It is quite possible to endure some time without household appliances and a TV set. The situation is much more serious if the operation of the gas boiler is interrupted during a power outage, even for a short period. It is especially unpleasant if the start-up of the power grid is delayed for an indefinite period. Do you agree?

On the forums, many masters argue that when the electricity supply is stopped with the gas equipment turned off untimely, the boiler may break. It is even worse if life-threatening carbon monoxide goes into the room. Are you ready to take such a risk, or is it still better to abandon an electrically dependent heating source?

We will not let you freeze or empty your pockets in vain, spending money on useless events. Let's talk in detail about what will happen to the gas boiler if the power supply is suddenly cut off. You will learn how to ensure the smooth operation of even the most expensive unit stuffed with electronics.

Which elements of the boiler depend on electricity?

Power outages for homes, not only in the hinterlands, but also in cities, occur quite often. They happen due to emergency situations, planned repair and technical work, breakdowns on the line. And the most unpleasant thing is that when the electricity is turned off, the operation of the gas boiler is paralyzed if it is of a volatile type.

The non-volatile gas boiler continues to function normally, even if a power outage occurs. The only exception is if a pump works in conjunction with it, and a system of gravitational circulation of the coolant is not provided.

Non-volatile boilers have the simplest, basic set of functions. They are less comfortable to use than their volatile counterparts. But their work is absolutely independent of the supply of energy to the home power grid, moreover, they are less likely to fail.

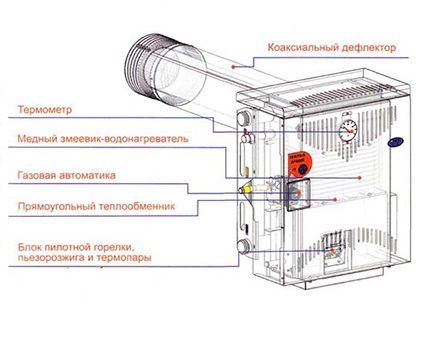

In a heating circuit with a boiler of the simplest type, the set of basic elements is approximately the following:

- natural draft smoke exhaust system;

- heat exchanger;

- a gas burner with nozzles for supplying gas, which is located in the combustion chamber;

- gas supply and ignition unit;

- expansion tank;

- mechanical thermal sensor;

- control module, which includes the boiler ignition system (mechanical or piezo), temperature control;

- safety group (safety valve, pressure gauge, air vent).

Volatile devices are more complex in the device. But is electricity really necessary and important for the functioning of a gas boiler?

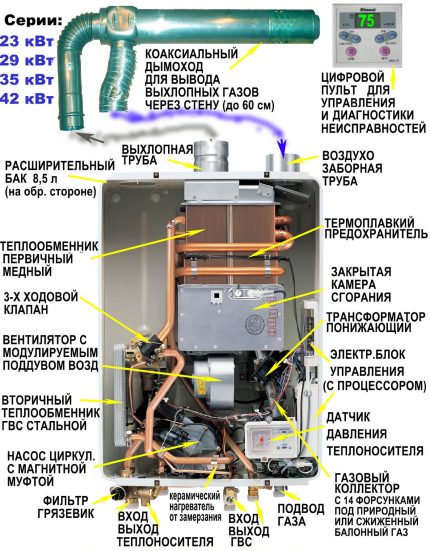

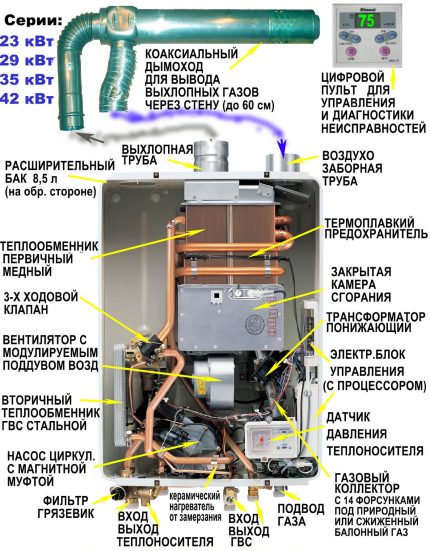

Depending on the model and brand, in addition to the same basic set of elements, in some cases, electronic and automatic type, they may include such functions as:

- forced ventilation system;

- built-in circulation pump;

- electronic system control module;

- shut-off and control valves on an electric drive;

- various sensors - water flow, temperature, flame supply, water pressure in systems, manostat, emergency complexes;

- piezo ignition unit with electric drive;

- automatic temperature controllers;

- notification and remote control system;

- display with the output of the current indicators of the device

Units of this type are more reliable and much more convenient to operate, and besides, they are economical. Automation can be set on and off modes, reducing fuel consumption, creating a comfortable microclimate at home, not worrying about safety and performance.

Modern boilers are crammed with electronics.When choosing a device, also install a voltage stabilizer to protect against power surges

The only negative, after a power outage, a volatile gas boiler will not be able to work fully. It is difficult to say which functions will be absent altogether, it depends on the boiler model. Some units have a combined control system - mechanical and electronic.

It is certain that forced ventilation, automatic control of the flame supply to the burner, pump, display, electronic control module, in general, all devices operating on an electric drive and a constant supply of current will not function.

But is everything so scary?

Different boilers - different consequences

Cooling down at home is not the main danger. Indeed, for serious cooling of housing, 3-5 days are needed, depending on the quality of the thermal insulation, the heated area, the temperature outside and other circumstances. Electricity will probably appear by this time. Except for serious accidents.

Such shutdowns bring more harm to the boilers themselves. And that's not all. Consider the implications for different types of aggregates.

- Electrical.

For them, a power outage is the least dangerous. They simply turn off, and after the resumption of the power supply, they resume work as usual. As a rule, there are no consequences. - Liquid fuel.

Usually there are no special consequences for them either. When the light goes out, the fuel pump simply stops working. Fuel does not flow to the burner, its residues are used, after which the flame is extinguished. But in some situations, this leads to damage to the heat exchanger. The reason is the strong overheating of the liquid in it. The situation is relatively rare, but it does take place. - Gas.

Here the consequences are more serious. The fact is that gas is supplied regardless of the availability of energy. Without electricity, the automation does not work, but the fuel continues to go to the burner and burn. At the same time, circulation pumps, temperature sensors, and flame sensors also do not work. At this time, the liquid, when it enters the combustion chamber, heats up rapidly and can be brought to a boil. It is impossible to start re-ignition without electricity, and therefore the gas that is supplied to the burner begins to gradually seep out into the premises. These leaks can be quite abundant. In ventilation boilers with closed chambers, gas leaks into the room are excluded. But here the gas goes into the chimney, which is also bad. - Solid fuel.

They are the most sensitive to blackouts. However, non-volatile units are most often used, for which the interruption of the electricity supply does not play any role. Otherwise, the consequences are critical. The owner cannot extinguish the flame by shutting off the fuel supply, as in other boilers. Even if you close the flap. It is prohibited to extinguish fire with water. Consequence - at least the heat exchanger fails. But there can be negative consequences for the entire system.

Are power outages dangerous?

Sellers of non-volatile devices and uninterruptible power supplies tell customers blood-curdling stories that look quite believable. A person who does not understand anything at all about the structure of the boiler will believe that in the event of a loss of current, the gas supply to the burner continues.

What is really going on? When the temperature sensors, the electronic control unit and the pump are turned off, uncontrolled fuel combustion in the combustion chamber occurs, which means that the liquid in the heat exchanger overheats.

Accordingly, the pipes do not withstand, they deform, and the water from them bursts, extinguishes the burner of the atmospheric gas boiler. Gas enters the room and creates an explosive situation or simply poisons people and animals. And if the boiler is equipped with a pressurized ventilation system - to the street. This is also unsafe and not environmentally friendly.

Do you agree that it sounds believable and scary? Have you already decided to run for a non-volatile boiler? But in vain!

Do not avoid carrying out maintenance on gas appliances and their components. Testing will show their performance, especially after power outages

In fact, electrically dependent boilers occupy a leading position in the sales market. They are installed in summer cottages, private houses, with owners who spend half a day at work, non-residential premises in which long-term repairs are being carried out.

Power outages, as mentioned earlier, are quite frequent. And for some reason there is no data on hourly large-scale tragedies of carbon monoxide poisoning or explosions.

In addition, such a dangerous device would not be certified and could not comply with GOST in any way, which means that gas workers will not be allowed to operate it.

Now for the technical details. In fact, there is a reliable system in the devices that ensures the shutdown of the boiler in the event of force majeure, including a power outage.

How to deal with intermittent power outages?

In regions remote from large cities, this is a common problem. And so as not to worry about what will happen to the boiler if the light is turned off, there are two solutions.

Solution # 1. Generator

This option is more suitable for country houses and, in general, is not particularly convenient. Yes, generators provide good autonomy, but they are inconvenient. It is imperative to take care of proper exhaust gas discharge. Plus, the generators make a lot of noise during operation. Therefore, we cannot recommend such a solution to everyone.

Solution # 2. Uninterrupted power supply unit

Modern UPS models allow the boiler to work autonomously from 1 hour to several days. Plus, they perform the function of a stabilizer, which also solves the problem of voltage surges. The built-in stabilizer evens out even the smallest surges, and thanks to the possibility of connecting several batteries, a very high autonomy can be achieved. Plus, the stabilizer ensures the batteries themselves are safe during recharging. Thus, the service life of the system is significantly increased.

Gas supply cut-off safety devices

As part of the automation of a gas boiler, a shut-off valve is often used as a fast-acting shut-off system, popularly called simply a shut-off valve. Unlike other shut-off valves, the valve has an automatic actuation.

Its main purpose is to supply gas to the burner at the required pressure at a given power and to completely cut off the fuel supply in the event of a malfunction. This process is carried out by means of control devices with built-in sensors.

Gas piezo units are non-volatile, but can be used for both types of boilers

Automation differs in the type of ignition - piezo ignition and electric ignition are distinguished.

Piezo ignition - this is when the start is done manually, by pressing a button. It monitors the operation of the flame - a thermocouple, which is heated by an igniter and generating a constant current, ensures the open state of the valve.

As soon as, for some reason, the pilot burner stops supplying an open flame, the solenoid valve closes and the gas flow stops. Piezo ignition is a volatile automation element.

Electric ignition unit connects to the power supply. The launch is carried out from an electric spark in an automatic mode. This system is volatile and in the event of a power outage, the device valve shuts off the gas supply.

It looks something like this. The differential relay has two contacts. During normal operation of the heater, one block is closed.When there is any change in the operation of the boiler, for example, the power is turned off, the second unit is triggered, and the first one is opened. The relay moves, the diaphragm flexes and the gas supply is cut off.

How long do they turn off the electricity?

If you, having lived for a year or two in a village, have not experienced frequent and prolonged power outages, this does not mean that they will not happen.

Nobody is insured and practically nowhere. Even in places close to large cities, there were cases of weekly blackouts due to weather conditions.

In 2020, because of the strongest freezing rain, entire settlements of the Moscow region sat without stable heating for a week.

Usually, the period for which the supply of current is interrupted depends on its cause:

- Short-term disconnection for a period from half an hour to 2 hours in connection with a scheduled check of networks or exceeding the limit consumption.

- Elimination of emergencies of a simple nature, connection of new subscribers - from 3 to 6 hours.

- Short circuits, KTP malfunction - 12-24 hours.

- Serious accidents associated with negative weather conditions, the inability to quickly repair the line - from 1 to 3 days.

If the first 3 situations are quite bearable in terms of timing, then subject to weak thermal insulation of the house structure or the presence of tenants who are contraindicated in coolness, the latter option is highly undesirable. In addition, even these terms cannot guarantee that even after their expiration, the electricity supply will resume, it is better to play it safe.

Many people put an alternative source of heating, for example, a stove, a fireplace, and this, no doubt, is a reasonable combination, when someone is at home constantly and can control the heating, but it is much easier and even cheaper to install a backup power supply system.

How to choose a redundant power supply?

The most popular option is an uninterruptible power supply, or UPS for short. It provides a secondary power supply to the device in case of a short-term power outage on the line.

Most often it is used to provide power to a computer, so that a person has time to modify, save information and exit the system in normal mode in the event of a power outage from the main source.

Of course, an ordinary uninterruptible power supply from a computer is not suitable for a gas boiler. The maximum that he can do is to extend the functionality of the device by 2-3 minutes, since at the output it gives an approximation of a sine wave or a meander, and the boiler requires a pure sine. Consider this when purchasing the device.

A competent choice of UPS for the boiler will allow you to ensure the supply of fuel even in the event of a power outage on the line

Ideally, an uninterruptible power supply with a capacity of 300-600 W is suitable, with the ability to connect a battery up to 600 A * h. The capacity of such a battery will last for 3 days.

But if you, for some reason, want to save money, please note that:

- 50-100 A * h, will prolong the operation of the boiler for a period from 3 to 8 hours;

- 200 A * h - enough for about a day of uninterrupted functionality.

More than a day of shutdown requires a more powerful power source. And here it is best to choose an inverter gasoline generator, which also has a pure sine wave. With the help of these devices, the gas boiler will work in a stable mode after disconnecting the load.

Why do fire tube boilers leak?

Returning from another business trip, we thought about this question. Too often, lately, we have been invited to perform chemical flushing of a fire-tube boiler, which already has cracks and flows in the welded or expanded areas.

Of course, we perform flushing every time, but we are thinking about why boilers of this type start to leak.

Just yesterday, a brigade returned from the Komi Republic. Chemical flushing of the KVM-4.0 (KVT-4000) boiler, manufactured by OOO Kovrovskie boilers, was carried out. We have already met these boilers before.They work on wood chips, have a non-standard layout (this is not an explicit fire tube boiler). The boilers are excellent, have a high efficiency, the customer spoke very flatteringly about them.

Before cleaning, the Customer informed us that the boiler had already been brewed several times, that most likely there is a lot of scale in the boiler and this is the reason for the leak.

Indeed, we spent almost double the rate of Krathol reagent to flush this boiler and, according to our feelings, there is still scale in the boiler.

At the same time, after flushing, a leak was again found in the boiler (most likely held by a layer of scale, which we removed) and, naturally, we climbed into the furnace to study the situation.

Here is a video from the firebox:

Also a photo of this place of the tube sheet:

In the photo, you can see that in the center and on the right side of the photo, around the pipes, you can see the weld spots.

This boiler is not very old, manufactured in 2020. Yes, there was a layer of scale inside it, outside there was a thick pasty layer of soot from burning wood. But the leaks are localized only in this place, although gradually spreading in different directions.

What are the reasons for this phenomenon? The customer has already called the representatives of the boiler manufacturer. The parties will cut this part of the tube sheet and investigate the causes of the leak. We will inform you about the results additionally!

Or another example.

Last year, in the Moscow region, at a confectionery enterprise, I had a chance to wash the ICI CALDAIE AX 500 boiler. And also, we were called after the boiler started to flow.

Pictured: Leaking steam boiler ICI CALDAIE AX 500

In this case, the leak was in the lower part of the boiler, it was the lower smoke tubes that were leaking. As it turned out later, a dense insoluble sediment lay inside the boiler, on the pipes and tubesheet. Apparently it interfered with the heat transfer and the welding spots started flowing.

Although it was the front of the boiler, near the burner. Typically, the maximum temperature from the flame drops to the opposite side of the boiler. Or are we wrong?

There is another idea why the fire-tube boiler flows precisely at the welding points. Occasionally, the weld may contain non-metallic impurities that are less tough than metal. Perhaps for this very reason, overheating in these places leads to leaks in the welding places.

What will dear readers say?

What will happen after the power supply is restored?

One of the most pressing consumer questions is whether the volatile gas boiler will turn on automatically after a power outage?

Depending on the boiler model, after the electricity is reconnected, it can ignite in automatic mode or only after manual start. Devices with piezoelectric ignition will require mechanical activation.

Devices with an atmospheric burner, as well as units with the aforementioned pressurized system, are able to turn on independently, and even without losing the set automatic parameters, if they are equipped with an electric ignition and a pressure switch.

However, auto power on does not always work either. After a large number of subscribers are de-energized, with the resumption of electricity, the pressure in the gas pipeline may drop for some time, respectively, the pressure switch is triggered, the equipment does not turn on and it can only be started manually later.

For those for whom this question is relevant, it is enough to install a delay relay or, as it is also called, a "time relay". Then your boiler will not start immediately, but after some time, when the pressure in the gas pipeline will most likely equalize.

The time relay allows you to delay the auto-start of the electric ignition until the presumable equalization of the gas pressure

In some cases, the electronic control module displays an error after the power supply. This means that there was a small emergency before the shutdown. The decoding of the code can be found in the instructions for the heater.

By the way, not all of them can be eliminated on their own; to solve individual problems, you will need to call a specialist from GorGaz or a service department.

What are the ways to protect heating equipment from overheating

Manufacturing companies try, in order to increase the consumer attractiveness of their products, to include any guarantees of its safety in the technical passport of boiler equipment. The uninitiated consumer does not have the slightest idea about the means of protecting the heating boiler from boiling.

There are currently the following ways to ensure the protection of solid fuel units used for autonomous heating systems. The effectiveness of each method is explained by the operating conditions of the boiler equipment, and the design features of the units.

In most cases, manufacturers recommend using tap water for cooling in the data sheet for a heater. In some cases, solid fuel boilers are equipped with built-in additional heat exchangers. There are models of boilers with external heat exchangers. Used by a safety valve to prevent overheating. The safety valve is designed only to relieve excessive pressure in the system, while the safety valve opens access to tap water when the boiler overheats.

Important! In the presence of cast-iron heating devices, such a measure is fundamentally wrong. Cast iron heat exchangers are afraid of a sudden temperature drop. The supply of cold water to the circuit can lead to the loss of the integrity of the heat exchanger housing. (cast iron heated to a high temperature will simply burst upon contact with cold water).

If the temperature of the coolant exceeds the 100 ° C mark, it creates an excess pressure that opens the valve. Under the influence of tap water, which is supplied under a pressure of 2-5 bar, hot water is displaced from the circuit by cold water.

The first controversial aspect of tap water cooling is the lack of electricity to power the pump. The expansion vessel does not have enough water to cool the boiler.

The second aspect, which sweeps aside this cooling method, is associated with the use of antifreeze as a heat carrier. In the event of an emergency situation, up to 150 liters of antifreeze will go into the sewer along with the incoming cold water. Is this protection method worth it?

The presence of a UPS will allow maintaining the operation of the circulating pump in a critical situation, with the help of which the coolant will evenly disperse through the pipeline, without having time to overheat. As long as there is enough battery capacity, an uninterruptible power supply ensures that the pump is running. During this time, the boiler should not have time to heat up to the critical parameters, the automation will work, starting the water along the spare, emergency circuit.

Another way to get out of a critical situation will be to install an emergency circuit in the piping of a solid fuel unit. Shutdown of the pump can be duplicated by the operation of the reserve circuit with natural circulation of the coolant. The role of the emergency circuit is not in providing heating of residential premises, but only in the ability to remove excess heat energy in an emergency.

On a note: the installation of the emergency circuit can be replaced by the installation of a bypass, which in extreme cases will divert the overheated boiler water to the expansion tank or heat accumulator.

Such a scheme for organizing the protection of the heating unit from overheating is reliable, simple and convenient in operation. You will not need special funds for its equipment and installation. The only conditions for such protection to work are:

- the presence of an expansion tank or storage tank in the system;

- use of a check valve only of the petal type;

- the pipes in the secondary circuit must be of a larger diameter than the conventional heating circuit.

Conclusions and useful video on the topic

How to choose a UPS for a gas boiler correctly. Purchase criteria and nuances:

So, as we found out, a power outage will not spoil expensive volatile equipment. All systems dependent on electricity will simply shut down and the gas supply will be shut off by a shut-off valve.

And if you also have a UPS installed, you will not even notice a short-term interruption in the supply of current to the line.

Please write your comments in the block below, ask questions, post photos on the topic of the article. Tell us about how your boiler “behaved” after turning off and starting the power supply. Share useful information that will be useful to site visitors.

What to do if the heating boiler is leaking: causes of the problem and how to quickly fix it

From the author: hello, dear friends! The heating boiler is the main element of any autonomous heating system. It is he who is responsible for the temperature of the coolant. Naturally, this equipment must work flawlessly, only in this case the entire system will function properly.

Of course, as with any other device, this one can experience various malfunctions. Many of them can be solved by simply adjusting the regulators. But if the heating boiler is leaking, what to do? This situation is serious and requires a quick solution.

However, not every drop of liquid found outside the unit necessarily means a leak. For example, if the boiler and the pipes adjacent to it are completely covered with moisture, then very often this is ordinary condensate that has formed on the elements of the system when they cool down. This phenomenon occurs due to temperature differences. The so-called "dew point" is formed, which leads to the appearance of moisture.

In addition, condensate may not form on the boiler itself, but in the chimney, and then drip from there. In this case, moisture gets on the burner, which is fraught with poor performance. But it is still not a leak. This phenomenon can be eliminated by installing a special glass for collecting moisture, which is installed in the chimney.

Both situations described above are characterized by one symptom: no pressure loss in the system. Based on the readings of the pressure gauge, you can easily determine what the problem is. If the matter is really in the formation of condensate - it does not matter if it is about the boiler itself or about the chimney - then this will not affect the pressure in the heating system in any way.

But if you see that this indicator is less than necessary, and this is accompanied by a puddle under the heating equipment, then in most cases this indicates a leak. In such cases, it is important to know how to fix the leak and to do it as quickly as possible. Of course, you can invite craftsmen or simply purchase a new boiler. But this is not always available. And if it happens in the middle of winter, then waiting for a fix is fraught with freezing of the system.

Therefore, let's figure out what reasons can lead to a leak, how to fix the problem and make sure that it does not reoccur.

Leakage reasons

Of course, any leak doesn't just happen. There are quite simple situations when some kind of connection is loosened - for example, the central screw on the circulation equipment or the fitting connecting the pipe to the boiler. In such cases, it is enough to tighten the corresponding element, and the problem will be solved.

But there are also more serious situations when a hole forms in the boiler itself. If its appearance has nothing to do with mechanical damage, then it was influenced by certain factors inherent in the operation of your equipment. Let's take a closer look at them.

Corrosion

Corrosion of metal is a real scourge of any plumbing equipment. The heating boiler is no exception. Constant interaction with water is favorable conditions for the development of corrosive processes.

Of course, this does not mean that your boiler will rust very quickly. It all depends on what material its "filling" is made of. Ideally, it should be copper or stainless steel. These materials do not rust or build up with scale, therefore they are excellent for the production of such devices.

But the problem is that all their excellent qualities come with a high cost. Therefore, when choosing water heating equipment, the decision is usually made in favor of boilers, the internal elements of which are made of ordinary steel or cast iron.

Cast iron does not rust, but it is rarely chosen. First, its weight makes it difficult to transport and install equipment. Secondly, cast iron does not tolerate temperature changes well - it can crack at the same time, which, by the way, will also lead to a leak. Therefore, this material is not very suitable for heating heating equipment.

As for ordinary steel, it has excellent characteristics that are necessary specifically for a heating boiler, and it is inexpensive. But there are always problems with rust. Many manufacturers add an anti-corrosion coating to it, but, as practice shows, it does not guarantee 100% protection.

Corrosion is not just a red coating on the boiler walls. It gradually destroys the metal. Sooner or later, this will definitely lead to the formation of a hole.

A separate factor should be considered the quality of the water used in the heating system. The content in it of a large amount of air and various impurities leads to high corrosive activity. Therefore, it is categorically not recommended to use ordinary water for this purpose - for example, river or well water. You must purchase distilled. This is a bit of a hassle, but believe me, the constant repair of heating system elements will cause much more difficulties.

Increased pressure in the system

Each boiler is designed for certain parameters of the system's operation - in particular, pressure. To monitor this indicator, manometers are installed. If you see that the pressure is too high, this may indicate some problems in the work.

For example, an expansion tank has broken, air locks have appeared, some filter is clogged, a safety valve has stopped functioning - all this provokes an increase in pressure. A boiler that cannot withstand such a pressure from the inside simply bursts.

Burning out the walls

The last common reason for boiler leakage is the burnout of its walls. This does not apply to electrical equipment. The problem arises when there is contact of the tank with an open flame. Thus, gas, solid fuel and the like equipment is at risk.

Avoiding this problem is quite simple - you must initially select the right equipment. Two factors can lead to burnout:

- improper location of the fuel combustion chamber;

- too little equipment power.

With the first case, it is clear - too strong contact with fire leads to burnout. As for the power - if it is too small, then the boiler constantly has to work at the limit of its capabilities. That is, the flame is lit as strong as possible, hence the negative effect arises, leading to the appearance of a leak.

Leak elimination methods

So, we figured out the reasons. Now let's talk about how and what to fix the hole so that you don't have to buy a new heating boiler. Strictly speaking, welding is usually used to repair metal products. To do this, you need to follow a few simple steps.

- Disconnect the boiler from electricity or wait until the fuel burns out in it and the equipment cools down.

- Drain all coolant.

- Disconnect the heat exchanger.

- Weld or solder the hole.

Of course, for this you need to have at least a little skills in working with a welding machine or with a soldering iron. But you can do without welding. The first three steps are performed in the same way: turn off and drain the boiler, disconnect the heat exchanger. And then apply "liquid welding" according to the instructions.

Perform all these actions only when you are at least relatively sure of the result. If in doubt, it is better to call the master. This is especially important in the case of gas boilers, where any poor-quality work can lead to very negative consequences. Therefore, to repair them, it is necessary to hire specialists licensed for the relevant type of activity. Good luck!

seberemont.ru