Modern solid fuel boilers are very different from their predecessors. Simple design and stable operation make them irreplaceable elements of autonomous boiler rooms. It is believed that cast iron devices last the longest. Such equipment is produced by many domestic and foreign manufacturers. Among them is the Proterm brand Bober solid fuel boiler.

Features of boilers Beaver

The main distinguishing feature of Bober Proterm heating devices is their sectional structure. The body is made of separate elements fastened together. The boiler parts are cast from high quality cast iron.

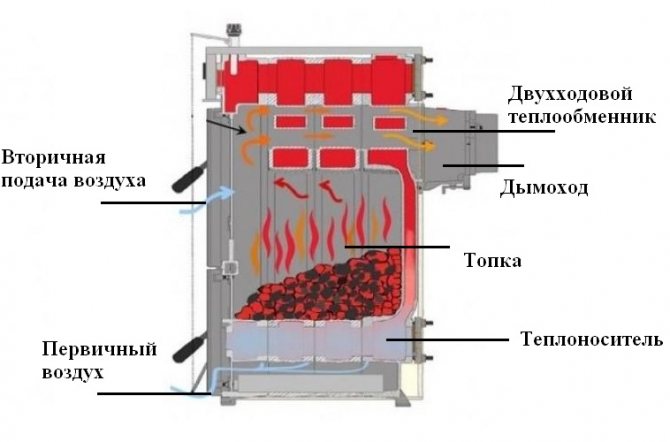

The assembled structure is a heat exchanger framing the firebox. The original shape allows the temperature to be evenly distributed over the entire space of the combustion zone. This reduces the risk of temperature extremes, overheating and low temperature corrosion.

Other features:

- large heating area of the coolant (two-pass heat exchanger);

- suitable for heating residential and industrial buildings;

- it is possible to connect an external boiler for heating service water;

- the cooling circuit protects the system from critical temperatures;

- open combustion chamber (takes air from the room);

- ease of installation and operation;

- mechanical power adjustment;

- 2 years manufacturer's warranty.

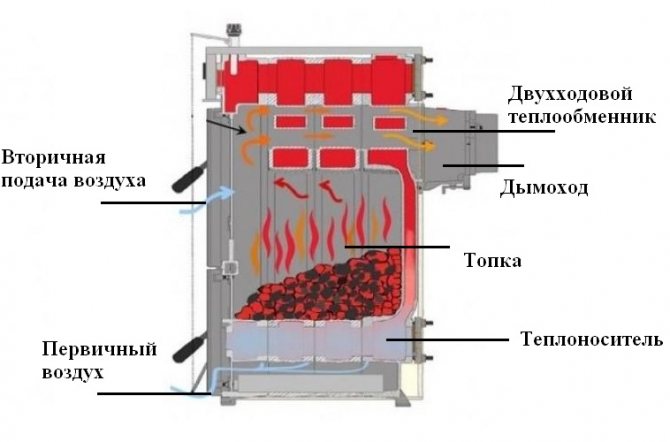

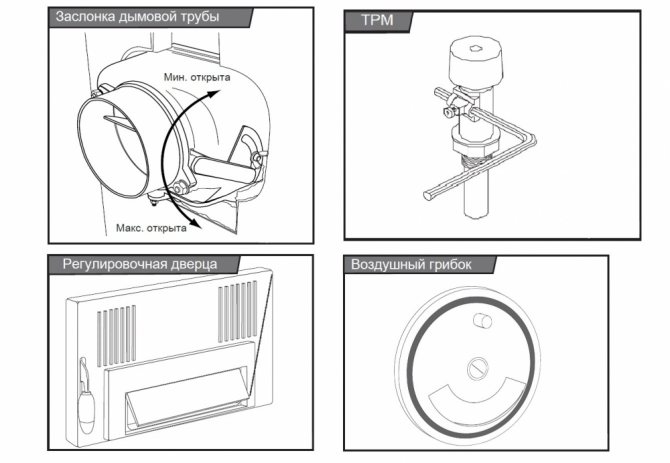

Traction control methods

The Bober Protherm boiler power adjustment is carried out in mechanical and manual modes using three devices.

Control devices:

- TPM (thermomechanical power regulator);

- flap on the combustion chamber door;

- chimney draft limiter.

TPM adjusts the primary air supply under the grate. The unit is located on top of the body and is connected by a chain to the blower door. The required coolant temperature is manually set on the regulator. To maintain it, the device adjusts the degree of opening of the damper. When the temperature drops, the chain stretches and the blower swings open. If the hearth is too hot, the chain is loosened and the door is closed. In this way, control over the intensity of combustion is achieved.

The air fungus on the firebox door regulates the access of secondary air directly to the hearth. Adjustable in manual mode.

The chimney damper is responsible for the draft in the chimney. The boiler cannot operate in a fully closed state. The more the damper is opened, the stronger the draft and the more intense the combustion in the hearth.

To monitor the parameters of temperature and pressure, a thermomanometer is located on the front panel.

Benefits

The main plus of the Protherm Bober solid fuel boilers is their efficiency. The special design allows efficient use of the fuel resource.

Other benefits:

- simplicity and reliability: prefabricated sectional design allows you to replace individual parts in case of failure;

- high efficiency up to 80%: achieved due to the large area of heat removal;

- durability: a cast-iron heat exchanger can last for decades;

- non-volatility: the device does not require electricity to operate;

- safety: a built-in thermostat protects the unit from overheating.

disadvantages

Bober Proterm devices have disadvantages that may be significant for some buyers.

Their disadvantages:

- short burning time of one bookmark (2-4 hours);

- the need to constantly be on duty at the boiler (put fuel on, throw out ash);

- front loading only (inconvenient to fill coal).

Types and general arrangement of solid fuel structures

To understand this problem, we will study several typical models of such units. But first, a little general information to understand the essence.

In the direction of combustion of combustible material, solid fuel boilers are divided into:

- installations with bottom ignition;

- installations with top ignition.

The former are of the traditional type, when the combustible material is ignited from below. The second includes units with slow burning of fuel. Therefore, they are called long-burning solid fuel boilers. For example, firewood from above is supplied with air from above and at the same time presses the load. So the fuel is very slowly burned inside the cylindrical chamber from top to bottom, and its loading through the door is very rarely necessary.

The "insides" of the solid fuel boiler

The main elements that any solid fuel boiler should have are universal:

- a firebox is a chamber inside which, in fact, fuel is burned;

- ash pan, located under the firebox, separated by a grate through which ash is poured from the firebox;

- a water jacket is a heat exchanger through which water flows for heating, going to the heating system of the house;

- chimney with a damper, which is needed to shut off the chimney after the end of combustion.

The material for combustion in solid fuel boilers can be various items, now we will also list them:

- Of course, it is classically firewood.

- Another classic option is coal.

- Peat briquettes.

- Pellets, sawdust and other materials.

Honestly, it's best to have a unit that can run on any of these fuels. This will maximize its efficiency for heating your home. But first, we will consider each type of boiler separately.

What kind of fuel can be used

Bober Proterm heating units operate on coal with a fraction of 4 cm or more and wood.

The moisture content of the wood should not exceed 20%. Failure to comply with this condition reduces the power and service life of the device. When damp wood burns, soot and tar deposits accumulate in the boiler cavities. The length of the logs, depending on the model, is 32-68 cm. The diameter of the wood is from 4 to 18 cm.

The operating time for one load of wood is 2 hours, for coal - 4 hours.

Reviews about the technical characteristics of the model

View gallery

The power of Proterm Bober 20DLO is 19 kW. The burning time of coal reaches 4 hours. Before purchasing a model, you should pay attention to its dimensions, they are equal to 935x440x440 mm. The volume of water to be replaced is quite large and amounts to 19.9 liters.

The equipment weighs, according to buyers, a lot. The mass reaches 230 kg. The working pressure can be equal to the limit from 0.8 to 4 bar. When connecting, you need a chimney diameter, it is equivalent to 130 mm. Buyers point out that firewood will burn out faster than coal. This will take 2 hours.

Model range and prices overview

The DLO series is available in five models with a power range from 19 to 48 kW. The principle of operation of the boilers is identical. Products differ in technical parameters and cost.

20 DLO

Model 20 DLO is suitable for heating residential and industrial areas up to 190 m². Unit capacity: 19 kW for coal and 18 kW for wood.

The design is based on a prefabricated cast iron body. On top of it, faceplates with thermal insulation are superimposed. There are two doors in front. A combustion zone is located behind the top. Behind the bottom there is an ash compartment. The exhaust gas paths are fenced off with a smoke protection plate, which prevents the room from smoking. The supply and return pipes and the flue gas outlet are located at the rear.

When combusted, the fuel generates heat, which is transferred to the water. The rest of the fuel material falls into the ash box. Flue gases go through the channels into the chimney.

The cost of the model is 67,600 rubles.

30 DLO

The model has a similar structure to the previous one.Differs in higher output: 24 kW. The firebox accommodates 37 cm logs. The unit is capable of heating a room up to 240 m².

Price: 81,500 rubles.

40 DLO

The heat generator is designed for large quadratures up to 320 meters and has a power of 32 kW. The loading chamber can hold firewood up to 43 cm long.

You can buy a solid fuel boiler Bober 40 DLO for 88,800 rubles.

60 DLO

The most powerful option in the range: 48 kW. Designed for heating buildings up to 480 m², equipped with a forced circulation heating system.

Not suitable for gravity circuits.

A spacious firebox allows you to burn logs up to 68 cm in size.

The cost of the device: 124,300 rubles.

Comparative technical characteristics of the models are presented in the table.

| Model / Specifications | 20 DLO | 30 DLO | 40 DLO | 60 DLO |

| power, kWt | 19 | 24 | 32 | 48 |

| A type | Solid fuel | |||

| Number of circuits, pcs. | 1 | |||

| Mode | Heating | |||

| Installation method | Floor | |||

| Electrodependence | there is | |||

| Number of heat exchanger sections, pcs. | 4 | 5 | 6 | 10 |

| Combustion chamber type | Open | |||

| Material | Cast iron GG20 | |||

| Coal power, kW | 19 | 24 | 32 | 48 |

| Wood burning power, kW | 18 | 23 | 29 | 45 |

| Working time on wood, h | 2 | |||

| Coal burning time, h | 4 | |||

| Firewood length, cm | 32 | 37 | 43 | 68 |

| Efficiency,% | Up to 80 | |||

| Temperature range, ° С | 30—85 | |||

| System pressure, atm | Up to 4 | |||

| Indication | Thermomanometer | |||

| Security | Thermostat | |||

| Chimney diameter, cm | 15 | 18 | ||

| Height, cm | 93,5 | |||

| Depth cm | 64 | 74 | 84 | 124 |

| Width, cm | 44 | |||

| Weight, kg | 230 | 262 | 305 | 455 |

| Warranty period, months | 24 | |||

Prices for a range of solid fuel boilers Protherm Bober DLO

solid fuel boilers Protherm Bober DLO

Reviews about the technical characteristics of the model

View gallery

Having considered in more detail the above-described model of the Proterm Bober boiler, you can understand that the combustion time of coal and firewood remains the same. The overall dimensions of the unit are limited by the following parameters: 935x440x1240 mm. The maximum log length, according to buyers, is quite large and amounts to 680 mm.

The section of the workpiece reaches 180 mm. The device weighs, as consumers emphasize, quite a lot, the weight is equivalent to 455 kg. The volume of the contained water is 39.8 liters. This solid fuel boiler has a 150mm chimney.

Installation and maintenance recommendations

Boiler equipment will last as long as possible, provided it is correctly selected and operated.

Choice

The power of the Bober boiler must correspond to the area of the heated building. It is believed that heating ten square meters of premises requires 1 kW of thermal energy.

When buying a unit with a lower output, it will not be possible to achieve a comfortable temperature in the home. With a slope upward, there will be prerequisites for premature failure: the formation of condensation and resin in the cavities of the device. In this case, a dirty heat exchanger will not cope with its function.

Installation rules

Installation work must be carried out by an organization that has the necessary permits.

Features of the installation of equipment Bober:

- a place for a boiler room is chosen with an operating ventilation system in residential and non-residential (corridor, basement) rooms with a temperature of 5-35 ° C;

- the heat generator is installed on a non-combustible flat base: floor or foundation;

- the combustible base is preliminarily covered with a sheet of steel on the sides and in front, placing a fire retardant gasket under it;

- on the front side, leave a free space of at least 0.6 m for ease of use;

- behind and from the side for access to the nodes, an interval of 0.6 m to the wall is also used;

- the chimney and heating system elements are connected according to the instructions;

- carefully check the tightness of the connections to the heating pipes and the chimney.

Recommendations for use

Maintenance of Protherm Bober heaters is carried out by the user and service specialists.

Basic rules of daily care:

- use small chips and paper for kindling, do not use flammable liquids and explosive substances;

- do not overheat the coolant above the maximum permissible parameters;

- do not lower the water temperature on the return line below 50 ° С;

- before adding a new portion of fuel, shut off the air supply to the hearth and wait for the smoke to be removed by opening the chimney damper;

- when performing manipulations with a working boiler, use protective thermal gloves;

- do not store fuel material near the heater at a distance of less than 0.8 m;

- clean the ash box several times a day so that the accumulated mass does not interfere with the flow of air under the grate;

- for collecting ash, fit containers made of non-combustible materials;

- once a month, clean the internal surfaces and the boiler chimney from soot;

- when resin accumulates on the walls, burn it out, heating the coolant to the maximum temperature;

- When the unit is shut down, clean it, lubricate the rotating parts and close the doors.

In addition to the above, it is necessary to carry out maintenance (maintenance) of the unit once a year. It is performed by a representative of the service company.

In the process of maintenance, it is checked:

- functioning of control and protection units;

- the performance of the dampers;

- tightness of joints. Read the grundfos circulation pump in our article.