During the construction of private houses and apartment renovation, a wide variety of materials are used, including insulation. For the purpose of arranging thermal insulation, mineral wool, foam plastic and extruded polystyrene foam are actively used today.

The latter type includes such an innovative product as Technoplex (50 mm). The characteristics of the material allow you to use it at any stage of repair and construction, so we suggest that you familiarize yourself with it better.

Description and features of the material

Insulation "Technoplex" is made of polystyrene granules, which are mixed with a special foaming compound and graphite under the influence of high temperature and high pressure. The viscous mass is sent to molds of a certain size, where it solidifies and is cut into sheets of standard parameters.

The final product is smooth and firm. The structure of the sheet consists of a large number of small closed cells that do not allow air to pass through. Due to this, the characteristics of "Technoplex" (50 mm) are quite high. Graphite additives significantly improve the thermal insulation properties and enhance the strength of the boards.

The products are sold in rectangular packaging, the size and weight of which depends on the size of the material.

https://youtu.be/55_vup3Fm3o

What is a Technoplex?

The thermal insulation system is represented by plates, the production process of which involves the use of nanosized particles of graphite, which reduce thermal conductivity and significantly increase strength.

Extruded polystyrene foam has a uniform structure, which consists of air cells of 0.1-0.2 mm. Extrusion production technology consists in mixing polystyrene granules and an expanding agent under high temperature and pressure conditions.

The area of application of the Technoplex includes individual and industrial construction. Due to its high resistance to mechanical damage, stress and moisture, the insulation is successfully used at all stages of the construction of engineering structures, from pouring the foundation base to the arrangement of the roof. Technoplex is ideal for insulation of "cold bridges" and the production of sandwich panels. In this case, it is necessary to purchase a heater with a thickness of more than 20 mm, which provides for the presence of a special L-edge. It is the L-edge that improves the tightness of the connection of the plates and prevents the appearance of "cold bridges".

In private housing construction, extruded polystyrene foam is suitable for insulating balconies and loggias, basements and foundations, facades and internal walls, as well as floors.

Dimensions of extrusion insulation

In order to correctly determine the required number of slabs, you should study in more detail the characteristics of Technoplex 50 mm. How many plates are in the package, and what size they are, you can, of course, check with the seller, but it is better to have this information in advance.

So, from the information from the manufacturer, we know that the described slabs are of two types:

- with dimensions 118 x 58 cm;

- size 120 x 60 cm.

Also, insulation sheets can have different widths (from 20 to 100 mm). But since slabs with a width of 50 mm are considered the most versatile, then our article is devoted to them. One package contains 6 plates of the same size.

Technoplex for aboveground structures

House insulation by Technoplex using the wet facade technique.

There are practically no restrictions on the use of Technoplex thermal insulation: wall insulation outside and inside, floors and attic floors, roofs,. The only limitation is the steam room in the sauna, mineral wool is more suitable there, since it is undesirable to heat extruded polystyrene foam above 75 degrees.

Insulation of a house by Technoplex can be carried out with or without a crate. All types of work are available:

- ventilated facade;

- wet facade;

- all interior works, including plastering.

The material does not need hydro and vapor barrier installation. Insulation for the floor Technoplex can be laid under a heavy layer of screed, which is especially important when pouring concrete over the ground. For example, for. Thermal insulation is installed on horizontal surfaces without additional adhesives. Slabs are glued to vertical surfaces with universal construction glue or glue-foam. Additionally, extruded polystyrene foam can be fixed with plastic dowels (fungi) or wooden slats.

Despite the presence of locks at the ends of the slabs, the joints must be additionally sealed; for this, ordinary mounting foam is suitable.

The method of insulating a house outside by Technoplex "wet facade":

- insulation sheets are attached to the prepared wall;

- additionally, each sheet is fixed with 4-5 dowels, the joints are sealed;

- the first layer of plaster is applied;

- before the first layer dries, a fiberglass mesh is recessed into it, a plastic corner is attached at the corners;

- the mesh is tightened with a second layer of plaster.

The last stage is decorative finishing. The wall can be left smooth or made "bark beetle", then primed and painted. No less effective is the use of Technoplex for insulating a loggia. The advantage of this material over conventional foam is the equal degree of thermal conductivity at a lower thickness. With internal insulation in small rooms, this has weight. It is preferable to use Technoplex for the insulation of the balcony outside, in order to exclude the transfer of the dew point to the internal walls if the thickness of the thermal insulation is incorrectly calculated.

Positive features of the material

Technical characteristics of "Technoplex" (50 mm thick) indicate that this material can significantly save the budget, as it has improved thermal insulation properties. In comparison with ordinary foam, the capabilities of this product are twice as high, and if you look at the thermal insulation performance of fiberglass plates, it becomes clear that their capabilities are 1.5 times less.

In addition, a number of positive properties of the material should be noted:

- Increased strength. Extrusion material is more than 5 times stronger than foam.

- High density indicators. "Technoplex" is able to withstand heavy loads, which makes it possible to use it when arranging the floor.

- Resistant to moisture. The dense and solid structure of the material does not allow moisture to pass through itself, while the foam is able to absorb liquid, albeit in small quantities.

Despite the fact that the Technoplex material (50 mm) has rather high characteristics, it still has one drawback - poor vapor permeability. This fact must be taken into account when buying extrusion plates for certain jobs.

Technoplex Technonikol insulation properties

Extrusion Technoplex does not shrink over time, has chemical resistance (however, it is afraid of solvents and gasoline), is not subject to decomposition and decay. The manufacturer offers a material with the lowest possible thermal conductivity in comparison with brick, high compressive strength and mechanical damage, with a long service life and high resistance to moisture.

Technoplex technical characteristics 30 mm - 200 mm

Installation of Technoplex is carried out on glue for expanded polystyrene or by fixing with dowels with a wide head. Technoplex is warmer in comparison with brick, 50 mm of insulation replaces a wall of 600 mm of foam block. If we compare the extrusion of TechnoNIKOL with foreign counterparts, then the cost of Technoplex is lower, with the same characteristics of the insulation. The area of application of the Technoplex slabs is quite wide.

Due to its high resistance to mechanical damage and moisture, XPS Technonikol is used when pouring foundations and ending with insulation of the attic for the winter. The L-edge of the insulation boards prevents the appearance of "cold bridges". The material does not lose its declared characteristics even at 100% humidity, and the absence of formaldehyde in the composition guarantees safety for humans and non-toxicity.

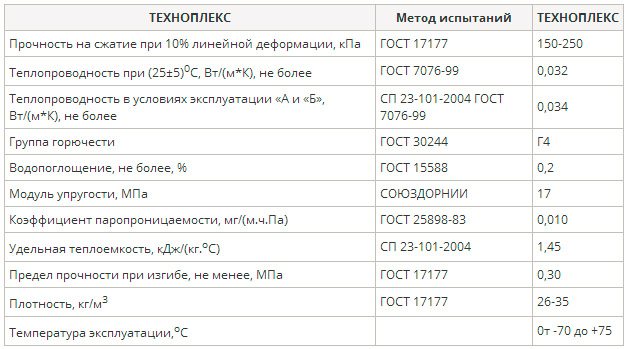

Technical and physical characteristics of the material

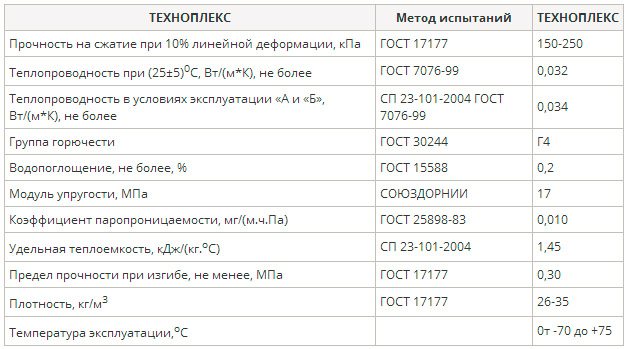

The manufacturer indicates the operational and other properties of the insulation on the packaging. Having carefully studied the instructions, you can understand that the technical characteristics of Technoplex (50 mm) look like this:

- sheet thickness - 50 mm;

- average material density - 26-30 kg / m³;

- compression resistance - up to 25 tons / m²;

- indicator of water absorption of the material (per day) - 0.2% of the total volume;

- use in the temperature range - from -70 to + 75 ° С;

- flammability class - G4;

- heat capacity index - 1.45 kJ;

- vapor permeability coefficient - 0.01 m / h / Pa;

- bending strength - not less than 0.3 MPa.

As you can see, with a low weight and minimum thickness, the material has the ability to withstand heavy loads, which significantly expands the scope of its application. It is also important that this type of insulation is not prone to decay, rodent and fungus colonization. During operation, it does not emit harmful substances into the air and remains resistant to most chemical compounds (except for gasoline and organic solvents).

What to choose - Technoplex or Penoplex? Brand overview

Technonikol and Penoplex are the main manufacturers of extruded polystyrene foam in the Russian Federation, their products are rightfully in demand in private and industrial construction. Their cost, performance and operational characteristics are largely similar, the question of which brand is better to choose is quite relevant. Some users believe that there is no difference at all between Technoplex and Penoplex and that the only difference is the color and size of the plates, others give weighty arguments in favor of the manufacturer they have chosen in their reviews. Only a comparison of assortment and properties will help to find the truth.

Description of material, features and characteristics

Technoplex is a specialized brand of expanded polystyrene from TechnoNIKOL, manufactured by the extrusion method with the addition of nanosized graphite particles. This insulation is produced in the form of dense non-shrinking plates of a silver color of a standard size (it is noteworthy that, upon agreement with the manufacturer, you can buy Technoplex plates with other dimensions). The recommended area of application mainly concerns interior work: thermal insulation of floors, balconies, partitions and ceilings.

Penoplex is made by the same method, but with the introduction of some brands of fire retardants. This allows you to significantly expand the working range, making it almost universal. This building material is advised to choose when protecting foundation structures from freezing (including recessed ones), insulating roofs, floors, facade walls. The size of the boards for Penoplex is always the same: 1200 × 600 mm, the thickness varies from 20 to 150 mm. Insulation color - orange.

Both varieties tolerate temperature extremes well, retain their stable shape and properties during operation and are resistant to biological influences.Both Technoplex and Penoplex have plates with an L-shaped edge; they are recommended to be purchased if it is necessary to exclude cold bridges. Like any other XPS expanded polystyrene, they are afraid of organic solvents and compounds with toluene and acetone, but inert to other chemical reagents.

Comparison of features and prices

Penoplex is represented by 10 brands for private and industrial use, Technonikol - 9 (of which only one is Technoplex). An overview of the assortment shows that Penoplex makes an acceptance for professional construction, and its competitor - for an individual one. Despite the loud statements of the manufacturers, there are no radical differences between the brands. The average cost of 1 m2 of Penoplex insulation 50 mm thick is 230 rubles, for Technoplex with similar properties - 176, but with bulk purchases or third-party purchases, this difference is partially erased.

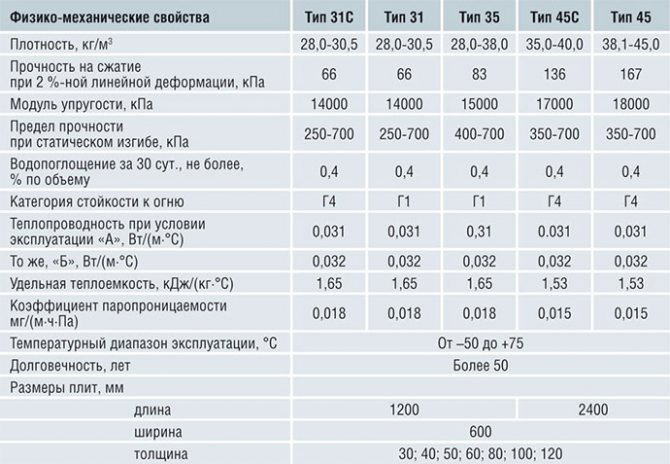

The results of a comparison of the main characteristics, taking into account the declared data of the manufacturers, are summarized in the table:

| Technoplex | Penoplex | |

| Initial density limits, kg / m3 | 26 to 35 | 25 to 47 |

| Minimum thermal conductivity, W / mK | 0,032 | 0,03 |

| Water absorption by volume,% | 0,2 | 0,4 |

| Water vapor permeability mg / m h Pa | 0,01 | 0,012 |

| Flammability group | G4 | G3 and G4 |

| Dimensions: L × W | 1180×580 1200×60 | 1200×60 |

| Slab thickness, mm | 20, 30, 40, 50, 60, 100 | 20, 30, 40, 50, 60, 80, 100, 120, 150 |

| Elastic modulus, MPa | 17 | 15-18 |

| Compressive strength at 10% deformation, MPa, not less | 0,2-0,25 | Depends on brand: 0.12 to 0.3 |

| Operating temperature, ° C | -75 to +75 | -100 to +75 |

Analysis of indicators shows that Technoplex better withstands the effects of moisture and steam and is not inferior in strength characteristics. Thanks to the introduction of fire retardants into the composition, Penoplex wins in terms of fire safety, although they have the same upper operating temperature limit. Materials equally well protect premises and buildings from heat loss (with a slight advantage of Penoplex).

User reviews confirm the characteristics declared by the manufacturers. Penoplex evokes more confidence when insulating external building structures, Technoplex - internal. There are no differences in the installation technology, many positively assess the convenience of working with the plates and the possibility of independent implementation. When cutting Technoplex or Penoplex expanded polystyrene slabs, a uniform finely dispersed structure with closed cells is visible.

Summary: whose products and when is it better to choose?

It is easy to see that there is not much difference between heaters, much is decided by personal preferences. Penoplex appeared on the construction market earlier and, accordingly, is more credible. But many consider it unreasonably expensive, and in the absence of strict requirements in terms of fire safety, they decide to purchase a more affordable Technoplex. The main criterion was and remains the target application - the insulation is selected taking into account the operating conditions and expected loads.

According to the stated information, Technoplex is positioned as an internal insulation, Penoplex - as a universal one. In practice, each brand has its own functional purpose, to determine which one is better to choose, you need to compare slabs with the same thickness and density. Many people make the mistake of comparing Technoplex from TechnoNIKOL or Penoplex, forgetting about the Carbon line from the first manufacturer. Counterfeits are found in both cases; products are recommended to be bought only from authorized dealers or checked for a corresponding certificate.

Scope of application

In what kind of work can Technoplex 50 mm be used? The characteristics and dimensions of the material practically do not limit the scope of its application, therefore it is very popular in many works.

So, "Technoplex" was actively used in the insulation of facades. For this purpose, it is mounted on a special glue (like polyurethane foam).Since extrusion plates do not lose their properties even underground, they are also used when creating a heat-insulating layer on foundations, and as a heater for underground utilities.

The material is no less actively used in the process of interior decoration. It is mounted both on vertical surfaces and in the floor screed.

What is expanded polystyrene

Penoplex is produced by the company of the same name according to its original technology and is foamed under pressure, extruded polystyrene. Approximately the same data can be found from open sources about Technoplex insulation, manufactured by TechnoNIKOL. Technonikol and Penoplex did not report details of the technological process, but the following conclusion can be drawn from fragmentary data:

- Granular raw materials - high-purity polystyrene are mixed with a gasifier, heated to a high temperature and pressed through calibrated micro-holes;

- When passing through a packing with several hundred micro-holes, the main flow of polystyrene breaks down into microfilaments, the polymer molecules stretch out, form bonds with each other and are simultaneously hardened by pressure;

- At the moment of exit from the spinnerets, polypropylene foams in a metered manner and turns into a porous material from millions of tiny frozen bubbles.

The general picture of the production of Technoplex and Penoplex is the same, but there are slight differences in the composition of materials and strength characteristics. According to Technonikol, the Technoplex contains a small amount of amorphous carbon or graphite, so that the rolls can better form a sheet of the required thickness.

For your information! In the cheapest and simplest production technologies, light freons mixed with carbon dioxide are used as pore-forming gases. Modern production methods involve the use of powder and liquid blowing agents.

"Technoplex" 50 mm: characteristics and customer reviews

At the end of this topic, let's say a few words about how consumers relate to the Technoplex material. If you study a huge number of reviews, you can understand that most of the specialists are attracted by the ease of installation of this insulation. They note that with his help, work on the arrangement of thermal insulation is carried out very quickly.

Many people emphasize ease of use, which is explained by the low weight of the material and the ease of processing. Among builders, slabs are valued for the absence of shrinkage and preservation of their original qualities for a long period of time. An ordinary buyer is attracted by the democratic cost - 990 rubles per package.

Based on all that has been said, one conclusion can be made - Technoplex plates are a fairly popular material that has already won the sympathy of a domestic manufacturer. It can be used almost everywhere, which means that the popularity of this insulation will continue to grow tirelessly.

Comparing Technoplex and Penoplex

In fact, the composition of technoplex and penoplex is much more complex, it includes stabilizers, flame retardants, antioxidants and substances that slow down secondary polymerization. The difference can be in temperature, pressure and use of the blowing agent.

What is the difference between expanded polystyrene

What is the difference? A powder or liquid gas-forming agent can be better mixed and distributed over the volume of polystyrene granules; therefore, such materials for insulation have more stable thermal insulation characteristics.

But this is not the only reason why in modern production of technoplex and penoplex they refuse to use freon:

- Freon gas remains in the sealed cells of new, not yet used material for some time, which is formally considered safe, but in practice it is better to get rid of it, since it often leads to lung problems, especially in children;

- Over time, the gas is displaced by air and water vapor. If for the production of expanded polystyrene, not the purest raw materials with styrene residues were used, then gradually part of the contents of the cells of the Technoplex will be squeezed out into the environment.

For "technical" brands of EPS, for example, penofol, such processes are of no particular importance. According to the manufacturer, it is better to use penofol for insulation of foundations, basements of a building, for use in the construction of highways, therefore, a mixture of freon and carbon dioxide is used for its production. The contact compressive strength of penofol is approximately equal to the strength characteristic of the Technoplex.

The use of the extrusion process allows to obtain a linear-oriented structure and very dense elongated pores. As a result, extruded polystyrene foam resists water and water vapor much better, has a higher bending and compressive strength. Therefore, all extruded polymeric polymers used for insulation - penofol, technoplex, penoplex, have the best strength characteristics than they differ from expanded polystyrene, or, in other words, polystyrene.

The main characteristics of Technoplex and Penoplex

The most reliable way to determine which insulation is better is to compare their main characteristics. The most important parameter is thermal conductivity, for foam, the coefficient is 0.029-0.030 W / m ∙ K, for technoplex - 0.030 W / m ∙ K. The difference is negligible, so both materials retain heat equally well.

The second characteristic concerns strength. According to reviews, penoplex is cut better and less deformed during installation. The flexural strength of the technoplex is almost two times lower than that of the penoplex, but its manufacturer initially declares that its products are better used for internal thermal insulation, and the penoplex better withstands the pressure from the heaving of the soil and the mass of the concrete foundation.

The third characteristic concerns water absorption. In this part, penoplex resists water better than TechnoNIKOL products, almost twice - 0.1% versus 0.2%. But both indicators are significantly better than foam -0.5% and mineral wool - almost 10%. In addition, extruded polystyrene foam practically does not change characteristics even after thousands of freeze-thaw cycles.

The last factor is the price of the insulation, in this case the technoplex looks better, its cost per square is 10-15% lower than the competitor.

Comparison of expanded polystyrene with other types of insulation

The main competitors of foamed polystyrene foam are mineral felts and fiber mats. When asked which is better, penoplex or mineral wool, it can be argued that for private one-two-story buildings it is better to use penoplex as the most effective heat insulator. For exterior decoration of high-rise buildings, it is better to use mineral wool, for one reason - absolute fire safety. Expanded polystyrene, even with the addition of a fire retardant, can emit a large amount of toxic gases during high-temperature heating, so for high-rise buildings it is better to avoid unnecessary risks.

On the other hand, it is better not to use mineral wool for damp basements and semi-basements, since the fiber instantly absorbs water. In addition, in the production of certain grades of mineral or basalt wool, phenol-formaldehyde resin is used, which is highly toxic and carcinogenic. It is better, in general, not to use such brands for insulating living quarters.

One of the competitors for the Technoplex is Isolon - a material based on foamed and modified polyethylene.Izolon, of all the materials listed, is best suited for insulating walls and ceilings inside residential premises. The coefficient of thermal conductivity and water absorption of polyethylene foam of the PPE brand is practically equal to the analogous characteristics of the technoplex. The PPE layer can withstand prolonged heating up to 80 ° C for 24 hours. Izolon PPE has good sound and noise insulation, and the main advantage is that the environmental friendliness and safety of such thermal insulation is better than that of the most expensive EPPS brands.

Polyethylene foam, even with strong heating, does not emit toxic decomposition products. The main drawback of the material is its excessive flexibility and softness. Isolon laid on the wall requires additional finishing with hard plates, for example, drywall or MDF. You cannot put a layer of plaster on the isolon or stick wallpaper, therefore it is better to use it in tandem with external EPSP insulation.

Extruded polystyrene foam

Technoplex is a tile insulation made of extruded polystyrene foam with graphite particles. Thanks to graphite, the slabs acquire a gray color and increased strength. 50 mm of Technoplex is equivalent to a wall made of foam blocks 600 mm wide.

Insulation is produced in the form of plates of various widths, lengths and thicknesses:

- Length - 1180/1200 mm.

- Width - 580/600 mm.

- Thickness - 20, 30, 40, 50, 100 mm.

Technoplex is operated at temperatures from -70 0 C to +75 0 C. Its water absorption is only 0.2%, which is a very good indicator. Thermal conductivity is 0.032 W / (m * K).

EPS insulation

It is a unique material that has the following properties:

- low water absorption, almost equal to zero;

- high strength;

- not subject to decay;

- low thermal conductivity;

- high frost resistance;

- not toxic to humans;

- easy to assemble;

- durability;

- light weight;

- environmental friendliness.

It is interesting:

depending on the composition and manufacturer, the insulation can be white, gray, blue, orange and even black.

The disadvantages of expanded polystyrene insulation include:

- strong flammability and intolerance to direct sunlight. This is important to know, because storing polystyrene foam in the sun can completely spoil the material, and this will be unpleasant;

- Although manufacturers claim that polystyrene foam is not gnawed by mice, consumer reviews show the opposite;

- And of course the price, but it is quite high.

But what is the difference between Technoplex and Penoplex? What's better?

Comparison

The main technical characteristics of the insulation are its thermal conductivity, water absorption and operating temperature.

The flammability group for both heaters is G4 (highly flammable).

Their cost differs by 10% (Technoplex is more expensive).

After comparing them, it is clear that there are no significant differences between these heaters.

Yes, Technoplex has slightly better characteristics, but the cost is also higher. Despite the fact that Penoplex is cheaper, with individual construction, the savings are insignificant.

Extruded polystyrene foam

Penoplex is a tile insulation made of extruded polystyrene foam. Unique thermal insulation properties are achieved thanks to the smallest air-filled cells.

Penoplex has a bright and recognizable orange color. Penoplex has excellent chemical resistance, but it is important to know that it absolutely does not withstand gasoline (as well as Technoplex). Due to its good strength characteristics, Penoplex can be used for outdoor insulation.

In the Penoplex line, there are different types of it (their names speak for themselves):

- roof (insulation of attics and roofs of various configurations);

- wall (insulate the basement, walls, partitions, facade);

- foundation (used as a basement and ground floor insulation);

- comfort (can be used for any work, but is especially well suited for insulating apartments, balconies);

- 45 (has the best characteristics of all types, is used in road construction and bridge construction).

... Penoplex is produced in standard widths and lengths - 600 mm by 1200 mm, respectively. But the thickness is different - from 20 mm to 150 mm.

Penoplex is operated at temperatures from -50 0 С to +75 0 С. Water absorption - 0.4% - is slightly worse than that of Technoplex, but still a very high rate. Thermal conductivity is 0.03 W / (m * K).

To find out which is better polystyrene foam or polyurethane foam, this material will help: