In this article, we will talk about what waste oil heating is and how to implement it in a country house. In addition, we will consider the most common misconceptions associated with the use of this type of fuel and explain why they are untenable.

But first, let's define what this fuel product is and what its main characteristics are.

Development is a cheap fuel, the value of which is obvious

Waste oil, or as it is also called technical oil, is used fuel and lubricants (machine, transformer or motor oil). The product, in accordance with GOST 26098-84, is fuels and lubricants merged from working systems, which have worked out their resource and have lost their original operational qualities established by the normative and technical documentation.

Transformer oil in the heating system increases the heat transfer of the batteries

Exhaust is a liquid synthetic petroleum product suitable for use as a lubricant, as an impregnation for wood and other porous materials prone to decay. But the main area of application of mining is the use as an energy carrier during the operation of liquid fuel heating boilers.

Features of the operation of heating equipment

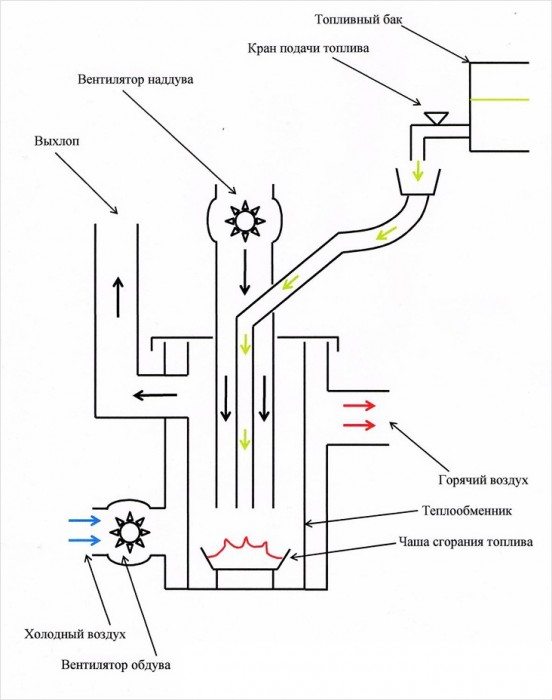

Pre-assembled boiler diagram

Modern waste oil heaters are liquid fuel hot water boilers, which, if necessary, can be operated with other types of energy sources.

Structurally, the equipment is a combination of the following elements:

- fuel supply pipe;

- preheating chamber;

- a branch pipe for supplying compressed air with an air mixture blower;

- burner with nozzle and blower;

- a heat exchanger for one circuit or two heat exchangers for a two-circuit installation;

- exhaust gas evacuation system.

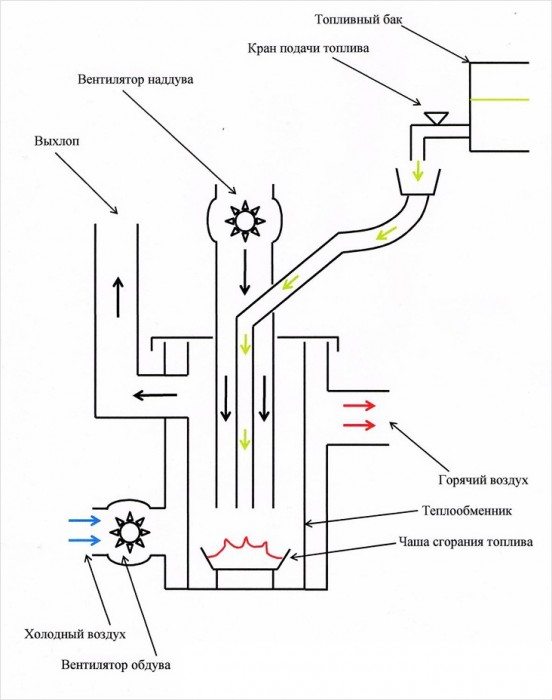

Diagram of a homemade burner for burning mining

The design of the device does not have an open flame combustion chamber. Moreover, the device does not contain elements that are exposed to strong heating, which provides an acceptable level of safety.

Among the advantages of the equipment, such points should be noted:

- The affordable price of the energy carrier, since mining can be purchased inexpensively in most car services, service stations, etc.;

- High efficiency of equipment and, as a result, the ability to heat both small summer cottages and full-fledged country houses;

- High fire safety of the heating process, since waste oil is characterized by mediocre combustibility in comparison with other types of fuels and lubricants.

A more complex version of the previous scheme

Among the disadvantages of this heating method, we note the following points:

- Lack of fully automated equipment on the market;

- The need to build a special storage facility for fuels and lubricants;

- The need to equip a special room for a boiler room;

- The need to establish contacts with organizations where fuel can be purchased.

So, as we could see, using a waste oil heater in a country house is profitable, but troublesome, and this must be taken into account when choosing these devices.

DIY stove for use in a car service

Like other types of boilers, installations operating using mining can be single-circuit or double-circuit:

- Single-circuit modifications allow you to heat the coolant circulating through pipes and radiators.

- The double-circuit modification allows you to heat the coolant and water used for household needs.

Important: Double-circuit units can be equipped with either two or one heat exchanger, which, in turn, insignificantly affects the comfort of operation of heating equipment.

Like other boilers, heaters operating with the use of working off can be equipped with an expansion tank for natural circulation of the heat carrier or an axial fan for forced supply.

After we have decided on the main design and operational features of equipment operating on waste oil, we will tell you about the most common myths and misconceptions typical for the use of this type of fuel.

Myth 1: Cannot be used - must be disposed of

Waste is considered to be a toxic product that must be disposed of immediately and is not suitable for subsequent use.

This is a typical fallacy that has no rational explanation. In reality, used oil is used all over the world as an inexpensive energy source.

Again, the degree of toxicity in this case does not exceed similar indicators typical for other types of fuels and lubricants. By the way, in spite of the fact that in the territory of the post-Soviet space, mining began relatively recently, many specialized companies abroad are purposefully engaged in the production of specialized equipment for this type of energy carriers.

Myth 2: Difficulty acquiring fuel

It is believed that mining is not easy to acquire, as the number of points of sale is limited.

This is another misconception, since the scope of application of various lubricants is extremely wide, and therefore fuel for economical heating of your home can be purchased at car services, agricultural machinery service stations, railway depots, ports and repair docks, power plants and substations, restaurants, etc. other catering establishments.

Important: There is no mistake with the catering industry, since vegetable oil that has served its life can also be used as fuel.

This list can be continued indefinitely, and in each of the listed organizations it is possible to agree on the constant shipment of one or another volume of mining, the price of which will be more than affordable.

For a better idea, a few numbers:

- Every small town with a population of 100,000 has at least 50,000 cars and trucks.

- The listed vehicles annually give out over 300,000 liters of mining.

- To the obtained figures, we add the volume of cheap mining fuel obtained as a result of the activities of small and medium-sized industrial enterprises with loaders, machine tools and other equipment, which must be lubricated during operation.

- To this we add hundreds of units of agricultural machinery in nearby state farms or in farms... Moreover, in each unit of such equipment, at least 10 liters of oil are replaced annually.

- Now let's count the number of compatriots who have specialized equipment for burning this promising fuel.... There are only a few such people, since few people know about this technology.

Consequently, you can use all this volume of almost free energy carrier, you just have to want it!

Myth 3: Environmental insecurity

Foreign-made boiler with a high level of automation

There is a misconception that the use of waste oil as a fuel is fraught with a lot of harmful emissions into the environment. In fact, each type of energy carrier based on oil emits a certain amount of harmful substances during combustion; it is a different matter than burning these energy carriers.

For example, you can burn diesel fuel with the gluttonous engine of a truck, which smokes, releasing clouds of suffocating smoke. At the same time, diesel fuel can be poured into a modern passenger car that meets all environmental standards. And we can say that in the latter case, the use of diesel fuel will be safe for the local ecosystem.

The situation is the same with working off. If you use a home-made boiler, the harm to the environment will be noticeable, with low productivity. On the other hand, if the heating is equipped with modern installations of such brands as DanVex (Finland) and CAEQ (Canada), the oil will burn completely, and practically no smoke will be emitted.

Important: Statistics on the use of modern burners of Western European production show that the combustion of mining is an order of magnitude safer for the environment than the combustion of coal, firewood and diesel fuel.

Myth 4: the need for licensing

Domestic boiler certified for use in the CIS countries

It is believed that the instructions for the installation and operation of waste oil heating equipment require mandatory licensing. In reality, this is not the case, since licensing is only mandatory for gas powered devices.

The use of mining as an energy source is equivalent to the operation of conventional liquid fuel boilers. Of course, you will have to take care of fire safety, but no one will control the compliance of the system with these standards.

Myth 5: Stopping equipment after stocks run out

The photo shows the operation of the burner

There is a popular belief that it is enough to run out of oil in the fuel tank and your heating system will become completely useless.

In reality, the situation is not so hopeless. Most of the modern burners installed in foreign-made boilers are versatile in terms of the fuel used. Thus, if you run out of oil, you can just as well use diesel fuel or gasoline.

Water - pros and cons.

One of the most common and readily available coolants is water, which is not surprising, because it has a lot of advantages:

- high fluidity (due to which it can penetrate everywhere),

- low viscosity,

- non-toxic

- easy accessibility,

- low cost.

And also water transfers heat very well.

But, unfortunately, this coolant also has disadvantages.

- Since the heating system of a private house often consists of metal elements, over time, due to interaction with water, they become unusable and rust. And where hot water passes (above 80 degrees), scale is also deposited on the pipes.

- Physical properties of water, due to which it freezes at temperatures of zero and below. Therefore, a house where water is a carrier of heat cannot be left without heating in winter, even for a couple of days. Indeed, when freezing, this liquid begins to expand, which can simply break the pipes.

In this regard, whoever uses water in their heating, it is necessary to constantly monitor the performance of the latter, as well as flush the system from rust and scale at least once a year.

Output

Now you know what heating systems are based on waste oil boilers. Moreover, you may have read general information about the cost-effectiveness of using such systems.

It remains to consider the prospect of using this equipment in your country house and make the appropriate choice, in which the video in this article will certainly help you.

Did you like the article? Subscribe to our channel Yandex.Zen

Nuances

To ensure smooth operation of the hydraulics, the lubricant must meet certain standards:

- On the territory of Russia, GOST has been adopted that meets international standards. Hydraulic fluids correspond to the number 17479.3-85, consisting of three groups of signs marking the field of operation, name and viscosity class.

- The hydraulic mechanism operates at high temperatures, therefore, the flash point of the hydraulic oil must be high, as opposed to the freezing point - it must be very low.

- Lubricants are thoroughly filtered, however, polymer additives accumulate on the filter element, which are added to the composition to increase the viscosity index. In an emergency, this is indicated by the pressure sensor. When changing the oil in the hydraulics, the condition of the filter must be checked and, if necessary, replaced.

- The quality and condition of the seals should be checked regularly to avoid leaks. The material from which they are made must be compatible with the oil used. It is advisable to select branded seals designed for a specific hydraulics.

- Oils for different hydraulic systems must not be mixed.