The need to attach a boiler room to a house from a bar arises in different situations for different reasons.

- Firstly, in the project you like, the original layout does not provide for such a room.

- Secondly, the house was planned as a non-residential, summer cottage, and later heating was needed.

- Thirdly, the project of a log house was deliberately selected so that there were no fire-hazardous boilers in the residential area.

One way or another, there is only one way out of all kinds of situations, including those described, - to attach a boiler room to a log house. This event may seem simple only at first glance, and does not require detailed study. It would seem that it could be simpler - he added the walls by 2 meters, covered them with a roof, installed a boiler and brought pipes into the house. However, if this issue is faced in practice, a lot of problems arise.

The main problems of the boiler house attached to the log house

In order not to overlook anything and return to this material, if necessary, like a cheat sheet, all information will be arranged "on the shelves":

- Fire safety. The boiler room is a high-risk room. Given this problem, what material to choose for the walls of the extension? If it is wood, how to protect it from fire?

- House shrinkage. The problem is relevant only for those cases when the extension begins to be built during the period of the most intense shrinkage of the timber. The structures of the boiler room and the pipes connecting it to the house should not interfere with shrinkage, and even more so suffer from it.

- Boiler room level. To equip the most efficient heating system, the boiler must be located below the level of the radiators, that is, in fact, below the basement of the house.

- Foundation. How to make, from what, and is it needed at all for such a structure as an attached boiler room?

- Physical binding of the extension to the house. So that communications are not broken at the point of passage through the border of the extension with the house, the first must somehow be "attached" to the second. In addition to pipes, an aesthetic moment should also be considered here - the gap between the boiler room and the house will not suit anyone in the future.

- Warming. Not every boiler will be able to heat even a small extension by itself, and it will not always work at full capacity. How to solve the problem with the possibility of water freezing in this room?

- Other problems. What dimensions should the extension be made, on which side the door should be, whether it is necessary to have a window and so on.

All these questions are given short and clear answers below. To form the information below, not only official data from generally accepted norms and rules were used, but also the experience of real people who already use a boiler house attached to a house from a bar.

General requirements for arrangement

The regulatory requirements for boiler rooms where gas and solid fuel boilers are installed are largely the same. There are several options for the location of the boiler in a private house:

- the boiler room is located in a separate building;

- an extension for the boiler room adjoins the house;

- in a private house a separate room is allocated.

Sometimes there are cases of placing the boiler in an external mobile module or in the attic. The choice is influenced by several factors: the scale of construction or reconstruction, the type of fuel used and the power of the boiler.

Room parameters

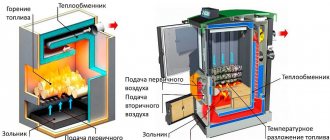

The operation of solid fuel boilers is common in regions where centralized gas supply is not available. Such equipment runs on wood, coal, peat or pellets.The boiler room must meet the following regulatory requirements:

- The ceiling is located at a level of at least 2.5 m.

- The minimum area is 8 m 2.

- Accordingly, the volume of the room should exceed 15 m 3.

- Regular loading of fuel and cleaning of the ash pan provides for the installation of the boiler in an easily accessible place. Compliance with this regulatory requirement is necessary in order not to create difficulties in preventive and repair actions.

- The installation of the boiler provides for the formation of a minimum gap of 10 mm between the equipment and the wall.

- For a solid fuel boiler, it is recommended to arrange a podium that rises 8-10 cm above the floor.

- For fire safety purposes, the walls and floors are finished with non-combustible materials. If this requirement is impracticable, the place in front of the firebox is protected by a steel sheet with a minimum size of 50x50 cm, the function of protecting the wall is performed by an asbestos screen or a metal sheet 0.25 cm thick.

- According to the approved regulatory requirements, a boiler room equipped in an extension can be equipped with two doors: inside a residential building and into an open space. The inner door is made of heat-resistant materials and is characterized by a high class of fire safety.

- Regulatory conditions provide for the organization of natural and electric lighting in the boiler room of a private house. The calculation of the natural flux of light is based on the volume of the room. For 1 m 3 of the room, 0.03 m 2 of glazed area is required. That is, with a minimum volume of a boiler room of 15 m 3, the area of the window opening is 0.45 m 2.

- If coal is used as fuel, the electrical wiring in the room should be of a hidden type, and the lighting devices are selected special, with hermetic protection. This is due to the high explosiveness of coal dust.

- The boiler room of a private house is equipped with a water supply and a sewerage system. To exclude the possibility of pipes freezing during the cold period, its insulation is called upon.

Requirements for the arrangement of the ventilation system and the chimney are regulated by SNiP 2.04.05-91. The key condition is that the ventilation process provides three times air replacement in the boiler room of a private house in one hour.

Chimney

Regulatory documentation for the equipment of a boiler room in a private house contains the following requirements:

- The size of the ventilation duct is calculated based on the power of the boiler: for 1 kW of unit power, there is 8 cm 2 of the inlet area of the ventilation structure.

Important! The diameter of the branch pipe leaving the heating unit must exceed the diameter of the flue gas outlet. - The flue duct has the same diameter along the entire length of the structure.

- Regulatory conditions imply the arrangement of a special hole to ensure the maintenance of the chimney.

- The arrangement of the chimney for a solid fuel boiler is similar to that of a furnace design. Its height should exceed 5 m, and the number of bends and turns should not exceed three.

In addition to the correct design of the chimney, according to regulatory requirements, the safe operation of a boiler room in a private house includes the presence of natural and forced ventilation.

Natural ventilation

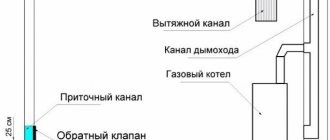

There are two ways to remove flue waste from the boiler house as a result of the combustion of solid fuel - naturally and forced ventilation. Natural ventilation is carried out due to:

- arrangement of holes in the ceiling and walls;

- window equipment with a window;

- forming a gap between the door leading to the room and the floor.

The installation of ventilation windows directly depends on the location of the boiler room and has features. When installing a boiler room in accordance with regulatory requirements on the first floor of a private house, an exhaust outlet is equipped above the heating unit.Oxygen-depleted air and combustion products that enter the room come out through it. The process is carried out due to the intake of fresh air from the street through the ventilation hole.

Remark! The supply ventilation duct needs protection from the ingress of debris, therefore it is closed with a metal or plastic mesh, the mesh size of which is 1-2 mm.

To prevent the outflow of fresh air from the boiler room, the air duct is equipped with a check valve from the inside. The exhaust opening is equipped in the same way. Installation of the valve is not provided there, and protection from precipitation by a visor will come in handy. To comply with regulatory requirements, it is recommended to make the inlet in the boiler room as close to the firebox as possible so that the fresh air flows quickly into the combustion chamber.

Such a boiler room ventilation procedure cannot be controlled, it is directly dependent on temperature, wind load and pressure level. According to regulatory requirements, the boiler room air must be renewed three times within an hour, therefore, they resort to the process of artificial ventilation.

Artificial ventilation

Forced ventilation is carried out by equipping the boiler room with electric fans located in the exhaust and inlet openings. Their capacity is calculated based on the volume of the boiler room, multiplied by three. For strict compliance with regulatory requirements, the result is increased by 10-30% to ensure a performance reserve. It is recommended that fans intended for a boiler room in a private house be purchased in copper or aluminum cases for stable resistance to high temperatures.

It is possible to save energy by equipping the boiler with an automatic ventilation control system. Installation of control equipment allows you to start the fans directly during the period of intensive operation of the heating unit and put them into pause mode when there is no load.

Foundation and physical anchoring to the house

The foundation is required for a boiler room of any size. It is advisable to perform it so that it is physically tied to the base of the house. Since the boiler room must be below the level of the house, not every technology is suitable for arranging the foundation. The optimal, affordable and proven option is tape.

The walls of the boiler room must be tied to the house. To do this, you can use almost any available fixtures and fittings. It all depends on the wall materials and other conditions.

Installation of modular boiler rooms

← previous articleTechnical conditions for gas (TU for gas) Technical conditions for gas is a document that allows owners of a boiler house to connect it to the central gas supply system ... the boiler room will work. The composition of the included auxiliary elements is related to whether the boiler room will be gas, liquid or solid fuel, two ...

Author: Alliansteplo

Date: 04/14/2015

The installation of modular boiler houses is carried out at the supplier - the boiler houses are delivered to the connection point already assembled, with a configured operating mode, therefore, their connection to the heated facility is carried out within a few days. The only thing left for specialists to do is to put the modular boiler room on the foundation prepared in advance.

For quick and easy connection, all block boiler houses are equipped with special systems:

- heating and fuel supply pipelines equipped with outlets;

- power supply cable equipped with a receiving device;

- drainage pipeline.

The installation of boiler rooms at the plant includes the equipment of the unit with equipment necessary for the operation of the system. Inside the block boiler room are installed several boilers (their number varies depending on the needs of the customer) connected to a common fuel line. The boiler room is supplied with water from the water supply network or from a water carrier, if there is no water supply at the place of deployment.

In addition to boilers, the installation of turnkey block boiler houses implies installation of heat exchangers, whose task is to transfer heat energy to the heating system. Traditionally, pressure gauges are located at the inlet and outlet of heat exchangers to monitor the pressure. To pump hot water from boilers to the heating system, they use circulating pumps, usually in the amount of two pieces: working and standby, so that in the event of a breakdown of the working pump, the standby one automatically turns on All heat exchangers and pumps are additionally equipped filters for water purification.

If a block boiler room operates from the mains, its system is additionally equipped with emergency power supply unit - usually a diesel generator. Its task is to maintain the efficiency of the boiler room in the event of power outages. When installing a modular boiler room, it is provided ventilation systemdesigned to cool the generator. Ventilation of a block boiler room includes:

- ventilation openings with windproof shutters;

- heat heaters;

- gas concentration sensors;

- internal temperature regulators;

- exhaust fans, shut-off and safety valves, etc.

Control of the entire block boiler house comes from a special point, which ensures the most uninterrupted, reliable and safe operation of all systems. In most modular boiler houses, the automation does not imply regular operator intervention: the boiler room can operate independently in accordance with the set parameters.

And the last point in the installation of a modular boiler room - chimney installation... The pipes are usually made of stainless steel and are led out horizontally through the side wall, joining the outer chimney pipe. The height of the pipes can be adjusted depending on the operating conditions of the modular boiler house.

Himself block made of insulated sandwich panels.

Installation of modular boiler rooms is a fairly simple procedure if it is performed by professionals. The design of the modular boiler house itself minimizes the possibility of making a mistake in the process of its installation on site, and preliminary design work carried out by competent specialists practically guarantees a trouble-free installation and timely launch of the modular boiler house.

For all questions, please call 8 (495) 781-81-55

In order to calculate the cost of a complex of necessary services or buy a boiler plant, send a completed questionnaire.

To calculate the cost of the boiler room, please fill out the questionnaire for the boiler room. The questionnaire can be completed online or downloaded. For any questions you may have: multichannel telephone e-mail

Fill out the questionnaire online

Calculate the cost of the boiler room

You may also be interested in

Features of operation of modular boiler houses Block-modular boiler rooms are, without any doubt, one of the most popular types of boiler equipment today.

Steam heating

Safety of a gas boiler house Safety of a gas boiler house depends on adherence to a certain set of rules, strict adherence to which minimizes the risk of an accident or any other dangerous situation.

Standby boiler plants Interruptions can occur in the operation of even the most reliable equipment.Boiler houses are by no means an exception: the interruption of the supply of electricity, gas, or simply failure of the boiler - the situation is quite "regular".

Installation of autonomous boiler houses It is autonomous boiler houses that are today considered the most rational and optimal solution to provide production, administrative and social facilities with heat and hot water supply. Autonomous boilers have advantages that centralized systems do not have, and at the same time, they are devoid of their inherent disadvantages.

What technology for construction should be applied

Based on our own experience, we can offer you the most profitable construction option. This is definitely a wireframe technology. Why exactly she? It just so happened that this method of construction has a number of advantages over other alternative options. Let's voice the main features of the production of such a construction:

- turnkey construction speed;

- the ability to perform at the same time finishing;

- saving on foundation installation;

- warm walls (significant savings on heating);

- favorable cost of work and materials.

So, let's briefly find out what you need to focus on in the first place if you plan to add a boiler room to a private house. The very first thing with which to start such a production is to draw up a plan of the object (design layout). It should reflect all the dimensions of the outer walls of the room, and also indicate the configuration of the roof. It is also important to study the condition of the soil in the suburban area and the strength of the main foundation of the existing house (to understand this information, you need to call our master to your site).

Further, the technical assignment for the object is already being drawn up, which is approved by the customer. Based on the agreed information, in this way, the estimate is further calculated. All upcoming stages of work must be agreed with the customer without fail - he must be aware of how and from what material the extension of the boiler room to his country house will be made. It is also important to choose a technically correct foundation - it should be combined with the foundation of the main house in its characteristics, otherwise deformations will appear at the joints of structures with each other after each winter.

Dimensions of boiler room with oil boiler

The volume of furnaces, regardless of the type, is identical. But there are specific requirements that relate to the installation of chimneys and the determination of fuel storage locations. These data, as a rule, are indicated by manufacturers in the boiler passports. But if they are absent, then it is worth proceeding from the following:

- the boiler outlet pipe cross-section must be larger than the chimney cross-section. Moreover, this ratio should be maintained throughout the chimney;

- the chimney must be straight or with a minimum number of elbows;

- a hole must be made at the bottom of the wall for the flow of clean air. Its area should be at least 8 cm² per one kilowatt of the boiler;

- the chimney must exit either through the wall or through the roof;

- it is imperative to have a cleaning hole in order to regularly audit and clean;

- chimney materials and fittings must be made of a material that is gas-tight;

- the base for installing the boiler must be anti-flammable. If there are wooden floors in the furnace, it is necessary to do the following: lay a sheet of asbestos, and on top - a metal sheet. You can make a brick foundation, which is then plastered or tiled.