The need for thermal insulation

Before a foreman who decides to optimize the heating circuit, two questions inevitably arise: why do this and how to insulate the heating pipes?

Thermal insulation of heating pipes on the street and at home is highly desirable for the following reasons:

- This measure helps to significantly reduce the loss of thermal energy during the transfer of the heat carrier (usually hot water) from the place of primary heating to radiators and other devices.

- Insulation of heating pipes on the street allows you to prevent thawing with subsequent subsidence of the soil layer in the places where the heat supply line passes.

- Covering heating circuit elements with an insulating layer is an excellent means of preventing corrosion processes (if metal pipes are used to supply heat).

- Since, as statistics show, when the heat carrier (including water) is transported over long distances, up to 25% of thermal energy is lost (in some cases, more), timely high-quality thermal insulation of pipes allows you to reduce the cost of paying for heat.

Materials used

Today, thanks to the development of the chemical industry, leading not only to an improvement in the quality of the final product, but also to the creation of new materials with increased ergonomics, a huge number of materials are presented on the market that allow you to insulate heating pipes on the street and in the house.

In addition, a large selection allows each craftsman to choose a product that ideally suits him in all technological characteristics - from operating conditions to cost.

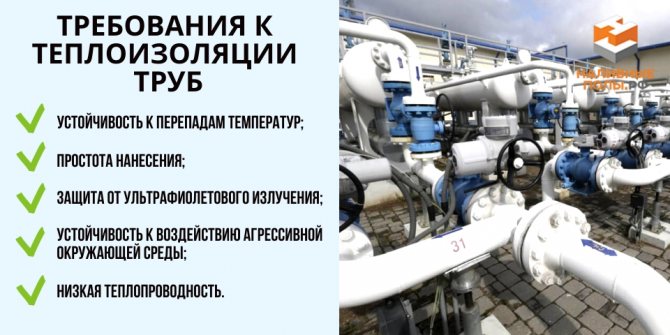

Insulation for heating pipes on the street or in the house must meet the following requirements:

- low thermal conductivity of the material - it is necessary to reduce heat loss to a minimum;

- incombustibility, fire resistance - allows not only to use the material on the hottest pipes, but also to provide additional fire safety of the building and adjacent areas;

- ease of use - it should be possible to install and change heating elements without applying much effort.

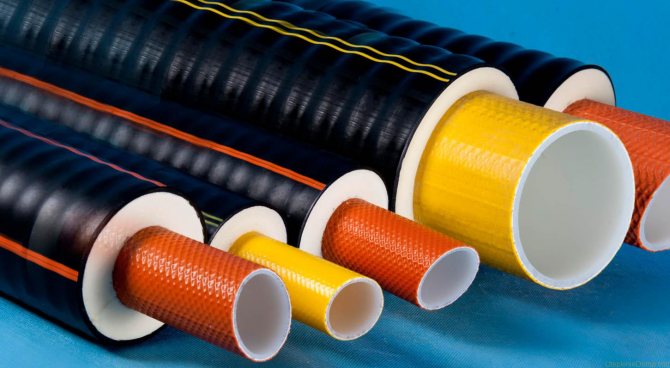

According to the method of application and the form of release, materials for insulation of the heating circuit are divided into the following categories:

- Sheet (piece) material.

- Insulation in a roll.

- Insulating casing elements.

- Filling heaters.

Below we will consider the most popular types of insulation materials.

Varieties of insulation materials

After insulating pipes in heating networks, the efficiency of the entire system increases significantly, the level of load on the heating boiler decreases and fuel economy increases. For this, pipe insulation of various types is used. When choosing a heater, it is important to keep in mind the functionality of the heat insulator and the features of the installation technology.

There are the following types of pipe insulation:

- in rolls;

- piece;

- in the form of a casing;

- sprayed heat insulators;

- combined options.

Insulating materials will allow you to insulate supporting structures, chimney pipes, ventilation ducts and various pipelines. When choosing materials for insulation of pipes for hot water supply or heating, laid outside the building through the air or underground, it is necessary to use moisture-resistant types of insulation. Among the universal properties of materials suitable for insulating heating pipes inside and outside the house are:

- reduced thermal conductivity;

- resistance to the influence of active chemicals. substances;

- non-susceptibility to the corrosion process;

- fire resistance;

- harmlessness to human health;

- ease of installation;

- long service life.

When choosing an insulating material for pipeline insulation, it is also necessary to take into account the diameter of the pipes, their location and operating rules, as well as the operating temperature range of the coolant.

Polyethylene foam

Thermal insulation for heating pipes made of polyethylene foam is in high demand. It has a very affordable price and is very functional. The thermal conductivity of the insulation is approximately 0.035 W / m • K. The cellular structure of the material makes it lightweight and protects pipes from unnecessary stress.

This type of insulation used for hot water supply and heating pipes is slightly flammable. If there are no open flames nearby, the material will extinguish on its own. During combustion, the release of toxic substances practically does not occur, which makes it possible to consider foamed polyethylene as safe for health. The material is not afraid of moisture, since it does not allow water and steam to pass through. It is perfect for insulating communications both in the basement and outdoors, including steel pipes.

On sale you can find polyethylene foam in rolls or in the form of ready-to-use casings with an internal channel for laying pipes of various diameters. The casing has good elasticity and a longitudinal cut is provided on the side to simplify installation over pipes. The cut itself and the joints of the insulation are fixed with tape for installation. In places with a complex configuration, material in rolls is used for insulation, which is wound in several layers and is also fixed on tape.

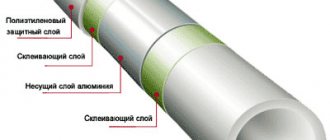

In addition to ordinary polyethylene foam, another, more modern type, called penofol, can be found on sale. The main difference between penofol and foamed polyethylene is its outer surface, covered with a layer of aluminum foil. The metal layer has the property of reflecting heat, which can significantly reduce the level of heat loss. Sleeves made of foam foam are characterized by increased flexibility, which allows them to perfectly fit pipes even in difficult sections with sharp turns.

Expanded polystyrene

Also, a polymer material that has become a traditional one, called, because of its rigidity, "shell". The insulation consists of two hemispheres with recesses for the size of the insulated pipeline elements.

- low cost;

- small value of heat transfer;

- moisture resistance - polystyrene foam does not absorb liquid;

- ease;

- ease of installation;

- the ability to combine with metals and polymeric materials.

The main disadvantage is the inadmissibility of using on excessively hot pipes.

Advantages and disadvantages of PSP insulation

PPS shell for pipe insulation for domestic and industrial use has the following advantages:

- Low thermal conductivity for efficient heat storage.

- Long service life - the material can be used for up to 50 years in a space isolated from sunlight, PPP does not rot and decomposes very slowly.

- Although conventional foam is not a strong and dense material, its density increases significantly when extruded (compressed). The manufacturer produces several groups of foams with different parameters; in the manufacture of the shell, a technology is used that allows you to select a material that is suitable in terms of density. The insulator can be made of the popular type - Penoplex, which has high strength characteristics.

- The shell structure is made in the form of prefabricated segments - this makes it possible, if necessary, to easily dismantle the installed insulator and use it repeatedly.

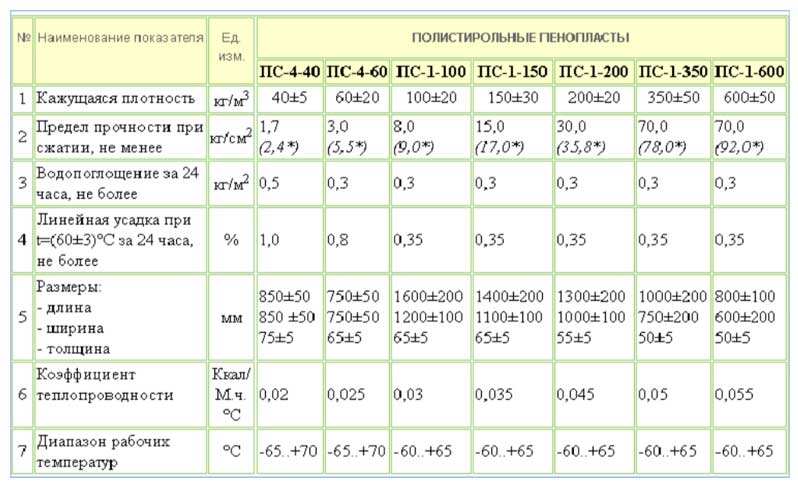

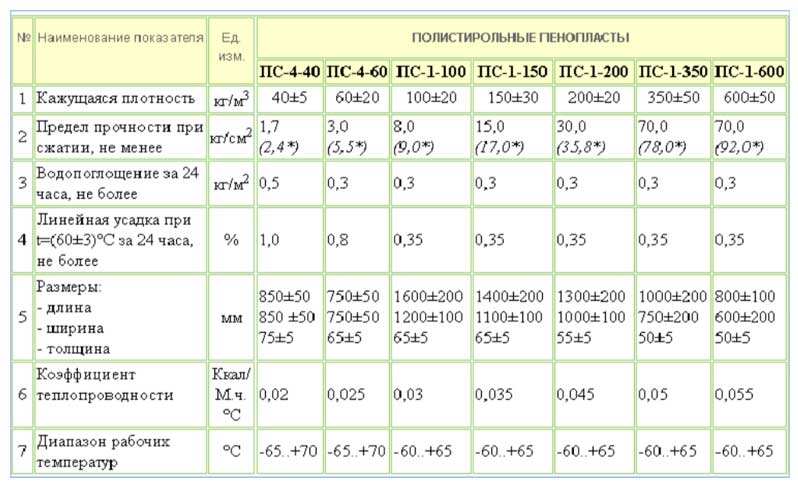

Fig. 4 Substation parameters

- Expanded polystyrene practically does not absorb water, therefore, after installation, they protect the pipeline from the negative effects of moisture.

- The material is resistant to ambient temperatures from -50 to +80 C. and is able to withstand temperature drops in a wide range.

- Polyfoam is not affected by natural chemical elements contained in soil and water (salts of various metals), it resists mold and mildew well.

- The casing is lightweight and is distinguished by the simplicity and speed of the installation method - it is within the power of one person to insulate pipes with its help.

- The shell is universal - it can be made to order of any size, used outside and inside the premises.

- The material is harmless to humans, unlike outdated glass wool, when working with it, the use of special protective equipment is not required.

- Styrofoam is considered to be an excellent noise absorber - this gives it an additional advantage when used in residential areas.

- The shell has a high decorative effect, pipes insulated with it do not disturb the interior of the room when open.

- Expanded polystyrene is slightly flammable and does not support combustion, after the disappearance of the fire source, it spontaneously extinguishes within two seconds.

Fig. 5 Example of insulation of a well PPS

The disadvantages of the material include its following parameters:

- Styrofoam decomposes quickly when exposed to ultraviolet radiation, therefore, its surface must be additionally protected in the open air.

- Many common chemicals in the home and construction industry degrade polystyrene, so it cannot be painted or coated with most liquid synthetic materials.

- When burning, the foam emits poisonous smoke, which causes great harm to human health.

Penofol with a heat-reflecting aluminum foil layer

This insulation roll is an aluminum foil with a layer of polyethylene foam applied. The material is lightweight, reliable and easy to use.

Whatever material a home craftsman chooses, pondering how to insulate heating pipes in the ground, he should remember that not only the type of insulation is important, but also the quality of the work performed; otherwise, the cost of the material will be in vain.

Uninitiated people may doubt the advisability of insulating the pipe running from the boiler room to the house along the street. In fact, why do we need hot line insulation?

How to insulate heating pipes

The range of modern heaters is impressive. Each material has disadvantages along with advantages. The use of each type of insulation must be economically justified and appropriate for the specific operating conditions. For example, if low temperature water is supplied in the heating pipes, then you can ignore the flammability of the material, since in the specifically considered situation, spontaneous combustion is excluded.

It should be noted that before installing the insulation on a metal pipe, the surface should be prepared:

- First thing clean the pipe from dirt and a destroyed layer of old insulation.

- Thereafter apply a layer of special anti-corrosion agent.

- Then you can proceed to installation of thermal insulation.

Why do you need to insulate street communications?

It would seem that this is an unnecessary occupation. Well, let's say the location of heating pipes in the open air, from the house to the boiler room, cannot be done otherwise. But they are always hot, so why also protect them from the cold?

In fact, outdoor pipe insulation is essential. The heat supplied through the highway is “lost” on the way in the cold. That is, the pipe, even in frost, will not freeze if a hot liquid flows in it. But the efficiency of the return will decrease, and accordingly the energy consumption will increase and, as a result, the prices spent on heating.

This is especially true for the DHW system.When insulating a pipe outdoors, the goal is primarily to maintain the temperature. The same measures will not be superfluous for the main pipelines in the autonomous heating of the house.

Features of pipe insulation with expanded polystyrene

Expanded polystyrene is called a modification of foam, consisting of small granules, which make up only 2% of the total volume of the product. The rest of the space is occupied by air. Microcells with thin walls do not allow heat to pass through and provide high thermal insulation properties of the material. There are two types of products - ordinary and extruded. The latter has much better performance characteristics, is not afraid of water, but it costs much more.

The communications of heating systems, hot water supply, water supply, sewerage, air conditioning are insulated with expanded polystyrene. Its use avoids freezing, clogging and destruction of structural elements. Correctly selected thickness of the product makes it possible to place plumbing systems above the freezing point of the soil and not dig deep trenches. The material is often used to insulate pipes for deep laying of communications - it practically does not rot and retains its properties for up to 50 years.

The amount of heat carrier loss when using expanded polystyrene is reduced to 6 W per hour, which is the recommended value in European countries. Effective insulation keeps the temperature of the energy carrier moving from the source of generation to the point of consumption. It saves heating costs.

Indoor communications are extremely rare. Outside the building, plumbing systems must be thermally insulated in such cases:

- The pipes are located with a slight slope in relation to the horizon.

- The items were buried shallowly.

- If there is a water supply from the well to the house, a sewage system from the house to the septic tank, a heating system from the boiler room to the buildings.

- If there are many turns in the system.

- It is also advisable to insulate pipelines embedded in walls or located under the floor or in the cellar. In this case, they give off some of the heat to the partitions or to the ground. This is especially true for heating elements.

For insulation of pipes with expanded polystyrene, a shell is made - a special structure of two or more parts. It allows them to be used in communications heated to +80 degrees, on air and underground routes. At high temperatures, insulating gaskets are additionally used, which are laid on the products before installation. In this case, the temperature of the coolant can reach +110 degrees.

Usually the finished shell is made of self-extinguishing expanded polystyrene PSB-S-15, PSB-S-25, PSB-S-35. Products of this density can be used to insulate pipes installed in any way, except for channelless ones. Stiffer cylinders, which are produced from workpieces of high density (for example, 50 kg / m3), are used for channelless stacking. An alternative to ready-made forms from this material can only be deep laying of communications.

A shell for pipes made of expanded polystyrene is made of different diameters from two or more pieces of 1 m length.The minimum diameter on which the cylinder can be put on is 17 mm, the maximum is 1220 mm. The casing with a diameter of more than 20 cm consists of 4 parts. Very large items are made from 8.

On the halves there are small projections and milling, which facilitate their joining. After laying, the parts are fixed in various ways - gluing, plastic wrap, tape, metal clamps. The connectors allow you to quickly disassemble the insulating layer and carry out repairs without destroying it.

You can also insulate pipes with narrow segments. A rarer case is the use of products without connectors, but they are inconvenient for installation, because put on before assembling the system.A good option is the use of samples that are covered with expanded polystyrene in the factory.

To protect against mechanical stress, the shell can be covered with foil, fiberglass, fiberglass, etc.

When choosing a shell, you need to focus on the following points:

- The dimensions of the insulator are selected depending on the diameter of the pipeline.

- The thickness of the material affects the quality of the insulation. The larger the layer, the less heat energy is lost. Typically, the wall thickness does not exceed 5 cm, which is sufficient to prevent water from freezing in the underground system.

- There are also cylinders on sale that can be used with a heating cable. They differ from standard shells by the presence of a groove for laying the wire.

- Many manufacturers make samples for individual orders, of any size and shape.

Technological requirements for insulating material

The modern market is rich in various offers, so there will be no problems with the choice. In order to reliably insulate the highway on the street, it is better to give preference to specialized materials that meet the following characteristics:

- low thermal conductivity;

- resistance to aggressive environment;

- wide range of operating temperatures;

- long service life;

- simple installation.

Several materials meet these criteria, and each option is subject to consideration.

Features of insulation with mineral wool

Material that does not need extra words. An old, reliable product for pipe insulation, indoors and outdoors. With its use, not only the insulation of the pipe from the cold is provided, but also protection from external factors. The material does not burn, is immune to acids, and is inert to alkalis and other chemical compounds. The cost of mineral wool, which is one of the lowest in the segment, also has a positive effect.

Like most porous insulation materials, mineral wool is hygroscopic and absorbs moisture well. This is a disadvantage. Water absorbed into the material will contact the pipe, causing a corrosion reaction. Therefore, using it as a heater for highways on the street, it is necessary to additionally provide waterproofing. But with an eye on which pipes are selected for heating the house. Plastic or polypropylene does not require such modifications. If the line is laid from metal pipes, then outside the insulation is wrapped with roofing material or foil films. Which will certainly affect the increase in the cost of work.

Technical characteristics and quality of expanded polystyrene

Simplicity and quality distinguish this type of outdoor heating pipe insulation. These are two polystyrene half-cylinders fixed with a special tape. At the joints, special grooves are provided to ensure a tight fit.

The cost of polystyrene foam insulation is not much higher than mineral wool. It is preferable to use it for insulating water pipes in the basement and attics. It is convenient to insulate them and risers. Simple design and easy installation, allow you to fix it even in hard-to-reach places, bypassing complex exits of pipe lines.

On a note. In everything, the positive material has a small drawback - the impossibility of processing folds, which makes you think about its use.

Reliable protection of communications with penoizol

Insulation of heating pipes with penoizol is considered one of the most reliable. In terms of quality, this material can be compared with polystyrene. The only difference is in the application. The pipe is insulated in the open air by spraying a liquid product, which, after solidification, acquires a shape characterized by high density. For individual heating, this is one of the best options. It is possible to treat the most inaccessible places with penoizol.

No additional work is required after processing.The material is absolutely inert to any impact: it does not absorb moisture, air does not pass through it, chemicals do not cause any harm to the structure. For decoration purposes, you can wrap it on top with roofing felt.

Liquid insulators for the protection of street communications

These are relatively new materials that can be used to reliably insulate heating pipelines. In this line, there are two types of insulators:

- Sprayable. Spray applied and requires special equipment;

- Painting. For application, use a regular brush or roller.

The advantage of both types of liquid insulators for heating pipes is the ability to apply to any, even the most inaccessible places.

Foamed polyethylene: when is the best time to use this material?

Such pipe insulation is sold on the market in rolls. This is a foil-coated film of various thicknesses. It is cut in parts and wrapped around the lines. The advantages of expanded polystyrene include the following qualities:

- moisture resistance;

- durability;

- easy installation;

- hygroscopicity.

Masters have different opinions about this material. Given the low thickness, at least 3 layers must be applied to create a cold air barrier. If polypropylene pipes are selected for heating, then at least 5 layers. The work is simple, but time consuming. In addition, many have doubts about the reliability. Insulation in 3 layers will protect the highway in regions with a mild climate. To prevent pipes from freezing in severe frosts, it is necessary to wrap them in at least 7–8 layers, and this is already a high material consumption and laboriousness.

Foamed rubber: market novelty on guard of heat

According to its characteristics, such thermal insulation of heating pipes located on the street surpasses all the materials presented above. But it should be noted that the cost of the material also ranks high. Therefore, the range of application does not apply to the private sector.

By class, thermal insulation belongs to roll materials, and of the positive qualities, the following can be distinguished:

- resistance to low temperatures (up to –40 ° С);

- immunity to ultraviolet light;

- fire safety.

Scope of PPP shell

The scope of application of expanded polystyrene (PPS) insulation affects all branches of industrial and municipal services, the technique is the most promising and can be used for insulation in the following cases:

- When insulating and protecting against negative temperatures of main pipelines passing underground and on its surface.

- For the protection and thermal insulation of water supply, heating and sewer pipes in municipal and private households.

- When insulating air ducts of ventilation and air conditioning systems.

- To protect the pipes supplying cold water from freezing when organizing individual water supply in country houses.

- When insulating wells and casing borehole pipes.

Places where communications need to be isolated

Each business has its own nuances. Insulation of the heating pipe and all related work is adjusted by the weather conditions in the region, and by the design factors of the systems. Insulation is necessary if the highways run underground, in open spaces, in attics and basements, and of course in open areas.

Polymer pipes are less susceptible to cold. But nevertheless, in severe frosts, heat transfer is disrupted in them. And, regardless of which of the heating options for a private house is laid, pipe insulation allows you to reduce heat losses, as well as protect them from abrasion and physical damage.

Despite the rigidity, metal heating pipes are also not omnipotent. They are exposed to external factors.In addition to the fact that they give off heat more intensively, the metal is also susceptible to corrosion. Insulation for the heating pipe and hot water supply is able to stop these shortcomings.

There can be no doubt that the insulation of heating pipes is necessary. Long years of operation have shown weak points, so engineers of many companies are struggling to develop perfect materials that help reduce heat losses.

Heat losses in the pipeline are one of the most pressing problems for both autonomous and central heating systems. In the event that utilities are involved in this problem in the regions, then in private houses thermal insulation for heating pipes is the concern of homeowners. And due to the fact that the volume of work is rather small, it is quite easy to do it yourself.

Functions of heaters for heating pipes

In a private house, the heating boiler can be located both inside the premises (for example, in the basement), and in a separate outbuilding for household purposes. In the second case, most often there is no centralized gas supply and solid materials such as peat briquettes, coal, pellets, and firewood are used for heating.

Often in private houses there is a sauna or a bathhouse located outside. This avoids complicating the design of the heating system by the presence of a tank for heating water. The water supply has to be led from the heating boiler, which can often be located at a considerable distance. When choosing a material for insulating heating pipes, the following conditions must be taken into account.

Reducing heat loss

The essence of any heat insulator and its main task is to protect the surface of the pipes from the negative influence of the environment. In this case, the reduced thermal conductivity of the insulation will reduce heat loss and the heated pipeline will cool down much more slowly than in the case of non-insulated pipes.

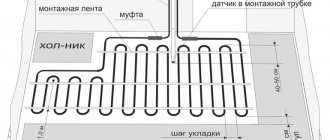

Almost all heating mains are arranged in such a way that communications pass both above the earth's surface and below it. For external pipes, a soft heat insulator is usually used, and in the case of underground placement, a hard insulating layer is created to compensate for the ground pressure.

Eliminate the risk of freezing

If hot water supply inside an individual heating system goes from the boiler to a building standing at a decent distance, then most often underground utilities are laid. In this case, it is important that the pipes go below the level of soil freezing. But if there is no possibility of locating the pipeline at a considerable depth, then long interruptions in the supply of heated water are possible if it is not used constantly. this happens because the remainder of the liquid in the pipes freezes in frost. To protect underground utilities from freezing, they are insulated by protecting them with a hard shell or a soft shell, which are located inside the pipe channels.

How to choose a heat insulator?

A wide range of insulation makes it possible to choose a specific type of thermal insulator that is most suitable for a specific situation and wallet.

Requirements for heat-insulating materials:

- a low coefficient in specific thermal conductivity, is the main condition for the suitability of the material to perform the main task (thermal insulation);

- sufficiently high thermal stability - the material must be able to maintain its characteristics and structure under high temperature conditions (105 ° C - in use, up to 700 ° C - in production) without any reaction with surrounding substances, not to be a catalyst of chemical reactions and not to emit harmful substances.

- chemical resistance - the ability of a material not to react with organic substances;

- sufficient hydrophobicity - water-repellent characteristics that prevent the heat-insulating layer from getting wet, due to the fact that when the pores are filled with water, the material becomes an excellent heat conductor and at the same time contributes to the formation of corrosion on the pipeline;

- vapor permeability - the ability of a heater to dry quickly if it gets wet;

- air permeability - a characteristic that prevents the heat insulator from filling up by air movement with dust particles, which increases the thermal conductivity of the insulating material (all solid heat insulating materials meet this requirement, for soft ones additional protection is needed);

- durability - the material must retain its characteristics and meet all requirements throughout the shelf life, which is indicated in the instructions for its use.

Expanded polystyrene and its types

Insulation for expanded polystyrene pipes

Styrofoam is a type of polystyrene. The feedstock is polystyrene, but polydichlorostyrene, polymonochlorostyrene and other styrene copolymers can also be used. The manufacturing technology is simple: a gas is dissolved in the polymer mass, which fills the styrene granules. The mass is heated with steam. Under the influence of temperature, the granules grow many times over until they fill the mold.

Most often, natural gas is dissolved in polystyrene. But if they want to get a fire-resistant version, the mass is filled with carbon dioxide. There is also vacuum expanded polystyrene: no air or gas is needed during its production.

Finished polystyrene foam consists of fine cellular granules. Inside them there are micropores, between them there are voids. The presence of numerous small cavities ensures high thermal insulation properties of the material.

The characteristics of expanded polystyrene are determined not only by the composition, but also by the manufacturing method.

Pressless

The polymer granules are dried, then foamed at +80 C. The blowing agent is isopentane. The operations are repeated twice. The material is dried in the form, since even with a good density - up to 37 kg / cubic meter. m, it is fragile. However, its manufacture requires almost 2 times less isopentane, which provides an affordable cost.

Pressless expanded polystyrene is more often used for insulating building structures than pipes. The pores in it are open, it is sensitive to moisture.

Press

The prepared raw material is placed in a mold and heated to + 120–145 C under a pressure of 8–12 MPa. In this case, the particles of the mixture are sintered together, and the gas former releases gas. After cooling, the workpiece is removed from the mold and heated in chambers for 90–120 minutes. The polymer softens slightly when heated and the released gas is evenly distributed throughout the volume.

The pressed material has higher noise and heat insulation qualities. It belongs to electrical insulators and is used in the electrical and radio industries.

Extruded

Extruded polystyrene foam

Extruded polystyrene foam for piping is the best option. The structure of the material is fine-celled, very uniform, the cells are closed, so the insulation is not afraid of water. It is much stronger than the previous options and is actively used in construction.

Foaming agate is introduced into the polymer melt under a pressure of 10–20 MPa. The melt is quickly cooled to + 130–140 C and extruded. The material is produced in the form of plates and films and is used for thermal insulation of a wide variety of structures.

Instructions on how to insulate pipes yourself

- it is necessary to calculate and purchase thermal insulating materials;

- wrap the pipes with foil tape or foil. Foil in this case plays the role of a heat reflector;

- installation of insulation around the pipe. The rigid sectional casing and soft insulation just need to be put on the pipe.With regard to other soft materials, they must be cut into blanks equal to the width of the pipe diameter. Then wrap it around the pipe and fix it with clamps, tape or wire. With rigid insulation, the situation is more complicated. From it, it is necessary to create a kind of box around the pipe (or use pipe shells of the required diameter);

- inspect the pipe for the presence of "cold bridges" and eliminate them;

- fix thermal insulation on the pipe with metallized or plumbing tape;

- if necessary, cover the thermal insulation with a protective material (film), and seal the joints with adhesive tape.

The money spent on the purchase and insulation of pipes quickly pays off thanks to savings on payments for heating the home.