The retention of heat inside the room largely depends on the thermal insulation parameters of the structure itself and the finishing materials used. Insulating a house reliably means reducing heating costs. Today, the construction industry offers many varieties of insulation materials, which vary in their characteristics and cost. One of the most optimal options is Korund liquid thermal insulation, which is distinguished by its durability and excellent thermal insulation properties. Let us consider in more detail the features of the composition, selection criteria and application technique.

Features of ceramic heat paint

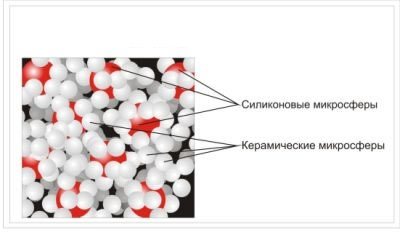

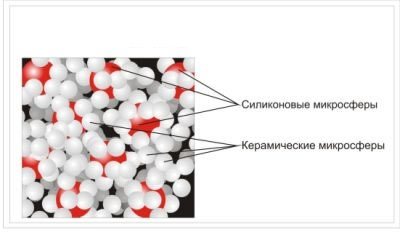

The unique composition of thermal insulation is also called heat-reflecting paint, since with a layer thickness of only 1 mm it can have a noticeable energy-saving effect. Due to this, thermal insulation of Korund is very economical in terms of consumption. The filler contains microscopic hollow spheres - ceramic, polymer, composite, glass balls, which are filled with rarefied air. Such microparticles can vary not only in composition, but also in the size of microgranules, percentage, homogeneity of components, etc.

Externally, the ceramic superfine paint is practically indistinguishable from ordinary acrylic-based paint. Despite the fact that today the construction market offers several varieties of ultra-thin insulating compositions, almost all of them have a similar structure:

- Warm paint is based on water-acrylic solution. Its properties make it possible to ensure uniform distribution of heat-insulating components over the working surface. In addition, the composition contributes to a better fixation of liquid ceramics.

- Also, the binder contains various kinds of additives that improve the performance parameters of the heat paint. The most common material additives include natural and artificial rubbers, silicone, etc.

Varieties of materials KORUND

Thermal insulation products of the KORUND company have several varieties:

KORUND ANTIKOR

A versatile material that can be applied directly to rusty surfaces. Before applying, it is enough just to walk on the surface with a regular metal brush to remove the dry layer of rust.

The insulation has an additional anti-corrosion property. This significantly reduces the cost of preparing the treated surfaces.

KORUND CLASSIC

The heat insulator is an ultra-thin material with good thermal performance. During transportation, the liquid composition of the insulation is practically divided into fractions.

KORUND FASAD

This type of material is applied in layers (thickness from 1 mm), so it subsequently looks like high-quality facade paint. FACADE heat-insulating paint has only positive reviews from buyers. This ultra thin liquid heat insulator is used for concrete surfaces.

FASAD paint also received excellent reviews in combination with ANTIKOR paint.

Liquid thermal insulation Korund: technical characteristics and principle of operation

The temperature range for thermal paint varies from -65 ° C to + 260 ° C. The main technical characteristics are vapor permeability and hygroscopicity of liquid insulation, which can be applied to almost any type of facade material: concrete, stone, brick, metal, plastic, etc.

This material guarantees the removal of condensation that forms on the walls and pipes in the room. The composition of such a warm paint includes special fixatives, catalysts, anti-corrosion additives, as well as a binder base on high-strength acrylic. Along with the content of microspheres, this composition is easy to apply and spread over the entire surface, providing good indicators of energy saving and thermal insulation.

An important argument to buy Korund liquid thermal insulation is the safety of the substance. Due to the content of natural additives and environmentally friendly components, the treated surface is non-toxic and does not emit any odors. This allows the use of heat paint for insulation of any premises. It is possible to create a stable thermal barrier even in children's rooms or dwellings where allergy sufferers are located.

The thermal insulation properties of the composition can be achieved in several ways:

- By convection, i.e. heat transfer by the heat paint layer itself. Due to the fact that most of the specific gravity of the liquid insulation consists of hollow balls, the losses due to convection in the composition are quite insignificant.

- The thermal conductivity of a material, when heat is transferred from a warmer part of a surface to a colder place. In liquid insulation, only 20% of the binder has thermal conductivity properties.

- Radiation is a phenomenon in which heat transfer occurs through the internal energy of the suspension. In energy-saving paint, microscopic spheres are endowed with reflection and heat dissipation properties. Almost 90% of the reflected radiation turns the working surface of the wall into an analogue of a thermos.

House, construction, renovation

| I'm not the last brute - it's still my turn. 05/28/12 12:32 PM Reply to the message Thermal insulation "Korund" - are there any reviews? user doka Ideal materials and designs have not yet been invented. 05/28/12 17:06 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user TSSB I'm not the last brute - it's still my turn. 05/28/12 17:19 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user doka Ideal materials and designs have not yet been invented. 05/28/12 10:10 PM Reply to the message Thermal insulation "Korund" - are there any reviews? user doka 05/28/12 10:44 PM Reply to message Re: Thermal insulation "Korund" - have any reviews? user egen

05/30/12 10:09 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user Accept 06/26/17 20:20 Reply to the message Thermal insulation "Korund" - are there any reviews? user doka 06/26/17 20:29 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user TSSB 06/26/17 20:35 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user egen 06/27/17 00:54 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user egen

06/27/17 1:13 PM Reply to message Re: Thermal insulation "Korund" - are there any reviews? user BOOGIMAN thermal paints are crap. there are no fantastic results, the paint is even worse than conventional thermal insulation. its only application is to protect against burns on curved surfaces. Here is a consumer test, the paint showed the worst result of thermal insulation. long video, but tough. there is a slight out of sync with audio. 06/27/17 14:09 Reply to the message Re: Thermal insulation "Korund" - are there any reviews? user BOOGIMAN

Go to forum |

Information on age restrictions in relation to information products, subject to distribution on the basis of the provisions of the Federal Law "On the Protection of Children from Information Harmful to Their Health and Development."

Some of the content on this page may contain information that is not intended for children under the age of 18.

Good day.Homes cold walls, mold. I heard about liquid insulation, which can be used to paint walls and insulate them. Read on the Internet someone praises someone scolds. I wanted to find out from someone who came across this material from personal experience how effective such thermal insulation is. What do you advise?

I used AKTERM in my cottage 3 years ago and wanted to see how cool [nanotechnology] was, to be honest, I was hoping for it. After the winter season, the result was negative, and yet there was still hope, bought KORUND, the result is the same complete disappointment. Conclusion - Oleg Schwartz is right, this is nano g-no. Someone believes in aliens, some do not. Just for those who believes in aliens.

For home, it's problematic. Doesn't let the walls breathe. In this case, forced ventilation will also be needed. As insulation - weak because all insulation is mainly due to wind protection.

I agree with Alexey's answer. Sometimes the opposite effect is observed, that is, it becomes even less comfortable in the house, namely, mold and dampness increase. If you need help in resolving the issue and you live in Moscow and the region, call tel. I try to help. The reason for the discomfort may be not only weak thermal insulation.

Four years ago, AKTERM Standard was used against condensation and freezing of walls - apply it to the walls, after gluing the wallpaper, the result is excellent from year to year, the apartment has become warmer and the walls are dry!

Liquid heat-insulating paints are a scam in its purest form. Unfortunately, this is also promoted to municipal facilities, rolling back considerable sums to corrupt bureaucrats. In order not to be unfounded, I am attaching the answer of the Institute of Building Physics to the request "full face" about the possibility of using the gastrointestinal tract as a heat insulator.

I used AKTERM in my cottage 3 years ago and wanted to see how cool [nanotechnology] was, to be honest, I was hoping for it. After the winter season, the result was negative, and yet there was still hope, bought KORUND, the result is the same complete disappointment. Conclusion - Oleg Schwartz is right, this is nano g-no. Someone believes in aliens, someone does not. Just for those who believes in aliens.

move the dew point to the center of the wall. by insulating the wall or outside or inside + drywall .. all the cases. it is possible to increase the temperature in the room and the ventilation of the room

good evening, buy wallpaper glue, Methyl, process the wall, right up to the joints, and start insulating the wall, I did this, for 3 years not a single mushroom mold has been observed.

Good day. We used Corundum to insulate the outer wall of a country house, the customer was against the insulation of the facade, the house was lined with silicate brick after applying thermal insulation directly to the brick, the condensate passed. Great stuff in some cases. But for a more detailed answer on the use of a particular material, it is necessary to see the object and understand the cause of mold. P.S. This is not an advertisement, and I have nothing to do with the manufacturers of this insulation.

AB Zashchita is ready to provide a free sample of Bronya liquid thermal insulation, so that you do not doubt the quality of our products. We provide a full range of services for the application of liquid thermal insulation, give guidelines and full advice on the use of our products. Information by phone (call is free).

We work with various thermal insulation, including in some objects we have been using TM AKTERM liquid thermal insulation for the last 4 years to insulate facades with liquid thermal insulation, I think this is not correct, since the thermal resistance of materials is much lower than that of traditional thermal insulation, the main application is metal surfaces (pipes, tanks , containers, vehicles, garages, hangars). AKTERM has a conclusion and recommendations from the Research Institute of Construction Thermophysics and Research Institute Mosstroy on what can be used for thermal insulation.There are also recommendations to use the product for a heat shield if you paint it behind the battery in the apartment so as not to heat the street, as well as paint the slopes with heat paint to reduce heat loss. The main thing is to use liquid thermal insulation correctly and for its intended purpose. After consulting with the manufacturer. We have already completed hundreds of objects with AKTERM teplokraskoy, a lot of positive feedback and there have never been complaints that someone's problem has not been solved.

You need to insulate the facade of your house to offset the dew point. If this is not possible, then all that remains is to apply liquid thermal insulation to the walls, at some objects with a similar problem I painted with AKTERM heat paint. Previously, we worked with various Volgograd and Ural manufacturers, but in my opinion it is more convenient to work with AKTERM. I recommend doing as follows: 1. all work is best done in summer in dry weather 2. walls are treated with an inhibitor of fungus and mold 3. treat the wall with primer 4. apply AKTERM heat paint on the wall in layers of 0.5 - 0.7 mm with interlayer drying 24 hours 5. The finishing layer is determined by visual inspection, there should be a white uniform color on the wall 6. The finishing layer can be painted or wallpaper pasted. I also recommend painting over window slopes and walls behind the radiators with heat paint to reflect heat. I am attaching a photo of examples.

A lot of comments have already been given, from which we can conclude that this type of thermal insulation is not entirely reliable, which I myself can confirm, since there was a bitter experience in finishing a bath that did not pass the test for the Russian winter. Therefore, choose traditional thermal insulation. For purely recommendation purposes, I can advise you on k-flex st insulation

I applied Astratek thermal insulation on the balcony and on the window slopes, the mold was gone. The result was fine for me.

For thermal insulation today it is not at all necessary to use traditional materials. The unique paint Korund, created on the basis of nanotechnology, has thermal insulating properties. The material is made of ceramic microspheres filled with rarefied air. The binder is an elastic anti-corrosion material. Additional ingredients added to the thermal insulation material make the paint resistant to frost and high temperatures. From the reviews on corundum insulation paint, you will learn about the effectiveness of the material.

- less than a month

- several months

- half a year

- more than one year

- more than three years

- more than five years

- I recommend

- I do not recommend

- I am at a loss to answer

Advantages of thermal insulation Korund

Liquid heat-saving paint is an innovative composition that differs from all existing coatings. Among the most significant advantages of its use, it is necessary to highlight the following aspects:

- The universality of the substance. It can be applied to any kind of surface, including untreated, if it is indicated on the instructions for use. Specialists use heat paint for processing brick, concrete, metal, plastic surfaces, as well as for thermal insulation of equipment and air ducts.

- Wear resistance. The applied layer of liquid insulation does not degrade over time. Corundum provides a guaranteed service life of up to 15 years, and with proper care (timely cleaning, high-quality finishing), this indicator can be doubled.

- Ceramic thermal insulation has good adhesion to any type of material, which provides good protection against moisture and air ingress.

- The substance is resistant to an alkaline environment.

- Liquid thermal insulation provides anti-corrosion protection and minimizes heat loss.

- Dry coating with heat paint reliably protects the treated surface from deformation due to temperature extremes, atmospheric influences and the formation of moisture.

- Ceramic insulation is practical and easy to apply to complex geometric surfaces.

- The material is ultra-light, so there is no additional load on the structure. Due to this property, heat paint is often used in roofing.

- The substance is quite convenient to repair, because in case of minor damage, the old layer can be easily removed by replacing it with a new one.

- Heat paint reflects up to 80% of the energy of ultraviolet rays.

- In addition, liquid insulation is resistant to fire. When heated to + 260 ° C, the applied layer is charred, and when it reaches + 600 ° C, the heat paint begins to decompose, releasing carbon and nitrogen oxide, which prevents the rapid spread of flame.

Advantages and disadvantages of the material

Thermal paint of this brand thoroughly fills the micropores of the surface that is being processed. In addition, liquid thermal insulation has the following advantages:

- Keeps warm well. Even 1 mm of the composition in terms of efficiency can be compared with 40 mm of roll-type insulation, for example, mineral wool.

- Ease of application. The mixture is applied to the surface like a regular paint: with a roller, brush, spray gun. At the same time, it does not emit any harmful substances, therefore, when working with it, it is not necessary to use protective equipment.

- Provides protection against destruction. Metal surfaces treated with Corundum will never rust, and wood will not dry out and rot.

- Doesn't attract rodents, insects and bacteria. The coating will not mold or rot.

- Light weight. The weight of the heat insulator cannot be compared with the classic roll material. This type of insulation will not load the foundation and supporting structures. Therefore, even fragile and unstable elements can be processed with Corundum.

- Lack of cold bridges and seams. With Corundum, you can create a reliable coating without any seams.

- Durability and safety. During the entire service life, no harmful chemical compounds will be released from the material. Therefore, they can also insulate living quarters where allergy sufferers live.

- Does not affect geometry. Compared to traditional materials for thermal insulation, Corundum has no effect on the geometric parameters of the building.

This kind of isolation and disadvantages are not without. This primarily concerns high cost... This material has appeared on the Russian market relatively recently, therefore it still has a high cost. However, this "minus" is fully compensated by the durability of the coating and excellent thermal insulation properties.

The disadvantages can also be attributed to the rapid polymerization of thermal paint, so you will have to work with it very quickly.

Disadvantages of ultra-thin warm paint Corundum

Despite the impressive list of advantages of the material, it is not devoid of some disadvantages. Among them, the following aspects should be highlighted:

- The high cost of heat paint.

- Since ceramic insulation is a relatively new product in the construction market, there is still no time-tested evidence that the material meets the declared characteristics.

The main types of thermal insulation

Liquid ultra-thin thermal insulation is presented in the sale of specialized hardware stores in several versions. The entire line of polymer compositions consists of the following types:

- Thermal insulation Korund Classic is a liquid suspension designed for roofing and facade works. Also, this composition has found application in the interior decoration of premises, providing reliable thermal insulation of walls in residential buildings and general buildings. In addition, the classic variety is highly effective for insulating concrete floors, self-leveling coatings, hot and cold water supply lines, as well as insulating window slopes.

- Corundum Anticorrosive is a special anti-corrosion compound that can be applied simply on a rusty surface, without any special treatment. This heat paint is distinguished by high adhesion to concrete and metal, creating a reliable protective and insulating layer. As a rule, this liquid thermal insulation Korund is slightly cheaper than the classical type and is used to create the first base layer of insulation.

- Facade is a type of heat-saving paint designed for the treatment of concrete surfaces, as well as buildings made of slag or foam blocks. The composition is applied in a thickened layer, thereby reducing the coefficient of labor costs for treating large surfaces. This type of warm paint is usually used for finishing.

- Winter - liquid thermal insulation designed for work in the cold season. The energy saving principle is based on the "thermal mirror effect", i.e. reflections of streams of heated air masses. This compound is versatile and can be applied to almost any surface at ambient temperatures down to -10 ° C.

Technology for applying material to the walls of the house

To apply corundum to the facade, the walls must be properly prepared. Preparation of a concrete base includes:

- Areas with flaking or loose finishes are removed.

- Gaps, even minor ones, are sealed with mortar.

- Coating wall surfaces with acrylic primer to reduce material consumption.

Preparation of a wooden base is as follows:

- Removing old paint.

- Then you need to manually or mechanically sand the surface of the wood.

- Treatment of the entire surface of the walls with antipyrine and antiseptics. It is advisable to use these water-based products.

Application of corundum facade consists in layer-by-layer application with drying stages of at least 24 hours between each layer. Water is used as a solvent. In this case, the instruction allows you to add:

- For the first layer, no more than 20% solvent.

- For all subsequent ones - no more than 15%.

Next, we proceed directly to applying corundum to the walls:

- The paint in a bucket is thoroughly mixed with a drill with a special nozzle until the consistency of heavy cream is obtained.

- The thinned paint is applied with a brush, roller or spray.

- The first primer can be made a little thinner than all subsequent ones.

- After completing the last layer and letting it dry, the instruction allows you to apply any decorative or textured paints to it.

Safety measures at work

Since the corundum facade material is mostly synthetic, when working with it, the instruction requires you to follow certain rules of personal safety:

- When working with this material, special goggles must be used to protect eyes from accidental paint splashes.

- Respiratory protection is not required when working outdoors. When applying liquid insulation indoors, you must use a respirator. In this case, you need to ventilate the room.

- It is also necessary to work in protective clothing with long sleeves and rubberized gloves.

The properties and scope of the corundum heat insulator make it possible to speak of its versatility. At the same time, it is beneficial to mix some types of this material. For example, in a facade or classic look, you can add corundum anticorrosive to increase the protection of metal surfaces from rust formation. At the same time, all thermal insulation properties remain at the same level.

General criteria and features of choice

Ceramic thermal insulation is not yet a fairly common type of coating, due to the high cost of production. However, experts say that this substance has exceptional performance characteristics, the value of which significantly exceeds the cost of purchase.To choose the optimal type of liquid thermal insulation, it is important to take into account the following features:

- The first thing that affects the final result of ceramic insulation treatment is the density of the composition. A high-quality heat paint is characterized by an indicator of about 0.6 kg per 1 liter of product. Those. the weight of a standard 10 liter bucket should not exceed 7.5 kg.

- It is also worth looking at the container with the solution "in the light" to determine the degree of its stratification. A good indicator of the quality and effectiveness of thermal insulation properties will be a dense top layer of the substance. As a rule, ceramic spheres have a light fraction that rises to the top. Thus, the thicker the top layer, the higher the thermal insulation properties.

- An equally important selection criterion is the structure of the suspension itself. To determine it, you need to grind a couple of drops of warm paint between your fingers. The qualitative composition contains microgranules of ceramic balls, i.e. the substance has a roughness.

- In addition, it is necessary to take into account the color of the liquid insulation. Corundum is produced in white, so a gray or yellow paint is a clear evidence of product counterfeiting.

Structure and composition

Corundum has a liquid consistency. Thermal insulation resembles a slurry or white paint. It can be insulated with a surface made of any material. The application method is the same as for conventional paint. After drying, a specific coating with elastic properties is formed. It has unique technical and thermal insulation characteristics. For comparison: 1 mm of corundum can replace 60 mm of mineral wool or a wall one and a half bricks thick.

The composition of the coating is unique

The composition of this coating is unique. Physicists and chemists of Europe and the USA have been working on its development for several years. It consists of microscopic ceramic balls filled with vacuum (rarefied air). These microspheres bind high quality acrylic polymers, thanks to which the material has excellent adhesion (adhesion) to all surfaces (plastic, metal, propylene).

The intensity of the action of rarefied air molecules located in spherical cavities endows liquid thermal insulation with unique properties.

Also corundum contains water. It takes 47% of the total volume. After application, part of the water evaporates, and part of it participates in the process of hardening of the applied thermal insulation.

In addition to the base, corundum contains additives that exclude the appearance of corrosion and the formation of mold and mildew in high humidity conditions.

Application area

Ultra-thin ceramic insulation Corundum is an innovative material that forms a durable elastic coating that reliably protects the surface from moisture, overheating and corrosion. This compound is used over a temperature range of -65 ° C to + 260 ° C.

The main areas of application of heat paint include:

- housing and communal services facilities (including processing of pipelines for various purposes, thermal insulation of facades, roofs, windows, walls);

- transport industry;

- oil industry;

- insulation of heat and power structures;

- construction industry.

Thermal insulation corundum - prices and discounts for wholesale buyers

PRICE for 1 liter - 330 rubles. FOR WHOLESALERS DISCOUNTS%

With all the positive qualities, Korund thermal insulation is also affordable. You can choose a convenient packaging and save on installation costs: the paint is applied with a spray gun or a brush. Consumers who have used Corundum clearly distinguish this warmth paint among similar ones. Even without special equipment, but simply putting your hand to the wall covered with Corundum, you will feel the warmth, while the unpainted wall will cool your palm.

Corundum - the warmth of your home!

| "Classic" - for all surfaces | "Antikor" - for rusty surfaces | "Facade" - for outdoor use |

|

Ceramic insulation technology

It is necessary to apply ultra-thin thermal insulation Korund on a previously prepared surface, regardless of the modification of the composition. The basic rules that should be followed before starting paint insulation include the following:

- If ceramic insulation is intended for wall treatment, the work surface should be cleaned of dust and dirt, and the existing gaps and chips should be expanded and filled with cement mortar.

- Before carrying out paint thermal insulation on concrete slabs, they should be cleaned of "cement milk".

- It is also necessary to process the wall with an abrasive wheel, sandblasting machine or a stiff metal brush.

- If you plan to treat a metal surface, it must be dedusted and degreased (the substances recommended by the manufacturer are Solv-Ur, Solvent). To paint objects made of non-ferrous metal, it is necessary to remove the gloss and apply a primer composition VL-02 or VL-023.

- It is also worth considering that it is necessary to dilute the ceramic heat paint immediately before applying it to the wall.

Important! It is recommended to mix the liquid thermal paint Corundum manually. However, for work with large volumes, it is allowed to use a construction mixer, the rotation frequency of which should not exceed 200 rpm. Otherwise, there is a risk of destruction of the hollow ceramic granules, which will negatively affect the thermal insulation properties of the composition. Typically, manual mixing takes 10-15 minutes. When working with a construction mixer, this figure will be 3-7 minutes.

It is also worth considering that it is necessary to add water to some modifications of the composition before starting work, so you need to carefully study the manufacturer's instructions. The volume of liquid depends on the purpose of the thermal insulation; in any case, the required proportions are indicated on the packaging of the composition.

The technique of applying ultra-thin thermal insulation Korund is carried out in three ways:

- using air spraying devices;

- by airless spraying;

- manually - using a roller or brush.

The manufacturer recommends applying the composition in three layers, while the consumption should be 1 m / m2. When working on thermal insulation with this composition, an additional flow of ventilation in the room is not required, as well as the use of special personal protective equipment.

To guarantee the effectiveness of the result, it is important to strictly follow the manufacturer's instructions and fully adhere to the recommendations indicated on the package.

Criterias of choice

Material patent belongs to. This organization has several official dealers, for example, ServiceInvestProject, TeploTrade and others. You should not buy products from sellers with a dubious reputation.

The normal state of the material of this brand is a white pasty mixture. Packaging - buckets made of durable plastic with different volumes. At the same time, information about the manufacturer must be indicated on the packaging.

The cost of thermal insulation varies depending on the region of sale and the type of material. The average cost of insulation is as follows:

- Classic - 390 rubles per liter;

- Antikor - 440 rubles per liter;

- Winter - 560 rubles per liter capacity.