In heating, water can reach 80-90 ° C. And if this is still normal for pipes with radiators, then such a temperature is too high for a warm floor. In order to be able to stay on the floors normally, a three-way valve is used. Although it is installed far from only for these purposes, it is indispensable in a system with almost any solid fuel boiler. Let's figure out what kind of mechanism it is, what it is for and how to choose the right three-way valve for the heating and water supply system.

What is it and why is it needed

This is what a classic three-way valve for a heating system looks like.

As the name suggests, this valve has 3 strokes. You can even call it a tap, since it belongs to the shut-off and control valves. It looks like an ordinary tee, but inside its structure is much more complicated. Roughly speaking, it serves to change the temperature of the water. There are two ways: at the first, the return is mixed with the supply to lower the temperature; the second method, on the contrary, divides the streams by dumping hot water into the return line. This is useful in various cases:

- Warm floor... The return flow and heating supply are connected to the valve. Since the return flow is colder, lower temperature water is supplied to the floors. In this case, the temperature of the remaining heating remains the same.

- Maintaining temperature... For the normal operation of almost any heating equipment, it is necessary that the return flow is not colder than the supply by 60 degrees. Otherwise, the boiler will not last long. Therefore, the valve takes water from the supply and sends it to the return line.

- Condensation protection... For the same reason. If water gets into the heat exchanger warmer than the dew point, condensation begins to accumulate on it.

- overheat protection... Modern boilers are equipped with various sensors. If it is, for example, a simple solid fuel boiler, it will continue to work even if it overheats. The three-way valve solves this problem.

- For piping an indirect heating boiler... To have hot water in the house, you can connect a boiler to the boiler. And then the water will be heated by heating. The three-way tap serves for uninterrupted supply of hot water. It opens when the temperature of the water in the boiler drops.

- When organizing a bypass... In some cases, it is required to direct water along an alternative path - bypass. For example, for more efficient heating. The easiest way to do this is through a three-way valve. It will open and close at the right time.

But why install a valve when you can just lower the temperature? The question seems logical, but in fact, in ordinary boilers at low temperatures, the heat exchanger quickly fails. For this mode of operation, a condensing boiler is better suited, but their price is much higher. Therefore, it is better and easier to install a three-way valve.

As you can see, there are many ways to use it. In some cases, it is used to improve the energy efficiency of the system. In others, it is an indispensable device for connecting equipment.

Valve design and operation

Structurally, a three-way valve for heating with or without a thermostat consists of a metal body with three branch pipes. Inside the body there is a mechanism that automatically controls the coolant flows. This mechanism is of two types:

- Saddle... It is controlled by a working rod that moves up and down. The end of the stem is made in the form of a cone.The valve has a seat inside which is partially or completely overlapped by the tapered stem tip as it moves.

- Turning... Its regulator is a ball or sector that has an opening for the passage of liquid. This ball turns, opening or shutting off the coolant flow. The principle of operation is the same as that of a conventional ball valve.

Let's take a quick look at how a three-way valve with a thermostat works. The temperature of the coolant is kept within the specified limits by the valve. When the temperature changes with respect to this limit, the volume of the expanding liquid (gas), which is in the thermostat, changes. The fluid presses on the stem, which opens the line with cold or hot fluid. Thus, the temperature is again equalized to the set values.

The device and principle of operation of the three-way valve in the heating system

To make it easier for you to understand the principle of operation, I propose to consider this scheme:

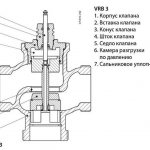

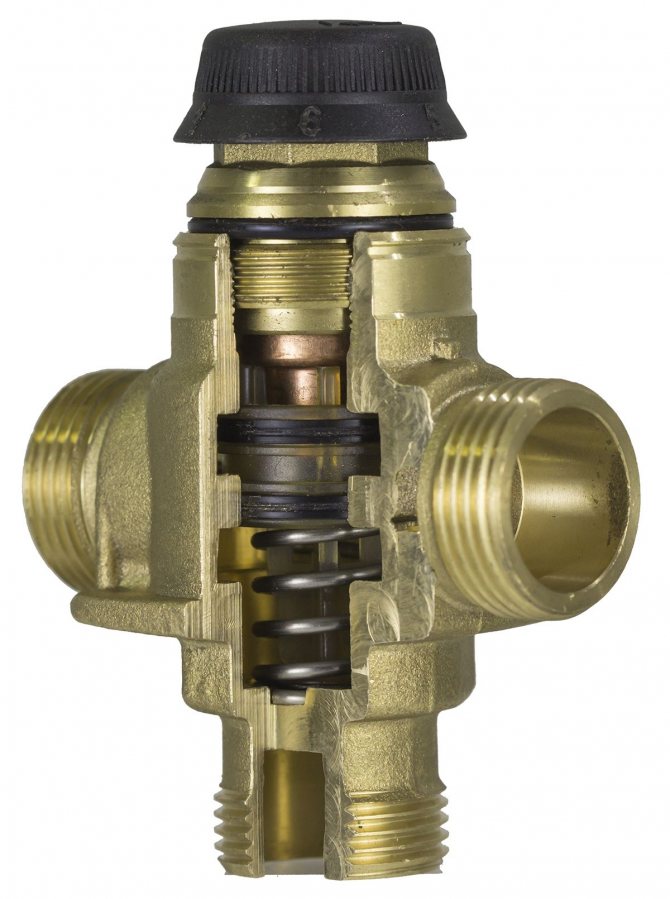

Sectional design of the three-way valve.

When a certain temperature needs to be reached, the stem rises, opening the duct. This is similar to the principle of operation of shut-off valves. And the mechanism itself is called a saddle. Instead of a rod, a ball or rotating sector is sometimes used. Exactly the same as in conventional ball valves. This mechanism is called rotary. On the diagram, they can be depicted as follows:

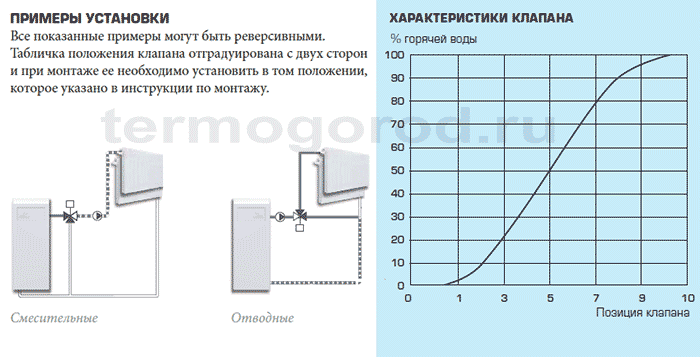

I will talk about what exactly controls the rod or the ball a little later. For now, let's take a look at each view. Let's start with the mixing valves:

As you can see, hot water comes in on the left, and cold water from below. The stem rises if necessary, allowing the two streams to mix.

And this is how the work of the separating valve looks like. Here, on the contrary, hot water enters on the right, and can come out to the left or down. If the temperature is normal, the stem rises. If a higher temperature is required, the stem is lowered, sending hot water down. That is, to the return line.

From the instructions for the valve type VMR from Mut International.

Typically, thermo-mixing and separating valves do not overlap completely. But the switches, as you can see, close one of the pipes, and open the other. There is no mixing or separation.

Sectional view of a typical 3-way valve.

Design features of the motorized valve

The design of the motorized valve is different for the separating, mixing and switching models. All types of control valves have a metal body, which is internally divided into three parts, between which there is a regulating device - a stem. It is in its shape and principle of operation that the design of the three-way valve differs.

We recommend that you familiarize yourself with: Using PVC-U pipes in pressure systems

An electric actuator is a part that combines all three types of three-way valves. With the help of a built-in drive with a controller, automatic regulation of the water temperature is carried out due to the response of the device to changes in the water temperature. An electric drive, which is also called a servo drive, is a motor, but it does not rotate around its axis, like conventional devices, but makes a turn in a limited radius.

Attention! Externally, a three-way motorized valve can be recognized by the presence of a rotary lever made of plastic, on which there is a mark for denoting a scalar value.

How to choose a three-way valve for a private house heating system

Now you know for what cases certain types of valves are used. But this is not the only selection criterion, because the valves have several methods of temperature control and different flow rates. And the material of manufacture may differ. Let's take a closer look at this.

Temperature control method

Manual.

Let's start with manual adjustments.Here the stem is connected to a valve or handle, under them there are marks, with the help of which the temperature is regulated. This is the simplest and cheapest method, so some people consider it more reliable. But I believe that everything depends on the company: if the valve is of high quality, then it will work no less with automatic adjustment than with manual one.

| Benefits | disadvantages |

| Low price compared to other types of valves | You have to independently react to all changes in environmental conditions |

| Works without connecting electricity | The heating circuit does not heat up evenly |

Thermostatic.

If a thermostat is built into the structure, such a valve is called thermostatic. It is usually configured only once. Then he himself selects the position of the stem, based on temperature fluctuations. A heat-sensitive liquid or gas is responsible for this: when the temperature rises, they expand and begin to move the stem. These valves are electronic and mechanical. A three-way valve with a thermostat is much more convenient than a manual one, since they work automatically, but it also costs more.

| Benefits | disadvantages |

| Automatic temperature control | High price compared to manual valves |

| Uniform heating of the heating circuit | |

| Mechanical models run without electricity |

Servo driven.

The most accurate are three-way valves with an electric drive. They have a built-in thermostat, but they are controlled by an electronic unit that works on a servo drive. When the temperature changes, the thermostat sends a signal to the controller. And he already controls the drive by raising or lowering the stem.

| Benefits | disadvantages |

| Does not require human participation in temperature control | High price |

| Highest precision of all three-way valve types | Dependence on electricity |

| The highest quality and uniform heating heating | Higher energy consumption compared to electronic thermostatic valves |

I think it is better to opt for the middle option. Manual adjustment is inconvenient and the motorized valve is expensive. And such accuracy is rarely required in a domestic environment.

Manufacturing material

The durability of the product depends on the material used for the manufacture of the case. I want to say right away that sometimes there are valves made of silumin. Although they are much cheaper, I do not recommend paying attention to them. And there are many other reliable materials:

- Black carbon steel valves are durable and relatively cheap. Unfortunately, they corrode, which is why they are usually plated with nickel or chromium. Stainless steel is also often used, but such products are more expensive.

- Cast iron is strong, durable and non-corrosive. But usually these are old-style valves, since more advanced materials are now used.

- The most popular are brass and bronze products. They are durable, strong and rustproof materials. In industrial conditions, where the temperature exceeds 200 degrees, they cannot be used, but they are ideal for domestic needs. I advise choosing these three-way valves, if the material is not listed in the specifications, it can always be identified by its characteristic color and texture.

I would also like to say about ceramics. It is practically not used as a material for the body. But the internal details are often made from it. This is due to the fact that ceramics are not attacked by chemicals. It is also durable.

How to choose and connect to the system the most important element - a security group

Temperature range and working pressure

When choosing a three-way valve, the temperature adjustment range should also be taken into account. For example, a thermo mixer for an underfloor heating is usually set to 30-40 ° C. Although this range is the most comfortable for obtaining hot water. The maximum pressure that the valve can withstand also differs. Some models can withstand up to 16 bar.Although usually in domestic conditions more than 6 bar is not required. In general, the working pressure values for these devices are regulated by GOST 26349-84.

Other

Of course, do not forget that three-way valves have different diameters of the connecting pipes. The most common home sizes are 1 and ¾ inches. The thread can be internal or external.

The number of liters that passes through the valve per hour depends on the throughput indicators. It should be chosen so that the valve has a coefficient slightly higher than the calculated result. For example, if 2 m³ per hour flows through the system, a valve with a capacity of 2.5 m³ per hour should be selected.

But the capacity varies depending on whether the valve is fully open or slightly open. The ratio of these indicators is called the dynamic range of regulation. The higher the ratio, the better the throughput is maintained. The best ratio is considered to be 100: 1, but it is quite rare. The most common indicators are 50: 1 or 30: 1, valves with such indicators can be safely taken.

For many aspiring plumbers, the three-way valve is fraught with mysteries and mysteries. In this article, I will try to explain how a three-way servo valve from three different models will work. We will consider the logic of operation and the electrical circuit for connecting the servo drives.

Option 1:

Price from 6,300 to 9,200 rubles. There may be options for SKUs.

Option 2:

The price is about 2500-5000 rubles, if you try to find it on a Chinese website and order from China.

Option 3.

An expensive option, but there are a lot of options. The price can be about 15-20 thousand rubles.

Wiring diagram for a three-way valve with a servo drive for DHW

The valve can be installed both on the supply line (supply) and on the return line of the pipeline (return).

Many will ask the question:

- And where is it better? For supply or return?

In terms of DHW functionality, this is not important. But there are some nuances why you need to put on the supply or return.

Nuances between supply and return:

1.

The three-way valve is placed on the supply in order to unload the return line of pipelines from any valves that can block the passage of the coolant. Simply put, to drain the water from the heating system. Also helps in starting up the heating system. Filling the system with water and releasing air is better. The three-way valve on the return line will interfere with pouring and draining water from the heating system.

2.

Also, a three-way DHW valve is placed on the supply in order to obtain the correct distribution of hydraulic resistance relative to the pump on the pump line. I expressed myself, of course, difficult. But if you begin to study how the pressure is distributed at each point in the heating system, you will understand the difference in how different valves affect the pressure distribution. This influence will be stronger the more the loss occurs on the valve. Simply put, a low critical pressure may appear in the system at some point. And low pressure can cause cavitation in pumps and not only in pumps.

3.

At very high temperatures (90-110), the three-way valve can be installed on the return. Basically, this should be done where there are solid fuel boilers. Where there is no high temperature protection. The high temperature leads to a leakage of the valves.

Anybody

Do you know why you need to put a hydraulic accumulator on the return line of the pump? Or thinks you can put it anywhere? Do you know why the pump is put on the supply or return?

Answer:

This is because the distribution of pressure at different points of the pipeline changes from where these elements are located. And in some cases, again, the reason becomes the convenience of pouring and draining the coolant in the heating system. Also helps to avoid air pollution and much more.

And why

in the boiler equipment instructions it is recommended to keep the pressure at least 1.5 Bar? Because the pressure in the boiler heat exchanger must not be reduced! A decrease in pressure leads to cavitation of the coolant in the heat exchanger. It also leads to early boiling of the coolant. And all this leads not only to a decrease in the boiler power, but also to the deposition of scale in the heat exchangers, which leads to the deposition of scale and overgrowing of the heat exchangers. This, in turn, will lead to a short service life of the boiler equipment.

Do you think

If the pressure gauge shows 1.5 Bar, does it mean that the pressure less than 1.5 Bar cannot be present in the system at the same height as the pressure gauge?

Answer:

This can be and more often it happens with the owners, who independently figure out where the pump and the accumulator will stand. And they do not understand how the pressure will be distributed after that.

You can learn more about the distribution of hydraulic resistance here: https://infobos.ru/str/601.html

Also, how does the accumulator affect the pressure distribution: https://santeh-baza.ru/viewtopic.php?f=2&t=93

Why do you need a three-way valve for DHW?

The main task of the three-way valve for DHW is to redirect the movement of the coolant from the heating system towards the indirect heating boiler (another heat exchanger) and back in automatic mode.

As soon as the command came to heat the indirect heating boiler, it is necessary to redirect the coolant towards the BKN coil. The heating signal is generated by a special relay located at the BKN (Indirect Heating Boiler). That is, the BKN has a built-in electrical thermo-relay, which provides a switching contact.

Schemes of operation of boilers with three-way valves for obtaining hot water supply

What is an indirect heating boiler?

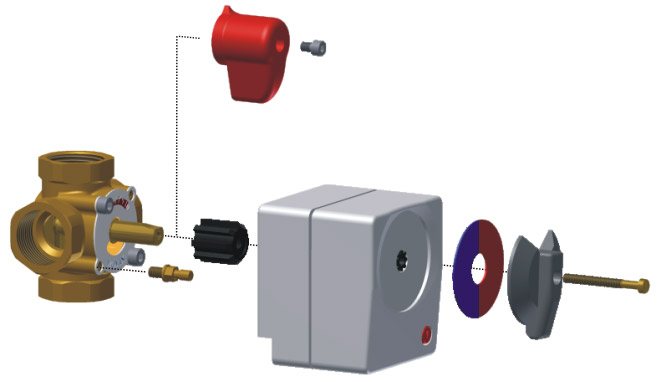

What does a DHW three-way valve look like?

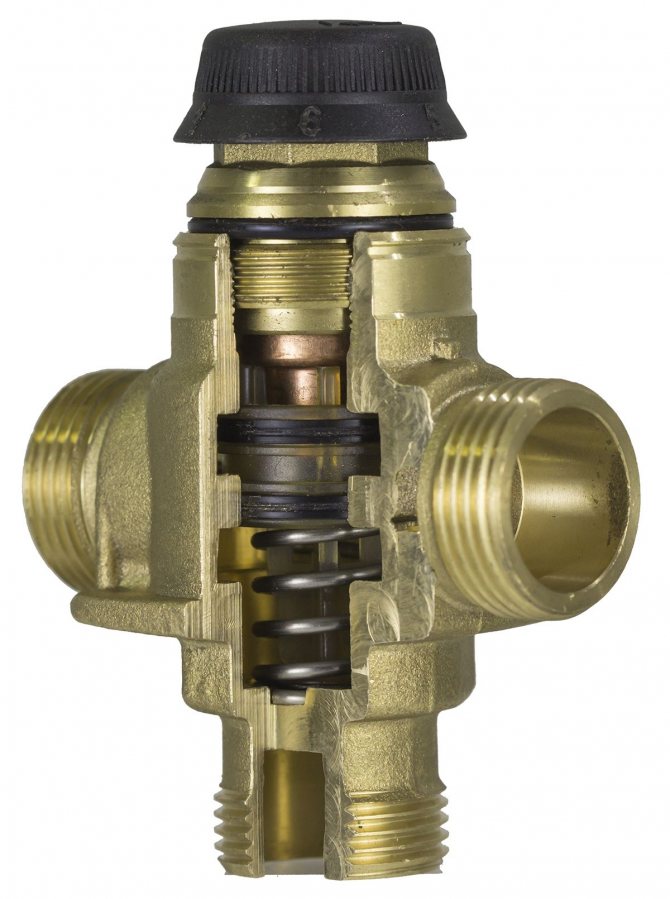

The valve itself can have a variety of shapes. The valve may have a moving stem. There may also be a valve with a rotating mechanism.

Option 1 and option 2

Are valves with stem movement.

Option 1.

Suitable for a private house for up to 8 people and 4 bathrooms. This is a certain stringent valve standard and is not subject to different capacity options. Simply because such a valve is often located inside a wall-mounted boiler. And it often has its own specific diameter and capacity. Unfortunately, I was unable to find its bandwidth.

Option 2.

There can be many options in terms of throughput and choice of diameters.

Option 3.

The rotary valve is called

rotary mixing valve

... The rotary mixing valve can be used not only for mixing, but also to simply redirect the flow of the heating medium to another pipeline.

Option 3

designed primarily for high flow valves. It has the ability to use valves with a large diameter (flow capacity). That is, you can use a different variety of valves with any possible diameter:

Rotary mixing valves.

A servo drive (electric drive) is mounted to such valves.

Option 1.

How does such a valve work? Switching speed approx. 8 seconds.

Such a valve is designed to be inserted inside the boiler. But you can buy it separately. And use it somewhere outside for your own personal functions. This three-way valve model can be installed on various boilers from different manufacturers. Therefore, to buy or order such a valve, you need to contact a store that sells wall-mounted boilers. And ask the seller to order this particular part (Three-way valve 3/4 for Thermona THERM boilers). Suggest to indicate the article: 21053. You can also order it on the Internet by entering into the search: Three-way valve 3/4 for Thermona THERM boilers article 21053.

This valve has one drawback:

From personal experience, has defects in work. That is, when switching direction, the motor cannot stop.And this causes the clamps to crack. This problem occurs when the servo is in a hot environment. That is, it works well for the cold. If the boiler operates at 75 degrees or more, such a problem may appear. I personally ran into this problem and mechanically know why this is happening. There is not enough groove length into which the retainer falls. The motor does not stop in time and the latch function does not disconnect the power contacts of the motor. How this problem is solved is described on the forum: https://santeh-baza.ru/viewtopic.php?f=22&t=266

Wiring diagram of the valve for DHW boiler Thermona?

Wiring diagram with boiler and boiler

More details about the operation of the circuit are written here:

The servo has three pins, one common. If you give a voltage of 220 Volts to two contacts (direction 1 + common) There will be one position. For another position, you need to give a voltage of 220 Volts to the other contact (Direction 2 + common). The phase and zero of the 220 Volt network is not important.

The servo itself does not have an electronic board. There, the motor runs at 220 volts. This motor has 2 contacts, closing 220 Volts, the motor turns only in one direction.

But in addition to the motor itself, there is a mechanical logic for its operation. This logic cuts power to the motor if a certain valve position is reached.

If you short-circuit 220 volts to certain contacts, you get the desired servo action.

Valve position 1:

Common terminal + terminal 1

Valve position 2:

Common terminal + terminal 2

There is no need to remove the voltage, the motor will turn off by itself when it reaches the desired turn. The servo has a mechanical switching structure. And it will turn itself off when the angle of rotation is reached.

Switching speed approx. 8 seconds. Written in the boiler manual.

Option 2.

Servo-operated valve Honeywell VC4013. Switching speed 7 seconds.

Option 2

works the same as

option 1

.

Two-way and three-way valves are available in models from 1/2 "to 1". Throughput up to 7.7 Kvs

The work of this valve is written here:

Option 3.

The most difficult option that requires more detailed study. Has a variety of work functionality.

If you have a more efficient heating + DHW system with higher costs. It is not possible to use the valves of option 1 and 2, since they have a small capacity!

What is bandwidth?

This device consists of two parts:

1.

Rotary mixing valve (optional diameter)

2.

Servo Drive (Electric Drive)

A 3-way valve connection kit is sold with the servo.

The principle of operation of option 3 is the same as for options 1 and 2. Give voltage to two conductors for a certain position.

The ESBE 3-way valve must be selected for the servo to fit the valve. And servo manufacturer ESBE. Below there will be a catalog of valves and servos for acquaintance.

ESBE three-way valve

Valve Models That Will Help You:

At 25: ESBE VRG 1313MG25 Kvs = 10 m3 / h. article: 11601000

At 32: ESBE VRG 1313MG32 Kvs = 16 m3 / h. article: 11601100

At 40: ESBE VRG 1313MG40 Kvs = 25 m3 / h. article: 11301200

At 50: ESBE VRG 1313MG50 Kvs = 40 m3 / h. article: 11401200

These valves require a torque of at least 5 Nm to rotate. The servo gives 6 Nm. But make no mistake, because there are servos with 3 Nm torque.

What is Kvs?

ESBE servo drive

Servo drive model: ESBE ARA641 220 Volt. 30 seconds. Article number 12101100

Drive characteristics:

1.

Rotate 90 degrees. There is a setting for correcting the degree. You can do it a little more or move it a little to the side.

2.

3 point control. That is, 3 contacts of 220 Volts for control: Terminal 1, terminal 2 and common terminal.

3.

The time it takes for the actuator to turn 90 degrees depends on the model. Model ARA641 30 sec.

4.

Wire cable 1.5 meters.

5.

Torque force: 6 Nm.

Servo wiring diagram: ESBE ARA641

This device has three conductors: Blue, Brown and Black.

Blue

- a common conductor, usually Zero is shorted to it

Brown and black

these are position 1 and 2 conductors.

When a voltage of 220 volts is applied to the blue and black, the drive turns in one direction 90 degrees.

When a voltage of 220 volts is applied to the blue and brown, the drive turns in the other direction 90 degrees.

These servos have a button to turn off the direction of valve movement. That is, you can forcibly direct the valve to the desired position during repair or test.

Note that the larger the valve, the more torque may be required.

In the ESBE catalog

You can match other valves and servos!

For instance,

1.

Select not three-point (three-pin) control, but two-point control. That is, a constant voltage goes to one contact, and you simply give or take voltage to the second contact.

2.

The swing angle can be more than 90 degrees. For example 180 degrees.

3.

The closing time is not 30 seconds, but much longer. For example, you may need a smooth transition of up to 1200 seconds.

4.

Take a drive with a different torque force.

5.

24 or 220 volt drive.

6.

You can select the servo not only for switching, but also for obtaining the desired temperature by mixing.

Download ESBE catalog

for valve and actuator selection: esbekatal.pdf

If someone has a point-to-point signal from an indirect heating boiler or from some thermostat that only has a point-to-point contact, then an electromagnetic switching relay can be used.

This model should be looked for in specialized electrical and electronics stores.

Model:

ABB CR-P230AC2. Contacts 1 and 2 are supplied with 220 volts. Do not exceed 8 ampere changeover contacts. 8 A x 220 Volts = 1700 W. Withstand equipment up to 1700 watts. It does not apply to pumps and incandescent lamps, since the first start requires large currents.

In order to connect it to the wires, a special connector is used:

Base ABB CR-PLSх (logic) for CR-P relays

You should get the following:

That's all. Ask questions! Do you understand everything? Maybe something is missing?

| Like |

| Share this |

| Comments (1) (+) [Read / Add] |

A series of video tutorials on a private house

Part 1. Where to drill a well? Part 2. Arrangement of a well for water Part 3. Laying a pipeline from a well to a house Part 4. Automatic water supply

Water supply

Private house water supply. Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Pumping station of water supply How to choose a pump for a well? Setting the pressure switch Pressure switch electrical circuit Principle of operation of the accumulator Sewerage slope for 1 meter SNIP Connecting a heated towel rail

Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of a radial distribution of a heating system Diagram with a heat pump and a solid fuel boiler - logic of operation Three-way valve from valtec + thermal head with a remote sensor Why does the heating radiator in an apartment building do not heat well? home How to connect a boiler to a boiler? Connection options and diagrams DHW recirculation. Principle of operation and calculation You do not correctly calculate the hydraulic arrow and collectors Manual hydraulic calculation of heating Calculation of a warm water floor and mixing units Three-way valve with a servo drive for DHW Calculations of DHW, BKN. We find the volume, power of the snake, warm-up time, etc.

Water supply and heating constructor

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servos and three-way valves work Three-way valve to redirect the flow of the heating medium

Heating

Calculation of the heat output of heating radiators Radiator section Overgrowth and deposits in pipes impair the operation of the water supply and heating systems New pumps work differently ... Calculation of infiltration Calculation of temperature in an unheated room Calculation of the floor on the ground Calculationheat accumulator Calculation of the heat accumulator for a solid fuel boiler Calculation of the heat accumulator for the accumulation of heat energy Where to connect the expansion tank in the heating system? Boiler resistance Tichelman loop pipe diameter How to choose a pipe diameter for heating Heat transfer of a pipe Gravitational heating from a polypropylene pipe Why do they not like single-pipe heating? How to love her?

Heat regulators

Room thermostat - how it works

Mixing unit

What is a mixing unit? Types of mixing units for heating

System characteristics and parameters

Local hydraulic resistance. What is CCM? Throughput Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, DN and PN? Plumbers and engineers need to know these parameters! Hydraulic meanings, concepts and calculation of heating systems circuits Flow coefficient in a one-pipe heating system

Video

Heating Automatic temperature control Simple top-up of the heating system Heating technology. Walling. Underfloor heating Combimix pump and mixing unit Why choose underfloor heating? Water heat-insulated floor VALTEC. Video seminar Pipe for underfloor heating - what to choose? Warm water floor - theory, advantages and disadvantages Laying a warm water floor - theory and rules Warm floors in a wooden house. Dry warm floor. Warm Water Floor Pie - Theory and Calculation News to Plumbers and Plumbing Engineers Are you still doing the hack? First results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - orientation of the wall?

Regulations

Regulatory requirements for the design of boiler rooms Abbreviated designations

Terms and Definitions

Basement, basement, floor Boiler rooms

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial water pollution Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building? Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms divided according to their location?

Personal experiences of hydraulics and heat engineering

Introduction and acquaintance. Part 1 Hydraulic resistance of the thermostatic valve Hydraulic resistance of the filter flask

Video course Calculation programs

Technotronic8 - Hydraulic and thermal calculation software Auto-Snab 3D - Hydraulic calculation in 3D space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Hydraulic Calculation Tasks

Head loss in a straight pipe section How does head loss affect flow rate?

miscellanea

Do-it-yourself water supply of a private house Autonomous water supply Autonomous water supply scheme Automatic water supply scheme Private house water supply scheme

Privacy Policy

The best known manufacturers and models: characteristics and prices

Now I want to talk about the most popular and reliable three-way valves to make it easier for you to choose the right model.

TIM

Manufacturer from China. Offers fairly high quality products for heating and water supply at a relatively low price.

| A photo | Model | Specifications | Features of the | Cost, rub. |

| (ZEISSLER) BL3110C04 | Material: brass Temperature range: 35-60 Operating pressure: 2-5 bar Diameter: 1 inch | Mixing, for heating and hot water supply | 2 300-3 000 |

| BL8803 | Material: brass Temperature range: 38-60 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, external connection via American | 2 800-3 500 |

| BL8804A | Material: brass Temperature range: 38-60 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, with electric drive | 2 000-2 600 |

Esbe

This Swedish company is engaged in the production of various models of valves and controllers. I believe that the products of this company are of the highest quality. Expensive though.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| VTA321 | Material: brass Temperature range: 35-60 Operating pressure: 2-10 bar Diameter: ¾ inch | Mixing, for heating and hot water supply | 6 000-6 500 |

| VTA372 | Material: brass Temperature range: 20-55 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, high throughput | 7 000-8 000 |

| VTC511 | Material: cast iron Temperature range: 60-75 Operating pressure: 3-10 bar Diameter: 1 inch | For solid fuel boilers | 8 000-9 000 |

STOUT

Joint production of Russia, Italy, Spain and Germany. The products are perfectly adapted to Russian conditions.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| SVM-0120-164325 | Material: brass Temperature range: 20-43 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, for heating and hot water supply | 4 500-5 000 |

| SVM-0125-186520 | Material: brass Temperature range: 30-65 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, for heating | 4 000-4 300 |

| SVM-0120-256025 | Material: brass Temperature range: 35-60 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, high throughput | 5 200-5 800 |

WATTS

One of the largest manufacturers of heating equipment in Europe. Huge range of products.

| Photo | Model | Specifications | Features of the | Cost, rub. |

| Aquamix 61C | Material: brass Temperature range: 32-50 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, for hot water supply | 5 200-5 700 |

| Aquamix 63C | Material: brass Temperature range: 25-50 Operating pressure: 1-10 bar Diameter: ¾ inch | Mixing, for underfloor heating | 5 500-6 000 |

| V3GB Watts Classic | Material: brass Temperature range: 20-50 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, with electric drive | 12 500-14 000 |

Fittings installation rules

Usually, on the body of a three-way valve, the manufacturer indicates the movement of the water flow with arrows. By these landmarks, you can also determine the type of valve. Connection to the system proceeds as indicated by the arrows. The place of installation should be convenient for subsequent adjustments or replacement in the event of a malfunction. For this, both return and supply are suitable. But read the instructions carefully, since not all valves can be installed for supply.

Since most of the valves are made of ceramic inside, they do not tolerate dirty water well. Therefore, it is better to install a filter in front of the valve. If this is not done, the appliance may become clogged. In some cases, it is enough to clean it, but sometimes even this does not help. Therefore, do not skimp on filters.

The electric drive should not be located at the bottom, and mechanical thermostatic mixers are also not advised to install this way, exclusively vertically. But I will say from my own experience that in some cases this is possible. And the reviews of some owners confirm this.

Layout of the three-way valve in the heating system

The simplest scheme in a system with a solid fuel boiler. Purpose: protection against condensation and overheating, maintaining the temperature in the heating circuit.

Heating scheme with an electric boiler and underfloor heating. Hydrocollectors are used to distribute underfloor heating to several circuits.

Use in piping using an indirect heating boiler, which allows you to organize hot water supply with a single-circuit boiler.

Steam valves

Control valves for steam are designed for use in heating, hot water supply, heat supply, ventilation and air conditioning systems in order to regulate the parameters of the working environment (pressure, temperature, flow, etc.), which can be water, air, steam and other liquid and gaseous media that are neutral to valve materials in contact with the media. The valve is controlled by the actuator. Our catalog contains products from Danfoss, Broen, Giacomini, ARMA-PROM LLC.

The Russian manufacturer offers single- and double-seated control valves for steam, equipped with an electric actuator, gas control valves, vf3, belimo control valves. Rotary control valves can be used both for joint operation with regulators and for manual remote control.

How to check a three-way valve for operation

First of all, an external examination should be carried out: there should be no cracks on the plastic and metal cases. As for the regulator, it should turn smoothly in all directions. To check the thermal head, it needs to be heated. For example, a building hairdryer. In this case, the stem should move in accordance with the indicators. If the valve has an electric actuator, you can check its operability using a tester, but for this you have to disassemble the electric actuator.

Conclusion

Three-way valves only look like a tee. Their device is much more complicated, and the scope of application is quite diverse. Choose a valve responsibly, consider models only from well-known, reputable manufacturers, fortunately, there are enough of them. And then this small but very important device will work for many years without causing problems.

Boiler room equipment