Advantages of a fireplace stove

Gas stove with hob

The versatile structure has the characteristics and characteristics of both a stove and a fireplace. In fact, this is a monoblock, inside of which there is a flue gas discharge channel. The structure has a firebox with a viewing glass and a stove for cooking. There are large spaces for the designer's imagination, because there are practically no restrictions in size, shape and cladding. Strict requirements are only in the correct observance of internal proportions.

Practical technical merits:

- Heating of the room occurs quickly if the ratio of the hearth and the area of the room is proportional.

- It is possible to separately use a firebox or a hot plate in structures where they are not combined with each other.

- The efficiency for this type of equipment reaches 80%.

- The structures are simple to maintain, since all furnaces are equipped with ash pans.

If the fireplace stove is designed professionally and the materials correspond to the thermal loads, such a unit can serve for several decades.

Even a well-made heating device requires the use of good fuel, otherwise no one can guarantee long-term operation.

Advantages of biofuel fireplaces

Let's talk about the main advantages of biofuel fireplaces and how a modern system works.

- To begin with, a biofireplace is a version of a home fireplace with a live fire that “plays” in a glass space, which ensures safety for people around (especially children and animals) and furniture.

- Installing a biofireplace is a mere trifle compared to its “wood-fired” version. There is no need to build a smoke evacuation system for an eco-fireplace.

- Fuel for the fireplace uses biologically pure liquid fuel - this is alcohol that burns without residue and does not harm the health of others. The combustion temperature of the fuel is low, and the evaporation of carbon dioxide is so small that an ordinary candle can be considered a more dangerous source of heat.

- Fuel for the fireplace is commercially available, and you do not need to allocate a separate room for storing it (for example, as with firewood).

- A wide variety of eco-fireplace models allows you to create such an interior that you have dreamed of for a long time. Individual models of hearths are selected in accordance with the design of the room where the fireplace will be located.

- The use of a bio fireplace does not imply the presence of soot and dirt.

- These fireplaces are affordable.

- A bio fireplace without a chimney is an excellent source of heat.

- And the main thing, perhaps, their advantage lies in the fact that the biofireplace can be easily installed in your own, even not too large apartment.

Place for a fireplace

The optimal location is in the kitchen combined with the living room

The location of the brick fireplace stove for a wood-burning house depends on the preferences of the owner and the tasks that it will perform. At the planning stage of the building, it is necessary to think over where the heating device will be located and take into account all the necessary conditions for this.

You can build a firebox against the outer wall. In this case, it will only heat the room in which it is located, and the neighboring ones, if it is not planned to hang doors on the interior openings. The option is suitable for small guest buildings or country cottages, where the fireplace stove is a decorative and functional element of the kitchen-living room.From the technical points, it is necessary to provide a foundation (it should not be rigidly connected to the foundation of the load-bearing wall), a layer of thermal insulation that will prevent heat from escaping through the wall to the outside, and the connection of the chimney to the outer pipe.

Another case is installation on two sides, when one part goes, for example, into the guest room, and the second with a hot plate - into the kitchen. This option is practical, since in any case, during the operation of the device, a larger volume of space is covered, and the smell of food being cooked will be cut off from the recreation area of people. From the point of view of saving money, the location is convenient, since you can only spend money on decorating the hearth from the side of the room, on the other hand, limit yourself to neat masonry. If a monolithic slab is not provided in the house, a reinforced concrete foundation should be poured under the building and the insulation of the firebox from the wall should be considered, if the latter is made of combustible materials.

In one-room houses with the main spacious room, you can put the stove in the middle, then the heat will be evenly distributed around the entire perimeter and effectively heat the building.

Household use

Biofireplace in classic design.

The location of the fireplace, its configuration, power are limited only by the imagination of the person who wants to have it at home. This versatile home can be located in an apartment or in a country house.

Provided that biogas is used as fuel, a gas fireplace for summer cottages without a chimney is an ideal solution. In this case, an open hearth can also be installed. This design is mobile and can be moved from place to place. If a stationary version of the fireplace is provided, the original brickwork will serve as an addition.

We must not forget about security measures. If the fireplace is built-in, it is necessary to comply with all fire safety requirements and sew up the walls with thermal insulation material.

If summer time is devoted to the dacha, then the rest of the year is spent in the apartment. But even here you want comfort, warmth and home. There is a great variety of options for the location of a gas fireplace for an apartment without a chimney. It is equipped with a special hardened steel gas burner, automatic gas sensors and a piezoelectric element. The burner can be hidden behind the wood decor. You can connect the fireplace to the cylinder yourself without contacting special services. Another nice bonus is the presence of a remote control for the power of burning the flame.

We advise you to find out what is fraught with transferring the battery to the loggia.

Read: what materials are used for the roof of the house.

Find out how to properly insulate a balcony and what materials are needed for this.

There are a number of nuances when installing such an add-on for a home interior:

- in view of the fact that gas is used as fuel, special attention must be paid to the integrity of the cylinders;

- it is necessary to observe fire safety and not save on a fireplace with automatic gas shut-off functions.

Structural calculation

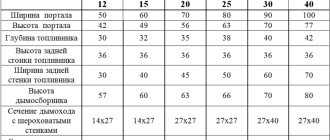

The fireplace stove for heating can be folded out of bricks, observing the proportions

A fireplace stove for heating a house belongs to this type of structure that is not done by eye, each size matters here. The question is not about the decoration (you can cover the heater as you like), but only the main working elements of the structure:

- firebox;

- ash pan;

- chimneys.

The exceptions are products where heat-resistant brick is at the same time a facade one - here 100% compliance with proportions is necessary. There are many cases when ignoring such recommendations ended up shifting the entire massif after testing the focus for operability.

Any fireplace stove is laid out according to a certain pattern. There are a lot of such drawings, it is easy to calculate your installation using them.The linear dimensions of the selected scheme are taken as a reference point, which adapt to their existing building clinker - proportionally increase or decrease them. The drawing assumes an ordinal visualization of the masonry. Having calculated the amount of material in each row, they go to the total number of the masonry worker on the load-bearing parts, refractory to the firebox, and also determine the need for steel lintels and plates.

Necessary tools and material for construction

Bricklaying tools for brick stoves

The tool you need to build a furnace:

- Mason's trowel for applying mortar to the masonry plane;

- pavilo-level and plumb line to maintain the vertical and horizontal position of the rows and walls of the building;

- a steel square and a pencil, required when marking parts of the clinker for cutting;

- grinder with a victorious circle and a metal cutting disc for cutting concrete structures and steel strips;

- tape measure for taking measurements;

- a bucket to serve the solution and a mixing container;

- a rubber hammer for tapping the clinker after laying on the mortar;

- pliers and nippers required when cutting reinforcing mesh;

- construction twine for tightening the front line of the wall rise.

The construction of a fireplace stove is a more demanding task than just walls, so measuring instruments must be checked without fail.

Brick is used as the main building element for masonry. Most often these are varieties of ordinary, obtained from clay, or options for futor material. All mixtures based on refractory clay are suitable for bonding. Also required is sheet steel about 3 mm thick, metal strips, corners, nails and masonry mesh.

Fireclay bricks are irreplaceable materials in the construction of furnaces. This is due to their high heat resistance. Elements are used to organize the combustion space, less often as front ones. Brick of clinker grades, due to its large mass and density, is more suitable for building a foundation for an installation. Curly already goes to the cladding when creating a certain decorative look.

Do-it-yourself brick fireplace stove

Making a furnace from clinker is a task for an experienced craftsman in this matter. The difficulty lies not so much in observing the sequence of laying the masonry, but in the exact keeping of the proportions of the firebox, ash pan, configuration of the chimney and all its transitions. But if you do not have professional skills, you can try to build a furnace yourself. It is important to choose a working diagram and slowly draw line by line along it.

Double-sided design

Double-sided fireplace stove with heat-resistant glass door

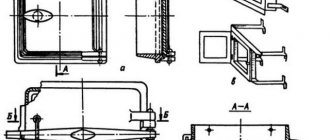

For beginners in the furnace business, you can consider simple double-sided fireplace stoves - devices with a through firebox. The advantage of such a structure can be considered the ability to heat two adjacent rooms at once. There are no intricate passages with turns and slopes with a certain angle - the chimney goes straight up, passing from the smoke-collecting hood into the pipe along a trapezoid.

An easy-to-implement double-sided fireplace stove consists of the following elements:

- base - a foundation poured out of concrete or laid out of stone;

- ash pan area - a wide part or base of the heating device, where there is a niche, closed on both sides by blowing doors;

- grate group, which is a dividing element between the firewood burning area and the ash collection site;

- a through combustion chamber, where on both sides there are fireproof glass doors or a door on one side and a stove on the other;

- smoke-collecting compartment for accumulation of combustion products;

- trumpet.

A slight deviation from the proportions will not lead to the stove not working. It is important to pay special attention to the ratio of the size of the firebox and the space above the furnace for collecting smoke.The volume of the elements should be approximately the same, or you can slightly increase the smoke collection hood. The latter should also in its upper part resemble a trapezoid, the upper base of which is the entrance to the pipe.

Small design

Built-in appliances in such structures need insulation with refractory materials

A brick fireplace stove for one hob burner is also not difficult to make with your own hands. It is a square-shaped firebox 2.5 bricks in length, where there is an ash-pan with a door at the bottom, in the middle part there is a glass door for storing firewood (through which you can observe the burning flame), the top cover ends with a cast-iron stove with circles. In such a structure, you don't even need to lay out a pipe. The chimney is represented by a channel to the side from the firebox, which is connected to an external metal or galvanized pipe.

It is not necessary to talk about the high decorative possibilities of such a wood-burning heating device due to its simplicity, but if you choose a high-grade refractory material and do the work carefully, perfectly keeping the level, making the jointing, you can achieve an attractive appearance.

Fireplace from Super Isola in a niche

On the fireboxes and stoves from the presence of a fixed rate of 75 rubles. for 1 Euro Equipment marked FIX PRICE!

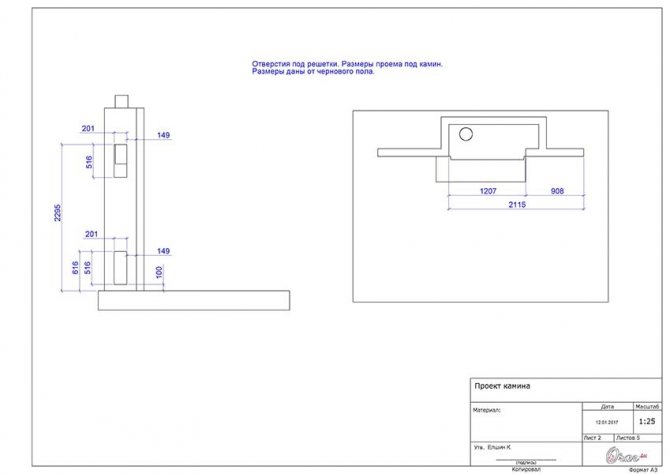

It all started with a preliminary calculation of the cost of materials and fireplace installation. Then there was a trip to the object for measurements and a draft design of the fireplace with drawings of the convection duct was carried out. After all the approvals, we delivered the materials and completed the installation, which took two full days.

The design project of a room with a fireplace allows us to clearly understand the essence of the structure and gives direction for our work. We see what the final result should be and adjust the dimensions of the fireplace to this result.

The composition of the project of the built-in fireplace.

The Vulcan chimney was installed before us. The support platform is set low, but the project has shown that the height allows the firebox to be connected. We have a design project, draft design and drawings of the convection chamber, bought a Stil-Kamin 62/76 k firebox from Brunner and we are starting to install it. The first stage is to sew a pipe (not insulated stainless steel) into a Super Isol box. We additionally wrapped the pipe up to the brick mine with Super Strength. The second stage is the sheathing of the back and side walls. To provide a 3 cm gap between the walls and the box, we made spacers - Super Isol squares, which are glued to the wall, and insulation sheets are already fixed to them. Then we installed a fireplace insert in the prepared place and connected it to the chimney with stainless steel pipes and outlets.

After installing and connecting the fireplace insert, we just need to put Super Isol under the firebox and sew up the front part of the convection box. Air inlet and outlet grilles are located on the left side wall in the adjacent room. The size of the grates is 490x170 mm. The cross-section of the grates meets the requirements of the furnace manufacturer and is about 700 cm2.

The first part of the work is completed. The firebox is sewn into a Super Isol box, connected to the chimney, and we carried out the first firebox to check the operation of the fireplace. Further, a frame made of profiles with sheathing with sheets of gypsum fiber board with a width of 1670 mm will be mounted. A marble portal will be attached to this structure.

Convection fireplace inserts

0%

Horizont VD 850/620 Line Extra Kobok fireplace insert

RUB 291 617 RUB 291 617

Availability

- On order

Out of stock Add to cart

-20%

STOCK!

Albero 16 G.H Fireplace insert Hitze

RUB 127 800 RUB 102,240

Availability

- In stock

Out of stock Add to cart

-20%

STOCK!

Albero 16 L.G.H Fireplace insert Hitze

RUB 140,760 RUB 112 608

Availability

- In stock

Out of stock Add to cart

0%

Vertical LE VD 670 × 900 fireplace insert Kobok

RUB 257,570 RUB 257,570

Availability

- On order

Out of stock Add to cart

0%

Horizont VD 970/700 Line Extra fireplace insert Kobok

RUB 351 842 RUB 351 842

Availability

- On order

Out of stock Add to cart

0%

Horizont VD 800/570 Standart fireplace insert Kobok

RUB 212,250 RUB 212,250

Availability

- In stock

Out of stock Add to cart

0%

W2 fireplace insert KawMet

RUB 60 691 RUB 60 691

Availability

- In stock

Out of stock Add to cart

0%

Horizont 670/570 Standart fireplace insert Kobok

RUB 144 679 RUB 144 679

Availability

- On order

Out of stock Add to cart

Fireplace materials and accessories

0%

Skamotec 225 (Superizol) 1220x1000x30 insulation for fireplaces

RUB 4 051 RUB 4 051

Availability

- In stock

Out of stock Add to cart

0%

Fireplace grate 17x17 white

RUB 880 RUB 880

Availability

- In stock

Out of stock Add to cart

0%

Fireplace grate 17x30 white

RUB 1,250 RUB 1,250

Availability

- In stock

Out of stock Add to cart

0%

Fireplace grate 17x49 white

RUB 2 450 RUB 2 450

Availability

- In stock

Out of stock Add to cart

0%

Fireplace automatics RT08 OM Grafik

RUB 37 397 RUB 37 397

Availability

- In stock

Out of stock Add to cart

0%

Skamotec 225 (Superizol) 1000х610х40 insulation for fireplaces

RUB 2,493 RUB 2,493

Availability

- On order

Out of stock Add to cart

The fireplace is a complex structure with many subtleties and nuances. If you build a fireplace from scratch, then you will need a reliable fireplace chimney and fireplace cladding. You can order accessories and equipment for the fireplace from us, we will calculate the quantity for the project and ensure the delivery of the entire set to the object.

We are in touch Callback Chat We need to measure

design, manufacture, installation of fireplaces

Brickwork - sequence

After arranging the foundation, you must strictly follow the order

The initial stages of laying the foundation and preparing the refractory mortar should be carried out in advance. Ordering process:

- The bottom row is laid out on roofing material, exposing the clinker with a rub. The area of coverage should be the same size as the bottom sole, excluding the thickness of the cladding material

- This is followed by the installation of the blower. The door can be of different lengths, but it is desirable that its height does not exceed the height of the fourth row of the building. All these levels are laid out, forming a niche inside for the accumulation of ash.

- The next fifth line of chamotte is the overlap plane of the ash pan and the base for the installation of the grate group, from which the furnace section begins. With the help of it, they make a protrusion forward.

- After installing the grate, the next four levels up to 9 inclusively erect the firebox. One of the walls of this compartment (usually the front one) is a metal frame with a cast-iron or glass door installed in it. This is a viewing window and an entrance for laying firewood.

- If the design provides for an open version, the firebox continues to be erected up to the twentieth row and somewhere around 16, 18 rows, the base of the mirror is mounted.

- Then they switch to the vertical installation of chamotte and make a slight tilt with extension inside the structure. This narrowing continues to be done up to level 21.

- The next two elevation lines form the so-called chimney tooth, which protrudes 20 cm forward inside the firebox, after which the other two lines go to the shelf device.

- Then they begin to form a smoke collector, the back wall of which runs smoothly, and the front one narrows like a trapezoid to the size of the pipe passage. This progressive narrowing is carried out approximately in the next 9 orders.

The subsequent masonry is the construction of a brick chimney, each row of which has the same dimensions regarding the internal section for the passage of smoke. At the junction between the smoke collector and the pipe, it is necessary to build in a smoke damper, which can be of a retractable or rotary type with a control knob brought out.

All construction activities for the construction of the furnace structure must be carried out by controlling the angles of vertical elevation using a plumb line. Large deviations are unacceptable here, which will complicate further cladding.

Simple and reliable design

High aesthetics of biofireplaces.

The possibility of the location of fireplaces is varied and, depending on this, they are divided into floor, wall, table (in terms of their compactness do not exceed the dimensions of a candle), ceiling and corner.

Positive aspects of using:

- the absence of a chimney makes it possible to place the hearth anywhere in the room;

- versatility and ease of maintenance will not take much time for ignition;

- there is no need for constant cleaning of surfaces from soot;

- in terms of its heat transfer it is similar to a heater with a capacity of up to 3 kW;

- excellent aesthetic beauty;

- the relaxing properties of fire allow you to relieve stress and relax;

- the flawless design of the lines will suit any interior, decorate it and add variety to the environment.

The main elements of a fireplace without a chimney:

- a biofuel burner made of metal or ceramic (it is important to pay attention to the power of the fuel module in order to obtain the required heat transfer);

- refractory body of laconic design made of forged metal, glass, cermets, stone and other fire-resistant materials;

- firewood in the fireplace is used decorative, ceramics or stone.

Ignition scheme

Fireplace without chimney in the apartment.

To ignite the fireplace you need:

- fill the fuel module with bio-ignition (only when the fireplace is not working, extinguish and let cool);

- set fire to the wick (it is advisable to use a long lighter in this case);

- level the flame using the special regulator.

Features of biofuels

Biofuel is a special substance obtained from natural components that, when burned, does not form smoke, soot and soot. If you use such fuel in liquid form, then 1 liter is enough for about 4 hours of operation of the fireplace. The efficiency of such a fuel is 95%. It is made from plant components by fermentation of potatoes, cane sugar and other crops. The second method is to obtain alcohol from wood or straw by hydrolysis of these products. The third method of obtaining fuel in the processing of vegetable and animal fats from oils of organic crops and food industry waste.

Important: it is forbidden to use pure alcohol during ignition.

Some fuels are produced with various aroma additives.

The gas obtained from the processing of garbage is also a type of biofuel.

We recommend that you learn how to make a warm floor on the balcony yourself.

Read: how to make a blind area with your own hands.

Due to the fact that during the combustion of biological ignition carbon dioxide and water vapor are released, the flame has a very rich orange color. If you buy biofuel with the addition of sea salt, you can fully enjoy the play of fire and the natural crackle of wood.