Work on ensuring the correct functioning of heating equipment does not end with its installation. Maintenance requires a certain level of knowledge from the owner and constant monitoring of the state of the system. It is important to understand why the pressure in the gas boiler drops or rises, why the equipment functions with differences.

The article presented by us describes in detail all the reasons for pressure instability in the heating agent and hot water preparation system. We will show you how to troubleshoot and keep the readings in the normal range. Our recommendations will help you cope with emerging breakdowns and prevent malfunctions.

What should be the pressure in the heating system

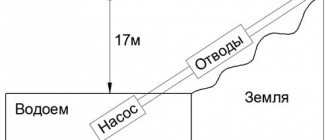

Heating systems can be divided into two types - closed and open. When open, the pressure regulation function is performed by a leaky expansion vessel.

The tank is installed at the top point of the heating circuit and serves to hold the heat carrier expanding during heating, to remove air, and also acts as a safety valve. The operating pressure in such a system depends mainly on the temperature of the heating water.

Most often, when organizing heating in houses and apartments, closed heating systems are used. They are more effective, safer, but require constant pressure monitoring.

It is very important to monitor the pressure, temperature of the coolant, respond to any signs that are not characteristic of the normal operation of the heating system - knocking, frequent discharge of hot water through the safety valve, cold sections of the circuit

The head in a closed circuit occurs due to forced circulation carried out by a pump. Abnormal pressure can lead to equipment failure.

The nominal pressure in gas boilers of various models may vary, it is determined by the technical characteristics of the equipment

When designing a heating system, the pressure is calculated taking into account the height of the water column, the length of the system, the characteristics of the connected equipment, and the cross-section of the pipes.

To adjust the working pressure, you need to focus on the following parameters:

- Technical characteristics of a gas boiler. The manufacturer indicates the capabilities of the equipment and its settings in the instructions.

- Heat carrier temperature. The higher the temperature, the greater the pressure in the circuit; as it decreases, it decreases. Therefore, the adjustment and measurement of pressure in the gas boiler and the heating circuit must be carried out before and after heating the coolant.

- The volume of the circuit and expansion tank. The size of the accumulator has a direct effect on the pressure in the heating circuit, on the range of its fluctuations.

- Allowable pressure values for the least "weak" element "of the system. The pressure in the system should not exceed the permissible values for each of its elements. For example, polypropylene pipes, which, on average, are designed for a pressure of 25 bar at room temperature of the coolant, at a temperature of 90 ° C withstand an increase in pressure only up to 7-9 bar.

The minimum pressure in the circuit can be 0.5-0.8 bar, the exact standard values are indicated in the instructions, in accordance with them the pressure sensor is adjusted to the required value. If the pressure in the heating system drops below 0.5 bar, an emergency situation arises, in which a shutdown or damage to the gas boiler is possible.

The highest pressure in the system is up to 3, rarely up to 4 bar.For a five-storey building, pressures are set up to 5 bar, for a ten-storey building up to 7 bar. When making settings, it is necessary to adhere to the difference in pressure between the outgoing and return pipes - it should be 0.3-0.5 bar. After starting the heating, check if this is the case.

Control devices

To control the water pressure in the heating boiler and heating system, manometers and thermomanometers are used. The latter are combined devices for monitoring two parameters at once. After starting the circuit, it is necessary to control the indicators so that they do not go beyond the normal range.

In some double-circuit floor and wall boilers, traditional dial gauges are absent. Instead of them, electronic sensors are installed here, information from which is transmitted to the electronic unit, after which it is processed and displayed. Another approach is also possible - if the heating unit is devoid of a pressure gauge, it is provided by the safety group.

The security group itself includes the following nodes:

- Manometer or thermomanometer - to control the temperature and pressure in the heating circuit;

- Automatic air vent - prevents contour airing;

- Safety valve - relieves the coolant pressure when it rises excessively.

Be sure to provide this unit in a closed heating system.

How to check the pressure in the boiler and the circuit

Control over the pressure in the system is carried out using instruments that measure and reflect the pressure in the circuit using a digital or mechanical dial. The sensors are installed by the manufacturer on the boiler outlet.

During the installation of the system, pressure gauges are also installed near the collectors that distribute the coolant to various parts or floors of the building.

A safety group for boilers in the heating system helps to control the temperature regime, the pressure in the circuit, protects the equipment from destruction, diverting excess pressure outside

Additional pressure control is required when using boilers for heating water, in underfloor heating systems. A drop or increase in pressure can be observed in different ways in different parts of the heating system.

The closed loop allows to increase the pressure in the system, which increases its safety, since at higher pressure the boiling point of the liquid increases

When starting the gas boiler, check the manometer readings while the heating water is still cold - the pressure should not be lower than the minimum value, which is indicated by the red adjustable arrow of the manometer. The setting is carried out by a representative of the company with which a contract for service and gas supply has been concluded.

The initial setting is made when heating is first started. In the future, the pressure is checked every week, if necessary, the system is fed with water. Make-up is carried out at a coolant temperature below 40 ° C.

Purpose and types of air relief valve

If you are wondering why the pressure in the heating system is dropping, then you should first use the air relief valve. In industrial boilers, before entering the boiler, water goes through the stage of removing dissolved air. If initially it contained up to 300 g / m 3, then after it becomes suitable and corresponds to indicators of 1 g / m 3. But such technologies are quite expensive, therefore they are not used in private housing construction.

If you are also worried about why the pressure in the heating system drops, then the coolant may be oversaturated with air. This interferes with the circulation of the liquid, while some areas overheat, while others cool down. To solve the described problem, air vents are used, which are automatic or manual.Each variety is installed in different locations where there may be a risk of air accumulation. Valves called can have a radiator and traditional design. As for the configuration, it can be angular or straight.

The reasons for the increase in pressure in a gas boiler

To detect an increase in pressure in a gas boiler, in addition to the pressure gauge readings, frequent discharge of water through the safety valve and blocking of the device help. Having determined the high pressure, first of all, excess air is dumped through the Mayevsky taps and the boiler is turned off. There can be several causes of malfunctions.

The normal upper pressure value is provided by the system by dumping the excess heating medium through the safety valve into the drain

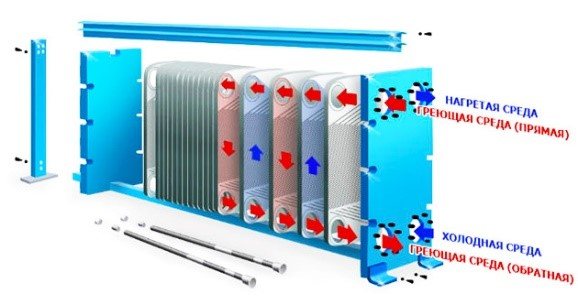

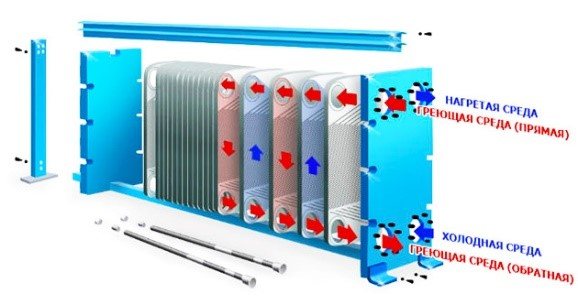

An increase in the pressure in a gas boiler can be caused by damage to the partition of the secondary heat exchanger, which simultaneously serves to isolate and increase the contact area of two circuits - heating and hot water supply.

The secondary heat exchanger draws water from the heating circuit for the preparation and supply of DHW in a double-circuit boiler. Damage to the partition leads to the pushing of water from the DHW circuit into the heating system, increasing the pressure in it.

The secondary heat exchanger serves to service the hot water supply system. The DHW water heats up as a result of contact with the heating medium in the heating circuit. A metal baffle protects the system from mixing the two circuits, damage to which leads to the exchange of fluids and disruption of normal pressure

Replacing the heat exchanger will solve the problem. It is possible to carry out repairs on your own, but it is undesirable to do this, since interfering with the operation of gas equipment requires knowledge and experience in this area. In addition, self-repair of the boiler will deprive you of the right to warranty service.

A failure in the operation of the automation of the gas boiler or a loose impeller of the pump, which sucks in air, also increases the pressure in the gas boiler. Equipment malfunctions that lead to abnormalities in the normal pressure may be the result of a factory defect, a breakdown of the control board, or an incorrectly configured system. Only a qualified technician can fix this kind of problem.

Norm and control

We have already said that the pressure in a gas boiler should be in the range of 1.5-2 atmospheres - this is the norm for a system that is put into operation and is in a heated state. In multi-storey buildings heated by centralized boiler houses, this figure is higher. Here, pipes and batteries must withstand not only high pressure, but also water hammer - this is an abrupt increase in pressure.

If drops are typical for centralized systems, then for autonomous heating they are rare - the volume of the coolant here is not so large that serious jumps are observed. In a cold state, the normal indicator is 1-1.2 atm., And in a heated state, a little higher.

In private households, autonomous heating systems are used, powered by single-circuit and double-circuit boilers. The latter are becoming more widespread. In addition to heating, they solve the problem of preparing hot water. One circuit in them heats the coolant circulating through the pipes, and the other ensures the operation of the hot water supply system.

Increasing the pressure in the heating circuit

What to do if the pressure in the heating system rises excessively?

First of all, you need to establish the reason, and there may be several of them:

- Incorrect filling of the circuit, its airing. Due to the rapid filling of the heating line, air locks can form in it. To avoid this phenomenon, fill it slowly when starting the heating.

- The temperature in the circuit is too high. Any increase in temperature and coolant leads to its expansion and an increase in pressure in the system. It is necessary not to allow too much increase in order to protect the heating equipment from critical loads.

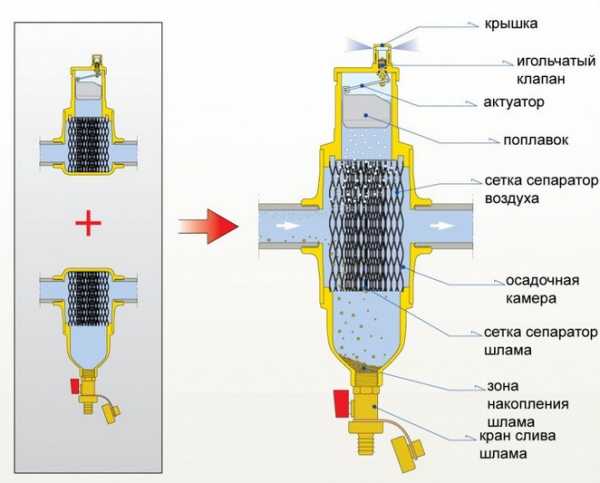

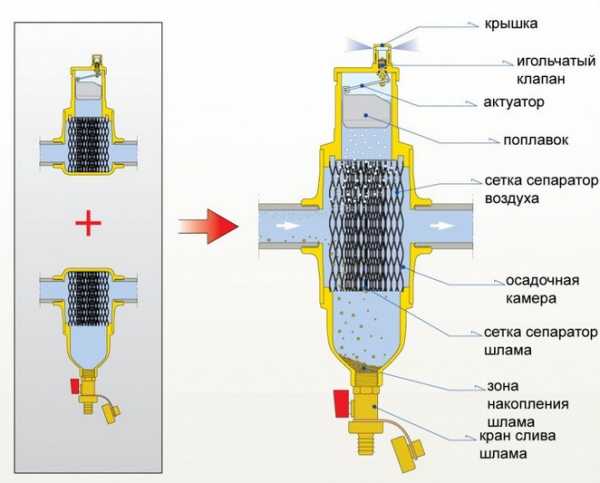

- Stopping the movement of the coolant. The reason may be a closed shut-off valve, blockage of the mud filter, air plugs.

To identify the problem area, it is necessary to examine the entire contour step by step.

It is necessary to check and clean the filter immediately after the first start of the boiler, and then again after a week. Then, routine checks and cleaning are carried out once a month or season, depending on the degree of contamination of the coolant

Leaks can be caused by a breakdown of the make-up valve - wear of the valve gasket, mechanical damage to parts, scale trapped between the seat and the gasket. If the tap passes, then the excess water coming from the water supply system to the heating main increases the pressure in it, because the pressure in the cold water supply is always higher. It is necessary to tighten the tap or replace it if it fails.

Air locks are a common cause of heating system problems. They can be caused both by malfunctions of the gas boiler itself, as well as problems in the circuit or improper start of heating.

Restarting the system will help to troubleshoot - its slow filling with coolant, starting from the lowest point, until water flows from the top point of the circuit. At the same time, all air bleed valves must be open. Airing the system can lead to both an increase and a decrease in pressure.

Pressure drop

An increase in pressure in closed heating systems is not the only problem, in some cases there is a sharp drop in operating pressure, while among the reasons why the pressure level drops, the following should be highlighted:

- hidden leaks of the system, the appearance of corrosion, loosening of connections, leaks of fittings;

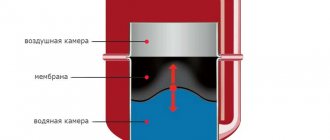

- rupture of the tank membrane, which requires replacement or repair of equipment;

- pressure drops in the system are observed if the nipple is poisoned, such an air leakage leads to a deflation of the tank, and this causes damage to the membrane;

- there are cracks on the boiler heat exchanger, which leads to a coolant leak;

- pressure drops associated with the appearance of air bubbles lead to a decrease in the overall temperature in the system and its shutdown;

- one of the reasons for a decrease in pressure can be a sour or slightly open tap used to discharge water into the sewer system.

The main reasons for the decrease in pressure

Common reasons why the pressure in a gas heating boiler drops are:

- Coolant leak. Damage to the heating main leads to a leakage, loss of heating water and a decrease in pressure.

- Cracks in the heat exchanger. Leaks in the boiler itself will not only lead to a decrease in pressure, but can also provoke more serious equipment breakdowns, damage the electronics.

- Diaphragm rupture in expansion tank. Through damage in the rubber baffle, the liquid enters the air compartment and the pressure in the circuit is reduced.

To determine the place of a leak in the system, it is fed to normal pressure and the operation of the circulation pump is stopped. Step by step it is necessary to inspect the highway, identify the problem area and troubleshoot.

How to determine the culprit of the loss of pressure?

So, the most important thing is to understand what exactly led to the loss of pressure. To do this, follow the algorithm. First, we take a regular paper towel and wipe off all the fittings. In this case, after each joint, you need to carefully examine the napkin - if there is a wet spot on it. If there is, the reason has been found. If not, you need to move on.

Secondly, we spread dry newspapers under the batteries and wipe all the pipes with the same blotter napkin.If a wet spot is found, the leak is localized. If not, go to the next item. Thirdly, we measure the pressure in the expansion tank and pump it up. This can be done with a regular bicycle pump and a factory pressure gauge. The head no longer drops - congratulations, you solved the air pocket problem. But if after pumping up the pressure drops sharply or does not deviate from the initial one, your hydraulic tank has a torn membrane. If the pressure drops smoothly, we move on.

Fourthly, we shut down the boiler and close the valves on the pressure and return pipes, cutting off the heater from the system. We measure the pressure for an hour - if it has not dropped, then the water heater itself, or rather its heat exchanger, is to blame. Also in the boiler Navien

or any other two-circuit installation, the air vent or pressure relief valve may malfunction. Fifthly, we check the shut-off valve on the branch to discharge the coolant into the sewer. If it is weakened, it needs to be blocked or replaced (it is better to cut another one downstream). After localizing the leak or determining the cause, you can begin to eliminate it. How to do it? We will discuss this below.

How does the operation of a hydraulic accumulator affect pressure?

Expansion vessel problems that affect the head in the heating circuit are very common. Incorrectly calculated volume of expansomat is one of the most characteristic prerequisites.

Malfunctions can result in improper installation, low or high pressure in the air chamber of the tank, damaged diaphragm - each of the reasons can lead to disruption of the circulation of the coolant in the system.

Expansion tank: device features and volume

If a small tank is installed in the heating system, it cannot compensate for the expansion of the heating water during heating. At a temperature of 85-95 ° C, the water expands by about 4% and its excess volume is released through the safety relief valve.

In order for the expansomat to fully perform its compensatory function, its capacity for systems with a gas boiler must be at least 10 percent of the total volume of water in the circuit.

If you install a tank with a volume of more than normal, then the pressure fluctuations will be even less. Reducing pressure drops has a positive effect on the operation of the system and the service life of heating equipment

Damage to the tank membrane leads to the fact that water completely fills its volume and the pressure in the circuit drops. If you fill the volume of the circuit by opening the make-up valve, this will create a new problem - when the coolant heats up, it will not have much to expand and the pressure in the system will increase more than normal. The situation can be corrected only by replacing the rubber partition.

The tank should be installed only on the return pipe, in front of the heating boiler. So the tank will have a minimal effect on the operation of the circulation pump, which is installed after the gas boiler. In addition, here the water temperature is lower and the negative effect on the pressure in the system and on the tank membrane will be less.

Air chamber pressure setting

The pressure formed in the air chamber of the expansomat can also lead to an increase or decrease in the pressure inside the heating system. It is possible to check and pump air in the tank only if there is no coolant in the tank.

To do this, shut off access to the common circuit with shut-off valves and drain the water through the drainage drain. Then the pressure in the air chamber is measured and inflated / deflated to the required values.

You can check the pressure indicators in the expansion tank using a car pressure gauge, pump it up using a car pump

To set the pressure of the expansion vessel, the air chamber must be 0.5 bar higher than the expected maximum system pressure. After the pressure in the equalizing part of the tank is adjusted, the circuit is filled with cold water to the expected pressure.

Then the air is released from the air chamber until the pressure in the heating circuit and the tank starts to decrease simultaneously - here it is necessary to simultaneously monitor the pressure in the system and in the expansion tank.

In this phase, changes in indicators are hardly noticeable, therefore, it is necessary to be ready to immediately stop bleeding air from the expansion tank as soon as a simultaneous decrease is detected.

How to prevent air from entering the system

In order not to face the question of why the pressure in the heating system drops during operation, it is important to correctly commission the equipment. Before starting, the system as a whole and each connection separately are inspected. The system must be pressure tested, for this the compressor is pressurized 25% more than the working head. If a strong decrease in pressure has not occurred within 20 minutes, then the system is equipped correctly, it can be put into operation.

But if the pressure in the heating system constantly drops, then it is important to find the leak and eliminate it. A characteristic whistle may indicate such a problem. It is necessary to fill the system with cold water, this should be done gradually. Before starting, all taps are opened, which will allow air to be released. Unscrew the plugs in the batteries, this will remove air from the system. If the design allows, then the valve should be opened to vent the circuit.

In recent years, the number of those wishing to replace the old heating system with a new one, more modern and economical, has sharply increased. For many, this is due to the transition to an autonomous heating option, for some, for reasons of moral and physical wear and tear of heating units and appliances, and some are simply not satisfied with the outdated type of heating equipment. Such a massive demand for heating equipment and services for its installation gave rise to a large number of low-quality goods and non-professional workers who do not have sufficient qualifications.