Cast iron sectional radiators

The first development of cast iron batteries was carried out almost 150 years ago by our compatriot. A few years later, the Americans received a patent and finalized the design. Radiators gained popularity after the appearance of the central heating system, and their mass production was established during the industrial revolution.

The batteries, which were used in the USSR and now remain in many houses, have the MC 140 brand. The value "140" is the power delivered by one section. The working and test pressures of the battery are 9 and 18 atmospheres, respectively. The number of sections is from 4 to 10.

Today, cast iron radiators are gaining popularity again, thanks to the improvement of their construction and design.

The advantages and disadvantages of this type of batteries are approximately the same.

- Long service life (over 50 years);

- Affordable price;

- Resistance to mechanical damage;

- Corrosion resistance;

- High abrasive wear. Pebbles and sand in the water do not do much harm to the battery from the inside;

- Heating efficiency with the maximum number of sections.

- Large weight and bulkiness;

- Possibility of depressurization of joints;

- Accumulation of rust inside during long-term use;

- Unpresentable appearance;

- Difficulty in integrating radiators into autonomous heating systems, the impossibility of saving on the coolant;

- Difficulty cleaning.

Installation

A flat radiator is used for heating systems with forced circulation of the heat carrier, that is, where circulation pumps are used.

The heating system using a flat battery is a closed structure and includes a membrane expansion tank. It looks like this: the heat carrier under the influence of the pump goes through a direct pipeline, passes through the valve and then gets to the heat consumer, then passing through the air vent, goes through the return pipeline to the membrane expansion tank. And from there, the process is repeated anew.

Diagram of a closed heating system with flat radiators

If coin cell installation uses an open system, battery life will be significantly shorter. There is often no need to drain the water. There is always a high oxygen content in the liquid that is just poured, which will lead to corrosion on the radiator. It is not recommended to install thin devices in rooms with high air humidity, for example, in a bathroom. If you follow all the requirements and recommendations, the risk of corrosion is minimal.

It is possible to install flat radiators with your own hands one after the other, in this case the heat power will decrease by forty percent per meter, since the heat transfer through radiation after the second row will decrease. If they are installed in rows and equipped with plates on top, you get a structure that looks like one apparatus.

A flat battery is a closed flat type device along which a heat carrier moves.

When the battery device is used for a water heating system, with pipes made of plastic or metal, an anti-diffusion barrier must be installed. It will protect against the effects of oxygen masses.

Before buying coin-cell batteries, check the flat-panel battery specifications to see if they are suitable for your building. So, for example, when a gas boiler with a safety valve is used in a building, the liquid pressure should be at most 3.0 bar.

Pay attention to the temperature of the water in the pipes. The one who decided to change the radiators, throw out the obsolete ones and install new ones argues incorrectly

Before buying new radiators for heating, it is necessary to make accurate calculations, take into account the characteristics of the building, the design of the installed or existing system, the technical characteristics of the device, entrust the installation work to specialists

The one who has decided to change the radiators, discard the obsolete ones and install new ones argues incorrectly. Before buying new radiators for heating, it is necessary to make accurate calculations, take into account the characteristics of the building, the design of the installed or existing system, the technical characteristics of the device, entrust the installation work to specialists.

Convection radiators

Convector type radiators are connected to a conventional heating system. The hallmark is a completely different way of functioning.

Panel, sectional or tubular radiators give off heat to the environment from their hot surface, which allows you to heat the room.

Convectors work differently. Their design provides for the presence of many thin air channels located between the ribs of the plates.

The air in the room passes through them, at the same time heats up, becomes lighter and rises upward, which ensures continuous movement and mixing of air, i.e. constant heating

This allows you to evenly warm up the room, which is not an important hindrance even the presence of many interior items and partitions

- They are lightweight, compact and reliable because made of copper, steel and aluminum - corrosion-resistant materials

- A relatively small volume of water is required in the system.

- They heat up quite quickly and also cool down quickly

- Such radiators allow heating rooms with high ceilings.

- A heating system with convector radiators allows you to make savings when purchasing equipment. Those. in such a system, pipes of a small diameter are used, a sufficiently low power of the circulation pump and the coolant itself has a small volume.

- Very simple installation, which can be carried out without special skills.

- There is a huge selection of appearance options for the convector body. What can be a beautiful addition to your interior. Replacing the housing is very simple and only takes a few minutes.

- Increased security, i.e. the heat exchanger is completely closed by the casing.

All batteries have functional drawbacks. The convector radiator is durable, economical, safe and beautiful enough. The only drawback is the high price, because they are made from high-quality and expensive materials.

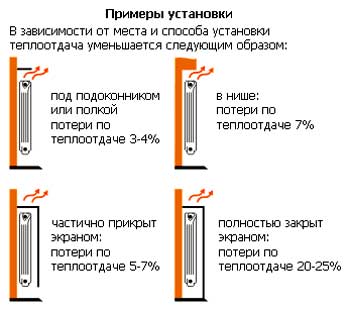

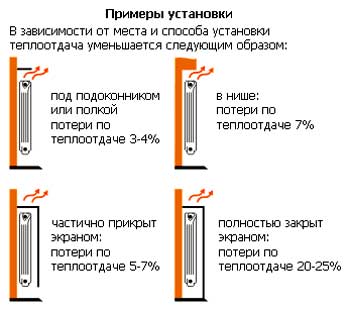

To correctly give preference to one or another type of radiator will help such a characteristic as power. It is easy to calculate it: in a room with a ceiling height of 300 cm and one window, 100 watts will be needed to heat one square meter. When the room has two outer walls, add another 20%. If there are two outer walls and two windows, add 30%. When the window exits to the north side - you should throw 10%. An important factor will be the installation of radiators, because no matter how good you buy the batteries, if they are installed incorrectly, there is still zero sense from this.

There are certain rules for installing radiators:

- batteries are always placed under windows

- their length must correspond to the length of the window, or at least half the length

- in the corner room, an additional pair of radiators can be installed along the outer wall

- it is better to mount heating risers in the corners. This will ensure that they warm up and prevent blackening of the wall and the formation of mold.

- they must be available at all times.

When choosing heating radiators, you should rely on the technical characteristics of the radiators and the heating system itself, as well as the budget. With proper study, you can always find a middle ground for yourself.

It will be interesting for you to read:

- Installation of sandwich chimneys through the wall of the house. Step by step technology

- How to heat a country frame house. Options and lucrative ideas

- Do-it-yourself furnace device for a house with a water circuit for heating

- A cap on the chimney and its installation in the house with your own hands

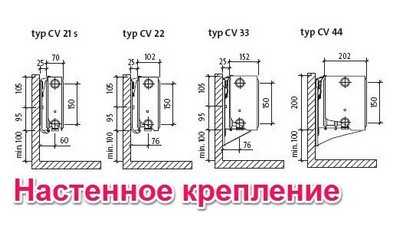

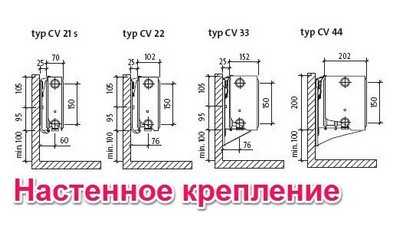

Varieties of panel thin batteries

All manufacturers use the same classification for thin flat heating radiators.

We are talking about five types of heating devices:

- Type 10. The simplest panel (stamped), without any decorative frills. It is classified as one of the popular products from the series "maximally flat panel radiators for heating": the depth of this structure is 46 mm. The most popular of this product line is the Kermi model.

- Type 11. Appliances of this type are characterized by the presence of one layer of convection ribs. The depth of the product was increased to 59 mm.

- Type 12. This design was somewhat complicated by dividing the two flat panels with a finning system. The thickness of the device is 64 mm.

- Type 22. An even more complex scheme is used here: in addition to two panels, there are two finning systems located between the planes. The depth of such a battery is 102 mm.

- Type 33. The most complex model, which includes three planes. The first pair of panels is divided by two ribbed sections at once. Another section is installed between the second and third panels. Due to the increased complexity, the depth of the device also increases: it reaches 157 mm.

It is important to know that the term "flat water heating radiator" is not used to refer to the last two models. Some manufacturers allow a change in thickness in both directions within 10 mm. All versions of panel heaters (except for the 10th type) use a protective top grill and side walls. Thus, the decorativeness of the product increases (this affects its price).

When buying and installing a thin radiator yourself, it is recommended to take into account the following tips from experts:

- Having made a choice in the direction of a flat steel radiator, it is better not to start the risky venture of installing it yourself. Even detailed installation instructions are not justified. The heating system is classified as a complex engineering structure, the organization of which must be carried out by specialists.

- Since panel radiators for heating cannot boast of a large area, it is not recommended to make them part of systems with natural circulation of the coolant. It is best to use such devices in forced circulation circuits where pumping equipment is available.

- If a forced water circulation system is used, it should only be closed. This requires the installation of an expansion membrane tank.

- Do not empty the system frequently. Pouring a new coolant is necessarily accompanied by the ingress of air into the system. Its presence has a negative effect on steel elements. While some preventive measures are being taken by manufacturers, it is undesirable to put the system at risk.

- It is undesirable to equip very humid rooms with panel flat batteries. This leads to the fact that metal surfaces sooner or later begin to rust.

- Any ribbed layer on the radiator becomes a place of accumulation of dust and dirt, which is rather difficult to clean. It is possible to remove such dirt only with the help of a powerful vacuum cleaner.

Steel panel radiators

These radiators are rectangular panels:

The panel radiator is made of two steel sheets welded together. Vertical grooves are extruded in the sheets through which the coolant circulates.

Steel panel radiators are made of one, two or three panels. Vertical pipes are welded to the rear sides of these panels to enhance convection:

Pipes to enhance convection at panel radiators

Panel radiators are produced with a height of 300 ... 900 mm, a length of up to 3 m, and a depth of 60 ... 165 mm.

The plus of panel radiators is a low weight, so they can be mounted alone, powerful brackets are not needed, and the wall material can be not only concrete or brick, but also wood and some kind of frame sheathing (as you probably guessed, the comparison carried out with cast iron radiators).

In panel radiators, it is easy to control the temperature of the coolant, due to the low thermal inertia of these heating devices.

Cons of steel panel radiators:

- panel heating batteries are designed for low pressure (6-8 atm. - working and up to 13 atm. test), hence their sensitivity to water hammer;

- the inner surface of the panels is subject to corrosion;

- poor hygiene, since dust and cobwebs accumulate between the panels, and it is very difficult to get to this muck.

From all of the above, we draw conclusions: it is more correct to install panel radiators in private houses and take care of the quality of the coolant.

Coin Battery Composition

To create steel flat batteries for heating, two plates connected by welding are taken, made by the method of conventional stamping. Between them there is some space called "channel", where the heating medium enters later. Also, the structure is equipped with special pipes, to which elements of the heating system of the house are connected during installation.

An additional element of the appearance of flat batteries can be ribs, which increase the convection capacity and heat transfer by about 60%. However, due to the extra space, these types of flat radiators will collect dust, which is why they are preferable to install them in rooms with strict sanitary conditions.

Coin battery device

The common minus of steel heating batteries

The “weak link” common to all steel radiators is oxygen susceptibility. Well, that is, they rust, as everyone knows. Moreover, they rust not so much from the outside as from the inside, when the coolant is drained from them.

This does not mean that steel batteries should be completely disowned. You just need to understand in which heating systems they should be installed. Steel batteries are suitable for closed systems. As a rule, this is in private homes.

That's all about steel radiators, I hope now you can decide exactly which heating radiator to choose.

When arranging a home with a heating system, it is necessary to pay special attention to heating devices, in particular, radiators. It is on them that the level of warming up the room largely depends.

Among the variety of such elements, I would like to note thin heating batteries. They are much lighter in weight than cast iron heat exchangers, which makes their installation easier and more convenient.

Disadvantages of plate radiators (convectors)

Heating radiator classes

There are 4 classes of heating devices:

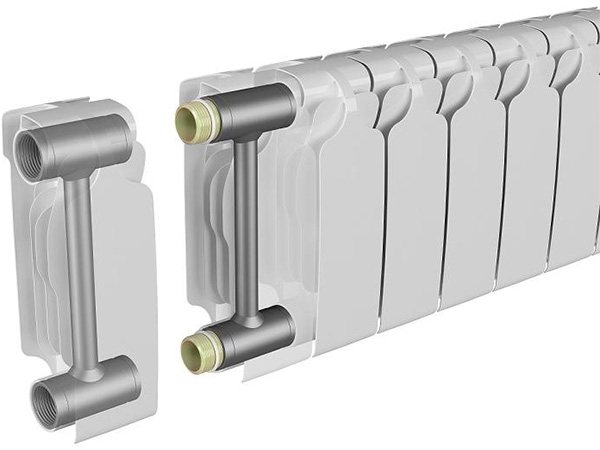

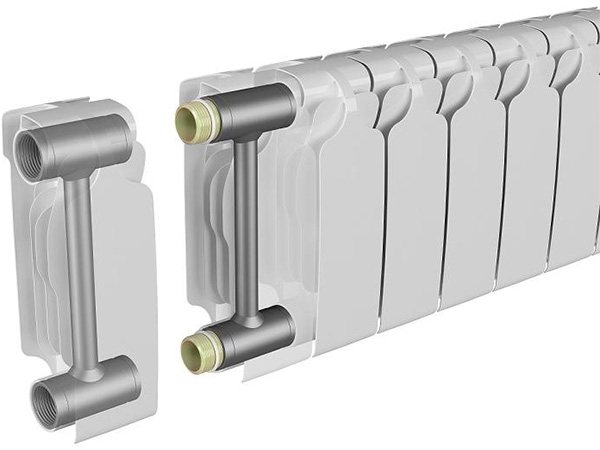

Sectional type radiators are known to everyone. They are made of cast iron, aluminum, steel. There are models for the production of which two materials are used (usually steel and aluminum). Such batteries are called bimetallic.Sectional radiators are assembled from separate sections (sections), receiving at the output a heating device with the required power, given to them in the external environment during operation.

Sectional radiators are assembled from separate sections (sections)

Plate heaters are so named because they are made of several plates that are mounted on curved or straight pipes. The pipes, in turn, circulate a coolant (water). Another name for plate heating devices is convectors. They can be electrical and non-electrical.

Photo: tubular radiator in the interior

Tubular radiators are made of several tubes connected by collectors. They look pretty original. Such radiators are often found in apartments where the interior is made by professional designers. Pipes can be made of any size and shape, for example, in the form of a specific shape.

Photo: panel radiators of different sizes

Panel heating radiators consist of panels that receive heat from a heat carrier circulating in the space between them through channels formed by stamping. There are models with one, two and three panels.

Let's consider in more detail each of the types of heating radiators.

Steel tubular heating radiators

The design of tubular radiators can be very attractive, often they are made in the form of interior items, as in the photo. They have the following parameters: height 190 - 3000 millimeters, depth - no more than 225 millimeters, length has no limitation.

Experts recommend: if steel tube-type heating radiators are being installed under the window, make sure that they are at least 75% of the width of the window opening in length.

These devices have the following parameters:

- working pressure is not higher than 12 atmospheres;

- pressure testing up to 25 atmospheres;

- the maximum temperature of the heat carrier is 120 ° C.

Since tubular devices are able to withstand strong water shocks, they are considered the ideal solution for installation in apartments in multi-storey buildings.

Plate radiators

Along with sectional, tubular and panel heating devices, plate heating batteries are also widely used. In terms of the level of heat transfer, they are second only to panel-type heating devices. But compared to them, they have a much lower price, they can operate at a pressure in the system of more than 10 atm (up to 17-20 atm) and allow hidden installation in floor niches.

Obsolete finned heater.

A significant difference between plate heating batteries and other types is in the way the room is heated. In all other structures, up to 70-80% of the power is spent on heat radiation and heating walls and objects in the room, from which the air is then heated. In the plate type, this power serves to heat the air directly and equip it with convection (mixing) in the middle of the room. Hence the second name for these heating systems - convector heaters.

Air heating is at the same time both a positive quality and a minus, which predetermine the area of use of these devices. And the thing is that heating rooms to the required temperature with the help of heat radiation, although it takes more time, but the effect of it lasts longer, and for finding people, the conditions created are better suited from the point of view of comfort.

There is a heat-reflecting aluminum plate behind the heating device.

Ribbed ones, on the contrary, can in a short time warm up large air volumes to the required temperature, but at the same time they make significant air flows, which make discomfort for people present in a motionless position.Actually, this is the reason for their use in the corridors of public buildings, staircases, gyms, warehouses, etc. In other words, where there are large volumes of premises and there is a constant movement of people (or does not happen, as in warehouses).

Obsolete plate heater in the entrance of a house for housing

Design and types

The design of a plate heating radiator is based on one or several straight, U or W-shaped tubes, to which a lot of metal heat exchange plates are perpendicularly welded or otherwise fixed. The heat carrier moving through the tubes heats these plates, and they then transfer the received heat to the space of the room.

In most cases, the finished device is placed in the middle of a thin-walled body, which serves to protect it from burns and cuts against the sharp edges of the plates. The housing or casing also protects the fins of the heater from dust and damage from mechanical factors. However, there are models, mainly radiators made of steel with increased thickness of fins and trimmed edges, which are intended for operation without a casing, "as is."

Old ribbed battery.

Along with the shape and size, the following main types of plate heating batteries are distinguished.

- By the material of the device: steel; copper; bimetallic in combinations: steel - copper, steel - aluminum, less often copper - aluminum.

- By the number of pipes: single-pipe and multi-pipe with a manifold.

- By the method of connecting to the backbone: with side and bottom connections.

- According to the installation option, there are pendant heaters and built-in type in the floor niche. The latter are placed either specifically on the floor or on the insulation material.

Obsolete plate heating radiator.

If we talk about the pros and cons, then the obvious positive qualities include cheapness, high heat output and the speed of heating the air. And also reliability due to the small number of connectors. The most serious disadvantages: uneven temperature distribution across room levels and high requirements for cleanliness. Although, the latter is more correct to call the secret positive quality of steel plate heating radiators.

Finned heater, behind which there is an aluminum heat-reflecting plate.

Summarizing. The overwhelming majority of manufactured heating devices operate on the principle of convective air circulation. However, there are models with a built-in fan. Based on this, this raises the price and the overall energy consumption of the device, but by increasing the intensity of air mixing, it partly solves the problem of a sharp difference in temperature along the height of the room.

Existing types of radiators

In modern heating systems, various radiators can be used, which can be classified as follows.

By design, devices are:

- sectional - the most common type; as the name implies, they are a set of series-connected sections, and the efficiency of their functioning will depend on the material from which they are made, overall dimensions and the number of elements; their main advantages are the ability to build up during operation with insufficient radiator power, as well as reliability, durability;

Figure 1 - Sectional heating radiators

- panel - unlike all other types, this type has an attractive appearance, a wide range of standard sizes; the device of such devices is quite simple: two panels between which a collector and vertical thin plates are located; this design provides a high heat transfer coefficient with a minimum volume of the coolant; have low weight, low cost; however, it should be borne in mind that such products have a short service life due to low resistance to water hammer and susceptibility to frequent clogging with scale and other deposits;

Figure 2 - Panel heaters

- lamellar - they are often called convector; this is the cheapest and simplest version of radiators, which is a core in the form of a heating pipe, to which thin-walled steel plates are welded; Despite their reliability, such devices are not very popular, because have a low heat transfer coefficient (according to available data, it is 35-40% lower than that of sectional ones), uneven heat distribution, unpresentable appearance;

Figure 3 - Plate radiator

- tubular - they are an all-metal structure, the device of which, as a rule, includes the lower and upper collectors, interconnected by curved vertical cuttings; such radiators are distinguished by their original appearance, reliability, uniform heating of the room, however, they have a high cost.

Figure 4 - Tubular heating device

By the type of material, they are distinguished:

- cast iron heating devices - they are produced in section, are considered traditional and until recently were the most popular due to their high inertia (ability to retain heat for a long time), heat transfer, durability, corrosion resistance, resistance to hydraulic shocks; high weight and fragility are noted as disadvantages;

It should be noted that the early models of cast-iron radiators had an unattractive appearance, but in recent years devices with a beautiful design have appeared on the market, which has led to their demand in modern heating systems, despite the emergence of new types of devices.

Figure 5 - Modern cast iron heating radiators

- aluminum radiators - they are also produced in sectional, but unlike cast iron, due to the design feature, each section has a large heat transfer surface; such devices are distinguished by their lightness, low cost, visual appeal, and the ability to withstand high (up to 1.8 MPa) pressure in the system; can be of various sizes, allowing you to choose the best option for each specific case;

It should be borne in mind that aluminum radiators have application restrictions. Due to their low corrosion resistance, they are not recommended for use in centralized heating circuits, in which the composition of the coolant is not constant.

Figure 6 - Aluminum appliances for heating systems

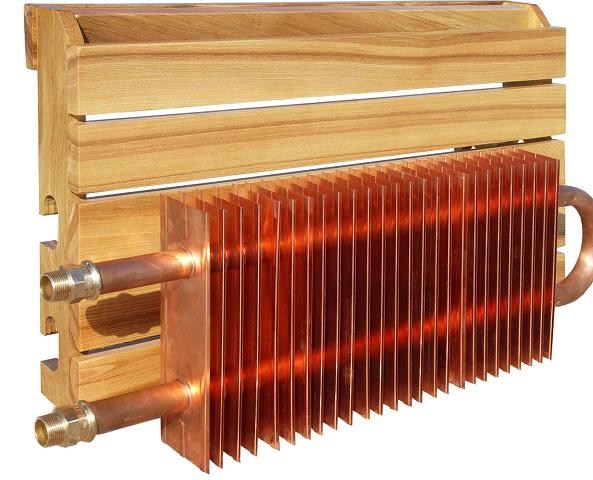

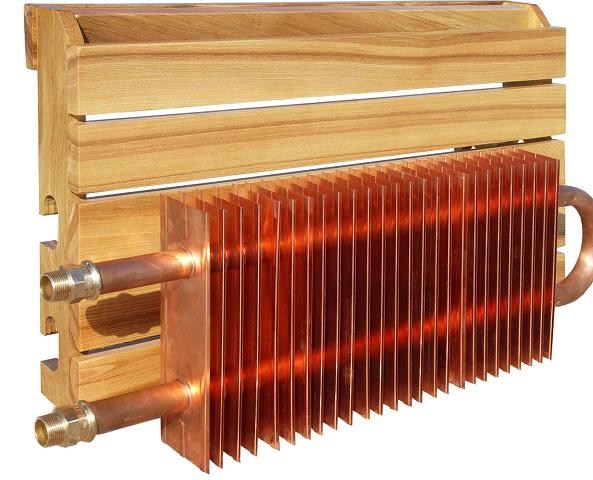

- copper batteries are distinguished by their reliability, durability, increased heat transfer, resistance to aggressive environments; however, they have a high cost and rather complicated and expensive installation, which limits their use;

Figure 7 - Copper plate radiator

- steel appliances - there are panel, plate and tubular; they are distinguished by a high heating rate and the degree of heat transfer, are lightweight, but have insufficient corrosion resistance;

It is required to remember that steel radiators are characterized by reduced inertia, therefore, when the temperature of the coolant in the heating system decreases, they cool down quickly.

- bimetallic batteries are a modern type that combines the advantages of sectional and plate models; structurally represent a steel or copper core to which aluminum panels (sections) are attached. Among the advantages of such radiators are high heat transfer, reliability (insensitive to pressure drops in the system and the chemical composition of the coolant, exclude leaks). Among the disadvantages should be called the high cost, the complexity of cleaning external surfaces.

It should be borne in mind that the presence of air (oxygen) in water can cause corrosion of the steel element of bimetallic heating devices, and, consequently, reduce their durability.

Figure 8 - Device of a bimetallic battery

By the method of heat transfer, radiators can be divided into:

- radiation (radiation) - these include sectional (cast iron), tubular devices;

- convection - panel and plate models;

- convection-radiation - bimetallic, aluminum and steel sectional radiators.

It should be noted that this division is conditional, since all heating devices generally transfer heat by means of both convection and radiation, but differ in the predominance of each of these processes.

Aluminum radiator

It is widely used to design a heating system in a private house. They became popular due to their design and high heat output. The cost of such radiators depends on the manufacturer.

Radiators of domestic manufacturers will cost less, but after getting acquainted with the reviews of consumers, it is worth giving preference to foreign counterparts, but their price is much higher.

When choosing an aluminum radiator for a localized system of your own home, you must adhere to a list of very significant conditions for selection and operation:

- An aluminum radiator is the most susceptible to circulated fluid. It is required to strictly observe the required level of acidity of the water, otherwise such radiators will become unusable within several years;

- Aluminum radiators have a threaded connection. which increases the risk of leakage;

- The high heat output of aluminum radiators has a downside. When the radiators are heated, the warm air flow rises very quickly, which leads to a temperature difference between the floor and the ceiling.

Sectional aluminum radiator

This means that when choosing aluminum radiators, there is a need to make accurate calculations for the area of the room, since the floor can remain cold.

But aluminum radiators also have undoubted advantages:

- Relatively light weight, which makes it possible to mount on drywall walls;

- Sufficiently aesthetic appearance

- The presence of special taps that allow you to regulate the temperature.

The relatively low price, good design and instant heat dissipation are the secret of the popularity of aluminum radiators.

These are quite acceptable radiators for a heating system in a private house. Observing strictly the norms of selection and use, such radiators will heat your cozy home for a long time.

Features of operation

When using the technique, you must adhere to the restrictions:

- the temperature of the coolant should not exceed 110-120 ° С;

- the recommended working pressure, depending on the model, varies between 4.5-10 MPa;

- a small volume of working fluid used implies forced circulation;

- the maximum permissible acidity of water is 8.5 RN;

- steel products are not recommended to be installed in damp rooms.

Flat panels are not intended for installation in apartments with district heating. Experts do not advise frequently replacing the coolant in order to prevent oxygen from entering the radiator cavity. Optimal conditions for the use of products are a closed system with a circulation pump and a membrane-type expansion tank (the latter protects the equipment from water hammer).

Which heating battery to choose for your home

Shopping list? Don't like the look of the batteries in your home? Do you think their sharp corners and elevated surface temperatures are dangerous for your little child? Buy a screen for a radiator and install it - it will not take much time and will not require serious financial investments. Meanwhile, such a product is able to provide:

Plate radiators for heating: characteristics, photos. Heating radiators Plate heating radiator: features of old.

With the onset of the warm season, it's time to think about the efficiency of the heating system. If it needs to be replaced, summer is the best time for installation work. At the height of the heating season, it will not be possible to replace the radiators.

Thin metal plates are set on the tubes. They are designed to increase the level of heat transfer between the heating element and the room air. Plate batteries are used in public premises and industrial buildings, industrial workshops. In frequency housing construction, they have not received proper distribution for a number of reasons. However, they are widely used for heating multi-apartment buildings, where centralized heat supply dominates. With good insulation of the building, a plate heater is able to maintain the air temperature at the proper level with a minimum consumption of thermal energy.

Important: there is an opinion that now a cast-iron radiator is worse than Soviet times.

Radiators are an integral part of heating systems if heated floors are not used instead. It is not always easy to combine their appearance with the interior. This can be made easier by using radiator shields. The screens are attractive in design and shape, so there is always something to choose from. What materials are the screens made of and which one is better to choose? This will be discussed in the article. A screen for a heating radiator has several purposes.

Modern heating radiators are of several types. Depending on the material from which they are made, these devices have different characteristics. That is why problems often arise with how to choose the right heating battery.

To decide which heating battery to choose, you need to pay attention not only to the size and appearance of the radiators, but also to their features.

RELATED VIDEO: Choosing a heating radiator // FORUMHOUSE

Steel Battery Specifications

Battery specifications include:

- heat transfer;

- inertia;

- working pressure.

Each type of heating structure has its own technical features. Heat dissipation depends on several factors:

- sizes radiator;

- availability protective casing;

- function convection;

- masses.

The protective cover reduces heat transfer, and the presence of a convector increases it.

Inertia - the property began to quickly heat up and cool down, depending on the temperature of the carrier.

Weight each radiator is determined by the model and dimensions. But, in comparison with their cast iron counterparts, steel batteries are much lighter.

Working pressurethat steel heating devices can withstand depends on the specific model and wall thickness of pipes and sections. So, panel batteries are able to withstand pressure up to 40 atmospheres, whereas tubular models will not carry the above 13 atmospheres.

Plate heaters

Introduction

A plate heater is a bent or straight pipe for a water supply, with steel plates strung on it. A heat carrier moves through the pipe, and the plates significantly increase air convection. Structural simplicity determines their low cost. For aesthetics, the convector heater is closed with beautiful boxes made of thin white painted steel.

Steel plate radiators - general information

Steel plate heating devices in simple speech are called "" accordions ". The appearance of an accordion is made by plates strung on a pipe for a heat carrier.

A characteristic feature of this type of radiator is its high reliability. The plate radiator has no connections other than the inlet and outlet of the coolant. As a consequence, the heating device itself simply cannot flow, there is nowhere to push the heat carrier.

Due to the huge number of plates, and the direct movement of the heat carrier, the design heats up the radiator to a high temperature. To save it from touching, the key frame of the heater is covered with a decorative cover. Convection holes are provided in the upper cover of the casing.

Convector heaters have low thermal inertia, which means they can be controlled automatically, in other words, thermostats can be installed in systems with plate heaters.

Plate heaters form a rather powerful curtain of heat. This property of convector heaters makes it possible to use them in floor heating systems. True, the design of floor convection heaters differs from wall convector heaters, but the principle of heating is the same.

Cons of plate heating devices (convector heaters)

- The convective type of heating devices does not make it possible to equally warm the room. The batteries are warmer than the opposite wall of the room.

- Convector heater plates are a wonderful dust collector. It is difficult to clean them. Over a period of time, dust reduces their heat transfer.

- The appearance of the plate heaters is not pleasing, although there are nice models.

Variations of plate heaters

As options, plate heating devices are used for floor heating (duct convectors) and plinth heating of the room.

Connecting convector heaters

There are two types of convector heaters for connection. This must be looked at at the time of purchase. The first type is a convector heater with side connection. The second type is a convector heater with bottom connection0. It is completed with a valve insert.

Heating capacity of plate heaters

The heat output of convector heaters depends on their length and the number of rows with plates. The height of all convector heaters is 200 mm.

Thus, the heat output of a convector heater in a "one line" 600 mm long is 347 W. It is also 3000m long and gives a heat output of 1730 W. A heater in 4 "strings" 3000 mm long gives a heat output of 4179 W, and it will give off 1393 W of heat with a length of 1000 mm.

The calculation of the heating device is carried out according to the standard calculation scheme for the sections of heating devices, taking into account all correction factors. Let me remind you how this is done. (read the publication: The simplest calculation of the heating system)

- For 1 sq. meter of area with a ceiling of 3 meters, you need 100 watts of heat.

- For a room of 16 sq. meters, a heating device of 1600 watts is required. This is under good conditions: one window, ceiling 3 meters, the room is not angular. If this is not the case at all, we use the correction factors:

- Two windows k = 1.8: 1600 × 1.8 = 2880W;

- Corner room k = 1.8: 2880 × 1.8 = 5184W;

- Ceiling 2.65, k = 2.65 / 3.0 = 0.88: 5148W? 0.88 = 4547 W;

- PVC window k = 0.8: 4547W × 3637 W.

A standard window has a width of 1400 mm, which means that under each window it is necessary to install 4-section plate heaters with a length of 1400 mm, with a heat output of 1950 W. The data are taken from the passport of Purmo heaters. That's all!

Specifically for Obotoplenii.ru

Determination of the thermal power of plate heating devices

The formula for determining the thermal power that a steel plate heating radiator can give, and a real example of calculating this parameter, are given below. To calculate the power of the device, it is enough to know the heat loss coefficient of the heated room, the area of the room and its total volume. The passport of any radiator indicates its design power at a hot water temperature in the system of 60C. Also, the attached documentation contains recommendations on the heated area for a specific radiator model.

The heat output (power) of heating devices depends on the length of the body and the number of plates. The standard height of radiators is 200 mm, the number of plates varies. For example, the heat output for a radiator with one tube and a body length of 600 mm will be ≈ 347 W.With an increase in the length to 3000 mm, the heat transfer will increase to 1730 W. But with the same length of the body (3000 mm) and an increase in the tubes to 4, the heat transfer will already be 4179 W, and if the length of the body is 1000 mm, four tubes with a coolant will give 1393 W of power. ... Therefore, which radiator is better to buy for a particular room is determined based on the following requirements:

- For heating 1 m2 of a room with a ceiling height of 3 m, you need to spend 100 W;

- For a room with an area of 16 m2, the radiator must have a thermal power of 1600 W, despite the fact that no more than one window is equipped in the room, the room is not corner and the ceiling has a height of no more than 3 m. For other initial conditions, correction factors Kp are introduced:

- For two windows Kp = 1.8 / 1600 x 1.8 = 2880 W;

- For a corner room Kp = 1.8 / 2880 x 1.8 = 5184 W;

- For a ceiling with a height of 2.65 meters Kp = 2.65 / 3.0 = 0.88 / 5148 W x 0.88 = 4547 W;

- For PVC windows Kp = 0.8 / 4547 W x 3637 W.

A standard metal-plastic window is 1400 mm wide, therefore, to fully block cold air flows, a radiator of four 1400 mm long sections with a capacity of 1950 W is installed under it.

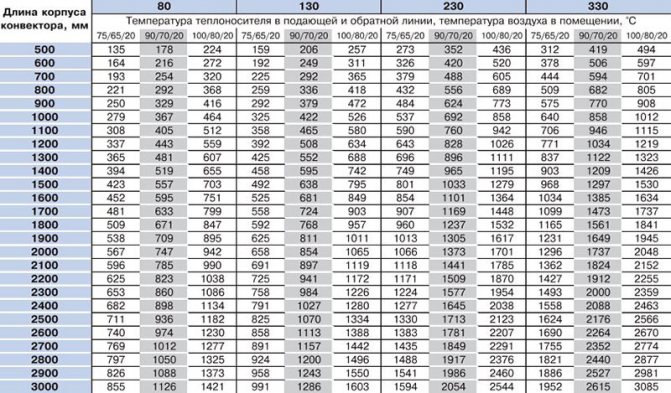

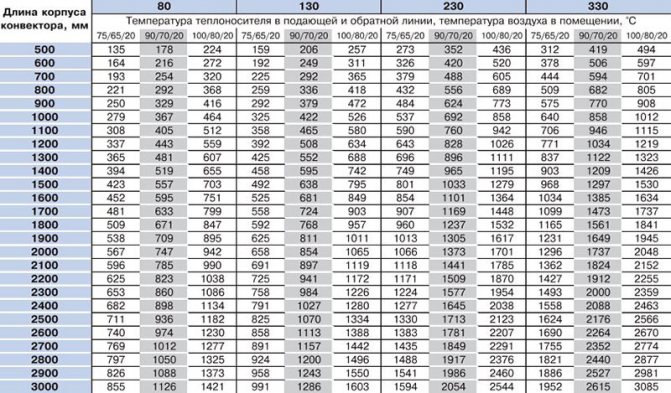

Power table

The heating radiator works like this:

- Under pressure or by gravity, the coolant moves through the tubes of the battery, heating them;

- The tubes heat the plates welded to them, and together the structure heats the air between the elements of the radiator, which rises up to the ceiling of the room;

- Cold air masses under the pressure of warm air descend to the radiator, where they heat up;

- Then the cycle is repeated.

That is, in any radiators with a coolant, the room is heated due to air convection.

Plate radiators have one distinctive feature: due to the small diameter of the coil, an insufficient amount of coolant passes through them per unit of time, so it is necessary either to keep the temperature in the boiler constantly high, or to install radiators with a large number of plates (sections).

High power radiators

To increase the efficiency of a plate heating battery, a metal corrugation is put on its body, which simultaneously acts as a protective casing. The corrugated surface increases the heat transfer area, which leads to an increase in the volume of warm air.

In old models of plate radiators, convection (movement) of air occurred naturally - due to the movement of warm and cold air currents. New models have built-in electric fans, and therefore it is only necessary to increase the temperature of the coolant without increasing the radiator area in order to achieve the maximum possible heat transfer from the device. That is, in modern models, artificial (forced) convection occurs.

Plate radiator with fan

To date, manufacturers offer to buy radiators from the following materials and different designs:

- The steel radiator has both tubes and steel plates. Although its strength is high, heat transfer is characterized by inertia;

- The copper radiator has increased power and heat exchange. All this is accompanied by the high cost of the device, but if you decide to buy it, choose a copper coil and steel plates: this will be cheaper and will not affect the quality and durability of the radiator;

- An aluminum radiator is the cheapest model with minimal heat transfer inertia, but it cools down as quickly as it heats up. The case is not as strong as in the first two models, and the metal itself is affected by corrosion due to low-quality coolant. Therefore, it is better not to install such devices in central heating.

Radiators from different alloys

Advantages and disadvantages of plate heating devices

Advantages:

- Simple and reliable design;

- Cheap cost, repair and maintenance;

- Duration of operation;

- Rapid heating of heated rooms.

Plate radiators made of steel are capable of operating under a pressure of up to 20 at and a heat carrier temperature of up to 1200C. The design of modern devices is strikingly different in variety from the old-style models, and this quality helps not only not to disturb the design and interior of the premises, but also to create a new one, since there is no need to hide a beautiful and original designed radiator behind panels or casings.

Disadvantages:

- The premises in the house are heated only due to the natural movement of air masses, and an increase in heat transfer is possible only by including an electric fan in the circuit;

- High inertia of plate radiators made of any metal or alloys due to the thin walls of the devices - the metal heats up quickly, but just as quickly and cools down when the coolant supply is stopped;

- Difficulty caring for the radiator - due to the small distances between the plates between them, it is difficult to remove dust.

Plate radiators in interior design

Connecting radiators

- As is already known, a plate radiator before sale is completed with a tap and a valve insert with a thermostat for automatic regulation of the temperature of the coolant and air in the room;

- Some models are equipped with mechanisms for connecting the radiator to the heating circuit under the floor or built into the walls of the room;

- The main radiator connection diagrams are side or bottom: When connected to the side, the radiator fittings are located on the sides, which does not interfere with connecting them to the vertical riser. When connected horizontally, the radiator is connected via a fitting.

- With the bottom connection, the radiator fittings are brought out from below, so the horizontal connection does not pose a problem, and for the vertical scheme, the radiator is connected through fittings.

Lower radiator connection

Radiator side connection

Practical and organizational conclusions

The principle of operation of plate devices is the same as that of water devices - they increase and maintain the temperature in the room due to streams of warm air.

- The reliability and strength of steel radiators is much higher than that of devices made of other alloys and metals, therefore they are recommended for operation in a central heating system.

- Copper radiators do not corrode, but in high pressure systems it is better not to install them. Another disadvantage is the high price.

- Aluminum radiators are the cheapest of all, have excellent heat transfer, but mechanically weak housing, which also corrodes quickly in an acidic environment.

Since the connection of the plate radiators is carried out through the bottom or side fittings, they can be mounted directly on the floor, embedded in the floor surface or hung on the wall of the room. For each individual case, you can choose your design and technical equipment of the device.

Choosing heating radiators for a private house which is better

When the construction work on the house is completed, the question arises of how to arrange the heating system so that the house is warm.The main component of the heating system is, of course, heating radiators. Their choice must be approached with particular seriousness, because the strength, durability and reliability of your heating system depend on it.

Consider the main advantages of the heating system of a private house:

- Its work is carried out at low pressure, which favorably affects the operation;

- In this system, there are no large hydro-shocks, this provides a wide range of radiator selection;

- Observing the necessary technical conditions for the acid balance of water, the choice of radiators is very wide.

Taking into account the above, the choice of radiators should be carried out taking into account the maximum heat transfer coefficient and a good price-quality ratio. If you do not go into details, any type of radiator can be used in a private house. But knowing the benefits of one or the other still does not hurt.

For the manufacture of radiators, the following types of materials are used: cast iron, aluminum, metal (steel), bimetal.

Panel radiators

To get a panel radiator, you need to take two steel sheets, make them fins and weld them together. Connect the structure to the pipes of the heating system, start up the coolant and enjoy life.

There can be from one to three panels. They all come in various sizes. The design is lightweight. Such radiators can be controlled by automatics.

Photo: panel radiators

- Painful sensitivity to pressure surges;

- Difficulty leaving;

- Sensitivity to the composition of the coolant;

- Work at low pressure (7-9 atmospheres, short-term - 12-14 atmospheres);

- Rusting.

Experts advise installing batteries in private houses with a high-quality coolant.