressure, it is imperative to open the air valve on the radiator, if any. This will prevent the possibility of damage to pipe connections or other elements from internal pressure in the system.

Further operation of the heating, where the boiling of water in the boiler was once recorded, is permissible only after elimination of possible malfunctions. This is done in practice in one of the ways described below:

- Installing a heat accumulator (TA)

- Acceleration of water movement by installing a circulation pump or eliminating areas with poor permeability of the coolant

- Correct setting of the pump, excluding the appearance of a cavitation effect

- Installation of additional sections to existing radiators or placement of new batteries in rooms with insufficient comfortable temperature

- Elimination of possible sources of air entering the heating system

Boilers with semi-automatic ignition.

Heating equipment equipped with Eurosit 630 automation, or similar, is semi-automatic, because the main burners are ignited by the wick flame, which burns throughout the entire operation of the boiler.

Reasons and methods for eliminating water boiling in boilers with semi-automatic ignition.

Malfunction of the coolant temperature sensors.

The temperature of the water in the heating circuit is monitored by sensors (thermistors), which are located in the flow and return lines of the boiler.A serviceable sensor, when the temperature of the coolant changes, changes its resistance. For example, at 25 ° C it will be approximately equal to 10 kΩ, and at 45 ° C it will be 4.913 kΩ. By the type of design, the sensor can be overhead (takes parameters through the copper wall of the pipe) or submersible (contacts the coolant without an intermediary). If the probes are not inspected in time, then a non-metallic coating will form on the contact surface, impairing heat transfer and causing them to be damaged.

To investigate the state of the thermistor, a tester is connected to the sensor contacts in the ohmmeter position. If it commits:

- resistance in the range of 1 - 30 kOhm, which means the sensor is serviceable;

- 1 or 0, the probe must be replaced.

Temperature sensor replacement procedure:

- Depending on the type of probe, it can be unscrewed or removed from the pipe.

- Before installing a new sensor, for overhead thermistors, on a prepared base, from which dirt, oxides, fat are removed, thermal paste, for example MX 4, is applied. For immersion probes, the seat is cleaned, and a fumlent is wound on the mounting thread.

If the probe breaks down in automatic boilers, a malfunction code will be displayed on its dashboard. Also, the coolant can overheat due to a pump malfunction and filter contamination. Methods for identifying and correcting such problems are described above.

Good day! Yesterday we installed 2 additional radiators (white aluminum) into the heating system in a private house, installed them, opened the valves, let water in and, as the radiator was filled with water, as usual, they bleed the air through the drain hole. After the work done, the pressure in the system decreased and, as usual, water was added from the central water supply system (our house is connected to the water supply system, which runs next to the house and we add water to the heating system from the central water supply system, everything is connected so that the valve is opened - water went). After all this, the boiler began to heat up and boil very quickly (in our house there are 3 circuits in the heating system, through which the first and second floors of the house are heated, a pump (3 pcs.) Is supplied to each circuit and one pump is supplied to the return. here, all the pumps are working, the air in all the radiators has been vented, and the boiler continues to heat up very quickly, literally from one thrown firewood. I beg you to help, what you can, I have been suffering for 2 days already, I don’t understand what the reason is.

Unfortunately, knowing practically nothing about the heating system of your home, we cannot help with specific advice. It's like in medicine: in order to make a diagnosis, the doctor must get the test results and examine the patient. And we are not even aware of "anatomy", you have not attached a diagram to the question. You need to know not only the general arrangement of heating devices, but also the structure of the boiler room, the location of the air vents, etc. But, even knowing these parameters, trying to determine the nature of the problem in absentia is to a large extent guessing on the coffee grounds. There can be many local reasons for the malfunctioning of the system, we will present the correct, in our opinion, algorithm for finding and eliminating them:

A manual air vent (Mayevsky tap) must be installed on each radiator

Poor circulation can also be caused by general contamination of the system, first of all, the batteries are clogged. The heater can be removed and blown out with compressed air or rinsed out with a powerful jet of water.

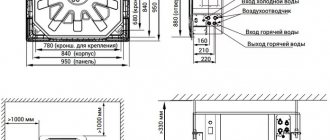

The diagram shows that air vents, automatic on combs (5, 11) and Mayevsky taps (13) are located on all heating devices without exception. This was done for a reason, but to eliminate situations like yours

Cats do not sleep on cold batteries.