Since time immemorial, people have been faced with the burning of wood. And since then, wood has been used as the main type of fuel, which is used to heat various rooms and prepare food. Despite the variety of combustible substances, wood remains a common fuel in the 21st century, due to its low cost, availability and ease of handling. For effective and safe use of it in stoves and fireplaces, it is necessary to possess some information about its physical and chemical characteristics.

Factors affecting combustion temperature

The maximum combustion temperature of wood depends on the species and can be achieved under the following conditions:

- the amount of moisture content is not more than 20%;

- a closed space is used for combustion;

- availability of oxygen in the required volume.

It is also possible to burn fresh firewood with a moisture content of 40 to 60%, while:

- raw firewood ignites only in a well-melted stove;

- heat transfer will decrease by 20-40%;

- there will be an increase in firewood consumption, approximately two times;

- soot will settle on the walls of the stove and chimney.

The efficiency of combustion will be significantly reduced due to the need for an increased temperature, which is used to evaporate water and burn tar in conifers. Under ideal conditions, beech and ash have the highest burning temperatures and poplar have the lowest. Beech, larch, oak and hornbeam are valuable wood species and are not used as fuel. In domestic conditions, birch and coniferous trees are used for burning wood in stoves, considering that they give the highest temperature during combustion.

What are the ways to clean the chimney

There are several ways to clean the chimney:

- folk remedies;

- use modern chemicals;

- ignite the chimney;

- mechanically remove soot deposits.

Using the first three methods, you can clean channels that have a slight degree of contamination. But if the walls of the chimney are overgrown with soot, then the mechanical method will be just right. The first two ways to clean the channel are to put on the hot fuel in the furnace a chemical or folk remedy and is set on fire.

Substances released during combustion actively decompose pollution. Part of the soot in the form of flakes breaks out of the pipe and falls down to the courtyard, the rest falls down to the channel bottom. Calcining the chimney although it belongs to folk methods, it is dangerous to carry it out on your own, you can start a fire.

Calcination is the combustion of soot in a pipe due to the high combustion temperature. To do this, the furnace or boiler must be made to work at full power, which is ensured by the supply of the greatest amount of oxygen. After heating, gases heated to a temperature of 600 ° C make soot burn in the chimney and clean it.

The method requires a preliminary check the integrity of the smoke channelwhich can collapse from time to time, even simple rodents can contribute. Openings can ignite flammable materials.

Mechanical way to clean the chimney

This difficult task will become easy if you read the information in this article. Before cleaning the stove, remove from the firebox all objects that are not properly fixed and may interfere. The stove and the hob, if any, are closed with dense cellophane or cloth, and secured with a load.

You need to start cleaning the chimney from below, for this they use special brushes, brooms... After freeing the accessible part of the pipe, the chimney should be cleaned from the side of the roof. To do this, you need to insure yourself with a mounting belt, and with the help of a sinker, try to push or pull out the soot layers inward or outward.

If a lot of garbage and soot accumulates in front of the stove, then you can get rid of it with a vacuum cleaner or a broom with a scoop. This work is usually done by men, as it requires some effort.

Soot can be attributed to the main enemies of the chimney, it and reduces cravings and gradually destroys the pipe. If the soot starts to burn, then not all channel materials can withstand this heating.

Chimney cleaning with potato peelings

To clean the stove in this way, melt it, then put potato peelings on the fire. The peel is pre-dried so that it burns well in the oven. The cleaners are put in a container, the size of a bucket and kept for several days. After this cleaning is ready for use as a cleanser.

During combustion, the purification releases starch, soot-destroying upon contact with her. If you carry out the work correctly, then the soot will fall out of the chimney in pieces for several days, falling into the firebox. To quickly clean the chimney, you can use mechanical cleaning items.

Using salt to get rid of soot

This method is more suitable as a prophylactic method for removing soot deposits, which it is desirable to use constantly. Salt is poured in an amount depending on the size of the furnace on the hot fuel.

When burning, salt particles will react with oxygen molecules and destroy the soot in the pipe... The effectiveness of the measures taken depends on the choice of the quality of the salt, but you can choose the right substance by trying to carry out such cleaning several times.

Which wood burns hotter?

As mentioned, wood is one of the most used fuels for heating homes outside the city. Considering that all firewood burns at different temperatures, you need to choose the ones that are better. The main condition for burning wood is the presence of oxygen, and this largely depends on the design of the stove. In addition, each wood has its own chemical composition and density. The denser the wood, the greater the heat transfer from it. Especially important for the greater heat transfer of wood during combustion? in addition to the density and the presence of oxygen, it has the moisture content of firewood.

Dry wood burns better and generates more heat than raw wood. Therefore, after cutting, they are folded into woodpiles and dried under a canopy for a year. Everyone who has had a chance to heat the stove with wood has noticed that some of them burn brightly, giving off a lot of heat, while others smolder and heat the stove a little. It turns out that everything depends on the heat output of the wood. According to this indicator, the most suitable species for burning in furnaces are birch, pine and aspen.

Prepare firewood in advance

Bring the wood into a warm room 2-3 days before lighting to increase its starting temperature.

The warmer the wood is initially, the:

- They spend less heat on their own heating and more on heating the room. You use heat better.

- The firewood achieves optimal combustion faster, which further increases its calorific value and reduces the amount of soot emitted. This is because the resin, creosote, tar, essential oils and other substances that are part of the wood do not burn at low temperatures and settle on the walls in the form of soot. And under optimal conditions, the combustion temperature is sufficient so that they burn out entirely and generate additional heat.

The difference between the combustion of "warm" and "cold" wood is immediately noticeable: cold wood emits a lot of smoke, which characterizes incomplete combustion.And warm dry firewood burns practically without smoke.

What is emitted when burning wood?

When wood burns, smoke is formed, consisting of solid particles (soot) and gaseous combustion products. They contain substances found in wood. The products released during the combustion of wood consist of nitrogen, carbon dioxide, water vapor, sulfur dioxide and carbon monoxide, which is capable of burning further.

It is estimated that each kilogram of wood emits about 800 g of gaseous products and 200 g of coal during combustion. The composition of wood combustion products also depends on the conditions under which this process takes place. He might be:

- Incomplete - occurs when there is insufficient oxygen access. As a result of combustion, substances are released that are capable of burning again. These include: soot, carbon monoxide and various hydrocarbons.

- Full - occurs when there is sufficient oxygen supply. As a result of combustion, products are formed - carbon dioxide and sulfur dioxide, water vapor - which are no longer able to burn.

Combustion of soot in the chimney

Soot is a product of incomplete combustion of fuel. During the operation of heating equipment, particles of unburned or partially burnt fuel containing resins and various oxides enter the chimney along with the flue gases, which settle on the inner walls of the chimney, forming a layer of soot and soot.

This leads not only to a narrowing of the internal channel of the chimney and, as a consequence, to a decrease in natural draft, but also there is a danger of ignition of these formations. The combustion temperature of soot can reach 1200C, which is almost twice the permissible thermal load on the chimney walls made of stainless steel AISI 430, and this leads to the destruction of the chimney channel and the danger of fire. The ignition of soot can occur from sparks caught in the chimney system, for example, from a fireplace, stove, fireplace stove.

Despite the fact that the burning time of soot is only a few tens of seconds, this combustion is very intense, to the extent that you can see a flash and a bright torch from the chimney mouth. Only ceramic chimneys Schiedel Isokern and Schiedel Rondo Plus can withstand such periodic ignition without loss.

Unfortunately, the fire of soot is not the only problem for the chimney. The accumulation of soot on the walls of the chimney system prevents the walls of the chimney from heating up, which leads to condensation of water vapor and vapors of resinous substances. Condensation forms when the flue gas temperature is low and the temperature difference between the inner and outer circuits of the chimney. This can be avoided by installing double-walled insulated sandwich-type chimneys.

Condensing, water vapor settles on the inner walls of the chimney in the form of water droplets, mixes with the oxides and sulfur impurities in the soot and form acids, which lead to metal corrosion and destruction of the chimney. That is why, when choosing a stainless steel chimney, you should pay special attention to acid-resistant steel grades such as AISI 304 and AISI 316. In addition, we strongly recommend not to refuse the presence of a condensate collector in the chimney system. It should be remembered that condensate discharged from the chimney system still poses a danger to your sewage system - aggressive constituents of condensate can corrode the walls of plastic pipes. Therefore, let's face it - it is not recommended to drain the collected condensate into the toilet.

So, if your choice fell on a stainless steel chimney, here are some tips, following which you can reduce the load on the chimney system, minimize the formation and accumulation of soot and soot in your chimney, and, thereby, ward off trouble from yourself and your heating equipment:

- use dry chopped hardwood firewood;

- do not forget to adjust the burning mode of firewood, for their more complete combustion;

- if possible, install an insulated sandwich-type chimney, as it reduces the formation of condensation;

- mount the chimney so that it has a maximum of vertical sections and a minimum of bends, since the greatest amount of soot and soot settles on them;

- provide for the presence of a condensate collector and an inspection window for cleaning in the chimney system;

- be sure to allocate time for a routine check of the condition of the chimney and its cleaning (preferably at least 2 times a year).

If you follow all of the above points, you will protect yourself and your home from fire as much as possible and you will enjoy the safe warmth of your hearth.

PS: Twice a night they extinguished soot in the chimney. Latvia. 01.21.2014

Over the past day, employees of the State Fire and Rescue Service received 12 calls related to burning soot in chimneys. Two such fires also occurred in Jelgava. According to the Jelgava municipality police, which was also called to the scene, the first call came at about 18.15 from a house on Garozas Street, and the second at about 20.30 from a house on Kazarmes Street. In both cases, the fire was quickly localized. Recently, such a fire in Jelgava was in a house on Matera street.

Rescuers remind that chimneys need to be cleaned regularly. The soot that has settled on the walls of the chimney can ignite at any time from sparks from the fireplace or stove and lead to the spread of fire to the roof or attic.

In turn, shortly after 3.00 am, rescuers were called to Zvana Street, where an abandoned garden house was burning.

Description of the combustion process

In the process of wood burning, several stages are noted:

- Warming up - occurs at a temperature of at least 150 degrees Celsius and in the presence of an external source of fire.

- Ignition - the required temperature is from 450 to 620 degrees Celsius, depending on the moisture content and density of the wood, as well as on the shape and amount of firewood.

- Combustion - consists of two phases: fiery and smoldering. For some time, both types occur simultaneously. After the cessation of the formation of gases, only coal burns (smolders).

- Attenuation - occurs when the oxygen supply is cut off or when the fuel runs out.

Dense wood burns more slowly than less dense wood due to the fact that it has a higher thermal conductivity. When burning raw wood, a lot of heat is spent on evaporation of moisture, so they burn more slowly than dry wood. Is wood burning a physical or chemical phenomenon? This question is of practical importance, and the conditions for maximum heat transfer and combustion duration will depend on its correct interpretation. On the one hand, this is a chemical phenomenon: when burning wood, a chemical reaction occurs and new substances are formed - oxides, heat and light are released. On the other hand, it is physical: during the process, the kinetic energy of the molecules increases. As a result, it turns out that the process of wood burning is a complex physicochemical phenomenon. Getting to know him will help you choose the right wood species to provide yourself with a long and stable source of heat.

The use of wood based on its heat capacity

When choosing a type of firewood, it is worth considering the ratio of the cost and heat capacity of a particular wood. As practice shows, the best option is birch firewood, in which these indicators are best balanced. If you buy more expensive firewood, the costs will be less efficient.

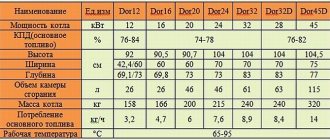

For heating a house with a solid fuel boiler, it is not recommended to use such types of wood as spruce, pine or fir. The fact is that in this case, the combustion temperature of the wood in the boiler will not be high enough, and a lot of soot will accumulate on the chimneys.

Low heat efficiency values are also found in alder, aspen, linden and poplar firewood due to its porous structure.In addition, sometimes alder and some other types of firewood are shot with coals during the combustion process. In the case of an open furnace, such micro explosions can lead to fires.

It is worth noting that whatever the wood is, if it is damp, it burns worse than dry and does not burn completely, leaving a lot of ash.

Features of the smoke that occurs when burning a fire

Throwing wood into the fire leads to increased emission of smoke and carbon monoxide - carbon monoxide. Moreover, the smoke appears in different colors:

- White is an aerosol consisting of small droplets of water and tar vapors coming out of cold wood. The smoke has a specific soot smell. As the log heats up, it evaporates, flames and disappears.

- Gray - comes from red-hot, but not burning logs and embers. It is formed at high temperatures from boiling oils and resins and condenses into a mist. Its particles are much finer than that of white smoke, and it itself is lighter and drier than it.

- Black is a burnt tar called soot. It is formed during the decomposition of hydrocarbons in a flame with insufficient oxidation.

Smoke from a fire lingers in the body for a long time and contains a large amount of harmful substances. This must be remembered by everyone who likes to sit by the fire.

Wood properties

Different tree species have the following physical properties:

- Color - it is influenced by climate and wood species.

- Shine - depends on how the heart-shaped rays are developed.

- Texture - related to the structure of the wood.

- Moisture is the ratio of moisture removed to the dry weight of wood.

- Shrinkage and swelling - the first is obtained as a result of the evaporation of hygroscopic moisture, swelling is the absorption of water and an increase in volume.

- Density is approximately the same for all tree species.

- Thermal conductivity - the ability to conduct heat through the surface thickness, depends on the density.

- Sound conductivity - characterized by the speed of sound propagation, depends on the location of the fibers.

- Electrical conductivity is the resistance to the passage of electric current. It is influenced by the breed, temperature, humidity, fiber direction.

Before using wood raw materials for specific purposes, first of all, they get acquainted with the properties of wood, and only then it goes into production.

Advantages and disadvantages of wood

Wood has the following advantages:

- excellent workability;

- light nailing;

- well painted, polished, varnished;

- has the ability to absorb sounds;

- resistance to acids;

- high bending ability.

The disadvantages of wood include:

- change in shape and size due to shrinkage and swelling;

- low resistance to splitting;

- rotting;

- damage by insects;

- lighting up if safety rules are not followed.

The use of wood in various sectors of the national economy

Wood is widely used in the following industries:

- plywood - veneer, plywood;

- woodworking - wood boards, matches, joinery, furniture;

- logging - raw materials used in the wood-chemical industry, consumer goods, firewood of all kinds;

- sawmill - various lumber;

- wood chemical - tar, charcoal, acetic acid;

- pulp and paper - paper, cardboard, cellulose;

- hydrolysis - feed yeast, ethyl alcohol.