Requirements to be considered when working with gas pipelines

Before passing gas to the stove and the boiler, it is necessary to find out what features should be taken into account when carrying out this type of work.

As a rule, gas does not differ in its pressure from atmospheric pressure. However, a typical excess of gas in the pipe can be 0.005 MPa or 0.05 atmospheres.

Since neither gas nor its propane-butane mixture are chemically aggressive substances

, they do not cause corrosion of steel pipelines.

In addition, the minimum viscosity of the gas allows it to be transported through a pipe with a small inner diameter. Therefore, it is quite possible to install a pipe that is no larger than 1/2 inch.

It should be remembered that most often when installing gas boilers with high power ratings, pipes with a large cross section are used. As a rule, the recommended parameters are indicated in the instructions that accompany any gas equipment.

Gas lines must be completely sealed.

This also applies to pipe connections. A gas leak, unlike a tap water leak, is a very serious problem that can lead to fire or explosion.

What to do if the diameter of the gas pipeline does not match the boiler connection?

Sometimes the inlet on the boiler may not match the diameter of the gas pipeline. For example, the gas branch pipe of the floor-standing boiler "Navien" is made at 1/2 ″, and the gas pipe is 3/4 ″. Is it possible to connect the device using a DU-15 1/2 ″ bellows connection instead of 3/4 ″? Such a transition is permissible, since it is local and does not offer significant resistance.

A modern private house, and even more so an apartment in an apartment building, cannot be imagined without gas equipment. It can be a stove, a heating boiler, a heating boiler, and other household appliances.

Gas is supplied to a house or apartment through a pipeline system, and from it to each individual consumer through flexible piping. Flexible gas supply can be made in several versions at once.

Steel pipes

Pipes of this type are used when laying a gas pipeline from the central highway to houses. They are installed above the ground.

In this case, only black steel pipes can be used. Galvanized pipes are not suitable. Outside, the pipes are primed and painted to protect them from corrosion.

The inner surface of the pipe does not require additional processing, because it will have a minimum content of water vapor, and oxygen will be completely absent.

Steel pipes can be connected using traditional methods using welding or threaded fittings. The latter can be made of either brass or cast iron.

To seal the connection, it is necessary to wind up the thread. In the places of the bends, locknuts are used as seals. The sealing material can be a soft and high temperature resistant FUM tape.

When sealing the threaded joint with tape, it must be borne in mind that it is not worthwhile to apply great efforts during assembly. If you choose to rotate the fitting even slightly in the opposite direction along the thread, it will be difficult to avoid gas leakage.

Natural gas connection

The gas boiler is designed to connect natural gas, the technical characteristics of which correspond to GOST 5542. Fuel, as a rule, is supplied from a low-pressure gas pipeline in the amount of 0.0013 - 0.0020 MPa.A filter mesh and a valve-regulator of the torch ignition device are installed on the supply line.

The gas solenoid valve maintains the stability of the gas pressure at the inlet to the boiler burner mechanism. Therefore, regardless of fluctuations in gas pressure on the line, stable, safe functionality with high efficiency is ensured.

The electronic control regulates the power of the gas burner within 40-100% of the declared nominal power.

Gas connection method

Before considering the options for connecting natural gas to the boiler, you should recall the established rules for the operation of such equipment. Gas fired boilers are hazardous technological objects.

Installation, connection and operation of such systems requires compliance with established safety standards.

Gas boilers are installed only inside premises suitable for installation (kitchens, corridors, utility rooms). This refers to the premises of public industrial buildings, private houses, cottages. All these properties must meet the requirements for the presence of effective ventilation.

As a rule, compliance is determined by SNiP 42-01-2002 and SNiP 2.04.08-87. When solving the problem of how to connect the boiler to the gas line, you need to remember that the operation of the equipment requires the construction of a mechanism for removing smoke into the atmosphere. In addition, it is necessary to ensure the supply of atmospheric air for an efficient combustion process.

Gas boilers that support the function of natural withdrawal of combustion products must be installed in the immediate vicinity of chimneys with natural draft.

For equipment, the design of which provides for air leakage directly at the installation site, a normal level of air discharge should be ensured. Inside such premises, the air must be free from dust and chemical impurities.

Technical nuances of connection

The process of connecting a gas boiler to a gas pipeline using a flexible hose is accompanied by its own technological and technical features. So, the laying of the gas pipeline and the subsequent connection to the boiler can only be carried out by gas specialists.

Before connecting the gas boiler, the connected section of the gas pipeline should be cleaned from foreign substances, impurities, and contaminants. This requirement is especially relevant for installation on used systems.

The gas inlet must be equipped with a gas shut-off valve, complete with a thermal lockout device (TAE). Before connecting the gas pipeline to the boiler, it is required to check the tightness of all joints and connections of the gas pipeline with a test pressure of at least 0.15 ATI.

The cross-section of the flue gas line must match the diameter of the nozzle on the flow protector. The narrowing of the passage part of the flue gas pipe is allowed, but only on condition of justification by calculations (according to GOST standards) of the correct functioning of the line.

The flue gas pipeline is made as short as possible, with a slight slope in the section of ascent to the chimney.

The gas supply line to the boiler is usually made on the basis of a metal pipe. It is allowed to build supply lines based on steel and copper pipes.

Meanwhile, the permitted installation of polymer pipes (multilayer, with a metallized layer) is also not excluded. True, polymers are allowed to be used only inside buildings no more than three stories high.

Using a flexible hose

It is permissible to connect a gas source to the boiler using a flexible hose.

Condition for the use of a flexible hose:

- resistance to gas environment;

- compliance with the working (test) pressure;

- compliance with the working (test) temperature.

The noted characteristics and parameters can be taken from the technical passport of the boiler equipment. In this case, the flexible hose used must have a diameter size of 20 mm, and the length of the sleeve can be no more than 1.5 m.

Connection with flexible hoses (sleeves) must be carried out in full accordance with the installation rules specified in the accompanying documentation of the product manufacturer.

Features of connection with cylinders

Flexible hoses (sleeves) are often used to connect the SG cylinders to the boiler plant. However, in order to turn on the boiler exactly in such a fuel make-up mode, it is necessary to perform a number of settings for transferring the equipment to operation with bottled gas.

If the boiler design supports a similar power supply option, the instructions describe the sequence of operations.

Here, the technological requirements for flexible hoses practically do not differ from the requirements for a connection with a centralized backbone. Also, the hose diameter is at least 20 mm with a length of no more than 1.5 m. However, the gas cylinder must be equipped with a pressure reducer set at 2.9 kPa (vapor medium).

For the cases of supplying boilers with bottled liquefied gas, separate standards have been approved, in particular, those related to the storage and operation of cylinders. For example, these norms prohibit placing vessels in areas open to sunlight, near heat sources and open flames.

One of the main prohibitions is the taboo on the installation of gas equipment directly inside buildings.

An overview of gas boilers operating on liquefied cylinder gas is given in this article.

Thus, the use of gas boilers in practice, including the domestic sphere, must be considered a responsible action, the accuracy of which determines the degree of safety.

Hose connections

To perform gas distribution, you can use not only pipes, but also rubber hoses. but these should be special double-layer hoses made of vulcanized rubber

... There should be a textile reinforcement between their layers. These hoses are used when connecting a torch or torch to gas cylinders.

Fittings of the required diameter are used as fittings connecting the gas hoses. The hose must be pulled onto the fitting by applying force and secured with an aluminum clamp.

To facilitate the assembly of the gas supply, made with a hose, grease must be applied to them before connecting the hoses. The same substance will seal the joint.

In the process of connecting the reducer to a gas cylinder, a connection consisting of a union nut and a gasket is used. As a rule, in this case, a gasket made of fluoroplastic is used. If the latter is lost or destroyed, vulcanized rubber can be used instead.

Gas hose

In appearance, the gas hose is a flexible tube marked in yellow. Previously, a device made of steel was used instead. When imported equipment appears on the domestic market, the range of necessary accessories is quite extensive. Purchasing a flexible gas hose for boilers is the first step towards increasing the level of safety in the kitchen.

Gas hose

When is the best time to use polyethylene pipes?

If you plan to lay the gas pipeline in the ground, then in this case you cannot do without polyethylene pipes. Steel pipes in this case are not the best option, since, laid in the ground, they are vulnerable to corrosive processes.

In theory, both cross-linked and regular polyethylene can be used to perform the gas supply.However, XLPE is practically not used as there is no benefit from being stronger and more heat resistant. But its price is higher when compared with ordinary low-pressure polyethylene.

In a store, identifying polyethylene pipes that can be used for gas supply is quite simple. A yellow line is drawn along their entire length.

It should be noted that compression fittings made of polyethylene are not used on gas lines. Their mechanical strength is limited, and it is not worth completely eliminating the possibility that no external influences will be exerted on the gas pipe.

Sleeve connections are also not suitable, for the implementation of which either rubber seals or glue are used. Most often, this method is used when it is necessary to connect PVC pipes intended for sewage. They are not suitable for gas, since they do not guarantee complete tightness.

It remains only to use three types of fittings:

- brass, which provide both tightness and mechanical strength;

- fittings for welding, which are connected with a soldering iron at low temperatures (it is recommended to set the temperature to 240 degrees Celsius);

- electrically welded, on which spirals are already applied, intended for melting of contact surfaces. They are expensive but can guarantee a high quality connection.

How to choose a hose for a gas boiler

First you need to decide on the place where the equipment will be purchased. Gas workers recommend buying the device only in a specialized store. The quality is evidenced by the certificate of conformity. Its absence is the first sign of a counterfeit product.

When choosing a hose, the consumer should be guided by the following factors:

- product price;

- material of manufacture;

- dimensions (length from 1 to 2 m, diameter - ½ and ¾ inches);

- type of fastening (two union nuts, a nut and a union);

- the nature of the thread (welded, glued together).

When buying a hose, you need to be guided by the recommendations of specialists. They will help you select products based on the data provided by the client. Before purchasing a gas hose, you need to evaluate its appearance. There should be no mechanical damage, cracks or scratches on the flexible tube.

New serviceable gas hose

Metal-plastic for gas

Reinforced-plastic pipes can also be used for gas supply. From the inside, pipes of this type are polyethylene already familiar to us.

Due to the fact that metal-plastic pipes are supplied in coils, it becomes possible to lay a fairly long gas pipeline without using a large number of connections.

If the pipes still need to be connected, then only press fittings should be used. With their help, it is possible to ensure the tightness of the joint, which will retain its properties for a long time. However, to make such a connection, a special device is required.

Varieties and features of boilers

Gas boilers are classified according to several criteria, one way or another affecting the way they are installed. These are the signs:

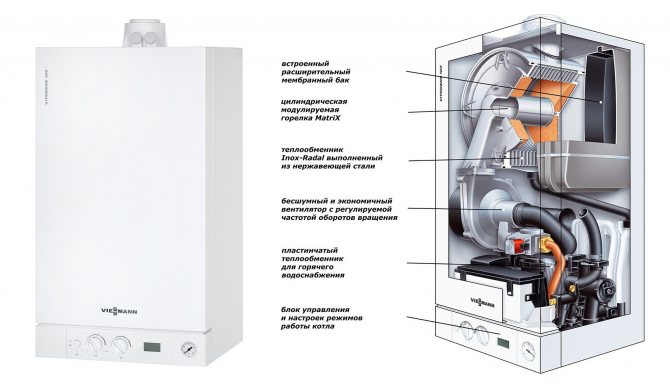

- Burner type (atmospheric or turbocharged). In the first case, the combustion products are carried away into the chimney or ventilation duct by natural draft arising from their heating. The air for the burner is taken from the boiler room. In the second case, both the intake of air and the removal of combustion products are forced through a coaxial (double-walled) air duct passing through the outer wall of the house. At the same time, the supply air in the outer pipe excludes the heating of the wall, which makes it possible to mount a coaxial chimney in a wooden house without additional thermal protection;

The photo shows the output of the coaxial air duct of the turbocharged boiler through the wall of the house.

- Ignition type... The piezo ignition burner attracts with its energy independence: it ignites once when the boiler is turned on. As soon as the coolant heats up to the set temperature, the main burner goes out, but the pilot burner continues to burn. A boiler with electronic ignition is volatile, but does not use a continuously burning igniter and, due to its absence, saves up to a quarter of gas;

All turbocharged boilers are with electronic ignition. The operation of a forced draft fan is volatile, so there is not the slightest reason for manufacturers to use a less economical operating scheme.

Gas boiler device with forced draft and electronic ignition.

- Possibility of independent connection of the DHW circuit (hot water supply). The double-circuit boiler has a separate heat exchanger for hot water preparation.

A single-circuit boiler, like a double-circuit one, can be used for DHW needs. However, in this case, the piping must necessarily include an indirect heating boiler - a hot water accumulator with a heat exchanger through which the heating system coolant circulates.

Boiler room with indirect heating boiler. The water in the tank is heated by the heating medium of the heating system.

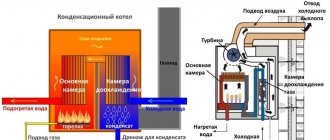

- Full utilization of the heat of combustion of gas... If traditional boilers use the so-called lower heat (heat released during the chemical reaction of oxidation of hydrocarbons), then condensing boilers utilize the higher heat of combustion. It includes the heat released during the condensation of water vapor, one of the products of natural gas combustion.

The advantage of condensing boilers is their economy, which provides an incredibly high efficiency.

The condensing boiler operates at a lower return temperature than the traditional return temperature - no more than 50 ° C (more often - 30-40 degrees). Therefore, it is usually not radiators or convectors that are used with it, but a warm floor - pipes with a heat carrier laid in a screed and turning the entire surface of the floor into a heating device.

Underfloor heating can coexist with radiator heating. It allows the return flow to be cooled to 30-40 degrees, which are optimal for a condensing boiler.

Installation requirements

The necessary conditions:

- The hose must be accessible.

- It is forbidden to connect several devices to one flexible element.

- The soft element is provided with sagging, twisting is not allowed.

- Docking is provided by a threaded connection. Welding and brazing are not applicable.

- In the presence of a metal braid, it is necessary to prevent the presence of condensation on its surface.

- The gas hose is changed after the end of its service life. This standard is set by the manufacturer.

It is better to entrust the installation of the connection to specialists in order to prevent leakage of the substance.

Advantages and disadvantages of gas lines

It is necessary to consider the advantages and disadvantages of gas connections, taking into account their type and material of manufacture.

| Type of gas supply | Dignity | disadvantages |

| Rubber-fabric hose |

|

|

| Metal braided rubber liner |

|

|

| Bellows type lead |

|

|

| Oxygen hoses |

|

|

| Reinforced PVC hose |

|

|

For the connection of gas equipment, only a duct with a corresponding marking is suitable. Do not use water hoses in the gas system.