Thermal properties of wood

The efficiency will directly depend on the thermal conductivity of the material. Any owner of a private house with a stone stove knows about this nuance. The quality of combustion also depends on one more indicator - the combustion temperature. By increasing the degrees, you can heat up the water in pipes or brick walls much faster, thereby protecting your home from severe frosts.

If you put a poplar in the firebox, you can observe a very high flame, but its temperature will not exceed 500 degrees, and this is not so much for heating the room. Ash, beech and hornbeam are preferred. They burn actively, but at the same time emit a temperature of 1000 degrees. This figure is ideal for heating a room.

Criteria for choosing the type of wood, depending on the purpose

When choosing the required material, you should know a few nuances. For example, if you use ash or beech, you can raise the temperature to high values, but if you use them for a bath or a furnace, then it is very expensive and unprofitable - firewood burns quickly. For this reason, people began to use a different wood - birch. Combustion of birch firewood is accompanied by obtaining 800 degrees.

Oak and larch are also often used. Their combustion temperature ranges from 840 to 900 degrees. When there is a need to make an open fire, a fire, light logs in the grill in your summer cottage or private plot, it is advisable to use pine. It is also often used to heat a home by placing it in an oven. The combustion temperature of the material is about 610-630 degrees. But for this reason, you will have to use about half as much firewood than using birch or oak.

Features of coniferous species:

- The combustion temperature is low.

- When placed in a fire, a large amount of soot and smoke is generated.

The appearance of smoke and soot is due to the large amount of resin contained in the wood. It settles on the walls of the chimney and therefore needs to be cleaned periodically after use. Therefore, conifers are not so popular for the firebox - the cleaning process is very laborious. Such material is used only as a last resort, if there is no other option.

Also, when making a fire, it is necessary to pay attention to the moisture content of the materials, since this percentage directly affects combustion. The wetter the wood, the worse it burns. But it also creates a lot of smoke.

Popular experience shows that in order to obtain the necessary heat for heating a house, it is necessary to use firewood from beech, oak, which is felled in winter, mountain pines, birch and acacia.

The strongest flames are ash, resinous larch, maple, pine or oak, felled during the summer.

Many people prefer to burn pine - this is one of the most popular options.

Fir, chestnut and cedar produce a little less heat.

Poplar, alder, and aspen have the worst heating capacity.

From all this, we can conclude that those firewoods that are the most weighty and dense form heat best.

What tree species should not be used to heat the fireplace?

It is not in vain that there are a large number of different trees on Earth. All this for you, friends! For your hot fires! Each type of wood has its own unique properties.

For example, beech and oak are considered "elite firewood". The flame burns brightly and evenly. During combustion, the crackle is smooth and pleasant to the ear. The heat dissipation of beech wood is the best among other types of wood. Oak firewood is similar in parameters.Their only drawback is that the cost of the logs is relatively high and there are difficulties in splitting them. But oak firewood burns for a long time and practically does not emit smoke.

Apple, pear and other fruit species. Their advantage is a pleasant smell. They heat living rooms, the fruity aroma of which becomes stable over time.

Linden and Poplar. Poplar is used exclusively for decorative purposes. Firewood gives off little heat and burns quickly. To heat the room, you will have to put firewood at intervals of 1.5 hours. Linden logs are the same. The flame is dim, the wood practically does not emit heat and smoke.

Alder and Aspen. The firewood of these trees has a unique property. When burning, they do not emit smoke and soot. In addition to this, their fire burns out the soot inside the chimney. It is recommended, at least once every few weeks, to heat the stove with alder or aspen wood so as not to

to prevent contamination of the inner cavity of the chimney with soot.

Firewood from coniferous trees: spruce, pine. They contain a lot of resin, which gives off a lot of soot. During combustion, in addition to tar, there is also a lot of soot in the flue gases, which leads to overgrowing of the inner cavity of the chimney. Spontaneous combustion of soot inside the chimney is often observed, which can render the chimney unusable. So, if you still want to see your home intact when you come home, do not heat it with coniferous wood.

Factors affecting the burning temperature of firewood

There are several factors that contribute to combustion:

- The type of wood used for combustion.

- Moisture content of the material.

- The volume of air entering the furnace.

These are the main indicators that you need to pay special attention to, since it is on them that the efficiency of wood combustion will depend, and the temperature that can rise during the combustion process.

Humidity level

The moisture content of the wood plays a key role in firing up, therefore such an important point requires separate consideration. Any tree that has just been felled has a certain moisture content. In most cases, this figure is 50%. But in some cases it rises to 65%. And this suggests that this type of material will dry for a very long time under the influence of high temperature before igniting.

Some of the heat will only go to remove excess moisture by evaporation. For this reason, the temperature will not reach the maximum value. Heat transfer under this condition will decrease.

To get the maximum benefit, there are a few basic options you should use:

- Drying is the most suitable option. To do this, the tree is cut into small pieces, and then folded into a dry place in a shed or shed. Under natural conditions, the drying process will take approximately 1 year. And if the firewood is stored longer and lasts two summers, then their moisture content will be 20%. This is already the optimal indicator.

- The second option is less preferable - to burn what is, not paying attention to moisture. But in this situation, you will have to spend twice as much firewood to form the desired temperature. In addition, you should be prepared to clean the chimney from soot.

The better the wood is dried, the higher the combustion temperature can be taught. And the release of heat also depends on this. Heat will not work with wet wood.

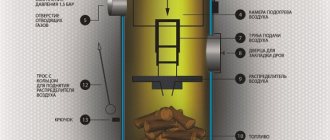

Warming up process

Heating up is the heating of a separate section of wood material to a temperature sufficient to ignite the entire surface.

Usually 120 degrees are enough for heating - the wood begins to char.

After that, the process will continue when coal is formed. When heated to 250-350 degrees, the selected material will begin to decompose into its components. Then smoldering begins, but the flame does not appear yet. At this moment, the formation of smoke can be observed.As the temperature continues to rise, the level of pyrolysis gases increases - an outbreak occurs. The wood will ignite completely.

Flammability of materials

The flammability is directly influenced by the percentage of moisture that is contained in the selected rock. An important role is played by the power of the heating source, as well as the cross-section of the wood and the air flow rate.

In order for the flame to ignite faster, it is desirable to use light wood, which has a large porosity. Wet wood will ignite very slowly as it will dry out before an open fire forms.

Burning also depends on the shape of the tree - it is advisable to use a rectangle, since the circle will inflame much longer. To speed up the process, it is necessary to select a material with a small section and sharp edges. It is important to ensure that the required amount of oxygen is supplied to the heated area.

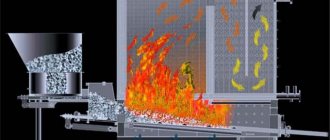

The device of the home stove also has a great influence on the burning temperature of wood and flammability. It can be made from different materials and this directly affects the combustion temperature of the materials put inside. If the stove is massive, then the wood in it will burn almost completely, but this process will take a very long time. Great care must be taken when using. Failure to comply with safety measures can lead to a fire in the wood-burning bath at a high combustion temperature of the stove.

In a stove stove, firewood often does not burn completely due to the fact that it cools quickly

The stove-stove, made of steel sheet, cools down quickly, while the heat is distributed over the surrounding space, but first it will pass from the combustion zone to the walls, and only then to the room.

Combustion process

Observing the operation of the oven, one might think about why the supplied air does not affect the color of the resulting flame. The oxygen must be chemically active and give the soot a bright color that can even turn white. But this phenomenon can be easily explained, because the size of the particle also affects the temperature. The smaller it is, the lower the temperature will be. Therefore, small hot particles form the same temperature as the gas that surrounds them. It should also be noted that each type of wood has a certain heat transfer. To find out these numbers, you can study the table, which shows all the thermal conductivity indicators for each type of material.

How to prepare firewood

Firewood harvesting usually begins in late autumn or early winter, before a permanent snow cover is established. The felled trunks are left on the plots for primary drying. After some time, usually in winter or early spring, firewood is removed from the forest. This is due to the fact that during this period no agricultural work is carried out and the frozen ground allows you to load more weight on the vehicle.

But this is the traditional order. Now, due to the high level of technology development, firewood can be harvested all year round. Enterprising people can bring you already sawn and chopped firewood any day for a reasonable fee.

How to cut and chop wood

Saw the delivered log into pieces suitable for the size of your firebox. After that, the resulting decks are split into logs. Decks with a cross-section of more than 200 centimeters are pricked with a cleaver, the rest - with an ordinary ax.

The decks are split into logs so that the cross-section of the resulting log is about 80 square cm. Such firewood will burn for a rather long time in a sauna stove and emit more heat. Smaller logs are used for kindling.

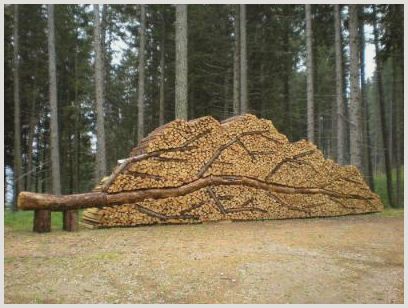

woodpile

Chopped logs are stacked in a woodpile. It is intended not only for storing fuel, but also for drying firewood.A good woodpile will be located in an open area blown by the wind, but under a canopy that protects the firewood from precipitation.

The bottom row of woodpile logs is laid on logs - long poles that prevent firewood from contact with wet soil.

Drying of wood to an acceptable moisture content takes about a year. In addition, wood in logs dries much faster than in logs. Chopped firewood reaches an acceptable moisture content already in three months of summer. When the woodpile is dried for a year, it will have a moisture content of 15 percent, which is ideal for combustion.

Combustion temperature measurement

It is very difficult to measure the combustion temperature at home. A regular thermometer will not work here. Of course, "by eye" it will also not be possible to determine the correct combustion temperature of a certain material. To lead such studies, you need to purchase a special device called a pyrometer.

But you need to know that a high burning temperature of firewood in the stove will not mean that they will release the required amount of heat. Therefore, you should also take care of quality equipment. In good stoves, it is possible to artificially reduce the supply of oxygen to the wood. Thus, it is possible to achieve an increase in the combustion temperature and a decrease in heat transfer.

Since it is very difficult, expensive, and sometimes impossible to measure the combustion temperature of different firewoods at home, you can rely on official data. All indicators have long been calculated in laboratory conditions by specialists through comparative analysis. To obtain the necessary results, the wood was thoroughly dried before testing - it was brought to an optimal state for experiments with open fire.

Thermal conductivity of materials:

| Wood species | Calorific value in calories |

| Birch tree | 4968 |

| Pine | 4952 |

| Spruce | 4860 |

| Alder | 5050 |

| Aspen | 4950 |

The concept of "burning temperature of wood" does not quite correctly reflect the main characteristic. It is necessary to pay more attention to the ability to generate heat. The unit of measurement for such a parameter - calories - is heat energy, which heats 1 gram of ordinary water by 1 degree.

Heating capacity

In practice, a person should be interested in the heat output of the selected material. This is the temperature that can be reached by burning a certain type of wood.

Firewood heat output table:

| Breed | Heating capacity in percent | Temperature in Celsius |

| Beech and ash | 87 | 1044 |

| Hornbeam | 85 | 1020 |

| Winter oak | 75 | 900 |

| Larch | 72 | 865 |

| Summer oak | 70 | 840 |

| Birch tree | 68 | 816 |

| Fir | 63 | 756 |

| Acacia | 59 | 708 |

| Linden | 55 | 660 |

| Pine | 52 | 624 |

| Aspen | 51 | 612 |

| Alder | 46 | 552 |

| Poplar | 39 | 468 |

A couple of phrases about calorific value

By its own chemical composition, wood is a complex material. It contains the key elements - lignin and cellulose. However, in addition to them, the tree contains:

- resin;

- proteins;

- tannins and other components.

When wood fires ignite in the stove (or simply when trees ignite in the wilderness), the mutual action of such components with air is performed at a chemical level. The calorific value of wood (like any fuel), or heat conductivity, is the amount of heat energy that a unit of weight of fuel material (in our case, 1 kg of wood) produces during combustion. To measure the value, kilocalories are used.

The chemical composition among a large number of tree varieties has the smallest fluctuations, which causes the differences in the number of emitted calories. In other words, the heat of combustion of many types of firewood can be as follows:

- for hardwoods, the indicator is 4460 kcal / kg;

- in conifers - 4560 kcal / kg;

- in mixed breeds - 4510 kcal / kg.

As you can see, the differences are minimal. At the same time, it is easy to understand that it is better to use conifers for the stove due to their greater thermal conductivity. Firewood is supplied exclusively to the market depending on volume, not weight.In other words, the main parameter for choosing firewood is cubic meters. Density plays a major role here, because the larger it is, the heavier the wood.

For example, let's take 1 cubic meter of birch firewood as a starting point. Then the ratio of the volume of different breeds will look like this:

- oak logs? 0.75 cc m;

- alder logs? 1.1 cc m;

- pine logs? 1.2 cubic meters m;

- spruce logs? 1.3 cubic meters m;

- aspen logs? 1.5 cubic meters m.

In other words, 1 cubic meter of birch and 0.75 cubic meters. m of oak firewood, 1.1 cubic meters m of alder wood (and so on) will give out the same amount of heat. Knowing this, now, depending on how much firewood costs, you can get profitable savings for yourself.

Practical advice

- If the house is heated by a stove and during the combustion process it smells of damp wood, then you must immediately examine your equipment. Perhaps the tightness and integrity are broken somewhere.

- A large amount of acids are released during combustion, therefore, the chimney should be built from reliable materials that are able to resist aggressive environments.

- If wood with resin is used, then thoroughly clean the chimney after use.

- To heat stones, for example, in a steam room, it is advisable to use firewood that burns weakly and emit a large amount of heat.

- For rapid heating of the steam room, a material with a high combustion temperature is used. In this case, the air supply to the furnace must be increased.

Having studied the material, you can understand what temperature of burning firewood is needed for the most efficient heating of the room.