Who releases

Produces boilers "Keber" Russian, part of the corporation "Tactical missile weapons". This company was registered in 2004. That is, it has been operating on the market for about 15 years. This company delivers exclusively heating equipment to specialized stores. The products from this manufacturer have earned very good reviews from consumers. Heating units from LLC "Trading House" Zvezda-Strela "are actually very popular among the population.

In addition to the boilers themselves, this manufacturer supplies the market with components for them. Finding spare parts for Keber equipment for owners of country houses, if necessary, will not be difficult.

Range

The Zvezda-Strela Trading House Ltd. supplies to the market boilers intended for installation in premises of various purposes. In addition to household, this manufacturer is also engaged in the production of industrial models of similar equipment. If desired, today you can also purchase gas boilers "Keber", both single and double-circuit. The first type of equipment is intended exclusively for space heating. Double-circuit boilers are additionally used to heat water.

Main technical characteristics

The assembly of Keber boilers is quite reliable. They can serve for a long time. Among other things, the manufacturer gives a guarantee for their operation for as long as 15 years. Thanks to high-quality components, Keber gas boilers are also considered very economical. If necessary, this equipment may also be used for heating premises in the Far North.

Gas-burners

Efficiency and excellent operational characteristics of boilers of this brand are ensured primarily by the fact that the manufacturer has provided for very high-quality Danko burners in their design.

These elements are:

- provide stable fuel combustion;

- are distinguished by high anti-corrosion properties;

- provide the most complete combustion of fuel.

The use of high-quality gas burners allowed the manufacturer, among other things, to reduce the size of the fuel chambers in Keber boilers. The efficient work of Danko in terms of fuel combustion, in fact, made this equipment so economical.

Basic information about solid fuel units

The high prices for diesel fuel and electricity, the costs of connecting gas equipment underline the advisability of the decision to purchase a boiler operating on solid fuel. On its basis, it is possible to create a heating system that does not depend on external energy carriers, since for the most part units of this class can operate without electricity or with minimal consumption.

Solid fuel boilers are used as central units of an autonomous heating system in areas where there are problems with the supply of main gas. And in some settlements, of which there are quite a few in Russia, a wood-burning boiler is generally indispensable.

What does it consist of

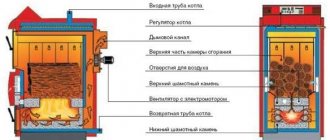

Diagram of a solid fuel apparatus

To understand how units of this class function, let's consider the device of a solid fuel boiler, which includes the following parts:

- Firebox - the so-called fuel combustion chamber and at the same time a heat exchanger. The design of the furnace includes: a portal for fuel supply, a zone for removing volatile combustion products, a grate, tanks for collecting ash and openings for air supply.In the process of burning solid fuel, the walls of the furnace heats up, the water heats up, which is around the furnace in the water jacket of the unit.

Firebox

- Water jacket... As a rule, in the firebox of a wood-burning boiler there are double walls, between which there is a coolant (hereinafter simply water) - this is the water jacket. When the fuel in the firebox starts to burn, the water in the water jacket heats up, resulting in heat fluxes that raise hot water to the top of the jacket. From this part of the boiler, hot water enters the heat pipe. Having passed through the entire heating system and giving off heat to the room, the already cooled water returns back to the water jacket through the lower branch pipe. In order to speed up the movement of water throughout the system, some solid fuel boilers are equipped with special heating circulation pumps. But still, most models are designed for open heating systems (that is, for those systems where water is circulated not by pumps, but by gravity). This is due to the fact that gravity systems are simple, reliable, economical and independent. They can be used even in areas where there are no signs of civilization.

Traditional solid fuel unit

- Carbon monoxide removal system... Due to the combustion of solid fuel, a large amount of smoke is formed in the unit itself, therefore a chimney is an obligatory component of such devices. The smoke is removed by means of heat-insulated pipes running from the boiler to the outside.

Chimney installation diagrams

Note! Some models are also equipped with forced ventilation units.

The device of a solid fuel unit with forced ventilation

- Temperature control and regulation system... It's no secret that any combustion is simply impossible without air supply. And, it should also be noted that the intensity of combustion just depends on the intensity of air supply to the furnace. And the device of solid fuel boilers involves the regulation of air supply using mechanical dampers and dampers. Such a control system is very simple and reliable - the damper is firmly connected to a special regulator. If the temperature rises too high, the walls of the regulator expand and the damper is lowered, thereby reducing the air supply to the furnace. When the regulator cools down, the reverse process occurs - the damper rises, thereby increasing the air supply and, as a result, the combustion intensity. Of course, this method may seem very primitive and outdated. However, it is also the most effective, which is why it is used in many models of solid fuel heating boilers. In addition, it still has no competitors, since the operation of such a mechanism does not require electricity, which costs a lot of money.

Classifications

A modern heating scheme with a solid fuel boiler can include both the simplest single-circuit devices and the most powerful high-performance and multifunctional units. Let's see what classifications solid fuel boilers are divided into.

By material of manufacture:

- Steel aggregates... Cheaper than their cast-iron counterparts, easier to maintain and much easier to clean with your own hands. But they are very demanding on the temperature in the return pipe of the heating system (at least + 60 ° C). Therefore, they need to install special valves that maintain the required return temperature (that is, hot water is mixed into the return pipeline from the supply pipeline).

Steel model Logano S121

- Cast iron units are durable, but they are more difficult to care for. It is recommended to purchase solid fuel boilers made of cast iron in cases where their constant continuous use is expected.And it makes no sense to buy a super reliable cast-iron unit only for emergencies. A cheaper steel boiler can handle this.

Cast iron model SIME SOLIDA 4

By the type of fuel used:

- Firewood, peat, woodworking waste, their derivatives in the form of special briquettes;

Logs

- Coal;

Coal

- Pellets (are granules formed as a result of processing wood, resin, pine needles and other organic materials);

Pellets

- Today there are models that work absolutely on all types of solid fuels.

By the way of heat transfer:

- Air;

- Steam;

- Water (most popular).

By the principle of fuel combustion:

- Traditional (we think nothing needs to be explained here).

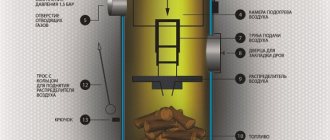

- Long burning is the latest innovation in heating technology. Long-burning solid fuel boilers are a vertical elongated combustion chamber, around which a container with water is located. Combustion in such a chamber is carried out not from bottom to top, but from top to bottom (you can compare this process with burning a candle). Thanks to such a system, complete combustion of the fuel is achieved, the burning time of one bookmark increases (up to 7 days), a stable and high temperature of the coolant and a decent efficiency.

Continuous burning device Stopuva 7

For the smooth and safe operation of such units, they are equipped with a fan for emergency extinguishing, a safety valve and a heating circulation pump.

Attention! Long burning boilers are automated and therefore require electricity. And, by the way, the instruction on how to control these devices is quite simple, and even a child can figure it out.

- Pellet - that is, functioning on special pellets. They consist, in fact, of the boiler itself, an automatic pellet feeding system and a hopper. An electronic control system checks the presence of fuel in the combustion chamber, and if it is not there, then turns on the mechanism for feeding pellets from the hopper. Quite convenient, but again volatile solution.

Cute pellet model

- Pyrolysis (gas generating). The uniqueness of this type of solid fuel boilers lies in the fact that, in addition to the combustion energy of solid fuel, they also use the heat release of gases that are formed during the combustion of solid fuel. As a result, much more heat energy is generated from the minimum volume of fuel, which means that the efficiency of the unit increases and its environmental performance improves.

Pyrolysis apparatus

Boiler automation

Of course, modern heating equipment should be not only economical and easy to use, but also safe. Natural gas is an explosive fuel, unfortunately. In this regard, Keber boilers have also earned relatively good reviews from consumers.

OOO Trading House Zvezda-Strela equips the boilers supplied to the market with the time-tested Arbat automation. In total, the units of this brand provide five levels of protection. So, for example, in the event of a pressure drop in the gas pipeline, the Keber boilers are automatically turned off.

If desired, consumers can also order from the manufacturer of this equipment and its complete set with even more reliable expensive Italian EUROSIT automation. Units of this type can be operated practically without any intervention of the owners of the house or staff in the production.

Which boiler to choose?

With the growing popularity of suburban housing, more and more people are faced with the issue of autonomous heating. This article will help you understand the types of boiler equipment (part 1) and choose the best option (part 2).

Part 1.

When choosing equipment for heating, first of all, they are repelled by the area of the heated room, operating conditions (climate, heat loss of the room), the available type of fuel and the need for hot water supply. Depending on these parameters, either electric boilers or boilers for solid, liquid or natural gas are used. Since it is very expensive to heat a house with an area of 80 - 100 square meters with electricity, and rarely anyone has the opportunity to supply a gas pipeline, preference is usually given to solid fuel boilers.

So, let's see how solid fuel boilers of different designs differ. First, about the types of boilers:

Classical direct combustion option, the most common and affordable. It is chosen when the price is a priority, when there is access to cheap firewood or coal and when you can sacrifice ease of use and your own time, since the efficiency of such boilers is relatively low and the fuel burns out quickly. As a result, for constant heating in winter, you will have to make up to 6-8 fuel tabs per day. Such boilers are best used for summer cottages and country houses without permanent residence, industrial premises, preferably with a separate boiler room, since a lot of fuel will be required.

Pyrolysis boiler Is the evolution of the classic boiler. Structurally, it is much more complicated (the design may differ significantly from different manufacturers), but at the same time it is much more efficient! Boilers of this type have an efficiency of about 80% and the duration of combustion on one tab of fuel (which is the same firewood and coal) can be up to 10 hours. It is clear that this significantly increases the comfort of use for everyday heating. How are these indicators achieved? The pyrolysis boiler has two combustion chambers. Fuel is loaded into one, where, when oxygen is deficient, it smolders, releasing gas, which then follows into the second chamber, passes through special nozzles, mixes with air and burns, heating the tubes and walls of the heat exchanger. Thus, the stock of combustible substances in the fuel is consumed more efficiently and the fuel burns out almost completely. The only nuance that should be taken into account is the moisture content of the wood. For pyrolysis boilers, this figure should not exceed 20%, since very wet and damp firewood burns with much lower efficiency and does not allow the boiler to go to normal combustion. With proper installation and proper operation, a pyrolysis boiler is much more efficient than a classic one.

Pellet boiler... By and large, this is the most ordinary boiler, but equipped with an additional combustion chamber (burner), a feed mechanism and a fuel storage tank. Pellets themselves are a type of fuel in the form of small granules from pressed sawdust and other woodworking waste. A boiler equipped with such a system has a number of unconditional advantages: + very small thermal inertia. The small volume of the combustion chamber burns a very small amount of fuel per unit of time. If you stop supplying it, the generation of heat will stop quickly enough (minimizes the likelihood of boiling and damage to pipelines). + high efficiency, since the fuel burns in a small chamber under a constantly high temperature and burns out almost completely. + excellent autonomy. A container (hopper) with a large supply of pellets is installed above the combustion chamber, which gradually enter the combustion chamber. Such a system can operate without human intervention for quite a long time in automatic mode, depending on the manufacturer and model, up to 7 days. Of course, with all the advantages, there are also disadvantages and the main one, of course, is the price. Moreover, the price for both equipment and fuel.

All of the above boilers can be steel all-welded and cast iron... Steel boilers are relatively inexpensive; in case of breakdowns, leaks, they can be repaired. Are prone to corrosion (in transient operating modes). A cast iron boiler is much stronger than a steel one and does not corrode. This is a plus. But on the other hand, due to its strength, cast iron is very fragile and is afraid of sudden changes in temperature. This is a minus. Such a boiler is strictly contraindicated to overheat, cool sharply, etc. That is, it requires increased attention and accuracy during operation. In addition, cast iron boilers are very heavy and in some cases may require laying their own foundations.

Long burning boilers... On the Internet, you can find a lot of articles on this topic, where pyrolysis boilers and boilers with a large vertical furnace are also called long-burning boilers. Although there is no separate type such as a long-burning boiler, but usually this is understood as boilers with a large volume of fuel loading and a controlled combustion process, from top to bottom (the so-called upper combustion boilers). This design makes it possible to significantly increase the burning time on one fuel insert, although the amount of heat generated does not increase, and the operation of such a boiler has its own specifics. For example, having loaded the fuel and starting the combustion process, you can no longer "throw" in the process until the already laid fuel burns out. The dimensions of the unit itself are very large compared to pyrolysis boilers with similar power options at a comparable price and burning time.

All types of boilers can also be equipped control automation, which allows you to burn fuel more efficiently and increases the comfort of use of the entire system. Automation precisely doses the air supplied to the combustion chamber, maintaining an optimal combustion mode, monitors the temperature, protects the system from damage, and saves energy due to the rational use of pumps. Also, automatic control allows you to conveniently control the operation of the DHW circuit, if any. This is a truly modern and effective solution in most cases, except for situations with a power outage or a complete lack of it.

Part 2.

We examined the main types of boilers, now we will figure out how to choose the best option from them.

Of course, you need to start with the power of the equipment. Power is calculated from the area of the heated room, the height of the ceilings and the estimated heat loss. It is important to consider here that it is necessary to take a power reserve of at least 20%. Why is this needed?

Firstly, a boiler for long and problem-free operation should not be operated in limiting modes. If you have a sufficient power reserve, then the operation takes place in a sparing mode and the equipment will last much longer.

Secondly, to compensate for heat loss (especially in the north).

Thirdly, the operation of a more powerful solid fuel boiler not at full capacity will increase the operating time on one fuel tab.

It is best to take a stock of 50%. For example, for heating a house with a living area of 200 sq. m. you need to choose a boiler with a capacity of 30 kW.

To date, boilers of all of the above types are produced in a huge number and in different price ranges. How to understand which manufacturer and which model range is worthy of attention? In order to understand this, you need to carefully study the characteristics of equipment from different manufacturers and compare the key parameters.

First of all, it is a brand and thickness of used steel... These are heat-resistant grades such as 09g2s, XH78T, boiler steel 20K and many foreign analogues, such as P265GH, P295GH, 16Mo45, 13CrMo45, 10CrMo910. The thickness of the steel used usually depends on the power of the boiler and its dimensions. So for boilers up to 100 kW it is 5mm. You can do less, but then the durability of such a boiler will be in question. For boilers from 100 to 120 kW - 6mm, from 150 kW - 8mm. Another important characteristic is combustion chamber size (furnaces). With the same power, this parameter can differ significantly. It is easy to guess that the larger size of the furnace allows you to load more fuel, use, for example, large firewood. Form and water jacket configuration, water content of the internal partitions, the front wall of the boiler. The more water-filled internal elements and the longer the hot combustion products pass inside the boiler, the more heat the coolant will receive.The higher the efficiency of the system. The water-filled front wall protects the front of the boiler from heating. Weight... A characteristic by which one can indirectly judge consumer qualities. The greater the mass, the correspondingly more metal was spent on the manufacture of the boiler, the more likely the unit itself is made more thoroughly. Of two boilers of the same power, but with different mass, the heavier one is preferable. Of course, you should not compare steel boilers with cast iron and boilers using different technologies in this parameter. Boiler water volume... Everything is simple here - the more water, the less chances the boiler will boil. With a larger volume of the water jacket, the boiler runs more smoothly.

All these characteristics can usually be found in the technical data sheet for the boiler, which can be viewed on the manufacturer's website or regional dealer.

These are the main parameters that must be taken into account when choosing a boiler, based on them, you can select and compare options that are close in price and power. In addition, there are a few more nuances that are worth paying attention to: + insulation of the firebox door (must be of high quality to avoid deformation of the metal) + door fastening (ideally collapsible in order to correct sagging after prolonged operation) + gate damper (the thicker the metal, the better, the longer it will last) + ash drawer (the larger, the more convenient it is to use) + dimensions of the revision windows (the larger, the more convenient it is to maintain the boiler) + removable jets (for pyrolysis boilers - again, it is convenient to clean, easy to replace when burning out) + dimensions of the pellet hopper (for pellet boilers, the larger the hopper, the higher the autonomy)

Also in many boilers today you can find built-in electric heating elements. This looks like a plus for the buyer, but in fact, such a solution is ineffective and will be appropriate only for a very small room. If there is a need to use additional electricity for heating, then it is much more efficient to use an electric one in a pair with a solid fuel boiler in one system. Such a system is certainly more expensive when purchased, but in the long run it pays off.

has been installing and servicing solid fuel boilers in the northwest for over 5 years. Our experience allows us to correctly select the equipment and configuration of the heating system so that the system works efficiently and reliably. Moreover, the company is interested in positive customer feedback and carries out annual monitoring of the installed equipment throughout its entire service life.

Technical characteristics on the example of model 12.5

Thus, using Keber boilers is quite safe and convenient. Excellent performance of this equipment is ensured, of course, first of all, by its well-thought-out design. The gas boiler "Keber 12.5", for example, has the following technical characteristics:

- power - 12.5 kW;

- Efficiency - at least 85%;

- control - mechanical;

- gas consumption - 1.62 m3 / h;

- total heating area - approximately 125 m2;

- maximum water pressure in the heating system - 3 bar;

- weight - 39 kg;

- guaranteed uptime - 22,000 hours

This floor-standing single-circuit boiler has an open combustion chamber. This modern model belongs to the group of non-volatile equipment.

Specifications and device

Keber boilers are distinguished by reliable assembly and long service life. The manufacturer gives a 15-year warranty. Also, the units of this brand are characterized by high efficiency.

The complete set of the Keber gas boilers device includes gas burners, thanks to which it is provided:

- stable heating of the coolant;

- the most complete combustion of fuel.

In addition, these elements are distinguished by high anti-corrosion properties.

Due to the fact that Keber boilers have gas burners, the size of their fuel chambers is smaller than that of similar heating devices manufactured by other manufacturers. Thanks to the special design of the Danko automatics, the fuel burns as efficiently as possible, even if the flame height reaches 7 cm.

The Danko nozzle is a certified design that is in no way inferior to European counterparts in quality.

Also included in the package is the Arbat automation, which is responsible for regulating the operation of heating equipment and its safety. There are five levels of protection. When the pressure in the water or gas supply system drops, the unit will turn off on its own. The design of the automation is simple, which has a positive effect on its reliability, and in the event of a malfunction, the repair will be simple.

It is worth saying that, if they wish, users can order a model from the Keber boiler manufacturer with a more expensive, but at the same time more reliable and high-quality Italian Eurosit automation. Such units can operate practically without third-party intervention.

You can read about the types of automation for gas boilers here.

The assortment of the company that produces Keber boilers includes a wide selection of models of different capacities: 10, 12.5, 16, 20 kW, etc.

Consider the technical characteristics of the device using the example of the Keber 12.5 floor model:

- type of execution - floor;

- combustion chamber - open;

- power - 12.5 kW;

- Efficiency - from 85%;

- mechanical control;

- gas consumption - 1.62 m³;

- weight - 39 kg;

- heated area - 125²;

- the maximum water pressure in the heating system is 3 bar.

Gas non-volatile boiler KS-G Keber 12.5 with EUROSIT automation

Consumer opinion

Despite the fact that Keber boilers are one of the cheapest brands of heating equipment in Russia today, they have earned quite good reviews from consumers. To the poles of these units, the owners of houses and apartments primarily refer to their impeccable work. For the first few years, boilers of this brand usually do not require any special maintenance at all. Some problems with their operation among the owners of country houses may begin to arise, judging by the reviews, only about 5-7 years after installation. At this time, it is recommended to clean the Keber boiler once purchased from limescale. This is primarily due to the fact that the water on the territory of Russia in most regions, unfortunately, is quite hard.

Thus, reviews of Keber gas boilers on the Web are mostly positive. The only thing is that sometimes the owners of country houses still criticize the work of the domestic automation of these models. It happens that after several years of operation, for example, the operation of the switch-on function deteriorates in Keber boilers. Burners are ignited in them only some time after pressing the "Start" button.

How to set up the heating system after starting the boiler

To set up the heating system, we need to carry out small manipulations with the control valves. The fact is that almost all circuits have one small drawback - the last batteries from the boiler, as a rule, do not have enough thermal energy. It simply does not reach there in the required volume and we will need to eliminate this drawback by distributing evenly the supply of hot water between all heating devices.

It is not difficult - the regulating valves of the first two or three batteries need to be screwed a little. If you go from the boiler, then the tap of the first battery is twisted by half, the second is slightly less, and the third is even less. Here you will have to experiment - it may take several days to achieve uniform heating of all batteries. But this does not matter any more, because in general the heating system is working normally, and the house is warm.

This is how, without making any effort, the first start-up of the boiler and the adjustment of the heating system are performed. As you can see, there is nothing complicated in this, and the money that the representatives of service centers take for it is not worth it. Better spend them on purchasing an electronic room temperature control system - this programmer will reduce the energy consumption of a wall-mounted heating boiler!

Yes, yes, this is exactly what you thought ... A wonderful series of computer (and later and not only ...) books, Simple and understandable, which was very useful to many.

Your new home has honestly looked after you all winter. Saved from bad weather, protected from precipitation, wind, cold ... But now the sun warmed up, long ago the trail was gone from winter snowdrifts. May. It's time to turn off the heating in the house. But as? There is so much of everything in the boiler room that you can open, close, switch, turn off ... Right there, almost like an airplane pilot :-) What to do? Look for the phones of "those guys" who put the boiler and call them for help? Oh no. This is not our choice. If a part of your life is your own house and if your house is not a part of a cottage village, you will have to be yourself and an electrician and a plumber, and many more ... with your own home. So back to our problem. Summer is knocking on the door. Heat outside. It is necessary to turn off the heating in a private house. But as? First of all, we determine what kind of boiler we have in our house. This can be done, for example, simply by looking at the documents that are for this boiler. If the boiler is double-circuit, then everything will be quite simple - you just need to switch it to the "summer" position. What exactly needs to be pressed and turned for this - read the instructions for your boiler - everything is simply and clearly written there. (For reference. A double-circuit boiler works something like this - the heating medium burns in a circle along the pipes and radiators and "looks" at the temperature of the coolant - if it becomes less than the owner (or the temperature sensor) specified, it ignites the gas and heats it. If the owner of the double-circuit boiler turned on hot water - the boiler "ceases" to care about the temperature of the coolant in your heating system and devotes all its efforts to only one task - to heat cold water to make it hot and give it to the owner. the street is frosty, and the owner of the double-circuit boiler is actively draining the hot water from the tap hour after hour - he risks freezing the whole family. The priority of hot water supply is the cleverly called this behavior of a double-circuit boiler.) It is a completely different matter for those owners who have a single-circuit boiler. I will tell you a terrible secret - a single-circuit boiler has only one circuit :-) Inside a single-circuit boiler there is simply no separate circuit that would be occupied only with heating and which could simply be turned off for the summer. But how is it done so that a single-circuit boiler, having one single coolant circulation circuit inside itself, still manages (and much more efficiently than a double-circuit one, with its misanthropic "priority of hot water supply") to drive the hot coolant both through the heating system and through the hot water supply system ? It's simple. Yes, inside a single-circuit boiler there is one single circuit, but outside the boiler, by a system of external pipes, valves, circulation pumps, etc., from this one you can create as many different circuits as you like. Well, just everything. Imagine. Here the heat carrier heated by the boiler's flame is running through the pipes - along the only circle that a single-circuit boiler has. He ran hot up the pipes, ran around all the radiators, gave all his heat to the house, ran the cold one back into his single-circuit boiler, warmed up, ran up again .. He's bored.He runs and runs in the same circle ... How to "pinch off" a piece of this flow circulating through the heating system, in order not only to heat the house, but also to heat the water with this "pinched off stream"? Yes, it is clear how. Very simple. We cut a tee into the heating circuit. That's it, now the coolant, having reached the tee, will split into two directions - one stream, as before, will run through the heating batteries - to give its heat to the house, and the second stream will run into the hot water supply system. Phew. Well, finally, we got to the hot water supply system for a single-circuit boiler. But in fact, there is almost nothing to tell about it ... A hefty barrel into which cold water flows through pipes, and inside this barrel there is a "spiral - serpentine" pipe through which a part of the hot coolant flow "pinched off" by us runs. That's all, actually. A hot coolant that runs over and over again inside a barrel of water gives off and gives off its heat to this water - trying to heat the water to the temperature of the coolant. This "magic barrel" in the hot water supply system is called an indirect heating boiler (or, more simply, "water-to-water boiler"). And that's all, the heating system, the hot water supply system ... Boiler and pipes and radiators, but now, now there is this water-to-water boiler. The whole system, or what? Well, almost ... Here, after all, at home we have with you, how to say it then ..., well, "they are not small." It is usually hard for the heat carrier to rush around these endless and, as a rule, very long circles - until you run from the boiler room to the farthest room ... but you still have to run back to the boiler to "warm up" ... To help the coolant move into the pipes, electric circulating pumps are cut into the pipes. I switched on such a pump and the one "like a taxi" moves the coolant through the pipe. Such a circulation pump also stands in the same heating circuit (where, until the tee was cut in, the coolant ran alone) and such a circulation pump stands in the pipe of that "pinched off" flow that runs in the boiler. In addition, in these heating and hot water supply systems there are "security groups", expansion tanks, many are many (often depends on the fantasy of those guys who put these systems in the house :-) taps, well, and something else that is not about this topic ... So so. So far, everything is elementary simple. A single-circuit boiler works and heats the house and heats the water, and, most importantly, now we already know how he does it. After a little thought, we understand that the boiler itself cannot be turned off for the summer - it is necessary to heat the coolant in a “pinched off” stream, otherwise the water in the boiler cannot be heated. This means that in order to turn off only the circulation of the coolant through the pipes and radiators of the heating system for the summer, you just need to shut them off with a valve - so look for and close such a valve on your main thick pipe going up from the boiler - look somewhere above the "pinch off into the boiler "Tee), while the valve that you find standing immediately after the" plucking tee, but not on the main thick pipe going up, but on its lateral branch (this valve determines a lot or little to "pluck" into the boiler) - on the contrary, must be completely open for the summer. All. Now the circulation along the heating circuit is off and the house is no longer heated. The circulation along the hot water supply circuit is fully open, which means there is hot water in the house in summer. Once having determined where and what kind of valve you have installed and once having switched from winter to summer - do not be lazy, write it down in detail in your own "house book" - believe me, you will use it more than once ..

There are some important nuances of the operation of a single-circuit boiler for a "short", as a rule, a hot water supply circuit, but I will talk about this in my next article.

There are a huge number of heating options for residential and non-residential premises.In particular, gas boilers are also used due to the reasonable price, high level of safety, and a large number of types. However, the rules must be followed. Especially know how to turn on a gas boiler when using it for the first time.

Gas boilers "Keber": instruction

Heating equipment of this brand, like any other similar one, can only be installed by licensed specialists. Before starting up in the boiler, all connections must be checked for tightness.

Instructions for turning on the Keber ignition head are as follows:

- turn the control handle counterclockwise to the ignition icon;

- without releasing the handle, press the piezo ignition button (a torch should appear);

- release the handle 20-30 seconds after pressing the button;

- check for the presence of a flame on the ignition head.

As you can see, the operating instructions for Keber gas boilers are quite simple. If there is no flame after performing the above steps, all four operations simply need to be repeated. In this case, it is necessary to increase the holding time of the handle.

Possible equipment malfunctions

Like any other equipment, floor-standing gas boilers "Keber", of course, can sometimes break down. Most often, owners of country houses with this equipment have the following problems:

- unstable operation of the igniter;

- shutdown of the burner some time after the start of work;

- lack of fuel supply to the injectors.

In the first case, the cause of a malfunction in the Keber gas boiler may be a clogged nozzle. Also, sometimes the igniter is unstable simply due to the fact that the meter does not allow a sufficient amount of gas into the system. To remedy the situation, the owner of a country house, respectively, needs to either clean the jet, or properly adjust the operation of the monitoring equipment.

There can be many reasons for the shutdown of the burner after starting work. But most often this happens due to the failure of the thrust sensor. It is unlikely that you will be able to eliminate such a malfunction yourself. Only a specialist called to the house can cope with it.

If the gas supply to the nozzles in the model equipped with the Arbat security system has stopped, then, most likely, the stem is jammed in the middle of its structure. In order to eliminate this malfunction in the Keber gas boiler, in this case, you should drip a little machine oil into the device. After that, be sure to check the unit for gas leaks.

How to remove air pockets?

Simply connecting the system by filling it with water is not enough. It will not work or its effectiveness will become extremely low. To carry out a full-fledged first start-up of the equipment, it is necessary to release all the air that has accumulated in the system from the system. A modern gas boiler may have a special system for automatically venting air when filling, but the efficiency of such systems is low. This means that manual air purging from the main and other systems is required during connection. Only then can the launch be carried out.

Removal of air plugs during connection is carried out not only at the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with the radiators. Especially for this, they are equipped with the so-called Mayevsky cranes, which you just need to open by substituting a basin under them. At first, a slight whistle will be heard - this is the air gradually leaving the system. If the plugs are removed, then water begins to flow. If the batteries are freed from air masses, then the taps must be closed. Such a simple procedure is carried out with each radiator, from which it is imperative to check and clear of plugs.When air is removed from all radiators, the pressure gauge needle will set at the desired value. Before turning on the gas boiler, it is necessary to add a coolant to the system, that is, to feed it with liquid.

Next, it is necessary to completely remove all air plugs from the circulation pump, which requires disassembling some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, then find a cylindrical part, which has a cover in the middle of the body, there is a slot for a screwdriver on it. The boiler must be started, that is, supply power, set the heating control to the required operating position. After that, a faint hum will be heard - this will start the circulation pump. You can hear gurgling, other sounds. Using a screwdriver, the cover in the found part must be slightly unscrewed, this should be done until the water flows. As soon as the liquid begins to seep out, the cap must be screwed back on. This procedure is required to be carried out 2-3 times, after which the air locks will completely leave the system, and the sounds and gurgling will disappear, the pump will start to work quietly. Immediately after this, the electrical ignition of the equipment will work, the gas boiler will start its work on its own.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up, begins to enter the normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. How effective the heating will be depends on the correct preparation, start-up, and adjustment of the system.

In the last article we talked about, but besides this, its launch is an important point. In order to perform the first start-up of the boiler, it is not necessary to invite specialists from the service center. Judge for yourself, this condition, under which a brand new boiler is put on a "free" warranty service, is not worth a pittance - anyway, in the future, if a breakdown occurs, you will have to pay both for spare parts and for the work of the master.

So what kind of free warranty repair can we talk about? Moreover, for first start-up of the boiler

you will also be charged a fee, and a rather big one, motivating it with commissioning. Don't want to waste your money? Then read on and learn how to independently start the boiler and debug the operation of the heating system, especially since it is not difficult.

The initial stage, which involves the first start-up of the boiler, is filling with water. I think you will definitely cope with this task without outside help. We look under the boiler, where all the communication pipes are connected, and we find there something resembling a faucet - it can be made in the form of a lamb, which is familiar to us, or it can be a flag or just a rotating pin. In any case, it is difficult not to recognize it, but in which case, its location can be determined by looking at the instructions for the boiler equipment.

Found it? Slowly we open it, we collect water into the system and wait for the pressure indicator on the boiler to reach 3.0 atm, and while the system is being recruited, we go and look through all the pipes and batteries for leaks. And along the way, we immediately eliminate them - we tighten the nuts and close the open Mayevsky taps.

After the pressure in the system has reached 3 atm., We turn off the make-up tap, we go through all the batteries one by one and with the help of the Mayevsky tap we bleed air from them. We return to the boiler again and add water to the system until the pressure indicator on the boiler shows 2-2.5 atm.

Well, the system is complete, you can start directly starting a gas boiler or an electric one, in principle, there is no difference in the process of starting them up. To do this, you will have to disassemble the boiler a little - do not be afraid, anyway, we will not climb where something can be broken.Our task is to get to the circulation pump - it is he, or rather the air accumulated in it, that is the reason for not turning on the boiler equipment at the first start.

The location of this pump is easy to see - it is a cylinder located with its end facing us, in the center of which there is a wide screw with a slot for a screwdriver. This is the screw we need.

Found this stumbling block? Then you can turn on the boiler in and set the necessary levers to the operating position - from this moment, it happens first start-up of the boiler

... Immediately after the boiler has received its energy supply, the circulation pump will turn on and the electronics will make vain attempts to turn on the rest of the equipment. It is at this moment that there is no need to rush, slowly unscrew the central screw of the circulation pump and release the air from it.

As soon as water flows from under the screw, we quickly close it and calmly observe the noisy operation of the boiler. Now the electronic gas supply valve will open, the electronic ignition will work and the boiler will start. It will gurgle, grunt, make some incomprehensible sounds, but this is normal - the boiler simply expels air that has hung in some places from the heating system. The design of the boiler equipment includes a so-called expansion tank, which is equipped with an automatic air relief valve - it is through it that the remaining air is removed.

After a few minutes, when the operation of the boiler stabilizes and the gurgling sounds subside, we check the pressure in the system and, if necessary, bring its value to 2-2.5 atm. By opening the water supply valve for the system. At first, while the heating is just getting better, the system can be replenished with water several times - you will periodically have to check the manometer readings and, if necessary, replenish the water volume in the system.

Well, we figured out how to start the heating boiler, the equipment is working fine, the batteries begin to warm up - it's time to start debugging the entire system.