Fan coil heating principle

How the fan coil works

The original name of the fan coil unit "fan coil" means "fan-heat exchanger". The device is called a fan coil. It is the final element of a chiller-fan coil system. The block consists of the following parts:

- heat exchanger made of copper tubes with aluminum fins;

- centrifugal fan;

- filter;

- Control block.

The pipeline circulates water (in regions with a mild climate) or ethylene glycol (for areas with low temperatures). Fan coil units are installed in each room, they function according to an individual program. The number of connected modules depends on the chiller capacity.

The coolant temperature is 35-55 °. A low indicator is sufficient for heating using a new technology.

Steel radiators are gradually giving way to alternative space heating systems. One of the modern options for heating a house is a fan coil instead of a radiator. Inside the block there is a heat exchanger with circulating hot water supplied by a main. The fan, which is part of the device, drives air masses through it. Forced circulation allows you to quickly raise the room temperature. The filtering device cleans the stream of warm air from dust and impurities.

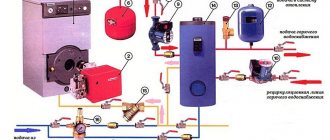

The fan coil unit is connected by a piping system to a heating boiler (chiller) and a hydraulic module. When installing the water circuit, there is no need to use expensive copper pipes. Insulated plastic lines will replace metal. High-quality thermal insulation eliminates temperature loss even over a considerable distance. One of the advantages of plastic is the low cost of material and installation work.

Chiller - external block of the air conditioning system

Chiller is a refrigeration machine with the ability to switch to a heat pump, installed outdoors or in a utility room. The hydraulic module consists of a pump, an expansion tank and a storage tank. A heating boiler is included in the device of the four-pipe system. With the onset of cold weather, a special valve turns on the heating mode.

The role of fan coil in the air conditioning system

A fan coil unit is an important element of a centralized climate control system. The second name is a fan coil. If the term fan-coil is literally translated from English, then it sounds like a fan-heat exchanger, which most accurately conveys the principle of its operation.

The fan coil unit is designed with a network module for connection to a central control unit. The robust housing hides the structural elements and protects them from damage. Outside, a panel is installed that evenly distributes air flows in different directions

The purpose of the device is to accept low temperature media. The list of its functions also includes both recirculation and cooling of air in the room where it is installed, without the intake of air from the outside. The main elements of the fan-coil are located in its body.

These include:

- centrifugal or cross-flow fan;

- a heat exchanger in the form of a coil, consisting of a copper tube and aluminum fins, mounted on it;

- dust filter;

- Control block.

In addition to the main units and parts, the design of the fan coil unit includes a sump for collecting condensate, a pump for pumping out the latter, an electric motor, through which the air dampers are turned.

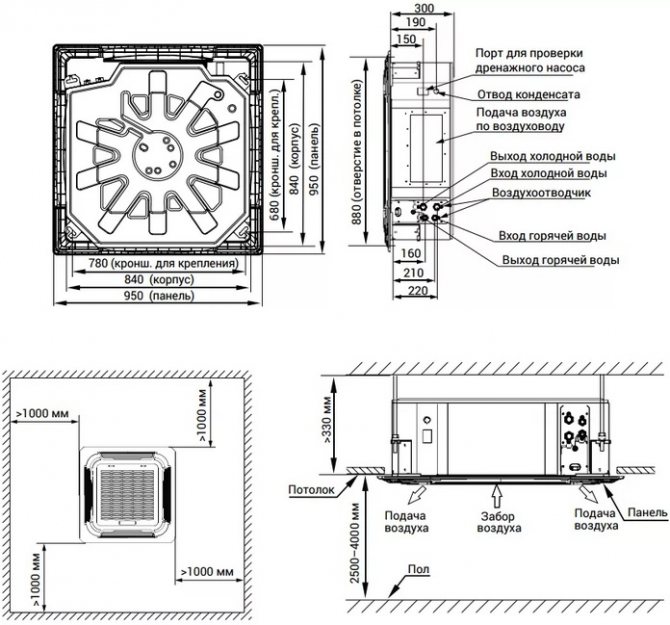

Pictured is a Trane duct fan coil unit. The productivity of double-row heat exchangers is 1.5 - 4.9 kW. The unit is equipped with a low-noise fan and a compact housing. It fits perfectly behind false panels or suspended ceiling structures

Depending on the method of installation, there are ceiling ‚duct‚ fan coil units mounted in ducts through which air is supplied ‚open frame, where all elements are mounted on a frame‚ wall or console.

Ceiling devices are the most popular and have 2 versions: cassette and duct. The first ones are mounted in large rooms with false ceilings. A body is placed behind the suspended structure. The bottom panel remains visible. They can disperse air currents on two or all four sides.

If the system is going to be used exclusively for cooling, then the best place for it is the ceiling. If the structure is intended for heating, the device is placed on the wall at the bottom of it

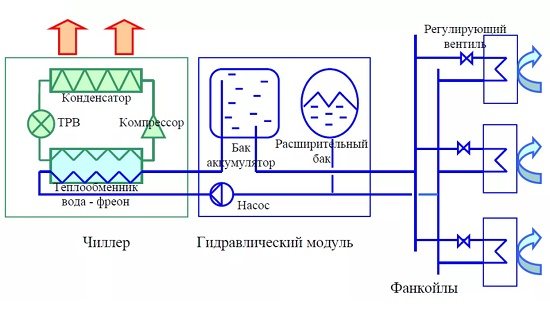

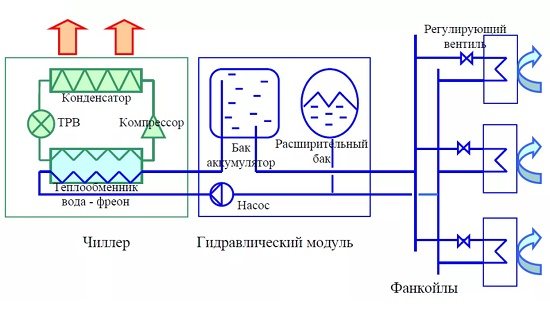

The need for cooling does not always exist, therefore, as can be seen in the diagram, transmitting the principle of operation of the chiller-fincoil system, a tank is built into the hydraulic module, which acts as an accumulator for the refrigerant. The thermal expansion of the water is compensated by an expansion vessel connected to the supply line.

Fan coil units are controlled in both manual and automatic modes. If the fan coil operates for heating, then the cold water supply is cut off in manual mode. When operating it for cooling, hot water is blocked and a path is opened for the flow of the cooling working fluid.

Remote control for both 2-pipe and 4-pipe fan coil units. The module is connected directly to the device and placed close to it. The control panel and wires for its power supply are connected from it.

To work in automatic mode, the panel is set to the temperature required for a particular room. The set parameter is maintained by means of thermostats, which adjust the circulation of heat carriers - cold and hot.

The advantage of a fan coil is expressed not only in the use of a safe and cheap heat carrier, but also in the quick elimination of problems in the form of water leaks. This makes their service cheaper. The use of these devices is the most energy efficient way to create a favorable microclimate in a building.

Since any large building has zones with different temperature requirements, each of them must be served by a separate fan coil or a group of them with identical settings.

The number of units is determined at the design stage of the system by calculation. The cost of individual units of the chiller-fan coil system is quite high, therefore, both the calculation and the design of the system must be carried out as accurately as possible.

Types of indoor units

According to the type of connection to the hydraulic circuit, a fan coil for heating a private house is of two types:

- Two-pipe - the unit is equipped with one water circuit. Its mode of operation depends on the temperature of the coolant. This is the most common and affordable type.

- Four-pipe - a device with two heat exchangers, in one of which cold water circulates, and in the other hot. The systems operate independently of each other, allowing quick changes in cooling and heating modes.

Mounting options

The design version of the fan coil is selected depending on the placement requirements:

The cassette fan coil unit is installed behind a false ceiling

- Cassette - blocks are placed behind false ceilings. An air distribution grille is directed into the room.The devices are produced in two and four-pipe. They are equipped with a condensate collection tray.

- Ducted - devices are designed for installation in a ventilation duct. Horizontal models are installed behind a false ceiling, vertical ones - behind a false wall. Powerful fans allow multiple rooms to be served. The units are controlled by a remote control.

- Wall-mounted - the console unit is placed openly, which simplifies the installation process. The device is manufactured with decorative appeal in mind. The case does not externally differ from the internal block of the split system. Works in two modes: cooling and heating. The device is completed with a remote control panel. When installed above a window, it creates a thermal curtain that excludes the appearance of a draft.

- Floor standing - the equipment is installed on the floor or at the bottom of the wall. Blocks replace radiators. Heated or cooled air is directed upward. Supplied with two or four-pipe heat exchanger. The option of horizontal installation under the ceiling is possible. The models have built-in and remote control.

The downside of the system is the increased noise level generated by the fan.

Air conditioning and fan coil: which is better?

Standard split systems are affordable, but quite expensive to operate when several consumers are connected. At the same time, they are not able to provide adequate comfort in areas with several rooms and walk-through zones. That is why it is more advisable to choose a more environmentally friendly and efficient fan coil for large objects. The chiller system will create a modern climatic complex that will satisfy the need for clean air with a certain humidity and temperature with minimal energy consumption.

Benefits of using fan coil units

- Thanks to the forced air circulation, fan coil units raise the room temperature faster than radiators operating on the principle of natural convection.

- The chiller-fan coil system heats the house in winter and switches to cooling in summer.

- The coolant temperature decreases.

- Heating costs are reduced, the savings are tangible for large houses.

- Automatic control simplifies temperature control. It is enough to set the desired indicators on the remote control.

- The risk of an emergency is minimized.

- Installing fan coil units provides the ability to choose a comfortable temperature for each room.

- Blocks with water heat carrier are more economical, durable and reliable heating elements than electric convectors.

Heating features

The layout of the heating elements is chosen based on the individual characteristics of the room. The fan coil in the heating system plays the role of a radiator, so it is preferable to install it at the bottom. The number of blocks in a room is calculated taking into account several factors:

- square;

- ceiling height;

- window sizes;

- winter temperature in the region.

Types of zoning

Multi-zone system allows you to heat some rooms and cool others at the same time

Air conditioning systems of varying complexity are used. To maintain the same temperature in all rooms of a private house, a single-zone option is suitable. Work algorithm:

- In summer, water circulates in the pipes with a temperature of 7 °. It is fed to the fan coil heat exchangers, which cool the air in the rooms. The unit's operation is regulated by a controller connected to a temperature sensor. The heated water is sent back to the chiller.

- In winter, the automation switches the coolant to the heating source (boiler, boiler).

A two-pipe scheme and blocks with one circuit are used. The house has a cooling or heating mode, but in some rooms it is possible to change the microclimate parameters.

The multi-zone system offers enhanced functionality.Some rooms are heated and others are cooled at the same time. This possibility is provided by the separation of cold and hot water on different branches. For installation, blocks with two circuits and a four-pipe connection diagram are required.

The microclimate in the house is regulated by thermostats. Sensors are installed in every room. When the set value is reached, the heat supply to the fan coil units and the electricity supply for the fan operation are cut off. The device enters power saving mode. In houses where central air conditioning is provided at the design stage, it is advisable to use fan coil heating. The universal system replaces two climatic systems - water heating and air conditioning.

Today, an indisputable fact is that heating a room using a household, semi-industrial split system, as well as any type of industrial air conditioner is much more efficient than conventional electric heaters. However, as the outside temperature drops, the efficiency decreases. Therefore, I would especially like to highlight the use of a chiller-fan coil system for heating a room.

How is heating with fan coil units? In this direction, a special group of equipment has been allocated, designed specifically for heating and this equipment is called - heat pumps. It should be noted that absolutely all types of fan coil units (wall, cassette, duct, floor-sub-ceiling) can heat the air, but keep in mind that warm air from the fan coil will rise up and the location of the fan coil at the top will have a bad effect for heating. This applies, to a greater extent, to channel and cassette fan coil units. For the best heating efficiency, fan coil units with a bottom position or with an adjustable air outlet in height should be selected. The very possibility of working on heating does not depend on the design of the fan coil. If the fan coil unit is paired with a chiller that can work to get cold and heat, then the fan coil unit can also work to heat the air. If the chiller is designed only for cold operation, then, accordingly, the fan coil unit can only work for air cooling.

In most cases, fan coil units are produced two-pipe, and they also have one heat exchanger inside the fan coil, and they are most often used. Nevertheless, many manufacturers also produce four-pipe fan coil units, which have two heat exchangers inside and these heat exchangers can each operate in their own mode, independently of each other. In this case, each heat exchanger is connected to its own chiller or any other system that prepares (heats / cools) the water for its further supply to the fan coil units. These heat exchangers operate independently of each other. As such a system for one heat exchanger, you can use an individual boiler or connect to central heating, if available, and connect the other to the chiller.

Such fan coil units have wider functionality, but in this case, such four-pipe heat exchangers can be used to heat the air. The efficiency from the use of fan coil units as heating devices is much higher than from the use of conventional heating radiators precisely due to the use of built-in fans inside the fan coil unit and more efficient materials in terms of heat transfer from which the heat exchanger is made.

An air-to-water heat pump is not only, but also an excellent option for comfortably cooling a house on a hot summer day.A real opportunity to avoid the cost of installing additional equipment for cooling the room is to use a ready-made circuit for hot water heating using fan coil units instead.

At first glance, fan coil units look like ordinary batteries, but their capabilities are much wider than that of radiators. They do a very good job of achieving the desired room temperature, even when installed in a low temperature heating system. In heating mode, the efficiency and therefore the economy of the heat pump are ensured. The improvement in heating performance compared to radiators is achieved through active air circulation. Because a fan coil is a heat exchanger in which a heat or coolant is supplied and with the help of a built-in fan, air is blown, which, depending on the water temperature, is either heated or cooled. The main function of the fan coil unit is to regulate the air temperature. The system with heat pumps and fan coil units allows you to simultaneously solve the problems of ventilation, heating, cooling and recuperation.

In winter, heated water is supplied to fan coil units for space heating. In summer, the heat pump cools the water supplied to the fan coil units for air conditioning.

The use of a heat pump with a fan coil system is a comfortable climate based on one equipment all year round.

How does fan coil heating work?

For the task of only heating buildings, there is a separate type of fan coil unit called heat pumps. Any type of equipment can perform heating. But when heated, the air will rise. Therefore, it is better to place the device closer to the floor. In this case, the most suitable are wall or floor-sub-ceiling models. Channel or cassette setups will not have enough effect.

The design of the heat pump is not critical to the performance of the system. The operating mode of the fan coil unit is influenced by the chiller. If it works for cooling and heating, then the fan coil unit will cope with both tasks. If the chiller unit only cools, then the fan coil unit will only lower the air temperature.

If it is necessary to use the fan coil only as a heating device, then two-pipe (single-circuit) models are chosen. They include one heat exchanger and one hydraulic circuit.

Sometimes the user wants one system to heat the air in winter and cool it in the heat. For this, a four-pipe device configuration is provided. Its difference lies in the presence of two evaporators and two hydraulic circuits. One lowers the air temperature, the other increases it. Each circuit is connected independently: one is connected to the chiller, the second to the heating system. Or they buy two chiller units, one of which is used for cooling, the other for heating.

The functionality of four-pipe (double-circuit) systems is very wide. It demonstrates greater efficiency compared to a simple heating system. High performance is achieved through the use of fans that improve air circulation in the room. Also, materials with better heat transfer are used in the heat exchanger of the apparatus.

An air-to-water heat pump is not only, but also an excellent option for comfortably cooling a house on a hot summer day. A real opportunity to avoid the cost of installing additional equipment for cooling the room is to use a ready-made circuit for hot water heating using fan coil units instead.

At first glance, fan coil units look like ordinary batteries, but their capabilities are much wider than that of radiators. They do a very good job of achieving the desired room temperature, even when installed in a low temperature heating system.In heating mode, the efficiency and therefore the economy of the heat pump are ensured. The improvement in heating performance compared to radiators is achieved through active air circulation. Because a fan coil is a heat exchanger in which a heat or coolant is supplied and with the help of a built-in fan, air is blown, which, depending on the water temperature, is either heated or cooled. The main function of the fan coil unit is to regulate the air temperature. The system with heat pumps and fan coil units allows you to simultaneously solve the problems of ventilation, heating, cooling and recuperation.

In winter, heated water is supplied to fan coil units for space heating. In summer, the heat pump cools the water supplied to the fan coil units for air conditioning.

The use of a heat pump with a fan coil system is a comfortable climate based on one equipment all year round.

Fan coil types:

Fan coil units universal (floor)

Universal fan coil units MYCOND have a wide range of applications. Most often, blocks of this type are installed on the floor in a vertical position or mounted under the ceiling in a horizontal position, where the free space under the ceiling is minimal.

Refrigeration capacity:

- 1.44-10.61 kW

Thermal power:

- 2.44-17.3 kW

Benefits:

- Wide range of applications

- Comfortable cooling for large areas and low heights

- Can be installed horizontally or vertically

- Low noise level

- Wide range of control accessories

Technical features:

- Static pressure up to 60 Pa

- Execution with or without legs

- Remote or built-in control panel

We also offer BRIZA fan coil units. It is a super slim and powerful fan coil unit for heating and cooling.

Fan coil unit Briza is a unique climate unit that includes two functions! A hybrid that provides comfortable warmth in winter and refreshing coolness in summer.

It will provide your home with an optimal climate throughout the year.

Power to the Breeze fan coil is provided by the original Low-H2O technology, combined with a virtually silent dynamic system. Briza is the thinnest fan coil unit on the market with similar performance.

Fan coil unit Briza is ideal for connection to low temperature heat sources such as heat pumps, solar energy systems and condensing boilers.

Thanks to the latest EC motors, Briza fan coil units consume 50% less energy than traditional motors. Briza is remotely controlled using the latest automation.

All this is complemented by a sleek, slim design with a flat front bezel, stylish grille and an impressive variety of colors. All color solutions of fan coil units can be provided in the form of original samples, and the painting itself will be performed exclusively for you at the production of the Belgian company JAGA.

Fan coil units cassette (ceiling)

Cassette fan coil units MYCOND are designed for air conditioning of various premises. The fan coil unit is installed in the under-ceiling space with the installation of a special decorative panel. Such blocks are widely used in office premises and sales areas.

The optimized design allows for higher volumetric airflow and increased productivity. The low height of the door closers allows them to be installed in rooms with a low ceiling height. Due to the compact design and low weight of the MCF-K series fan coil, the equipment can be installed without special mechanisms. The louvers of the indoor unit are profiled in such a way as to avoid additional noise.

The use of a fan impeller of a carefully designed shape made it possible to:

- reduce air resistance;

- get a more uniform air flow at the outlet;

- achieve a uniform distribution of air velocities over the surface of the heat exchanger.

Refrigeration capacity:

- 3.03-9.0 kW

Thermal power:

- 4.5-11.3 kW

Benefits:

- Uniform distribution of cooled air, which provides comfortable cooling of large rooms

- Low noise operation

- Easy to install due to compactness of the unit and low weight

- Uniform four-way distribution of cooled air, which provides comfortable cooling of large rooms

- Low noise level

- Ease of building a condensate drainage system thanks to built-in drainage pumps

- Ease of installation

- Wide range of control systems and accessories

- Possibility of optional equipment with fans with EC motor

- Available in 2- and 4-pipe versions

Technical features

- 3-, 4-row heat exchangers

- 2-pipe design, 4-pipe design

- Possibility of optional installation of an electric heater

- Low height of the fan coil unit

- Multifunctional controller and IR remote control

- Wide range of optional control panels

- Integrated condensate pump

- Stylish design that blends harmoniously with any interior

Fan coil units wall

Wall fan coil units practically do not differ externally from the internal blocks of conventional split systems. They are installed on the wall at a certain distance from the ceiling. As a rule, wall-mounted fan coil units come with remote controllers and a built-in three-way valve. Most often, this type of equipment is installed in small office premises. Refrigeration capacity:

- 1.87-3.81 kW

Thermal power:

- 2.57-5.2 kW

Benefits:

- Low cost of equipment and installation

- Easy connection to the refrigeration system thanks to the integrated valve

- Wide installation possibilities, since no special conditions are required

- Low noise level

Technical features:

- Possibility of optional equipment with fans with EC motor

- 2-pipe version

- Possibility of using infrared remote control

- Wide range of optional equipment and control systems

Fan coil units are in-floor.

CLIMA CANAL - complete climate control!

Despite its modest dimensions, the Clima Canal is a powerful device that allows you to provide heat in the most critical conditions. Quiet and discreet, Clima Canal creates maximum climatic comfort. This high-tech, fan-driven LOW-H2O * heat exchanger radiator has been specially designed to deliver record performance in an ultra-compact unit. At the same time, the noise level is imperceptible to hearing and amounts to 29 dB! In boost mode, the radiator develops even more power, providing ultra-fast heating and cooling.

The very definition of "fan coil" is inseparable from such concepts as a chiller and a hydronic module. Only in isolated cases can a fan coil unit be used separately and work with other climatic equipment.

Fan coil unit as a chiller element

Initially, the fan coil was used only in combination with a chiller and was its integral part, and since this whole system worked to cool the air in rooms with a large number of rooms, the fan coil was also intended only to cool the air in the hot season. Water was used as a working medium that circulated from the chiller to the fan coil and back to the chiller. The provision of such a continuous flow was provided by a hydronic module - its one or more pumps.

Over time, the processes of heat transfer were more deeply studied, and a well-grounded decision appeared - in addition to cooling the air, fan coils were also used to heat the air.To implement this function, the chiller was equipped with a 4-way valve and other auxiliary elements. If in cooling mode the refrigerant in the chiller moves in the direction: compressor - condenser (most often air) - throttling device - evaporator (most often plate) - and again the compressor, then in heating mode it moves in the opposite direction: compressor - evaporator - throttling device - condenser - compressor. It is in the evaporator, which in this case serves to condense the refrigerant, that a large amount of heat is taken from it, which heats the water that flows further into the fan coil units to heat the air in them.

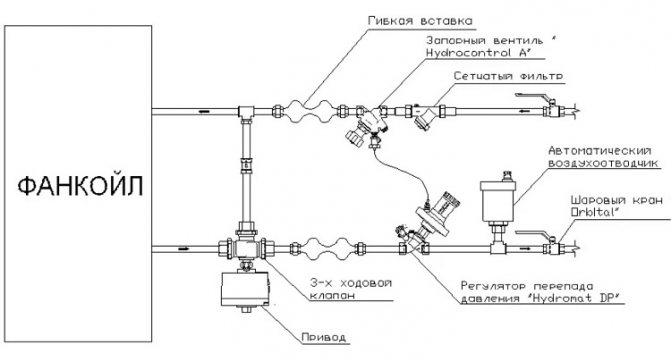

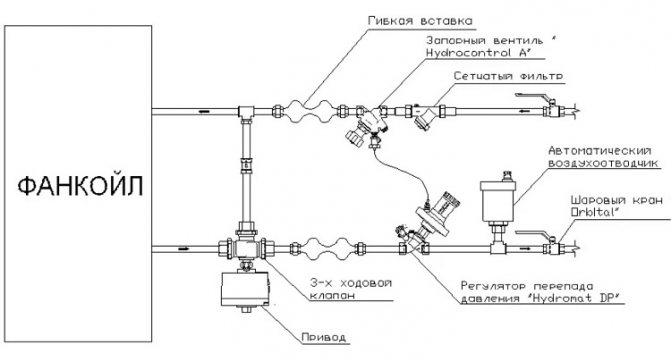

This function does not require any changes in the fan coil design at all. As before, the fan coil unit includes a heat exchanger through which water flows, a fan that blows air around such a heat exchanger, a temperature sensor, a port for receiving an infrared signal from the control panel (if any), an air filter, a condensate drain pan and 3- x directional valve (supplied separately).

Chiller working principle

A chiller is used as a source of heat carrier. It raises or lowers its temperature depending on the needs. The chiller duty cycle for cooling is as follows:

- The compressor compresses the freon to the condensing temperature;

- When the refrigerant enters the liquid phase, its temperature rises;

- In the condenser, freon is cooled from air or water (depending on the type of chiller);

- Passing through the expansion valve (thermostatic expansion valve), the refrigerant enters the evaporator;

- Freon pressure drops, it goes into a gas state;

- When boiling (evaporating), the temperature of the refrigerant decreases;

- Freon cools the water that circulates through the fan coil unit.

If the chiller is in heating mode, the cycle is reversed. In it, the evaporator and condenser change roles. It heats the water that circulates in the fan coil units and cools the air (or water in the case of a water chiller) in the outside environment.

Fan coil classification

Like other indoor units of various air conditioning systems, regardless of the operating mode, by location

fan coil units are:

- wall-mounted;

- cassette (single-stream and four-stream);

- cassette four-flow (standard and compact);

- channel (low - medium and high pressure);

- floor - under-ceiling

by design

fan coil units are subdivided into:

- two-pipe and four-pipe;

- two-row, three-row and four-row;

- hull and uncased.

by relative location

fan coil units are subdivided into:

- horizontally installed;

- vertically installed.

Fan coil efficiency

This is how a new name for a heat chiller appeared - a heat pump. In addition to using electricity or using natural resources to generate heat, another method of generating heat has been obtained, and it is 2-4 four times more efficient than the direct use of electricity in heating devices. The heat, which subsequently goes to heating the air passing through the fan coil unit, is obtained as a result of the operation of the refrigeration circuit, and in particular, from the operation of the compressor when the refrigerant is compressed. At the outlet of the compressor, the refrigerant can leave with a temperature of +60 ℃ to +100 ℃. This heat is then used to heat the water, which is fed to the fan coil unit, and then to the air. Since work for heat is also provided for in winter, then, in order to prevent freezing of water, it is changed to any liquid that does not freeze at low temperatures, then the same liquid will enter the fan coil units. In such situations, the initial selection and calculations should be made specifically for the fluid that will be poured in the future. Replacing one fluid with another during operation is prohibited.The efficiency of the heat supply system based on non-freezing liquids will be lower due to their increased viscosity, which entails additional resistance losses during heat exchange.

Where can fan coil units be used for heating?

All manufacturers produce chillers for both cooling and water heating, i.e., in most cases, they can operate both in cooling mode and in water heating mode, while the temperature of the water supplied to the fan coil unit for heating the air, usually + 40… + 55 ℃. There are separate cheaper models that work only for cooling or only for heating. The latter have a special name - heat pumps. They are installed in private houses, cottages and provide water heating not only for heating, but also for plumbing and household needs. Fan coil units of various types are used as indoor devices. Fast air heating, intensive forced air circulation and noiselessness put such fan coil units at the highest level among all possible heating devices. Fan coil units can be used separately, independently of the chiller. This option is possible if there is some other source of heating water (liquid), which is directed to the fan coil units. In this case, the water (liquid) temperature should not exceed +70 ℃, otherwise the fan coil will be damaged.

Initially, a fan coil unit is part of a system that also includes a hydronic module and a chiller. Fan coil unit is a complete unit consisting of components:

- heat exchanger - used to circulate water;

- fan - its task is to blow off the heat exchanger;

- air filter;

- pallet - a tank in which condensate accumulates;

- temperature sensor;

- sensor for receiving a signal from the controller;

- three-way valve (optional).

Chiller and fan coil connection

The harmonious functioning of the system occurs by connecting the chiller with one or more fan coil units by means of pipelines with thermal insulation. In the absence of the latter, the value of the efficiency of the system drops significantly.

Each fincoil has an individual piping unit, through which its performance is regulated both in the case of heat and cold generation. The refrigerant flow rate in a separate unit is regulated by means of special valves - shut-off and control valves.

To direct the chilled water to the heat exchanger, one pipe is connected to the fan coil, and the other, to drain the liquid, to the chiller. The system design allows mixing of the refrigerant with the heat carrier

If the mixing of the heat carrier with the refrigerant must not be allowed. the water is heated in a separate heat exchanger and the circuit is supplemented with a circulation pump. To ensure smooth regulation of the flow of the working fluid through the heat exchanger, a 3-way valve is used when installing the piping.

If a two-pipe system is installed in a building, then both cooling and heating occurs due to the cooler - chiller. To increase the efficiency of heating with fan coil units during the cold season, a boiler is included in the system in addition to the chiller.

In contrast to a two-pipe system with one heat exchanger, two of these units are included in the four-pipe system. In this case, the fan coil unit can work both for heating ‚and for cold, using in the first case the liquid circulating in the heating system.

One of the heat exchangers is connected to the refrigerant pipeline, and the second to the heat carrier pipe. Each heat exchanger has an individual valve controlled by a special panel. If such a scheme is applied, the refrigerant never mixes with the heat carrier.

Since the temperature of the coolant in the system during the heating season ranges from 70 to 95⁰ and for most fan coil units it exceeds the permissible value, it is preliminarily reduced.Therefore, the hot water flowing from the central heating system to the fan coil units passes through a special heating point.

Chiller-fan coil system

At the very beginning, the fan coil unit was inextricably linked with the chiller. Such an installation also included a hydronic module, which provided the movement of water in the circuit and was equipped with several or only one pump. Water has always been used as a coolant. The system provided only cooling of a large number of rooms in the summer heat.

As the process of heat exchange was studied, fan coil units were improved, and it became possible to use them for heating. To realize this idea, the chillers have been improved by adding additional elements to the design.

During cooling, the refrigerant circulates in the chiller unit in the following order:

- Compressor block.

- Capacitor.

- Throttling installation.

- Heat exchanger block.

- Compressor block again.

If there is a need to heat the air, the refrigerant moves in the opposite direction. In the heat exchanger, heat is exchanged between the refrigerant and water. The advantage of such a scheme of work is that the appearance of the heating function did not lead to a change in the design of the fan coil.

How to choose a fan coil unit for your home?

As mentioned earlier, for each case, the project is drawn up individually. The selection of equipment is carried out based on the requirements for power, the presence of any separate modes of operation of the system, the wishes of the buyer. When considering how to choose a fan coil unit, you need to pay attention to the following:

- Chiller capacity.

- Fan coil power.

- The length of the route connecting the elements of the system.

- Pipeline insulation method.

- Fan coil type: most often they choose channel, cassette or floor-to-ceiling for the house.

- System functions: whether only cooling will be carried out or heating of the house is required, is it necessary to add fresh air or its filtration

- Room area.

offers a wide selection of fan coil units from leading manufacturers at an optimal price-quality ratio. Professional craftsmen and managers will help you choose an individual system that meets your expectations.

The fan coil unit is air-conditioned and at first glance is no different from it.

Many people use air conditioning in the summer and, entering the store, do not suspect that this device is much better than an air conditioner.

Translated from English, fan coil means fan and heat exchanger. It makes it easy to regulate the air in the house.

The operating principle of a fan coil unit is quite simple. The air enters the heat exchanger and can then be heated or cooled.

This process depends on the program and type of device.

Thanks to the fan coil unit, you can solve the problem with a bad one. To do this, it is connected to a central air conditioner. It delivers a fresh air stream to the fan coil unit.

What are fan coil units?

Cooling units are classified according to many parameters:

- Depending on from the installation site

: wall and floor-sub-ceiling, channel (low-pressure, medium-pressure and high-pressure), cassette (single and four-flow (standard and compact sizes)). - By design features

: two-pipe (or single-circuit) and four-pipe (or double-circuit); 2-row, 3-row and 4-row; in the case and without it. - By location

relative to the plane: horizontal and vertical

Using fan coil units as a heat pump

A fan coil unit that provides air heating also has an alternative name - a heat pump. If earlier electricity and heat from gas or coal were used as a heating source, now it has become possible to fully heat buildings using a chiller-fan coil system. Moreover, this method is 2-4 times more effective.

The peculiarity of the fan coil unit as a heat pump is as follows:

- The compressor unit, compressing the refrigerant, raises its temperature to 60 ℃ -100 ℃

- The heated refrigerant transfers its heat to the water, which gets into the fan coil unit and helps to heat the air in the room.

- To ensure that the system can work for heating in winter, it is necessary to protect the unit from water freezing.

- To do this, even before the installation of the blocks, the water is replaced with a liquid that is not subject to crystallization, since it is impossible to make any changes during operation.

An important point is that initially all parameters are calculated taking into account the use of antifreeze liquid. Since its viscosity is much higher than that of water, the performance of the system may decrease.

What is the specificity of the air conditioner?

Under air conditioner means a device that:

- used mainly for room cooling;

- in the most common modifications, it has a refrigerant circuit in its design.

Devices of this type are presented in a fairly wide range of modifications. Among the most popular:

- compressor air conditioners;

- devices of the evaporative type.

In compressor air conditioners, the key element is the cooling circuit: a special refrigerant circulates inside it. Most often it is freon. It can be noted that its modern modifications - such as R-22 or R410A - are considered relatively environmentally friendly. Also, the design of the air conditioner includes:

- compressor;

- evaporator;

- fan;

- capacitor;

- throttle device.

The air conditioner works like this. First, refrigerant is fed into the compressor at low pressure. It then shrinks, causing its temperature to rise to about 90 degrees. After that, the refrigerant moves to the condenser, which is blown by a fan. Under the influence of a powerful air flow, the refrigerant quickly cools, and the air that passes through the condenser, on the contrary, heats up.

Air conditioning

Freon at the outlet of the condenser is in liquid form under high pressure. Its temperature is usually 20 degrees lower than that of indoor air. The refrigerant is directed from the condenser to the choke device. After - it is removed from it in a very chilled state. Then it enters the evaporator, where it turns into gas. This procedure is accompanied by the absorption of heat, as a result of which the air that is passed through the evaporator is cooled. After that, the refrigerant can again be started in the cycle - starting from entering the compressor.

Evaporative air conditioners are much simpler. Their design contains the following key elements:

- fan;

- wet filters.

The air is drawn by the air conditioner fan into the reservoir with wet filters, cooled, and then discharged into the room.

Fields of application of fan coil units for heating

Most of the chiller models are capable of heating / cooling. The temperature of the water that enters the fan coil unit to heat the air reaches about 40 ℃ -55 ℃.

There are also installations that work only for heating or only for cooling. The first type is called heat pumps. They are often used in private households. In this case, devices are used not only as an air heater for the room. They also heat water for showers, dishes and other needs. Such fan coil units are distinguished by their ability to quickly heat up the air, to ensure its intensive movement. In addition, they are virtually silent during operation.

If there is an alternative method of supplying warm water for your fan coil unit, you do not need to purchase a chiller as well. It is only necessary to comply with the requirements for the temperature of the liquid - no more than 70 ℃.