Long-burning pyrolysis boilers have high power and efficiency, while, if you install a more modern model, the automatic system will reduce human intervention to a minimum. A great convenience is the moment that one load is enough for a day, that is, the owner does not need to constantly monitor the fuel level. You can only throw in the required amount of firewood in the evening or in the morning and enjoy the warmth. But, like any other technique, pyrolysis boilers, in addition to their strengths, have their own weaknesses, which you need to familiarize yourself with before installing such a unit.

How does a pyrolysis boiler work?

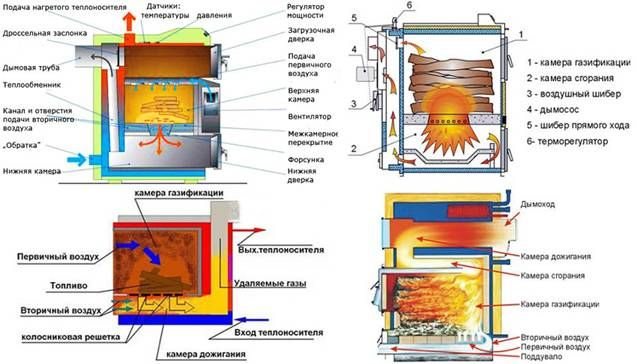

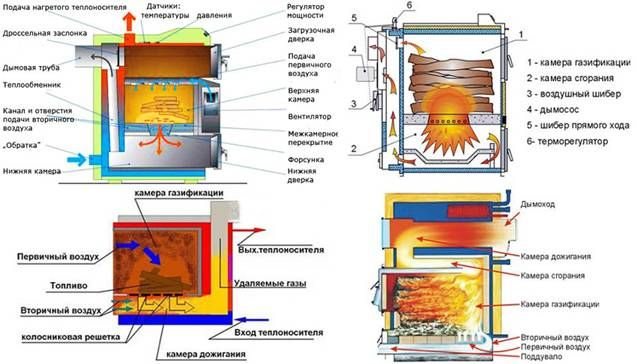

Long-term pyrolysis devices are a "laboratory" within which gas is extracted from solid fuels. It is he who is used in heating the house. Pyrolysis is a physicochemical process in which complex organic compounds decompose into simple components in the form of a solid, liquid or gaseous state. For this to happen, you need to provide a high temperature and limited oxygen access.

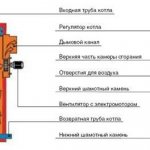

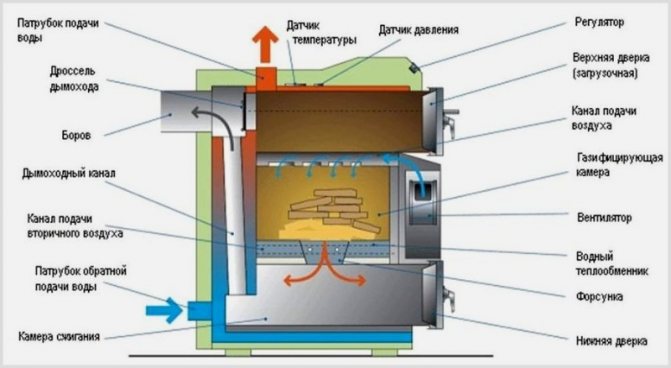

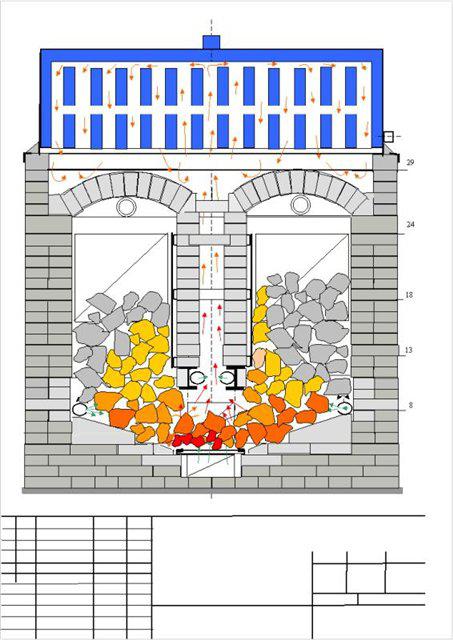

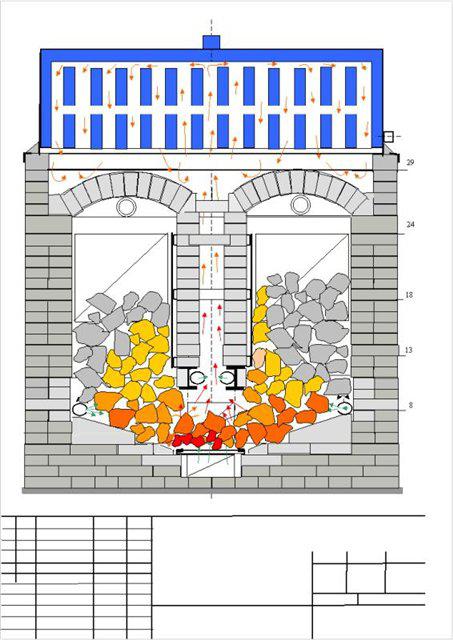

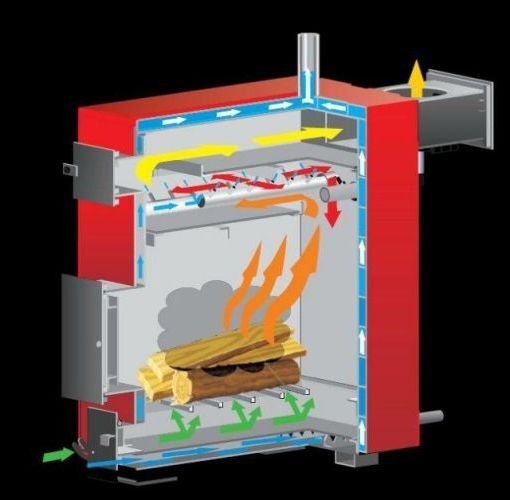

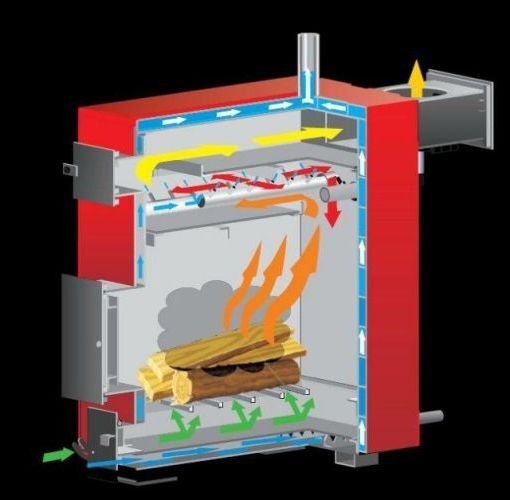

The design of the pyrolysis boiler has a two-chamber heating device, where in the upper part it heats up to 200-800 degrees, which contributes to the onset of an exothermic reaction of solid fuel. There is no oxygen, due to which the material slowly smolders. Having decomposed into CO and CO2, the mixture goes to the lower part of the boiler, where the combustion temperature is already kept at around 1100-1200 degrees. The two chambers are connected by grate bars. The result is the release of a large amount of heat (pyrolysis gas) intended for heating the house. The rest of the fuel that does not burn out is called coke or charcoal.

It is also worth noting that in the process of combustion of pyrolysis gas, it has to come into contact with a certain amount of active carbon at the outlet. This leads to the formation of a minimum amount of harmful impurities in the flue gases, which makes the operation of this installation safer. Thus, the bulk of the flue gas consists of water vapor and carbon dioxide.

It turns out that pyrolysis devices use not the solid fuel itself, but the gas produced from it. Thanks to this technology, these boilers show an efficiency of 85-90%, since here the material is burned with almost no residue. And at the very beginning of such an action, the material is dried, that is, from the moment of ignition to the last spark, a "useful" process takes place. And this is not to mention the fact that gas combustion is much easier to control, especially if the device is equipped with automation.

As for the duration and quality of work, then there are several fundamental points:

- weather conditions outside, in particular, temperature;

- the quality of thermal insulation in the house;

- what temperature they want to have in the house;

- what kind of fuel is used and what is its moisture content;

- how competently the heating system was drawn up and who was engaged in it.

If all the conditions (except for the first one) were fulfilled in accordance with all the requirements, then pyrolysis boilers of long burning, in comparison with their other solid fuel counterparts, show themselves much more efficiently.

A pyrolysis boiler or how I began to burn myself with car tires and everything that burns

Let's start with theory

Heating systems (CO) with a solid fuel boiler (TTK) are intermittent systems in which the boiler generates heat only when there is fuel in it.In this regard, the owners of the TTK, sooner or later, acquire heat accumulators, which accumulate the excess heat generated during the operation of the TTK and give it to the house after the fuel in the boiler has run out. TTC is usually divided into classic (grate) and pyrolysis (gas generating). The classic version implies ordinary combustion of fuel with the release of heat. Solid fuel pyrolysis boilers are distinguished by the fact that fuel and combustible gas released during its combustion are burned separately. This provides a higher efficiency, a wide power range, and simplicity of chimney requirements. By "ordinary fuel combustion" it is meant that the fuel in such boilers burns in the loading chamber, where all the same processes are going on simultaneously as in the pyrolysis of wood. For this reason, in classic (grate) boilers there is no way to obtain high-quality (complete) combustion of fuel. As a result of incomplete combustion of fuel, tar, resins (pyrolysis products), soot, ash are deposited on the boiler heat exchanger, and a heat-insulating layer is formed, which in turn forces the boiler to generously share the generated heat with the environment. As an advantage of classic boilers, it is sometimes indicated that, allegedly, it is possible to burn wood with high humidity in them, but as for me, to heat with raw wood is not to respect yourself. It does not matter in which boiler, pyrolysis or traditional, firewood, before starting to give heat, must go through the initial stages of pyrolysis, namely heating and evaporation of moisture. This means that if we use firewood with a moisture content of 20% for heating (this is for 10 kg of dry firewood, pour 2 liters of water on top), that is, a fifth by weight of ballast in them, for heating and evaporation of which part of the fuel will also have to be spent, which is no longer will be used to heat the house.

To be absolutely precise, the fuel does not burn "directly", the gaseous products of pyrolysis burn. This means that before the firewood begins to burn, that is, it is oxidized by atmospheric oxygen with the release of heat, they must be heated to the temperature of evaporation of moisture in them, after which the process of evaporation of this moisture must go through, and only then the actual pyrolysis and combustion of pyrolysis gases will begin ... Moreover, the processes of the first and second stages go with the absorption of heat, which is so necessary for the pyrolysis of the wood itself, without which there will be no combustion process itself.

My choice

If, after reading, you no longer plan to heat with raw wood, then based on your life experience, I would recommend the pyrolysis boiler. Before that, I already had two years of experience in operating the KALVIS-2-70 mine grate boiler. Of the identified shortcomings, I note that its heat exchanger could not be cleaned from resins deposited on it without preliminary heating to a temperature above 60 ° C. Ultimately, realizing all the technological flaws of this design, I decided to turn to specialists for its radical alteration. As a result of this deep modernization, I became the owner of a pyrolysis boiler.

Installation

It is better to place the boiler in a specially designated room for it, since I have not yet met boilers that do not smoke in the room when refueling with fuel (and mine, moreover, sometimes smokes also due to imperfect design).

In addition, boilers are usually equipped or, which usually make a pretty decent noise. The rest of the control mechanisms for CO units (circulation pumps, air damper drives, chimney damper and electric ball valves) operate almost silently. Among other things, you need to take into account that the boiler for its operation will require a large flow of air into the room in which it is located, which will cause cold drafts. From all of the above, it is better to place the boiler in a separate room in the body of the house.My chimney is located vertically without bends and is part of the inner wall of the house, and during the operation of the boiler it additionally radiates heat into the house. Since the boiler is a unit in which the generated heat is transferred to the coolant water, there are no "hot" parts on its surface, since it does not heat up above the boiling point of water. In addition, the water jacket on the outside is usually protected by a casing, the temperature of which rarely exceeds 30 - 35 degrees.

Procurement of firewood and more.

The main fuel for the pyrolysis boiler is wood. Any firewood is suitable: coniferous, deciduous, pine, oak, birch, etc. They all have approximately the same heating value. Hard species, such as oak, have a higher calorific value, but they are more expensive, so I don't see much sense in chasing them. Any dead tree, fallen or dead wood, is great for harvesting. The main thing is that the firewood is not raw and not expensive, it is better to be prepared personally, and it is more useful for the wallet and health (you can easily save on a subscription to a fitness club). Partly because when buying on the side it is difficult to comply with all of the above conditions, I do not like buying firewood. Somehow, in the first heating season, they brought a car of firewood from the leshoz, so their remnants in the spring released shoots and took root in my yard. Since then, I have been harvesting firewood only on my own. In addition to firewood, the pyrolysis boiler gladly consumes straw, pellets, shavings, peat briquettes and ordinary peat, sorted household waste (paper, plastic, packaging, everything except PVC) and all this is seasoned with used oil or any other waste of liquid hydrocarbons. But the best fuel for the boiler can be a car tire. The calorific value of a car tire significantly exceeds the calorific value of the best wood species and amounts to 32 GJ / t. It can be compared with it, perhaps, the calorific value of high-quality coal. In addition, the tire has zero moisture, which is also a positive point. Well, if anyone else has doubts that the tire can burn pretty decently, you can look at the gases escaping from my pipe and at the fire in the pyrolysis chamber.

Gases from burning tires

Fire of burning tires

This is how car tires, prepared for loading into the boiler, look like

The fact that not only I regard the tire as an excellent fuel can be judged by the number of ads that offer steel cord remaining after burning it.

Environmental standards and their violation I should also focus on the fact that in no case do I call for the widespread burning of car tires in home heating units. Living in a society among people, equipping our life, we should not cause inconvenience to our neighbors, including our actions should not violate the laws of the states of which we are citizens. The tire as a fuel is mentioned by me in this article only as a private successful experience, which became possible after a thorough modernization of a serial household boiler, subject to constant close monitoring of the combustion process through a video camera and operational control.

To ensure fire safety in the boiler room, I placed two automatic powder fire extinguishers of the Buran 2.5 type and an autonomous smoke detector on its ceiling.

Ignition

The boiler is easier to ignite

(such a tab is carried out through the lower firewood loading window), but if you wish, you can start the boiler with a full load (for such a load, the upper firewood loading window is used). When starting with a full load, I ignite the boiler through the pyrolysis burner using the previously inserted

(top view of the pyrolysis burner through the lower fuel loading window). Also, a small amount of

and

.

Combustion products

The pyrolysis chamber of the boiler (aka ash pan) must be cleaned every time after the heating cycle (about 10 - 12 hours of continuous operation), since its volume is limited, and pyrolysis gases still need to burn somewhere.

I try to clean the heat exchangers of the boiler through the heating cycle, that is, about twice a month, since the efficiency of removing the heat generated in the pyrolysis chamber depends on the degree of their cleanliness. Usually, after one heating cycle, a bucket of ash and almost clean steel cord from tires are left. Both ash and steel cord turned out to be a valuable product for further use. The products of complete combustion of the TTK fuel are carbon dioxide, water and ash. It is precisely the water vapor that turns the smoke white on an unheated chimney. The product of incomplete combustion of TTC fuel can be soot. A significant amount of it can color smoke black, and a small amount, mixed with water vapor, in various shades of gray.

Boiler design

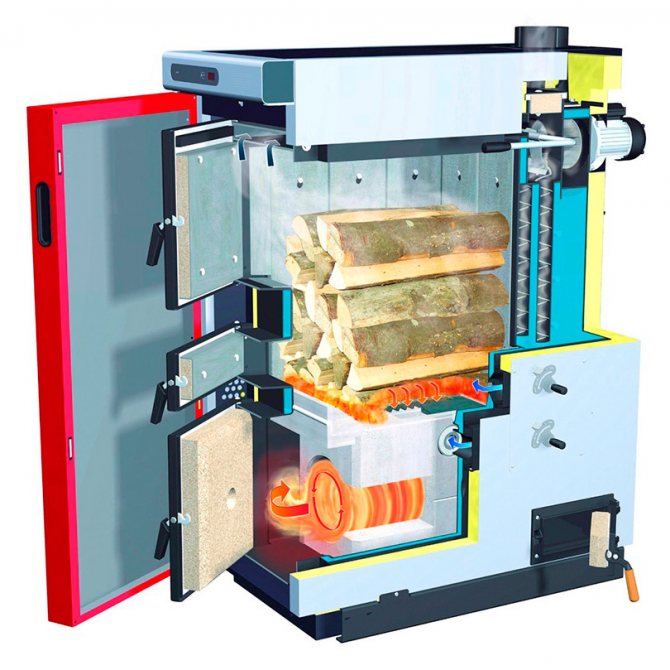

There are three doors on the front of my boiler:

- The upper door is needed in order to increase the volume of a single load. The more firewood you can load at a time, the less you have to do it.

- The middle door is needed to service the boiler (cleaning from ash, preparing for a new kindling), it is simply impossible to do this through the uppermost door. There is a loading chamber behind it.

- Loading chamber appearance

This chamber is also called a gas generator, since it is in it that the process of firewood pyrolysis takes place.

- A combustion chamber for pyrolysis gases is located behind the lower door.

Some details about the location of the combustion chamber

The combustion chamber (afterburner) is located under the fuel loading chamber in order to localize a certain volume of fuel involved in the combustion process. That is, in the pyrolysis boiler, only those firewood burns that are in the coverage area of the air dampers (this is below the middle door and a little at the height of the middle door), the rest of the fuel is just a reserve, which, as it burns out, sinks into the combustion zone. If the pyrolysis chamber is placed on top, and the fuel is ignited from below, then the flame rising from the bottom up through the wood will pyrolyze all the fuel at once and instead of burning we will get a lot of smoke and, as a result, resinous substances on the heat exchanger.

The air for fuel in my TTK is supplied through three air dampers to different zones of the boiler, which makes it possible to obtain the most efficient fuel combustion. The presence of 3 air dampers, a temperature graph in the chimney and a video camera in the pyrolysis chamber allows you to minimize heat losses and get the most efficient combustion of not only various types of wood, but also more high-calorie fuels, such as sorted household waste and worn out car tires.

A bit of theory Usually, in TT pyrolysis boilers, air is supplied in a strict pre-designed ratio without taking into account the characteristics of the fuel, its actual moisture content and the stages that it goes through as it burns out in the boiler. This leads to the fact that sometimes there is enough air for efficient combustion of the design fuel (for example, pine firewood), but more often there is either less air than needed (and then the products of incomplete combustion of fuel condense on the TTK heat exchanger in the form of tar), or more than necessary (and then the excess air not participating in the combustion process cools the heat exchanger, and carries away into the atmosphere the precious heat generated by the TTC).

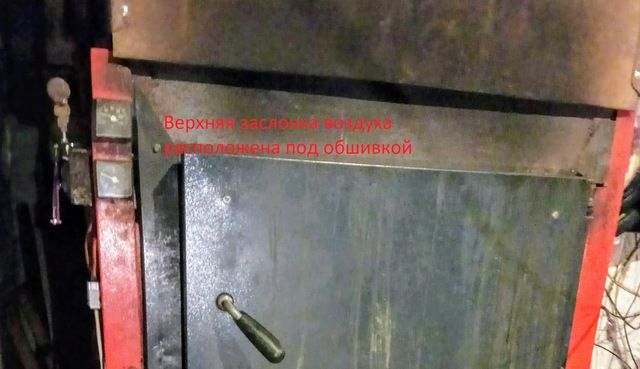

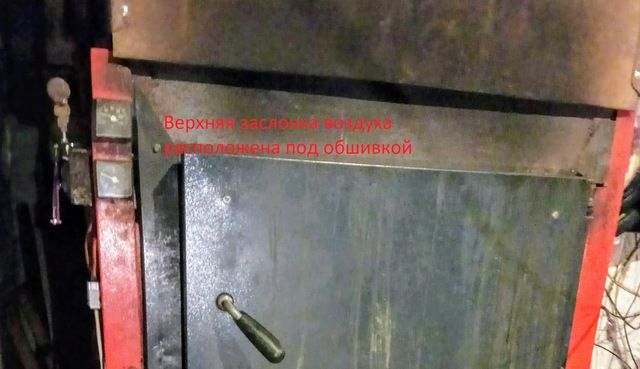

My boiler, like most pyrolysis boilers, was born with one damper (now it is medium in height, it is also the main one). The damper is located on the front of the boiler, below the lower fuel loading door. Air through it is supplied to the fuel located above the burner and covers about 100 cm3 of firewood.This is the amount of fuel that is involved in the main combustion process. The same volume of fuel forms a coal bed on which pyrolysis gases are ignited. The upper flap is located under the skin, above the lower fuel loading door. It appeared later, its task is to form an additional volume of pyrolysis gases, after the fuel located in the coverage area of the middle damper has passed from the first to the third stage of pyrolysis, and no longer emits a sufficient amount of combustible gases in relation to the supplied through it (middle damper) air volume.

Upper flap

The lower flap appeared already the last due to the need to supply an additional volume of air when burning more high-calorie fuel than firewood, for example, a car tire. The lower flap is located above the combustion chamber door and supplies additional air to the combustion chamber.

Middle and bottom flaps

Inexpensive but quite suitable servos are used as actuators for these dampers.

Heating system

Usually, the happy owners of the TTK go through the natural stages of evolution:

- The acquisition of the boiler and the knowledge of the first is the joy of the warmth brought by it into the house. They feed him with small portions of firewood, they feed him often and with pleasure.

- Then they try to stretch the time between feeding. Then they try to experiment with different types of food: they fire exclusively with oak, acacia, and even coal, which is rare in our area.

- In the end, the understanding comes that "the boiler exists for me", and not "I am for the boiler."

- After that, the owner of the boiler begins to look for a place in the house for a heat accumulator (TA).

I was more fortunate than the others, even in the process of designing the house, I planned a place for myself under the TA, safely past this initial stage. As a heat accumulator, you can use any container that can withstand the pressure in your CO (for me it does not exceed 1.5 kg / cm2), or make an indirect heating TA (the water circuit of such a TA exchanges heat with the boiler circuit through an additional heat exchanger), then it will be easier to fit into the space of the room. Here you can read more about mine. It should also be borne in mind that the temperature of the water in the TA often reaches 94 ° C, therefore, the material from which the TA is made and the pipe supplying the coolant to it must withstand these temperatures. The heat accumulator does not have to be installed in the boiler room next to the TTK (even better outside of it), it can be mounted in any room of the house convenient for you (you can even do this). I also had to purchase, although it was quite possible to get by

and the boiler circuit. It took the same

for the underfloor heating circuit and the radiator circuit, although life later showed that radiators in CO with TTK and TA are meaningless. Was not superfluous in CO with TTK and

, well, and then on the little things: an expansion tank, a ball valve with an electric drive of the TA circuit, the boiler circuit and the boiler circuit. Circulation pumps for indirect heating boiler circuits, underfloor heating and radiators.

Legend

Automation

In the course of the operation of its CO, it gradually came to the understanding that the system, in the form in which it was born, had significant flaws. It turned out that heating systems based on TTK + TA, it makes sense to comply with a number of conditions:

- It seeks to send to the TA only the surplus heat from the TTK.

- Cut off the TTC from the rest of the heating system (CO) after it stops generating heat, since after the fuel burns out, the TTC turns from the heat generator into its consumer and begins to suck the previously stored heat from the HA.

At first, it was necessary to manually connect the TTK to the CO during startup and also manually disconnect it from it. Manually divide the heat fluxes both at the beginning of the start of the TTC and already during the operation of the boiler, when an excess of heat is formed.In addition, the standard air damper regulator was too inertial and did not cope with the tasks assigned to it. And then it was decided to shift some of its simple functions for controlling the boiler onto the fragile shoulders of automation. The use of an electronic control unit (CU) saved me from performing many routine operations. Also, along the way, the BU copes with such a trivial task as protecting the TTK from overheating, that is, it does what the overwhelming majority of factory BU TT boilers do. My first TTK control unit was far from perfect.

Schematic diagram

Every time when I needed to correct or change the logic of the CO's work, my head swelled when I looked at this circuit and tried to understand how it works.

In the end, with the participation of kind people, the BU acquired the form that it has today, as well as the functionality that is so necessary for me. The screen graphically displays the current state of the main CO units that need to be monitored. At the same time, the screen is not overloaded with information, and it is easy to read. Additional information about what equipment is currently being used by the control unit can be obtained from the LEDs of the relay unit.

Circuit design

The control unit of my boiler is assembled on the basis of the Arduino Mega 2560 module. The choice fell on Arduino, because it is widespread, easily accessible, well-documented, there are many lessons on its programming on the network, a huge friendly Internet community that will help, prompt, teach. It is Arduino that allows you to implement the functionality of your device, limited only by your imagination. For example, your BU in winter can control the TTK, but it is enough to change the firmware in it and connect the power device connector to another group, and it will control the irrigation system of your personal plot or, for example, a greenhouse. You cannot do such tricks with a factory BU TTK.

List of control unit elements

Software

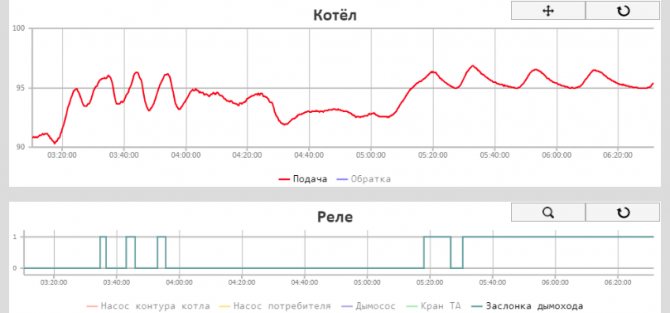

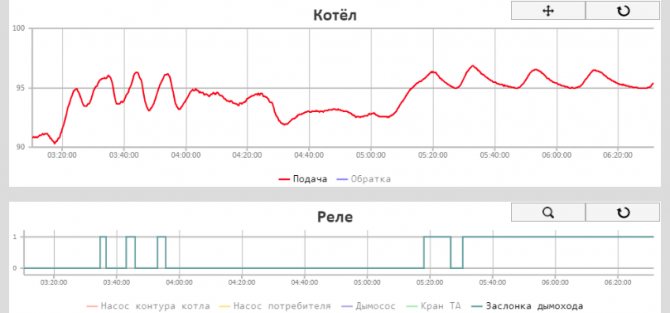

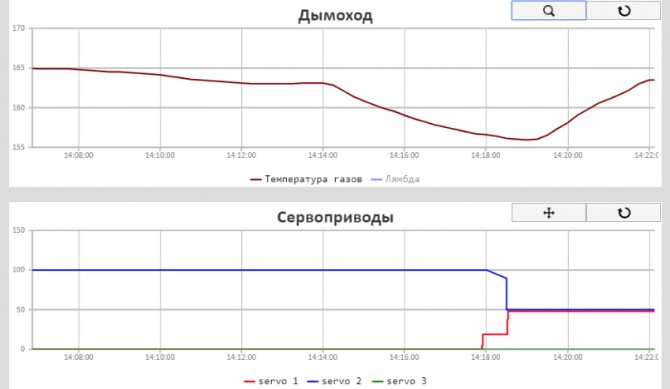

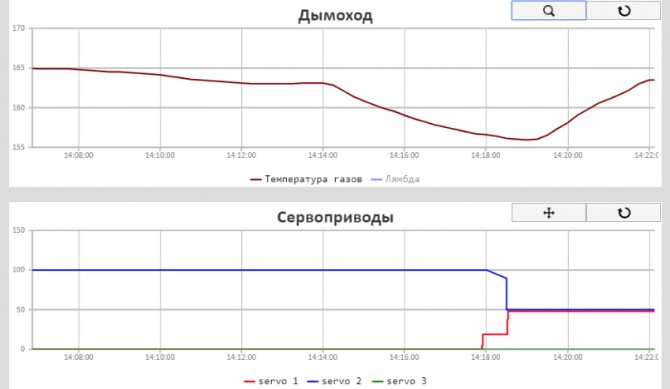

My boiler control unit is connected to a cloud service, this allows me to remotely monitor the state of the system, and, if necessary, also remotely, make adjustments to the operation of the boiler and the heating system as a whole. Why ask for remote control of the heating system and, in particular, remote control over the operation of the TTK? I believe that only a very courageous person can afford to leave a working boiler only under the supervision of a BU worth a little more than $ 100. I gained confidence in the need for remote control, as I gained my personal eight-year experience in operating the TTK. This service provides an extremely useful opportunity for graphical presentation of data from temperature sensors located at key points of the CO, which in turn not only gives an idea of the current static state of the CO, but also about the dynamics of the development of the processes taking place there. So, in particular, the data obtained from the "Graphs" tab give an idea of the current state of the CO, the correctness of the operation of its individual components in accordance with the program specified by the CU, and, in contrast to the data received from the CU monitor, give an idea of the dynamics of this data, the rate of change and direction of movement (increase or decrease), which is especially important at the time of threshold (critical) temperatures. Whether the TTC was replenished with cold water from the TA or not, we can remotely, promptly track "Boiler input" on the graph, and whether this make-up had the expected result of protecting the boiler from overheating, we can track it on the "Boiler output" graph. If the expected decrease in the water temperature at the inlet / outlet of the boiler did not occur, then for some reason the valve of the TA circuit did not open and the owner of the boiler needs to take adequate measures to protect the TTK. Also, the data obtained from these graphs allows you to quickly notice and eliminate the boiler operator's mistakes made when controlling the boiler.In particular, thanks to the "Chimney" schedule, I noticed in time that I had forgotten to return to the operating position the distribution flap, which directs the fuel combustion products bypassing the boiler heat exchanger into the chimney (usually it is transferred to this position when adding fuel to reduce smoke into the room), which in turn led to an overshoot of temperature in the chimney above 250 ° C.

Laddomat work schedules

The antiphase behavior of temperatures on the graphs "Boiler output" and "Boiler input" is due to the peculiarities of the operation of such a CO unit as Laddomat 21 (in the diagram it is designated No. 9). The fact is that it is his responsibility to ensure that the temperature of the coolant (in our case, water) at the boiler inlet is maintained above 55 ° C. This function is provided by a thermostatic valve, which is part of the Laddomat 21. Since the TTK + Laddomat 21 system is sufficiently inertial, we observe an antiphase temperature fluctuation on the graph. Such temperature fluctuation, on the "Boiler output" and "Boiler input" charts, indicates the normal operation of the CO as a whole.

Heat exchanger operating schedules

Upon reaching the threshold temperature at the outlet of the boiler above 85 ° C. BU TTK gives a command to open the ball valve (No. 13), while hot water is supplied not only to the heating devices of the house (warm floor and radiators), but also to the TA (No. 12), while the cold water coming out of the TA goes to the entrance to the TTK, which in turn leads to a decrease in the temperature at the outlet from the boiler. In other words, all excess heat is directed to the heat accumulator.

Overheating protection curves

If the usual measure (feeding the boiler with water from the TA) was not sufficient and the temperature at the boiler outlet continues to rise, then the BU TTK gives a command to close the air dampers and the chimney damper. This allows to reduce the boiler output and normalize the water temperature at its outlet. This protects the boiler from overheating.

Manual air damper control curves

The graph of the temperature in the chimney gives an idea of the stage at which the TTC is located (ignition, active pyrolysis or burnout of the remaining fuel) and, in conjunction with the video received from the pyrolysis chamber, makes it possible to conclude about the state of the pyrolysis chamber and, if necessary, remotely (via the website) Correct the position of the air dampers controlling the quality of fuel combustion. So, for example, 85 minutes after starting the boiler, the release of pyrolysis gases in the area covered by the middle air damper decreased, which led to a decrease in the smoke temperature. After changing the position of the dampers, the upper one - from 0% to 48% and the middle one - from 100% to 50% (where 0 - fully closed, 100% - fully open), the flue gas temperature increased again.

Graphs of the beginning of the active stage of pyrolysis

This part of the graph shows the beginning of the active stage of tire pyrolysis, this can be seen from the rapid increase in the temperature of the smoke and the temperature of the coolant at the exit from the boiler, and as a consequence, the increase in the boiler power. At this moment, it is necessary to correct the position of the air flaps during the active stage of tire pyrolysis.

Chimney graph

Looking at this graph, we can conclude that the duration of the boiler operation was approximately 20 hours and 30 minutes. After firing up, the boiler went into active mode (smoke temperature is more than 110 ° C) after about 30 minutes of setting firewood on fire. After another 30 minutes, the smoke temperature crossed the border of 135 ° C and the boiler went into free draft mode (the control unit turned off the smoke exhauster and opened the chimney damper). Then the boiler worked at its maximum power, up to approximately 14 hours and 30 minutes (at this time, most likely, the boiler was reloaded with fuel). In this mode, the boiler worked until 5 o'clock in the morning of the next day and when the temperature in the chimney dropped below 110 degrees. BU TTK put the boiler into sleep mode (turned off the circulation pump (Laddomat 21), No. 9, closed the ball valve of the boiler circuit No. 7, turned off the exhaust fan No. 5, closed the damper of the exhaust fan No. 4, opened the ball valve of the TA circuit No. 13). Further, the BU supplied the house with heat from the TA. I have only two TA, each with a volume of about 4 m3. I discharged them one by one, the heat accumulated in them was enough for me for about five days.

Thus, the graphs in the "History" tab make it possible to analyze the operation of the entire system over the past periods and predict the next launch of the TTK in accordance with the needs of the residents of the house. In addition, such a view from the outside provides insight for further improvement of the heating system.

Conclusion

Sometimes people ask me why I chose wood heating? I answer, I was just lucky that I didn't have a gas pipe nearby. Now I am a happy person, I don’t know how much “gas for the population” costs, I don’t take part in the discussion of heating tariffs, it just doesn’t bother me. Will a woman or teenager cope with a solid fuel boiler? I think so, especially if there is no other alternative. They managed somehow before, until a general "gas dependence" developed. They cope even now in far from poor countries, for example, Germany or Spain. By the way, I somehow, just in case (well, the disease will overcome, or frankly laziness will be) installed in addition to the TTK an electric boiler for 45 kW, but for 6 years I turned it on only once, when I checked it after installation. My good friends, worrying about me, sometimes ask: “Isn't all this fussing a burden to you? Have you ever had a desire to give up everything and move to a place where there is central heating? " So, not a burden, on the contrary, for me it is a very exciting activity for the realization of my creative needs. You see, I sing terribly, I dance badly, I don't paint pictures at all, what else can you brighten up the long winter evenings?

Vyacheslav glory2

Bath conditioners.

Suitable fuel

Pyrolysis boilers run on almost any type of solid fuel. This can be wood, coal (brown or black) or peat. Depending on what material is chosen, it will often be necessary to refuel the boiler. Since many users prefer to stock up on fuel in advance, it will not be superfluous to know what it should be.

The type of fuel material has the following nuances in combustion:

- soft tree varieties burn on average in 5 hours, while for hard species this time is 1 hour longer;

- brown coal takes 8 hours to complete conversion, and black coal takes 10 hours.

Many people prefer wood, but it can be replaced with other organic fuels - wood waste, fuel pellets and briquettes, peat, coal, waste from the food industry, which contains cellulose. Any fuel should have a moisture content of no more than 30%, and even better - 20%. Otherwise, there is a possibility that combustion by-products and too much steam will be released during combustion. And if the first ones are harmful to the health of the residents of the house, then the steam can disable the system, as it will lead to the formation of soot and tar. And this not only reduces heat transfer, but also puts system parts out of order. In addition, steam is the reason for a decrease not only in heating, but also in poor combustion, because it is practically impossible to make an ordinary fire from wet firewood.

Therefore, if it is not possible to buy ready-made fuel, then its preparation must be carried out correctly. Here you not only need to chop wood, but also thoroughly dry them and provide them with protection from moisture. Only in this case can you be sure that in winter the pyrolysis boiler will heat the house properly.

Classification of long-burning solid fuel boilers

When choosing a suitable unit, it is worth familiarizing yourself with the existing types of heating equipment of this type. Solid fuel boilers for long burning are divided into many subspecies according to various criteria. We suggest that you familiarize yourself with the classification that will allow you to make the right choice.

By the way of fuel combustion

Modern long-burning boilers implement two main combustion methods:

- due to pyrolysis;

- top burning fuel.

In the first case, heat energy is generated resulting from combustion. In the second case, the fuel burns out from top to bottom, due to which it is possible to achieve the complete completion of the process.

By material of manufacture

For the manufacture of solid fuel boilers, manufacturers use steel and cast iron. Steel models are adapted to operate on wood fuel, since its specific heat of combustion is less than that of coal and peat. Cast iron boilers with a water circuit allow the use of fuels of all types, but they have one significant drawback: fragility under mechanical stress and temperature fluctuations. This places high demands on the installation work. In addition, cast iron products weigh much more.

Attention!

Cast iron products can last much longer than steel ones.

Given this fact, units made of cast iron are a good option for houses in which they live permanently, and steel units are for. However, it should be borne in mind that with a long downtime, corrosive processes often begin, which can shorten the service life of the unit.

Advice!

If it is difficult to choose between steel and cast iron, you should pay attention to the combined option. These models show the best performance for both alloys.

By type of fuel used

When buying any heater, one of the most important factors in the selection process is the type of fuel used. The choice can be made in favor of a long-burning boiler for:

- coal;

- wood of any kind;

- peat briquettes.

Each material has its own combustion temperature. The type of fuel recommended by the manufacturer should be used. Which option is preferable depends on the location of the private house.

If a wood processing enterprise is located nearby, a solid fuel boiler for heating a private house that runs on wood is preferable. Here, at an affordable price, you can purchase production waste, which includes wood trimmings, sawdust, bark. Often, bark and sawdust are pressed to obtain briquettes, pellets and granules suitable for long-term combustion units.

Attention!

Some models allow the use of different types.

By the number of contours

They can be single and double-circuit. Single-circuit solid fuel boilers of long burning - for heating. The second option is designed for heating and heating water. Buying a model with a water circuit will cost more, but if you have such equipment, you can refuse to install it.

By boiler power

An important criterion for determining the amount of heat generated. Manufacturers offer units of various capacities. For rooms where the height of the walls is less than 3 m, he chooses a boiler at the rate of 1 kW / m². If water heating is required, the power requirements of the unit increase.

For the convenience of our readers, our team has developed a special online calculator.

Calculator for calculating the required power of a solid fuel boiler

The widespread gasification of cities, alas, does not provide a 100% opportunity to use all, without exception, natural gas.

This is due not only to the fact that the process of laying the gas pipeline is slow, but also to the personal preferences of energy consumers. Solid fuels have been popular at all times due to their availability, low price and high efficiency.

Features of operating and starting the system

The operation of a long-burning pyrolysis boiler has its own characteristics that distinguish these units from other solid fuel models. It has already been said above that the device has two chambers separated by dampers. But few people know that before starting the entire system, it is necessary to preheat the loading tank (up to 500-800 degrees).Only then can you start loading fuel.

The device works as follows:

- placing solid fuel in the foreflow;

- thermal distillation of the material;

- the transition of the generated generator gas into the combustion furnace;

- the heat exchanger recovers the heat of the flue gases;

- control of the supply of air flows to the antechamber

If you follow this sequence of actions, then a slow oxygen-free combustion of the material will take place in the boiler. And this already leads to an increase in the efficiency of the release and combustion of pyrolysis gas, due to which a comfortable temperature will always be maintained in the house throughout the day.

Accessories and add-ons for boilers

Today, more and more often, developers of thermal equipment turn to automation systems, the level of which can be determined by the user himself in the process of its design. In particular, gas-fired boilers can be supplemented with temperature control systems, programming panels, heat and moisture sensors, timers, etc.

As for design solutions, you should have in stock plumbing fittings to support the operation of water circuits - seals, fittings, adapters and other consumables. For a more thorough control of the parameters of the equipment operation, it is possible to intervene in the organization of the air supply system for more efficient fuel combustion. Technically, this function is performed by cast iron grates for boilers, which are laid above the blower in a special niche. By choosing the design of the required parameter with suitable hole sizes, it is possible to provide one or another level of combustion intensity. As an add-on, you can also purchase the boiler mentioned above - depending on the needs, its dimensions and capacity are selected.

Pros and cons

Like any other technique, pyrolysis boilers have their pros and cons. It is imperative to get acquainted with them. Firstly, this will allow you to prepare your house for such a heating system, and secondly, it will save you from unnecessary financial costs, because such a unit is not very cheap.

If we talk about the strengths, then they are:

- these models are easy to maintain, even simple breakdowns are quite capable of eliminating themselves;

- if there is no main gas supply, then a pyrolysis boiler is the best alternative in cold weather;

- one load of fuel lasts up to 15 hours, while other traditional solid fuel boilers require "refueling" every 5-8 hours;

- the level of efficiency reaches 85-90%;

- safe from the point of view of ecology - during combustion, almost 100% of the material is utilized, while there are no toxic impurities in the flue gases;

- CO2 concentration is 2-3 times lower than in other solid fuel analogues;

- during operation, very little ash is formed, so the need for cleaning occurs much less often, and the system lasts much longer;

- the coolant heats up much faster, so you don't have to wait long for comfort.

But for the sake of fairness, it should be said that pyrolysis boilers also have their drawbacks. Among them are:

- high price - the pyrolysis device costs 1.5-2 times higher than other boilers;

- pyrolysis boilers have one circuit, which makes it impossible to heat water for domestic purposes (except for special configurations);

- the device is powered by electricity, which means that if it disappears, then the boiler will stop heating;

- the fuel must have a certain moisture content (up to 20%) and if this requirement is violated, the boiler will not work;

- Despite the development of modern technologies, it did not work to make the pyrolysis models fully automatic - refueling is done only manually.

Although the disadvantages may seem significant enough to someone to refuse such an acquisition, in fact, they are much more effective than their counterparts. Moreover, this has been proven by more than one study.But they completely burn fuel, which gives the maximum efficiency in heating and leads to minimal heat loss. Such moments fully pay off all the disadvantages.

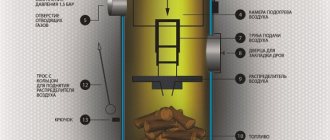

Features of the pyrolysis oven

If you install a pyrolysis oven in your garage or any other room, you can be sure that it uses oil very economically. In addition, fuel can be obtained almost or completely free of charge, especially if you are a car enthusiast. While working with the stove, you will not encounter the problem of the formation of smoke. The stove is completely incapable of emitting gases and vapors that are harmful to health. In addition to everything, the stove has a very significant heat dissipation. According to users' estimates, the efficiency reaches almost 80%. Thus, if you install such a stove in a room with an area of 42 m2, then it will perfectly heat the space.

Pyrolysis ovens are quite easy to use. For operation, it will be necessary to fill the compartment with oil. And if required, you can adjust the intensity of combustion until you can achieve the optimal level of heat transfer. The adjustment is made by closing or opening the blower cover, which is located directly above the filling hole. If it is necessary to obtain high power and heat the room in a short time, it is only necessary to fully open the lid, which will ensure the flow of air, through which it is possible to achieve heating up to 900 ° C.

The nuances of choosing a pyrolysis boiler

Having familiarized yourself with the strengths and weaknesses of pyrolysis boilers, you can already think about buying such a unit. But this purchase will be rational if there is an opportunity to always stock up on dry firewood.

When it is not possible to fulfill the requirements for fuel, it is recommended to pay attention to boilers that are combined. That is, they burn 80% of the pyrolysis material and 20% of the traditional one. You can also use them with other fuels, the moisture content of which does not exceed 50% - wood waste, peat, coal, etc.

It is best to purchase a boiler with a loading chamber that can accommodate firewood up to 65 cm. The inner coating is also important, which ideally should be made of high-quality ceramic concrete. It is it that allows you to maintain an optimal temperature regime inside the chamber, which ensures uniform combustion of fuel and protects the walls from burning out.

If you purchase a pyrolysis boiler with natural draft, then such a device must have an automatic regulation system. In this case, the fan speed will be controlled by the controller, which, in turn, receives signals from temperature sensors and water pressure devices. When the indicators begin to exceed the norm, the controller will automatically adjust the air flow to each of the chambers, and may even shut it off altogether. The only thing that is required of the owner is to set the temperature mode on the boiler display.

Some modern manufacturers of pyrolysis boilers have improved their models, creating the ability to work with another water circuit. This addition allows hot water to be supplied and can be switched on separately. This option is provided by the fact that the hot water coil is placed in the water jacket of the system. Therefore, during the movement of warm water, part of the heat goes to the second circuit, due to which an average temperature is obtained. Such designs have additional protection that prevents water from boiling in the event of a sudden power outage.

Pyrolysis boilers can heat not only the residential building itself, but also the adjacent outbuildings, where there is no plumbing. In this case, you need to pay attention to specially designed unit designs. In such models, there is no water jacket on the body. It is replaced by an air heat exchanger. It is capable of heating a square from 100 to 1000 sq. m.Of course, boiler modification plays a decisive role. But in any model there is an air damper that helps control combustion. This can be done manually or with a chain drive.

Finally, it is worth mentioning about the chimney for such boilers. Since there is no mechanical induction of traction, the chimney must provide the proper traction force, otherwise, all the smoke will go into the living rooms. For this, a special fan must be provided in the design.

Depending on the future operating conditions, a modification of the long-burning pyrolysis boiler is also selected. If a really high-quality unit is chosen, then the fuel in it will burn for at least 8-10 hours, and it will require replacement no earlier than in 18-20 years.

Popular models

Naturally, when buying such a device for yourself, it is worthwhile to study in detail the market and the models presented on it, it will also not be superfluous to study the reviews of the owners of pyrolysis boilers. This will help you make the right choice of a pyrolysis boiler. The most popular models are Bourgeois, Geyser, Motor Sich, Ochag. Next, let's take a closer look at these models.

Bourgeois K

The Bourgeois K boiler is made of steel 3 mm thick, which minimizes heat loss. It can heat an area of up to 200 m2, depending on the selected model. If the boiler is fully loaded, the duration of its operation is 8-9 hours. This type of device is independent of electricity. Low market value of about $ 300. It has established itself as a reliable device that can operate on various fuels.

Pyrolysis boiler Bourgeois K

Trojan

The Troyan pyrolysis boiler has a high efficiency of about 92%, characterized by uniform heating of the heating system. Trajan boilers TR series are equipped with a reliable mechanical automation system. The line is represented by models of various capacities from 10 to 30 kW, this will allow you to choose the unit in accordance with your room area.

Trajan pyrolysis boiler

For example 10 kW is designed for 80 m2, 15 kW to 160 m2, 30 kW to 330 m2. An average of 3 fuel loads per day are required. The advantages include the presence of a safety system against overheating of the heating system. It is possible to install a heating element, it is very convenient if there is a shortage of firewood, you can also combine these heating methods. The market value is about $ 700.

Hearth

Let us consider on the model Hearth KP-100, it can heat a room with an area of up to 1000 m2, it is equipped with automation, with the help of which it is possible to set the desired temperature. It is possible to load large firewood up to 70 cm long, the burning time of a fully loaded chamber is about 9 hours, it all depends on the room, how high-quality insulation is in it. Relatively low efficiency of about 80%. The control panel displays the temperature of the exiting heat and the power of the fan.

Pyrolysis boiler Hearth KP-100

Atmosphere

The Atmos DC 24 RC device is equipped with an exhaust fan, the fuel for the furnace is briquettes with a diameter of up to 100 mm and, as an exception, coal can sometimes be used in briquettes with wood. The combustion chamber is equipped with a rotary grate, which ensures good combustion. The device can heat up in a few minutes. The efficiency is 91%. Quite a high market value of about $ 1400.

Pyrolysis boiler Atmos

Motor Sich

The Motor Sich 16 kW device is designed for continuous burning, equipped with a large loading chamber, one load is enough for about 12 hours of operation, of course, this is an average figure, it all depends on the quality of the room insulation, from windows, doors. High efficiency of about 93%.

Pyrolysis boilers Motor Sich

The heat exchangers are made in a seamless manner, which minimizes the loss of transferred heat. The body is made of high quality steel with a thickness of 8 mm. Can work on wood, wood waste, peat.It is capable of heating an area up to 190 m2, two loads are required per day. Market value of $ 1300.

Geyser

The Geyser PK 20 model is designed to heat a room up to 200 m2, with ceilings no higher than 3 meters. Equipped with an automatic control system. Two loads per day are required, the efficiency is 87%, it has established itself as a fairly reliable boiler, unpretentious in maintenance, its cost is $ 900.

Geyser pyrolysis boilers

Review of well-known models

Among modern pyrolysis boilers, the companies BUDERUS, VIESSMANN and VIADRUS are especially popular and reliable. This is due to the fact that the quality is fully consistent with its price. Manufacturers take a responsible approach not only to the selection of materials, but to the assembly of devices itself. The boilers are fully automated, and this also applies to the ignition process itself.

Let's consider each manufacturer in more detail:

- Vitoligno 100-S by VIESSMANN - premium class (Germany). These units have a power rating from 25 to 80 kW, the efficiency level reaches 88%. The line of such models has a working pressure of no more than 3 Bar. The temperature indicator of the supply pipeline is 95 degrees, and the return pipe is 55 degrees. Logs up to 50 cm long can be used. The Vitoligno 100-S has an automatic control system that consists of a controller and a set of sensors. There is a fan in the chimney duct, which provides traction, as it serves as a smoke exhauster. The controller regulates the operation of not only the fan, but also circulation and network pumps, as well as three-way boiler piping valves.

- BUDERUS - premium class (Germany). Such boilers also have a number of their advantages, in particular, their efficiency is 88-90%, while their power varies within 20-40 kW. The working pressure here is the same as in the previous analogs - 3 Bar. The temperature indicator of the supply is 95 degrees, and the return is 55 degrees. But in this cauldron you can use 10 cm longer logs. Such boilers can be made of either cast iron or steel. Perhaps one of the most pleasant features of the BUDERUS models is their aesthetic appearance, because not everyone has the opportunity to hide the boiler out of sight.

- VIADRUS Нefaistos P1 - middle class (Czech Republic). For refueling, you can use pellets. This is convenient because the boiler is loaded only once a week and does not require refueling anymore. Although for the sake of fairness, it should be said that the duration of the work largely depends on the volume of the bunker. The entire system is controlled by automation. For safer operation, the burners are equipped with a fire extinguishing system connected to water. VIADRUS products are in no way inferior in their technical characteristics to the Germans, but at the same time they are much cheaper than their counterparts.

Of course, on the modern market there are many different models, both domestic and foreign. When preparing for a purchase, you should study the general technical characteristics of pyrolysis boilers, and then, focusing on your finances, choose a specific model.

Owner reviews

Anna Limeyko, 32 years old, Zaporozhye

I am a mother of a little son who is now 5 years old. When we were 3 years old, we were diagnosed with an allergy, and it was not possible to identify a specific irritant. Therefore, the doctor advised us to move out of town. So my husband and I decided to convert our dacha into a country house. There were no special questions with this, except for the heating. Friends gave us a solid fuel boiler and my husband connected it to the system. On the very first day of his work, his son had a terrible cough. As it turns out, such a unit produces a large amount of harmful impurities, which provoked an attack in the child. Having decided to change the boiler, we settled on a pyrolysis unit, and absolutely did not regret it. Firstly, we refuel it only in the evenings, and secondly, we have had it for more than a month now and our son has never had any health problems.And this is not to mention the fact that this boiler produces a minimum of ash and soot, which is why it is quite easy for me to take care of it.

Anatoly Reznichenko, 45 years old, Volgograd

I got the house from my parents. Heating there has always been only from a wood-burning stove, as in fairy tales. Having moved there, I decided to modernize the house. Since I understand these systems, I immediately settled on the version of a long-burning pyrolysis boiler. True, I had some problematic moments with the choice of fuel. But through experiments, I came to the conclusion that the best and most effective material is dry wood (moisture content not higher than 20%). At the same time, I recommend harvesting firewood 0.5 m long. And if we are to take a tree, then it must be pure wood, that is, the legs from old chairs or tables are not suitable. The fact is that they are processed not only with paint and varnishes, but also with all kinds of impregnations. That is, in the process of their combustion, toxins that are very dangerous to health can be released. Also, pyrolysis boilers can be filled with briquettes and pellets for heating, wood waste, some types of peat. When selecting a fuel or its alternative, you need to take into account the following moment: when the flow rate of the primary and secondary air is selected correctly, while the air humidity indicator is normal, then there will be no release of combustion by-products. Otherwise, high humidity can lead to the appearance of not only unwanted water vapor, but also tar with soot. And this will lead to a deterioration in the heat-conducting characteristics of the gas, which can provoke the damping of the boiler.

Alexander Nesterenko, 45 years old, Pskov

I have been interested in the topic of pyrolysis boilers for a long time. When I started to find out the prices for such a device, I was amazed. The minimum cost of this heating unit starts at $ 1,000, while, if you take a domestic manufacturer. And imported models are even more expensive. Therefore, I became interested in the question of self-assembly of pyrolysis boilers. As it turned out, a custom-made boiler is 1/3 cheaper than buying a ready-made unit.

Oleg Belozerov, 31 years old, Kazan

I want to leave my opinion about such a boiler. This device has an order of magnitude larger volume of the loading chamber, due to which I refuel it only in the evenings. This model is perfectly adapted to our latitudes, so no failures were observed during 2 years of operation. I would also like to say that such a boiler has a function for heating the air supplied to the combustion chamber. This boiler is very similar to the Polish model of the Irleh company. But since there is heating here, the quality of ignition of pyrolysis gases is much better. I would also like to say about safety, as my wife and I are waiting for replenishment. Despite the fact that the boiler is in the furnace, children always know how to find passages to any room. So, the loading compartment has a door combined with a ignition latch, and is also equipped with an additional hinged door. This allows not only me to carefully use the boiler, but if the child appears close, then he will not immediately open all the doors. Blago is a great option for houses with an area of 100-200 sq.m.

Nikolay Kulikovsky, 29 years old, Uzhgorod

And we have a Teplolov-type boiler installed in our house. It has a fairly simple design that even my girlfriend can handle. At first I used clean firewood, but as it turned out, such a boiler works great from waste wood (pieces), pressed briquettes and wood logs. But it should be said right away that the volume of the loading chamber is designed for elements from 40 to 90 cm. But in order to achieve the effect, the diameter of one log must be at least 10 cm, but not more than 25 cm. I also add sawdust there, but not so much. Another advantage I would like to note is the possibility of adjustment, and this, in turn, makes it possible to save money.One download is enough for us for 11-12 hours, while the area of our house is 94 sq. m. We were completely satisfied with this purchase.