Furnace types Engineer

In the Engineer series, there are three basic modifications: a convection wood-burning stove and its counterpart, coal-fired. Particularly noteworthy is the Gidravlik model, which works to heat the coolant and is built into an existing radiator heating system.

Regardless of the type of modification chosen, the furnaces have the following general characteristics:

- Material - furnaces are made of heat-resistant structural steel. To avoid deformation, a blind cast-iron door is installed on the combustion chamber. At the request of the customer, you can choose an Engineer stove with a cast-iron door with glass.

- Furnace steel thickness - combustion chamber and important components are made of structural steel with a wall thickness of at least 5 mm.

- The presence of a surface for cooking - the cooking and heating oven does not have a full-fledged panel for cooking. For this purpose, the upper horizontal surface of the enclosure is used.

- Connection to the chimney - in each model of the Engineer series, modifications with the upper and rear chimney outlet are offered, which greatly facilitates the installation and connection of the stove.

There are technical characteristics inherent exclusively in wood and coal stoves, as well as in the Hydraulic series. Before deciding on the choice, take into account the peculiarities of work and operation, the burning time from one bookmark of firewood.

Wood Burning Engineer

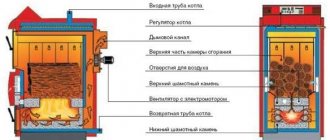

Metal hot water boiler Professor Butakov Engineer is a traditional model of wood-fired stove equipment. The principle of operation is based on the use of natural air convection.

An air heating boiler has the following differences:

- The special design of the combustion chamber - the series is distinguished by a larger volume of the firebox with a capacity of 120 liters.

- Convective channels - volumetric pipes are installed in the structure of the furnace, submerged by ⅔ of their size into the furnace.

Coal Engineer

Coal heating solid fuel stove Butakov Engineer, is the successor to the basic wood-burning model. Certain changes have been made to provide the necessary conditions for burning coal:

- The thickness of the furnace walls has been increased.

- Improved air flow into the combustion chamber.

The changes made led to better heat transfer, an increase in the operating time of the furnace from one bookmark to several days. Special mention should be made of the special design of the ash box, which allows removing the accumulated ash without interrupting the combustion.

Heating of the premises is carried out using an air-heating method. Furnace productivity Engineer Coal 16 kW.

Water Hydraulic Engineer

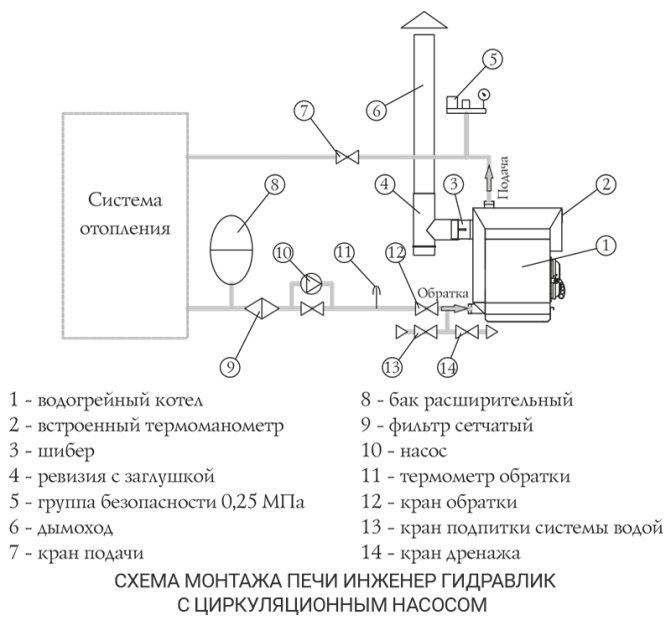

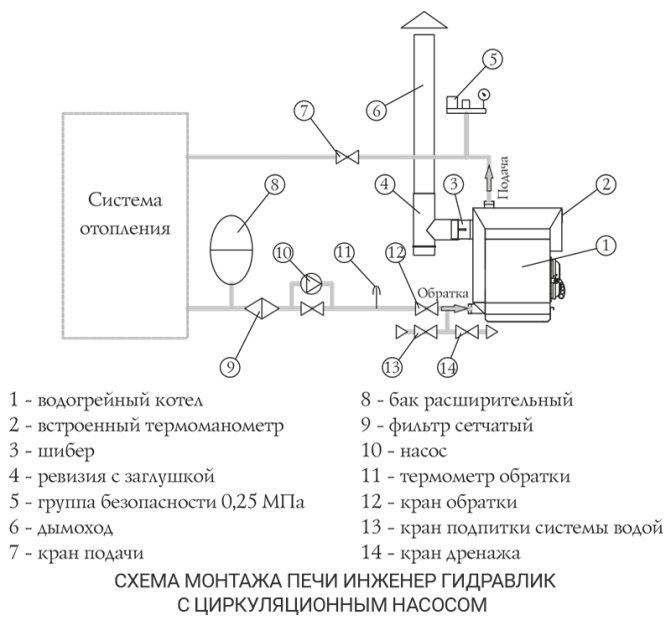

The water heating stove Termofor Engineer Hydraulik is intended for modification of existing heating systems. Performance from 12 to 26 kW, sufficient for comfortable heating of medium-sized buildings, up to 260 m².

In general, a wood-burning heating stove with a water circuit Engineer Gidravlik is a full-fledged solid fuel boiler, convenient in operation and maintenance. The advantage of the series is the built-in unit of tubular electric heaters (TEN). After the flame has died out, the stove continues to heat the coolant using electricity.

Pricing policy for the oven

The Russian company Termofor focuses on the domestic consumer market of heating equipment. For this reason, all manufactured stoves are offered at an affordable cost.

Several factors affect the price: the type of room heating, the presence of heat-resistant glass for the door, performance.

The average cost per model, depending on the configuration, is as follows:

- Hydraulics - about 30 thousand rubles.

- Wood Engineer - 17 thousand rubles

- Engineer Coal - 22 thousand rubles.

Features of hot water boilers

Hot water boilers have become popular among the owners of country houses. This simple and easy-to-use equipment provides an opportunity to heat a dwelling, workshop, workshop, premises for production without unnecessary worries and difficulties.

Hot air boiler with burner

Heating systems that operate an air-heating boiler or furnace are distinguished by a simple design and high efficiency. Comfortable heating units have the following functional areas:

- hot water boiler;

- heating stove;

- heating stove with a hob.

All models of the considered boilers with the possibility of air heating are different and can be equipped with:

- Cooking hob with multiple cooking zones.

- A door with a fire-resistant glass window.

- Self-cooling door.

- A separate glass door for observing the flame, like in a fireplace.

- A special installation of a chimney and other things.

How to properly heat the stove Engineer

Air-heating boiler Professor Butakov performed by Engineer working on wood and coal, derived model Hydraulics with a built-in water circuit, have a common structure and principle of operation.

The company has prepared some recommendations for the correct firing of furnaces:

- Air locks form in the chimney, especially after a long break in operation. If you immediately ignite the stove at full power, reverse draft will appear and the smoke will go into the room. Therefore, for a start, the stove and the chimney duct are heated by burning a small volume of finely chopped splinters. The firebox is started at full power after 10-15 minutes of maintaining a low-intensity flame.

- It is wrong to heat the stove solely with coal alone, while the Engineer and Engineer Hydraulics series are generally not designed for this type of fuel. The coal boiler is initially fired with wood. After warming up the furnace and creating the required temperature regime, a portion of coal is poured on top. Some experienced users recommend that the fuel is loaded in layers. A layer of firewood, a layer of coal. This prevents overheating of the combustion chamber, and during the heating, soot burns out in parallel. Learning how to properly heat the stove Termofor Engineer coal is not difficult at all. After 2-3 firing up in accordance with the instructions set out in the documentation from Termofor, the firebox will become a familiar and everyday activity.

- All wood-burning stoves for the house of long burning Engineer, work in the gas generation mode. To make solid fuels emit flammable carbon dioxide, certain conditions must be created. After heating the combustion chamber to a temperature above 200 ° C, the slide gate is closed.

All about installing the stove Engineer

To facilitate installation, each Termofor oven is supplied with detailed installation instructions. The company has thought of a convenient and simple design that facilitates installation work.

The engineer with his own hands should begin the installation of the furnace, it should be by determining the location. It will not be unimportant to decide which chimney to use when connecting.

Location requirements

The special design and use of a special base simplifies the installation of the Engineer oven and makes it possible to do the connection yourself.

Which chimney is better

Solid fuel heating equipment belongs to the class of stoves with a high temperature of flue gases. During combustion, inside the combustion chamber, the heating intensity reaches 450-550 ° C. Although due to the use of gas generation, the smoke cools down significantly at the exit, the temperature still remains sufficient to lead to burnout and deformation of a conventional steel chimney.

Additional requirements apply to traction performance. Insufficient pressure leads to reverse thrust, air congestion and other difficulties in operation.

Feedback from the owners and practice have shown that a sandwich pipe and a ceramic chimney remain the best choice for convection and hot water ovens. An additional plus of the systems is a simple self-installation of the chimney. Sandwich pipes and ceramics are assembled by the type of a constructor and do not require special skills for installation.

Reviews about furnaces Butakova Engineer

On the net you can find negative reviews about the furnaces Professor Butakov Engineer, but they are rather an exception to the rule. Basically, the owners point to the advantages of Termofor products:

- Affordable cost.

- Long service life.

- Simple design that allows self-installation of the stove in the house.

- Thermal efficiency, due to the ability to connect to a hot water heating system and air ducts.

All of the above factors ensure the uninterrupted and comfortable operation of Butakov's Inzhener series furnaces and explain the popularity of the models among the Russian consumer.

Heating a house with an air-heating boiler: pros and cons

Air heating is the most ancient heating system for houses in Russia. The Russian stove is the real progenitor of hot water boilers (VK) and is still used in rural areas.

The next "historical" modification of the VK is a stove-stove, widely known in the terrible years of the October Revolution and already a more modern version, in the form of wood-burning fireplace heaters. In all these examples, the heat from fuel combustion was not spent efficiently, and most of it was simply wasted.

Modern long-burning hot water boilers have given new life to the technology of air heating of buildings. Today the devices modernized by Russian specialists have become competitive in the boiler-building industry.

A new generation hot water boiler appeared in 2002 in the Novosibirsk region. It was invented by a heating engineer E.Yu. Zubkevich and named after his relative Professor Butakov. Today, this design belongs to the class of energy efficient devices that reduce the cost of heating the home and emissions into the environment.

Hot water boilers and ovens

Solid fuel boilers, Electric boilers, Oil fuel boilers, Combined heating boilers, Pellet boilers, Gas boilers, Hot air boilers and stoves, Large capacity industrial boilers, Marine boilers for heating, Boiler accessories, Boiler and pipe care products, Coal, Boiler sale equipment, Heat accumulators,

Household installations for air heating are widespread among the owners of suburban housing. This simple and easy-to-use equipment allows you to heat a house, workshop, workshop, warehouse or industrial premises without unnecessary problems and difficulties.

The online store of heating equipment Teplocom offers air-heating boilers and stoves of the Termofor and Teplodar brands.

Features of hot air heating systems

Heating systems based on the operation of a hot water boiler or furnace are distinguished by a simple design and optimal efficiency. Heating systems that are easy to use have several functional areas:

- Hot air boilers

- Heating stoves

- Heating and cooking ovens

All stove models in the Teplocom catalog operate on the principle of pyrolysis fuel combustion (gas generation): after the fuel is in the furnace, it evenly smolders and burns out layer by layer. The optimal air supply does not allow the wood to burn quickly, so the duration of burning in such units can be 8-12 hours.

Depending on the model, air heating units can be equipped with:

- hob for cooking, where you can place several items of utensils;

- a door with a window made of heat-resistant glass;

- self-cooling door;

- separate glass door for "fireplace effect";

- a certain location of the chimney and others.

Convenient online store catalog contains all the necessary information about each oven model; a large model range will allow you to choose the most suitable model for your current requirements. All additional questions regarding the purchase and operation of the furnace will be readily answered by the store specialists.

Advantages of household air heating equipment

- hot water boilers and furnaces are distinguished by their simplicity of design, which has a positive effect on the operation of the unit;

- most models are unpretentious to the grade of solid fuel and burn wood, briquettes and coal (depending on the model);

- the hot water boiler does not require the presence of electricity: the design of the unit provides an appropriate level of efficiency;

- household boilers and stoves are characterized by compact and ergonomic dimensions. The equipment can be easily placed in any convenient part of the house or other premises.

Copyright MAXXmarketing GmbH

teplocom.com

Pros and cons of hot water boilers

An air heating system is a complex of interacting devices and devices for transferring thermal energy released during fuel combustion to the surrounding space.

Modern VCs with a continuous burning system ensure continuous operation of the equipment without the presence of the owner or operating personnel.

The system no longer requires constant lighting and stopping of the furnace equipment, which saves fuel. The absence of batteries and piping systems reduces the overall metal consumption of the project and the costs of construction and installation work.

There are other advantages of VK:

- Low cost price.

- The system efficiency reaches 90%.

- The ability to install a duct system with the subsequent organization of air purification, for example, to fill it with silver ions, which is especially useful for allergy sufferers and asthma patients.

- Removing humidity in rooms.

- At elevated outdoor temperatures, the ducting can be used for the building air conditioning system.

- The absence of a water coolant protects the system from freezing, water hammer and other typical failures in the water network of coal-fired boilers.

- The boiler allows you to almost instantly heat up the air and has a simple integration into the ventilation system.

- Low cost of auxiliary equipment operating in the air heating circuit.

Despite its attractiveness, there are also "pitfalls" associated with air heating:

- The installation of the boiler and the air supply system can only be carried out at the facility under construction.

- The need for an additional power supply.

- To ensure high efficiency, the boiler is installed inside a room with a sufficient level of insulation.

Air-heating boilers - an overview of pyrolysis models Professor Butakov

A long-burning hot-water boiler reduces the cost of heating the home and has many advantages. After all, the use of air as a heat carrier can be an excellent solution for heating. The pipes will not deteriorate, as in the case of using water with impurities, water hammer will not be terrible, and you will not need to purchase additional equipment.

Long burning hot water boilers

Features of hot water boilers

Hot water boilers have become popular among the owners of country houses. This simple and easy-to-use equipment provides an opportunity to heat a dwelling, workshop, workshop, premises for production without unnecessary worries and difficulties.

Hot air boiler with burner

Heating systems that operate an air-heating boiler or furnace are distinguished by a simple design and high efficiency. Comfortable heating units have the following functional areas:

- hot water boiler;

- heating stove;

- heating stove with a hob.

All models of the considered boilers with the possibility of air heating are different and can be equipped with:

- Cooking hob with multiple cooking zones.

- A door with a fire-resistant glass window.

- Self-cooling door.

- A separate glass door for observing the flame, like in a fireplace.

- A special installation of a chimney and other things.

Advantages of air heating

There are many advantages to heating a house with air:

- The efficiency of the air heating system reaches 90%.

- When using filters, oxygen can be purified or filled with silver ions. This feature will be indispensable for people with allergic reactions.

- Excellent drying of the house from air humidity.

- If desired, the heating structure can work in a gentle mode. It is useful for maintaining the optimal temperature during the long absence of the owners.

- In case of heat outside, air heaters can be used to supply cool air.

- The continuous burning system will provide the owner with the opportunity to save on fuel and not visit the boiler room constantly.

- No need to install batteries and piping in your home interior.

- The ventilation system can be used with a solid fuel boiler to heat other rooms.

We offer you to watch a video about the energy pyrolysis hot water boiler and its principle of operation.

Air heating boiler installation conditions

So that, having bought an air heating boiler, you are not disappointed in the choice, and you do not have any difficulties with the installation of the structure, it is worth knowing some of the nuances. They should be taken into account without fail:

- Installation of an air heating system and specifically a boiler is carried out only in the house during the construction process. A plan and the necessary drawings must be drawn up in advance.

- This system will require a backup power source.

- To increase the efficiency, the boiler must be installed in the dwelling without fail, and the walls must have reliable thermal insulation.

- Ventilation of the room is necessary, since ventilation does not provide complete purification of the air from gas.

- Air ducts may not be needed if partitions are not installed on the second floor or the area of the house is small.

If you want to heat the house with an air-heating boiler, you can save relatively well on installation and do everything yourself, taking note of a couple of fundamental recommendations.

It will not be possible to carry out all the work manually, or rather, not for everyone. There are things that are better to entrust to specialists, for example, calculations. To make the right choice of a long-burning hot-water boiler, you need to know such characteristics as:

- required power of the unit, taking into account heat loss;

- the rate at which warm air enters the rooms;

- all kinds of heat loss;

- parameters of the airway system.

It is necessary to decide on the place of installation of the unit. There are no special requirements for the place, so in this case it is important to remember the main principles of installing gas or other equipment.

Hot-air boiler Professor Butakov

The first hot-water boilers Professor Butakov were created in 2002, and until the end of 2003, the production of units was carried out by the company independently. After that, the company decided to continue the manufacture of boilers at the production facilities of Tekstilmash under the supervision of Termofor.

Professor Butakov Model Student

Air heating boilers Professor Butakov are created for economical heating with air in houses and premises for production, as well as in garages, basements, greenhouses. Some models include cooking.

The range of products includes solid fuel models "Student", "Engineer" and "Associate Professor" and are intended for heating areas with a volume of 150-500 m³.

It is produced with power characteristics of 9-25 kW. All names have the same purpose, principle of operation, equipment and fuel used.

Creating boilers, the specialists of the company Professor Butakov tried to endow their units with the best parameters:

- Highly functional.

- High efficiency.

- Environmental friendliness.

- Fire safety.

- Maximum reliability.

- Availability

- Long service life.

- Interesting design.

Technical characteristics of air-heating boilers Professor Butakov are presented in the table below.

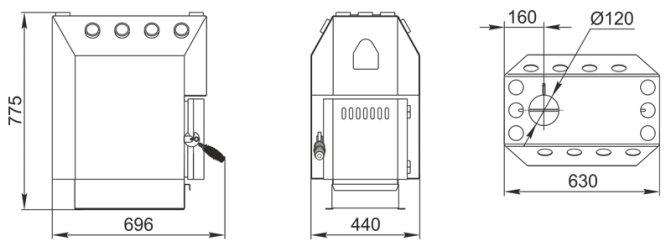

Model Student Engineer Associate Professor

| Maximum volume of the heating room, m³ | 150 | 250 | 500 |

| power, kWt | 9 | 15 | 25 |

| Efficiency,% | 85 | 85 | 85 |

| Dimensions (W x D x H), mm | 370x545x650 | 440x645x800 | 570x800x1000 |

| Weight, kg | 57 | 75 | 143 |

| Combustion chamber volume, l | 74 | 120 | 250 |

| Maximum volume of fuel loading, l | 20 | 40 | 100 |

| Fireplace door opening, mm | 210x260 | 260x320 | 320x400 |

| Double / number of convection pipes, (mm / piece | 46/14 | 55/14 | 70/14 |

| Total cross-section of heated air passage, m³ | 2,32 | 2,75 | 5,39 |

| Heating surface of convective pipes, m³ | 1,17 | 1,7 | 3,2 |

| Total area of heating surfaces, m³ | 2,2 | 3,3 | 6,5 |

| Chimney diameter, mm | 120 | 120 | 150 |

| Recommended pipe height, m | 4 | 4 | 5 |

| Furnace door | MD / NPV | MD / NPV | MD / NPV |

| Fuel used | MD + protective screens - firewood, coal / MD - firewood / ChDS - firewood | MD + protective screens - firewood, coal / MD - firewood / ChDS - firewood | MD + protective screens - firewood, coal / MD - firewood / ChDS - firewood |

You can get more information about Professor Butakov's boiler from the video.

An air heating boiler is a reliable and safe device to use, with many positive characteristics. It will serve well for those who do not have the time and desire to understand complex heating technology. Truly easy-to-use heating units provide long-term fuel burning and comfortable heating.

teplofan.ru

Furnace device

Today, the most popular among consumers are air-heating boilers of Professor Butakov, which have a wide range of applications: private residential sector, garages, greenhouses, industrial warehouse and basements.

The main structural parts of a typical hot water boiler:

- Lower drawer for collecting ash and regulating the amount of air entering the furnace.

- A door with a handle located above the ash pan may have a heat-resistant glass window.

- The combustion chamber, its volume affects the amount of fuel loaded and the operating time.

- A cast-iron grate is located under the chamber. The sides of the chamber are closed by the convection pipes crossing at the top.

- Chimney with a gate for adjusting the flue gas speed and draft intensity.

- In some VK models, an additional afterburner with two nozzles for oxygen supply is located at the top. It burns the gas that forms during smoldering.

A long-burning hot-water boiler is equipped with all the necessary automation devices, complete with temperature sensors and electronic control units. The automated fuel supply system and the increased volume of the combustion chamber allow the boiler to operate practically without the presence of a person.

Hot water boilers for coal and wood. How to do it yourself?

Principle of operation

Air heating boilers, unlike convection analogues, do not heat the coolant, but transfer heat energy directly to the air.

The apparatus consists of the following main parts:

- A pull-out ash drawer is located below, which serves to collect ash from burnt fuel and adjust the flow of air into the furnace.

- Above it is a door with a handle.It may have a glass window. You should pay attention to how the glass is attached. If the mounts are point, then there is a possibility that it will burst. It is better to purchase models where there is a fastening frame around the glass.

- There is a combustion chamber behind the door. The amount of fuel that can be loaded depends on its volume, therefore, the heating time.

The grate is located below. It is better that it is not steel, but cast iron. It is important that there are small bevels on the lower surface on the sides. - There are convection pipes on the sides of the combustion chamber. At the top, they can cross. It is desirable that the lower ends of the pipes are additionally protected, since they are exposed to the highest temperature.

- Above comes a chimney pipe with a gate - a metal plate that rotates at different angles with an external handle. This allows you to adjust the intensity of traction. Hot water boiler device

- The upper surface can be adapted for heating food. In this case, a cast iron cover with a ring can be opened to adjust the hole diameter.

- In some models, there is an additional afterburner at the top, in which the gas released when wood smolders is burned. Separately, two nozzles are introduced into it, through which oxygen is supplied there.

The principle of operation of a hot water boiler is very simple. Solid fuel burns in the combustion chamber. Convection pipes are heated, cold air enters them from below, and heated air comes out from above.

There are two stages of work. In the first, the fuel is actively burning, while a large amount of oxygen is supplied. At the second stage, the access of air to the furnace is blocked, the fuel begins to smolder and the stage of pyrolysis combustion begins. During this time, combustible materials slowly smolder, releasing combustible gas, and the boiler efficiency reaches 90%.

If you need to heat several rooms, a special collection with an outlet under the corrugation is placed at the outlets of the convection pipes. It is purchased separately if necessary. Corrugation leads to the right rooms.

There are also devices that can be installed between rooms in brickwork. They have openings on the sides of the front and back, which allows you to simultaneously heat two adjacent rooms.

Hot water boiler in brickwork

Some devices are additionally equipped with coolers for faster circulation of cold air through the boiler. This is ideal for a garage where you need to heat it up very quickly.

Fuels (coal, firewood)

Hot water boilers run on solid fuels.

- Dry wood. Depending on the model, you should select and cut wood of a suitable length. Compact models fit 30 centimeter logs, and large fireboxes 40 cm long. The less moisture they contain, the better they burn and give off heat. Almost all models can run on wood.

- Fossil coal. Its quality can vary markedly depending on the type and amount of impurities. The most effective type is anthracite, less productive - bituminous and brown coal. Also, the duration of burning depends on what brand of coal you heat.

- Pellets (high pressure compressed agricultural waste, peat or wood chips, paper). Produced in the form of granules. In such boilers, nothing else can be heated. Pellets

In terms of efficiency, this type of fuel is close to coal. Pellets are produced without the addition of chemicals, therefore they are safe and environmentally friendly. - Fuel briquettes. They are also made by pressing, but produced in the form of logs, they are also called Eurowoods.

In addition, there are universal devices on the market that can be fired with any solid fuel.

Advantages and disadvantages

Advantages of air heating equipment:

- High efficiency. On average, heating efficiency in this way reaches 90%.

- There is no need for wiring and installation of pipes and radiators for the coolant in the house.Installation is quick and much easier in comparison with classic boilers. Installation option in a wooden house

- Reduces humidity in the room, dries out the house. Environmentally friendly due to the use of natural fuels. Fewer combustion products are emitted into the atmosphere.

- Long-burning hot-water boilers rarely need replacing firewood.

- The devices are very reliable due to the simple internal design.

- Fast heating time. There is no intermediary in the form of a liquid heat carrier - the air is heated immediately, which is the ultimate goal. The temperature rise is felt already in the first minutes of the furnace.

- There is no problem of freezing of the coolant in the event of a long absence of residents. You can put out or re-ignite the firebox at any time.

Cons of air heaters:

- The need to additionally ventilate the premises. The burner cannot be completely sealed, part of the combustion products goes directly into the living room.

- After extinguishing the boiler, the house cools down quickly.

- The need to add fuel yourself from time to time. An air heating boiler cannot work in a completely autonomous mode for a long time. Loading firewood into the boiler

- The desired room temperature cannot be set.

- The first few times you need to heat new equipment on the street, so after purchase you will not be able to immediately mount the device.

Installation

The installation of a hot water boiler is quite simple. First of all, you should choose a place for it. It shouldn't be too close to the wall. If the floor or wall is made of flammable materials, they are covered with non-flammable shields. On the floor, you can make a screed and put tiles.

A number of models are designed for wall installation between two rooms. They differ in that the convection pipes are led out in front and behind the body. They are mounted either during construction, or you will need to disassemble a brick wall, put up the apparatus, and then lay it back.

Before installation, the boiler is heated several times outside. If this is not done, during the first starts it will smoke due to the burning of the paint.

After choosing a place, the chimney is connected. A standard pipe is suitable for the diameter of your model. If you are installing a chimney in your home, the end of the chimney should be extended above the highest point on the roof.

Chimney outlet

If wiring is required in several rooms, corrugation is additionally required. You can hide it under the ceiling by covering it with a box. It is connected to each other with reinforced tape or special tees.

How to make a hot water boiler with your own hands

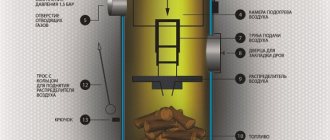

Having dealt with the device, you can make an air heating boiler with your own hands.

Creation and assembly consists of the main parts:

- The combustion chamber. It needs a metal cylinder. It can be made by cutting off the end parts from the barrel, or by welding a metal sheet, having previously bent it around the circumference.

- Ash box. Next, we make a box for an ash box. To do this, we weld on the side a metal sheet bent with the letter "P". Before that, we cut out two large holes in the cylinder, ash will pour out through them.

There is a grate below the ash hole. For this, slots are made in a rectangular sheet of metal. So that it does not move inside the cylinder, we weld two stops on the sides inside.From the end side, we weld a sheet that goes beyond the circumference, this will be the back wall of the furnace, ash box and convection pipes.

Boiler ash box

- Chimney. Cut a hole for the chimney on the opposite side. A chimney pipe with a gate is made. To do this, a through hole is drilled in a suitable pipe and a metal rod is inserted, which will be the gate handle.

A blade is welded inside, which regulates the thrust. On one side, the rod bends to make it easier to manipulate.At the end, the chimney is welded into the cylinder bore. - Upper combustion chamber for wood gases. From the top, we weld a steel sheet that does not reach the front edge of the barrel. From the front side, we weld two small diameter tubes that will serve as both legs and jets for the upper chamber. We weld two more legs at the back.

- Convection pipes. A cylinder is also welded in front. After that, we weld two arcuate sheets on the sides to the edges of the end walls. Between them and the walls of the combustion chamber there will be a space along which the air will rise and heat up. Boiler convection pipes

- Door. In the front, slots are made into which fuel will be laid. A frame made of square tubes is welded along the edges. The hinges are welded onto it and the doors are attached. They are provided with latches.

It is important to check the tightness of the seams before starting to use, otherwise the boiler will not work as efficiently as possible.

boilervdom.ru

Model range of boilers by Professor Butakov

- High school student, heating and cooking model, weight 49 kg, heat load 8 W, heating area up to 60 m2, cost up to 6800 rubles.

- Student, for private housing construction, weight 57 kg, heat load 9 kW, heating area up to 150 m2, cost up to 13,900 rubles.

- Engineer, for one-story houses and small utility rooms, weight 75 kg, heat load 15 kW, heating area up to 250 m2, cost up to 17,700 rubles.

- Associate professor, for non-residential industrial premises, weight 143 kg, heat load 25 kW, allows heating an area up to 500 m2, cost up to 28,000 rubles.

- Professor, for large residential and non-residential buildings, weight 57 kg, heat load 40 kW, heating area up to 1000 m2, cost up to 32,000 rubles.

The principle of operation of an air heating boiler

Air heating boilers can be made with different design solutions, but the principle of their operation is the same. In boilers of this type, air is heated from hot surfaces, which ensures continuous circulation of air flows in the room.

For efficient heating of adjacent rooms, a duct system is installed. If there are many rooms and the house has a complex, multi-level layout, forced ventilation is used to evenly distribute the heat flow and overcome frictional losses and along the length.

Modern VCs work on the principle of pyrolysis - a long process of smoldering firewood with a minimum supply of air in the combustion chamber, forming both gas and heat. The process takes place in two stages: ignition and gas generation.

When firing up, firewood or briquettes are placed in the firebox on the grate and ignited, while the gate and blower are left open. After the firewood is well heated, they are closed, thereby reducing the amount of air entering the firebox, and it is supplied only through the jets.

Secondary - represents a mixture of air and fuel combustion products. The fuel is not combusted completely, therefore, there are still flammable substances with a high temperature in the exhaust gases, therefore their "afterburning" is economically justified and will require additional costs. Secondary air is extracted from the upper part of the flue, and the volume and flow rate are adjusted manually or automatically using a damper, which is impossible in the old type of traditional boilers or furnaces.

Pyrolysis air-heating boiler BURZHUI-K TV-32

Description of the hot-water boiler BURZHUI-K TV-32

Solid fuel air-heating boiler (stove) "Bourgeois-K TV-32" with a capacity of 32 kW, operating on the principle of pyrolysis combustion, is a classic device used to heat air in rooms up to 330 m2, not equipped with water heating systems. One of the main advantages of an air heating boiler is the absence of the need to install an expensive heating system using a coolant, because air heating is the most profitable in terms of economic indicators and labor costs. It is mainly used in non-residential premises (greenhouses, warehouses, workshops, churches, temples, sales areas, etc.), as well as as backup heating. Like all boilers "Bourgeois-K", this stove is characterized by the most efficient processes of complete combustion of fuel and heat transfer.

The Bourgeois-K TV-32 boiler is an all-welded structure made of heat-resistant and corrosion-resistant steel, consisting of several combustion chambers. Primary air supply and gasification chamber (lower), gas afterburner and secondary air heating and supply chamber (upper). Additional equipment is the boiler's metal casing with a heat-resistant coating and a basalt insulation layer, which provides high-quality boiler insulation.

The process of wood gasification (pyrolysis) takes place in the lower chamber of the boiler (firebox or loading space) under the influence of heat and with limited air access. The resulting wood gas enters the upper afterburner, where it mixes with the already preheated secondary air. The gas / air mixture ignites and releases the resulting heat to the boiler water through the heat exchange surfaces. Thanks to this control of the combustion process, a quick heating of the boiler elements is achieved, which contributes to a clean combustion at full or partial load. The special efficiency of all combustion processes is due to the minimum amount of heat loss with exhaust gases, since there are no costs for traction and blast. The pyrolysis method of solid fuel combustion and the special design of combustion chambers ensure high boiler performance with low fuel consumption.

The main type of fuel for the Bourgeois-K TV-32 air-heating stove is firewood (wood logs with a diameter of 40 to 100 mm, moisture content not exceeding 50%), wood and peat briquettes. To achieve the rated power, the maximum permissible wood moisture content should not exceed 20%. Alternatively, you can use coal with a caloric value of up to 6000 Kcal. The volume of the loading chamber is allowed to fill only 80-90%, which is enough for continuous operation for 10-12 hours.

The temperature of the heated air is regulated by changing the position of the primary air supply door and by the draft in the chimney (with a throttle for regulating the vacuum in the boiler). The minimum operating temperature of the oven is 60 ° C (primary air door closed, throttle set to minimum draft: 90 °). The maximum temperature is reached by increasing the amount of air supplied to the combustion chamber by fully opening the door and throttle.

After cooling, combustion products in pyrolysis boilers are removed by natural draft. The smoke coming out consists mainly of carbon dioxide alone and does not contain any aggressive or harmful substances. In this case, ash is formed in much smaller quantities than in boilers of direct combustion, and there is no soot. All this reduces the frequency of cleaning and greatly simplifies its process.

The long-burning boiler "Bourgeois-K TV-32" is independent of electricity, easy to operate and easy to maintain. It can be used for intermittent heating (for example, off at night or on weekends). In addition, heating of large or multi-room premises (the boiler itself is located in the boiler room) is easily realized using a duct system. For this, the oven is equipped with a blower fan, which requires connection to a 230 V power supply (degree of protection: IP X4).

Despite the rather high cost of this heating boiler in comparison with analogues, the costs are quickly recouped due to economical fuel consumption, high efficiency and long service life.

The main features and advantages of the Bourgeois-K TV-32 hot-water boiler:

- Maximum power: 32 kW

- High efficiency: 82-92%

- Boiler type: air two-pass

- Pyrolysis fuel combustion

- All boiler elements are made of heat-resistant, corrosion-resistant steel

- Complete autonomy

- Non-volatility in operation (if the fan is not used)

- Special design of the combustion chamber with a large usable volume

- Full warming up of the room in an hour of work

- Efficient operation on virtually any solid fuel

- Ability to burn fuel with humidity up to 50%

- Economical fuel consumption

- Ability to work up to 12 hours on one tab of firewood at minimum power

- Extended interval between fuel loads

- Fireclay stones in the afterburner to maintain a high operating temperature

- Adjustment of air temperature from 40 to 120 ° C (increase to 300 ° C if required)

- Environmental friendliness (the amount of emitted harmful substances is minimal)

- Unique grate system (grates included)

- Thermometer

- Electric blower (blower fan) included

- Ease of management and minimal maintenance time

- Removal of combustion products by natural draft

- No need for frequent cleaning (low ash content)

- Does not require the organization of the heating system

- Minimum chimney height: 9 meters

- Versatility of use

- Possibility of intermittent use of heating

- Possibility of heating multi-room premises

- Reliability, safety

- Durability (minimum service life: 10 years)

- Does not require user training for operation

Installation standards

The conditions for installing VK are simple, but for specialists, there are many nuances that you need to know so that the user does not become disappointed in the choice of an air heating boiler.

Features of VK installation:

- The boiler is installed indoors during the construction of the building.

- Specialists must first complete the installation project, taking into account the actual heating and structural characteristics of the building, in accordance with which the main and auxiliary equipment will be selected.

- The system must be equipped with a backup power source.

- To increase the efficiency, the boiler should be installed in a room with good thermal insulation of the walls.

- The furnace must have a good ventilation system for ventilation.

- Air ducts make sense if you are installing them in multi-level buildings over 100 m2.

To select a VC, the following data will be required:

- VC power, taking into account heat losses in the building;

- the rate at which heated air enters the room;

- technical data of the duct system;

- place of installation of VK.

If the installation of the boiler seems to be a difficult and impossible task for consumers, it is better to entrust it to a company that will carry out the entire set of installation and commissioning work for the heating system at home, in this case, you can avoid inconsistencies and ensure reliable and safe operation of equipment for many years.

Air heating boiler installation conditions

So that, having bought an air heating boiler, you are not disappointed in the choice, and you do not have any difficulties with the installation of the structure, it is worth knowing some of the nuances. They should be taken into account without fail:

- Installation of an air heating system and specifically a boiler is carried out only in the house during the construction process. A plan and the necessary drawings must be drawn up in advance.

- This system will require a backup power source.

- To increase the efficiency, the boiler must be installed in the dwelling without fail, and the walls must have reliable thermal insulation.

- Ventilation of the room is necessary, since ventilation does not provide complete purification of the air from gas.

- Air ducts may not be needed if partitions are not installed on the second floor or the area of the house is small.

If you want to heat the house with an air-heating boiler, you can save relatively well on installation and do everything yourself, taking note of a couple of fundamental recommendations.

It will not be possible to carry out all the work manually, or rather, not for everyone. There are things that are better to entrust to specialists, for example, calculations.To make the right choice of a long-burning hot-water boiler, you need to know such characteristics as:

- required power of the unit, taking into account heat loss;

- the rate at which warm air enters the rooms;

- all kinds of heat loss;

- parameters of the airway system.

It is necessary to decide on the place of installation of the unit. There are no special requirements for the place, so in this case it is important to remember the main principles of installing gas or other equipment.

Heating equipment for home

Information about air-heating heat generators, chimneys, calculation of heat output and choice of fuel.

Air heating boilers - is it worth it?

This heating option will be cheaper than water heating.

In addition, the use of an air heating boiler excludes freezing, leaking and boiling of the coolant. After all, such a unit heats not the liquid, which is then distributed throughout the heating system, but directly the air. Thanks to natural convection, the room warms up much faster.

It is better to place small hot water boilers in the middle of the house so that the heat is evenly distributed throughout all rooms. Then you get the effect of a Russian stove. Note that people with very limited financial resources buy similar low-power ovens in small houses and spend the winter quite happily.

Air heating is also justified in the case when heat is required sporadically. For example, in the country, in a hunting lodge, workshop, service station, garage, utility rooms.

In order to heat several isolated rooms or the second floor, it is necessary to provide heat supply to each room. For wiring equipment, it is necessary to purchase a heat sink, which is hung on the side of the boiler-furnace, and connect convective tubes to it. You will also need to make a hole in the room where the heat will flow, and bring an aluminum corrugated pipe to it.

But first of all, it is recommended to install the unit in its permanent place of "dislocation" and heat it up in order to identify in which rooms the heat will be insufficient. Only after that is it worth deciding where the wiring is needed.

There was a case when the owner of a rather large house installed an air-heating boiler in the bathroom and made the wiring to the rooms. But here it is necessary to take into account that such a spider-heat generator with numerous branches from pipes and sleeves does not always look aesthetically pleasing.

In addition, it will also have to be heated and cleaned of combustion products (ash or slag) from the room.

It should be noted that not all models of this equipment involve a device for distributing heat flows. In this case, to supply heat to the second floor (for example, at a summer cottage during the off-season), it is sometimes enough to make additional ventilation holes.

For warmth and aesthetics

In recent years, one of the most common requirements among buyers is aesthetics. People want to see elements of antiquity in their interior, and heating boilers in the form of fireplaces with a glass screen are perfect for this.

You can, of course, buy a more economical simple version of the firebox, and after installation, decorate it with brickwork or special cladding. But here it is important to act not to the detriment of heat transfer.

Good heat transfer will be ensured only with proper equipment of convection holes for air circulation. Otherwise, heat will come to a greater extent from the glass, and heat from the furnace itself only after heating the facing material. Accordingly, the heated area of the room will be very small.

Finding a good fireplace master today is difficult, and the work will cost a lot. It is more profitable and less troublesome to purchase a ready-made fireplace, since it is provided with a sealed reliable glass and it is completely ready for use.

Determine the power

Traditionally, the power of the boiler is determined at the rate of 1 kW per 10 square meters (under optimal thermal insulation conditions and a ceiling height of no more than 3 meters). To ensure hot water supply when a double-circuit boiler is used, the additional power reserve must be at least 25%. In addition, manufacturers recommend that the main part of the time the unit works no more than 70% of its capacity (nominal, not maximum).

On average, a 13 kW model is sufficient for a 100 sq / m house without hot water supply. (10 kW + 30% of 10 kW as power reserve). To obtain more accurate data, it is necessary to take into account the climatic conditions of a particular region, the quality of the house insulation and the amount of heat for heating water.

It should be borne in mind that it does not make sense to install non-insulated boilers in a separate unheated stoker with walls in half a brick - you will simply heat the street. In this case, it is necessary to take a unit with basalt insulation between the casing and the walls. Long-burning boilers, as a rule, are all insulated.

What about the fuel?

When choosing boiler equipment, you need to take into account what type of fuel you plan to "heat up" with. For example, classic models of direct combustion can operate on any type of solid fuel - wood, coal, peat and wood briquettes, pellets. Coal is most often the most popular: when it is burned, more thermal energy is generated than from any other type of fuel, and there are no difficulties with the acquisition and storage.

Air heating boilers are traditionally fired with wood, but in addition to this, they are also capable of operating on lignite and hard coal, pellets and waste from the woodworking industry.

For the operation of long-burning solid fuel boilers, coal of the "nut" fraction - 20-70 mm is mainly used. With an optimized grate system, larger sizes are allowed. In terms of calorific value, pellets are comparable to natural gas and coal, but pellet boilers are fully automated and, therefore, volatile. In addition, such a "pleasure" costs more than 200 thousand rubles.

It will be somewhat cheaper to integrate a pellet burner into a conventional solid fuel (TT) boiler, since the cost of a high-quality imported burner is almost half. In terms of efficiency, pellets are comparable to gas. The main type of fuel for boiler-fireplaces is wood. Their design allows the use of pellets, peat briquettes and more.

There are few fireplaces and hot-water stoves that allow the use of coal. For example, the production unit has such a unit; the only “coal” model in the entire range is “Ognivo”. The instructions stipulate that this furnace assumes the use of coal as fuel. The metal from which it is made is much thicker compared to other models, and accordingly the weight is impressive - 120 kg. There are protective screens inside it.

There are other manufacturers who also allow the use of coal in some models of fireplaces, but, as they say, not aggressively.

The chimney is the most important thing

As mentioned above, a traditional brick chimney with wells is suitable for classic units. For long-burning boilers, an insulated straight chimney is required.

For such a chimney, sandwich pipes are usually used, which are not worth saving.

The thicker the insulation, the better. In order for the pipe to really work as a "sandwich", the thickness of the insulation must be at least 5 cm. In this case, the chimney heats up better, the draft is better, and less condensation is formed. Accordingly, less soot will stick.

Since the pipes are not sold entirely, but 0.5 or 1 meter each, when choosing it is important to note the tightness of the pipe connection, most reliably - a double tightness belt. Most reliable pipes and heat resistant chrome steel.It can withstand temperatures up to 750 degrees, that is, up to this temperature, the steel does not burn out, and while structural "black" steel, from which "homemade" is made, oxidizes already at 400.

Note: The burning temperature of wood reaches 700 degrees, and of coal - 900 degrees.

We add that in addition to the pipe itself, it will be necessary to purchase a head, clamps and sealant for the connection, tees (to be able to clean the chimney) and supports for fixing to the wall of the house.

The main difficulty in choosing a quality pipe is that the average buyer is unlikely to be able to distinguish low-quality steel from good. Therefore, the consultation of a specialist will be very useful in this matter. It will not be superfluous to pay attention to the label attached to the product - it must contain the steel marking and the barcode.

Hot-air boiler TV - air, two-pass with solid fuel gasification.

The boilers are used to heat rooms not equipped with hot water heating systems with a volume of up to 360 cubic meters. Efficient operation and high efficiency can significantly reduce maintenance time and save fuel. They do not require the organization of a heating system, the installation of boilers is possible at any time, even at the height of the heating season!

The TV boiler is an all-welded steel structure, which consists of several combustion chambers: the lower chamber is the gasification chamber and the primary air supply chamber, the upper chambers are the afterburning chamber and the chamber for heating and supplying secondary air. The boiler casing (additional equipment) consists of a metal sheet with a heat-resistant coating and a layer of non-combustible basalt insulation, which provides excellent thermal insulation of the boiler.

For TV boilers, the main types of fuel are: wood, lump peat, briquetted fuel, pellets, and coal with a calorific value of up to 6000 Kcal can also be used as a backup fuel. The most suitable size of wood logs is 40 - 100 mm in diameter. The length of the logs depends on the boiler size.

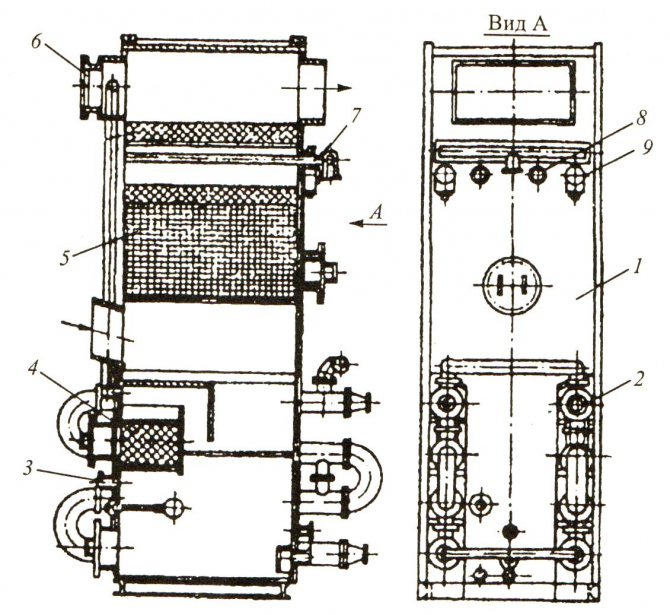

1 - boiler furnace,

2 - afterburner chamber,

3 - primary air supply chamber,

4 - secondary air supply chamber,

5 - heated air outlet branch pipe,

6 - throttle for adjusting the vacuum in the boiler,

7 - chimney pipe,

8 - branch pipe for intake of heated air

The principle of operation of pyrolysis air-heating boilers TV

The process of wood gasification (pyrolysis) takes place in the lower chamber of the boiler (firebox or loading space) under the influence of heat and with limited air access. The resulting wood gas flows through the heat layer, enters the combustion chamber, where it mixes with secondary air. Secondary air is supplied through injection burners, already preheated. The air-gas mixture burns in the afterburner, giving off the generated heat to the coolant through the heat exchange surfaces.

In an orderly, separate combustion, both solid fuel and pyrolysis gas released from it. With limited access of oxygen, solid fuel is pyrolyzed, and the gas released during this enters a special chamber for afterburning, mixing there with the heated secondary air. The process of gasification of solid fuel and the design features of the boiler allow the processes of fuel combustion and heat transfer to proceed most efficiently due to: continuous, natural supply of oxidizer (air) in sufficient quantity and the necessary mixing of the burned fuel (solid or gaseous) with it, as in the lower furnace space in order to optimize the pyrolysis process, and in the upper combustion chamber with secondary heated air within the concentration limits of ignition, - the design features of the combustion spaces, - the removal of combustion products after they have been cooled by natural draft, - the use of the most effective design principle of washing the heating surfaces, with certain speeds and directions of movement of the heat carrier, providing a high heat transfer coefficient, sufficient for operation in heating systems with natural circulation or with the use of pumped heating systems, with the same efficiency.

The sum of heat losses with exhaust gases from chemical and mechanical incompleteness of combustion is minimal (there are no costs for traction and blast), which largely determines the special efficiency of all combustion processes.

Boiler characteristics:

| TV-12 | TV-24 | TV-32 | TV-50 | TV-100 | |

| Thermal power, kW: | 4-12 | 8-24 | 12-32 | 18-50 | 35-100 |

| The volume of heated premises, m3: | 360 | 720 | 960 | 1500 | 3000 |

| Efficiency,%: | 82-92 | ||||

| Operating temperature range, ºС: | 60-120 | ||||

| Boiler productivity, max, m3 / hour: | 320 | 700 | 930 | 1030 | 1500 |

| Air duct connection diameter, mm: | 130 | 150 | 200 | 200 | 315 |

| Maximum fuel consumption (birch no more than 35% moisture): | 0,97 | 1,9 | 3,1 | 5,04 | 9,74 |

| Fuel used: | Wood, coal, peat briquettes. | ||||

| Duration of combustion of one load of fuel, hour: | 8-12 | ||||

| Chimney connection diameter, mm: | 130 | 150 | 180 | 200 | 250 |

| Minimum chimney height, m: | 7 | 8 | 9 | 9 | 11 |

| Chimney draft, Pa: | 18 | 20 | 22 | 23 | 30 |

| Outgoing flue gas temperature, ºС: | up to 220 | ||||

| Boiler weight, kg: | 250 | 340 | 410 | 550 | 910 |

| Degree of protection: | IP X4 | ||||

| Mains voltage, V: | 230 | ||||

| Power consumption, W: | 88 | 90 | 120 | 168 | 225 |

| Maximum heated air pressure, Pa: | 327 | 340 | 388 | 536 | 500 |

| Service life, years: | 10 | ||||

| Overall dimensions (height \ width \ depth), mm: | 1400x430x980 | 1540x530x1050 | 1620x630x1100 | 1820x770x1200 | 2150x850x1400 |

| Contents of delivery: | Boiler, grates, thermometer, electric blower, technical data sheet. | ||||

TV boilers manual

My personal rating of long burning heating stoves in 2013

Search posts by tags: just click on the topic of interest!

The beginning of the heating season.

The question will be raised more than once: "What is the best stove in the house?"

But I will take and make a rating of heating stoves, long burning, at my discretion!

I'll define it first. parameters by which I will select stoves (I will try impartially: I will mention both those that I sell and those that I do not sell)

I think the principles for selecting a stove for a summer residence should be as follows:

A) Reliability and fire safety of the structure, due to the factory manufacture of the furnace and the availability of the Quality Control Department at the plant

B) The duration of burning should be no less than 5 hours.

This means that the furnace must meet two criteria that give a long burning:

1) There must be nozzles (channels for afterburning gases inside the furnace), which allow you to obtain a mode of wood smoldering, with a closed supply of oxygen from other parts of the furnace (ash box, dampers of point air supply)

jets (afterburners) look like this (squares on the right or left on the walls of the furnace, the third channel is closed with a shiny plate):

in the diagram, I showed the device of the afterburners: in this particular case, these are pipes welded to the firebox from the outside, through which air is supplied to the inside of the firebox, even when the furnace door is completely closed and the ash box is pushed in

Afterburner channel close-up

The jets themselves may not be visible during a cursory examination of the stove, they can be located anywhere in the furnace and are closed from the eye. The main thing is that they are.

Some manufacturers make jets at the bottom of the firebox, others, as in the photo, in the middle, others at the top of the firebox, and still others in the form of cracks in secret places.

Usually, the presence of jets is written in the instructions - this is a significant competitive advantage. If it is written in the passport of the furnace, it means that there are 100% jets.

But sometimes they don't write

2) Large volume of the firebox + large opening of the firebox door = a large amount of firewood, pledged at the same time. This means that when choosing a stove, it is necessary to compare such parameters as "volume of the furnace" and "width + height of the door". It so happens that two stoves for the same cubic capacity of the heated room are arranged differently: one has a large firebox, and the other has a large door - the volume of firewood is the same as a result.

D) The presence of glass in the door. It seems, at first glance, a trifle, not essential, but during the operation of the stove, most people like to look at the fire. And it is a shame when there is a stove, but it does not come out to admire the fire, in the combustion mode.

E) The presence of a "tooth" (flame stopper), which "cuts off the flame", so that it does not enter the chimney, which means that the chimney serves for a long time.

This tooth looks like a plate / plates welded in the upper part of the firebox, covering the direct hit of the flame into the chimney

In the photo, the bump plate is marked with a dash-dotted line

F) The presence of some design solutions that increase the service life of the furnace, in contrast to competitors who do not use these solutions, I will write about them separately, for those furnaces that use the offset from competitors.

So, after I have determined the required parameters, here it is, the rating of the best ovens in 2013:

III most honorable place

Breneran (nee buleryan)

The stove is well-known, time-tested, fully meets all the criteria for an excellent stove.

Someone might say: the stove is morally obsolete

And I will object: it is like a car of the 20th century!

There are a bunch of different modifications, for any size, for any wallet.

There are only three downsides in my opinion:

- Controversial design

- Grateless burning system (well, I don't like grizzly systems, they are demanding to dry firewood)

- A bunch of disgusting quality clones.

I will dwell on clones in more detail.

The fact is that making a clone of Buleryan is quite simple: you need a garage, a pipe bender and a welder, but the pipes will be welded inside the furnace. And since the system is grateless, the coal will be welded.

At the same time, it is not yet a fact that clones are cooked with good electrodes, high-discharge welders.

In short, if coal lies on the welds, they burn out and quickly enough.

Open the furnace firebox and see: if there is no welding inside - this is the original, you can take it, the furnace is excellent

but if you see something like this (I took a specially grotesque photo to make it clear about the seams) - then to hell with it, no matter how attractive the price is

Here is a very good video review on Bulik

In short, here's what I think: almost all the negative about Buleryan on the Internet is negative about his clones, and not about the original.

If you buy, head into the firebox and look for seams.

There are seams - goodbye! no, thanks!

II place, even more honorable than III

Legion (nee PO) by Vira (nee "Burn it is clear")

The stove is a technological clone of the Fire-Battery stove, but it has one significant plus and two significant minuses.

- the stove is much cheaper than the original Fire - Batteries

- brewed by people, not a robot, unlike Fire-batari

- looks less simotically than Fire-battery, very, very similar to Butakov.

The most important thing is that the stove fully meets the criteria that I asked at the beginning, but its price is simply ridiculous, relative to competitors. This is due to the fact that the plant that produces it is young and at this stage of development "enters the market." Hence the price is low. Strategy, however.