Gas boiler piping in the heating system

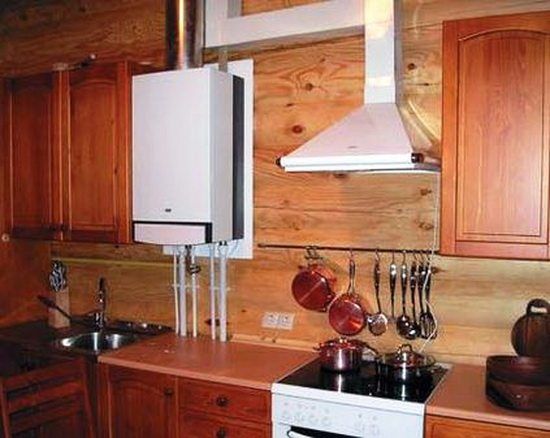

After the wall-mounted gas boiler has been installed and the heater is placed on the wall, the first step is to connect it to the heating system. Depending on which model is installed single-circuit or double-circuit, there are different strapping schemes. We will consider the connection process using the example of a wall-mounted double-circuit gas boiler.

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermal or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is quite enough for 1-2 points of distribution (for example, a kitchen faucet and a shower).

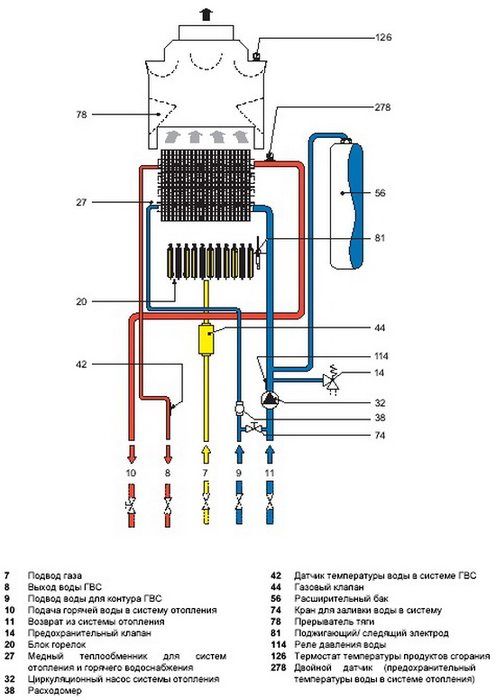

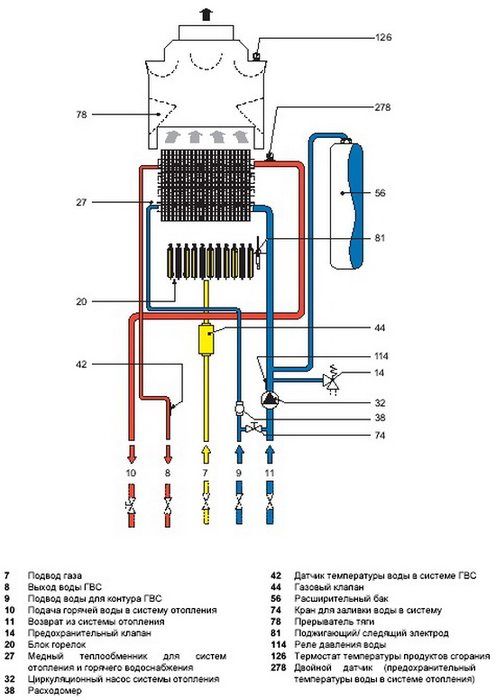

A modern hinged gas boiler is very compact and already contains inside itself the main elements necessary for the functioning of a forced circulation heating system, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

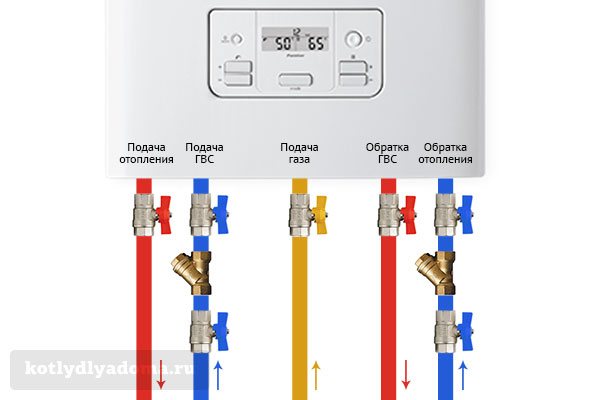

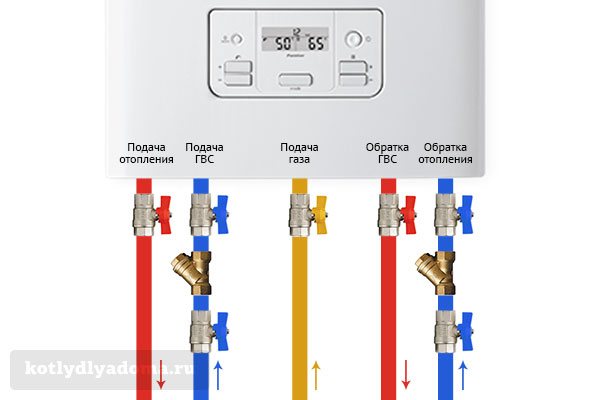

At the bottom of any hinged double-circuit boiler there are 5 nozzles. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas. The gas inlet is usually centered and colored yellow. All other lines can be arranged in any order, depending on the model of the gas boiler. Therefore, before starting the strapping, it is required to clarify the purpose of each of them in the operating instructions.

The piping of a wall-mounted gas boiler is carried out with polypropylene or metal pipes. The cross-section of the heating pipes is usually larger than the DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through the "American" nuts. Ball valves are installed on each line, for the convenience of dismantling the gas boiler without draining the coolant and to isolate the boiler from the heating system, if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or flax.

Coarse filters must be installed in the heating return line and in the DHW supply line. For the convenience of flushing and cleaning, they are also cut off by shut-off valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed on the hot water supply.

Such different gas boilers

The buyer, before going to the store to buy a gas heating boiler, needs to determine for himself several characteristics of the equipment. The first thing to remember is that all boilers are divided into two types:

Buying the first will be a little cheaper, but the second type of gas boilers is considered universal and can not only serve as a heating device, but also provide housing with hot water.

Another important detail to keep in mind when choosing an inexpensive gas heating boiler is the way to remove combustion products. There can be two of them: with atmospheric (a chimney is required) or forced (equipped with a special design to remove combustion products) draft.

Another very important division of boilers in catalogs is in terms of energy efficiency. Going on sale:

- Convection (such a gas heating boiler is found in many houses, due to its availability and good efficiency);

- Condensing (the obvious leader in production, since competent assembly allows you to increase efficiency up to 109%. This type of equipment is considered the most profitable).

What type of equipment to choose is still up to you: powerful floor-standing or beautiful, but no less effective, wall-mounted. In our online store you will find gas boilers from different manufacturers.

What kind of gas boiler?

If in your house the thermal energy produced by a gas boiler will be consumed only for heating and heating water, you can safely take the boiler power equal to the heat loss of the house (for preliminary simplified calculations, use this dependence - for every 10 m2 of heated area, 1 kW of boiler power is needed ).

All about the installation of a gas boiler

The goal of our work is an integrated approach to providing a reliable heating system. We can offer you a professional selection of equipment and components that meets your operating conditions for the boiler room, prompt installation of boilers and commissioning of the heat supply system on a turnkey basis.

Repair of boiler equipment

We provide warranty and service maintenance of heating equipment, repair and replacement of boiler components. Own service department, accurate diagnostics and quick troubleshooting. You can conclude an agreement for annual, seasonal or one-time maintenance of heating equipment.

Electrical connection of the gas appliance

Modern gas boilers exist with 2 options for connecting to the mains: a three-core insulated cable and a plug for connecting to an outlet. In both cases, you should adhere to the rule: the gas device is connected through an individual circuit breaker to the shield and you will definitely need to take care of grounding. It is recommended to use voltage regulators as well as redundant power supplies to prepare for a power outage.

The cut-off switch must be installed near the boiler so that it can be quickly and easily turned off. Do not ground the device to a heating or gas pipe. In order to provide good grounding, it is necessary to equip a ground loop or point grounding.

Boiler installation rules and regulations

Gas heating equipment is installed in accordance with the developed and approved technologies that ensure the safety of its operation.

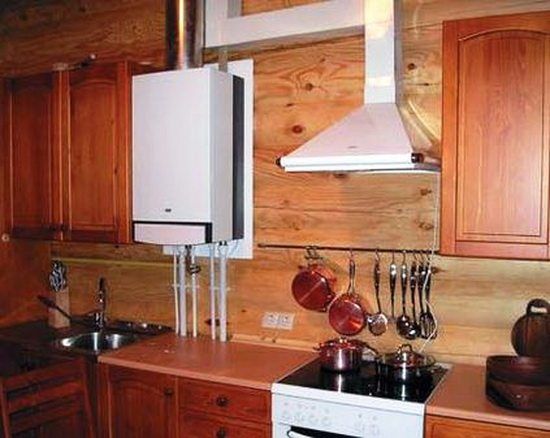

- The question of how to install a wall-mounted boiler begins with preparing a room for it. The room must meet certain requirements: the boiler room can be located anywhere in the house, except for the bathroom, living rooms and a toilet. However, when installing wall units, this requirement can be relaxed depending on the type of boiler. The volume of the room is from four square meters, the height of the ceiling is from two meters. Doorway width - at least 800 mm. Also, the room should be provided with natural lighting of the boiler through the window. At the same time, the size of the window must correspond to 0.3 sq. for every 10 sq. premises.

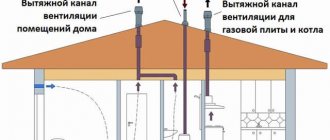

- The rules for installing a wall-mounted gas boiler regulate the supply of a certain amount of fresh air with the help of forced ventilation to the place of use of the boiler. An insufficient amount of incoming air may be associated with the accumulation of a substance hazardous to health and life in the room.

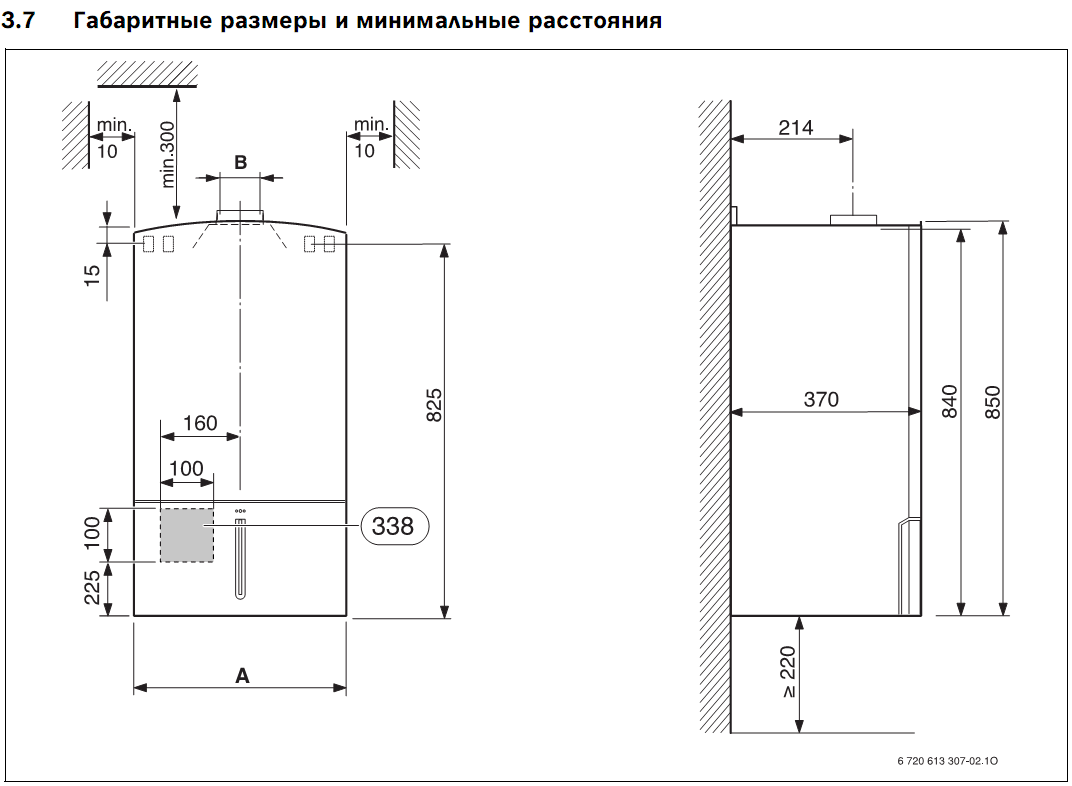

- Installation of a wall-mounted gas boiler: the standards for its placement are such that the distance from the wall to the surface of the boiler must be more than 10 cm. If this distance is less than the prescribed distance, the wall must be protected with a fire-resistant coating.

- Gas pipes can be metal, but not plastic.

- The chimney opening must correspond to the boiler output. Moreover, its height should be at least 5 m, provided that the chimney is installed above the ridge on the roof of the house. When installing a chimney, it can have no more than three bends.

- When organizing the power supply system, it is necessary to provide for the presence of an automatic machine with current protection and thermal protection.

- In the room where the boiler will stand, there must be a gas sensor linked to the relay. In the event of a gas leak, the sensor must send a relay signal to block the gas supply. In addition, an audible alarm should sound.

- Installation of a wall-mounted gas boiler, the standards for starting it oblige to provide the device with a gas meter.

- If there are other gas appliances next to the boiler, then the distance between the appliances is set at a mark of at least 20 centimeters.

- When installing a wall-mounted boiler, the requirements even affect the subject of the complete completeness of the equipment. The complete set of the boiler must comply with the standards and contain: manual, fasteners, a template made of paper for installation, special keys and fasteners.

- The installation height of the wall-mounted boiler is 80 cm - 160 cm from the floor surface.

If all these requirements are met, then there is no doubt about the reliability and fire safety of the gas heating system. It should be borne in mind that the heating system must be regularly maintained by the employees of the city gas service.

More on this topic on our website:

- Installation of a gas wall-mounted boiler - piping and connection schemes Often, private houses do not have access to centralized systems, so the owners have to independently decide how to implement.

Correct piping of a wall-mounted double-circuit gas boiler - device, diagram, connection Correct, competent, high-quality organization of heating a house contributes to an even distribution of heat throughout the living area. Connecting a gas wall-mounted boiler with two.

Strapping a wall-mounted double-circuit gas boiler - photos and diagrams Simple strapping of a wall-mounted double-circuit gas boiler, the photo of which you see on this page, can be done by your master, or you can.

Coaxial pipe for a gas wall boiler - installation with a photo In order not to spend money on a full-fledged chimney, you will need a coaxial pipe for a gas wall boiler. Installation, the photo of which is published on this one.

Connecting the wall-mounted boiler to the mains

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which practically does not require the intervention of the owner. Obviously, the control unit and the various sensors require a mains connection.

Double-circuit wall-mounted boilers are available in two versions: with the usual socket and with a cable for connecting directly to the vending machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then an individual outlet for a gas boiler should be located next to it, but not under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Attention! It is strictly forbidden to ground the wall-mounted gas boiler to the heating radiator or gas supply pipe. This is a gross violation of the rules for operating gas equipment and is extremely dangerous.

Boiler automation is very sensitive to the quality of the supply voltage. With an insufficient level or imperfect sinusoidal shape at the input, the devices quickly fail.To prevent frequent breakdowns and prolong the life of the unit, it is required to connect voltage stabilizers for gas boilers. To avoid stopping heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

GENERAL REQUIREMENTS FOR THE INSTALLATION OF HOUSEHOLD BOILERS

Important! Calculate ventilation area based on government regulations. For 10 kW of boiler power, 0.001 m2 is required.

It's important to know! 2 types of gas units, for example, two heating boilers, cannot be installed in the same room.

Particular attention is paid to the location of the bath. Smoke from a sauna chimney located close to a neighbor's house causes quarrels with neighbors, who may legally demand to demolish the building.

An email with instructions for password recovery has been sent to the email address you provided.

If the equipment is installed with a capacity of 150 kW or more, one of the prerequisites is access to the street. A second exit can be equipped - to a utility room (not residential). This could be a pantry or a corridor. Doors must be fireproof.

Coordination of the design of the treatment system allows you to avoid situations when a septic tank is mistakenly built near, literally a meter from a well for drinking water. The cleaner is placed at a distance of at least 5 m from the dwelling and 3 m from the boundaries of the site. The system should not be located far from a residential building, as this often leads to blockages.

When planning the future use of the site, it is recommended to draw its diagram. The land should be divided into zones, in one of which a residential building will be erected, and in others - a garage and other necessary outbuildings. According to GOST, buildings must be removed from the fence and the house for the following intervals (m):

- at least 1 - outbuildings for storing inventory;

- 6 - from the windows of a neighbor's house;

- at least 12 - premises for housing livestock;

- 6 - summer shower;

- 8 - toilet and compost pit.

If you have any doubts about the correct installation of the outlet near the sink, buy a waterproof outlet as shown in the photo and your doubts will disappear.

The installation of gas boilers must be carried out in the basement, basement room or in a separate room on the ground floor, if its capacity exceeds 150 kW. At lower rates, the installation of heating equipment can be carried out in the kitchen.

Technical conditions, as well as the project for the installation of equipment must be agreed with the representative of the gas service at the place of arrangement of the system.

Building planning is governed by the following standards:

- SP 30-102-99. Sets the norms for the distances between IZhS objects and other extensions. Thus, a residential building should be located at a distance of at least 6 m from dwellings, garages and ancillary buildings on a neighboring site.

- SP 4.13130.2009. The main document establishing fire safety measures. Observance of protective distances between buildings is designed to protect buildings from fire and prevent the spread of fire due to their proximity.

- SNiP 30-02-97. Regulates the placement of buildings in horticultural associations. In some cases, by decision of the local administration, the standard applies to the objects of individual housing construction, private household plots and summer cottages.

- SNiP 2.07.01-89. Regulates the area related to the general development of the settlement. Unlike previous standards, this regulation regulates the placement of buildings on the site from the point of view of the local authority, not the owner.

Technical conditions, as well as the project for the installation of equipment must be agreed with the representative of the gas service at the place of arrangement of the system.

Building planning is governed by the following standards:

- SP 30-102-99. Sets the norms for the distances between IZhS objects and other extensions.Thus, a residential building should be located at a distance of at least 6 m from dwellings, garages and ancillary buildings on a neighboring site.

- SP 4.13130.2009. The main document establishing fire safety measures. Observance of protective distances between buildings is designed to protect buildings from fire and prevent the spread of fire due to their proximity.

- SNiP 30-02-97. Regulates the placement of buildings in horticultural associations. In some cases, by decision of the local administration, the standard applies to the objects of individual housing construction, private household plots and summer cottages.

- SNiP 2.07.01-89. Regulates the area related to the general development of the settlement. Unlike previous standards, this regulation regulates the placement of buildings on the site from the point of view of the local authority, not the owner.

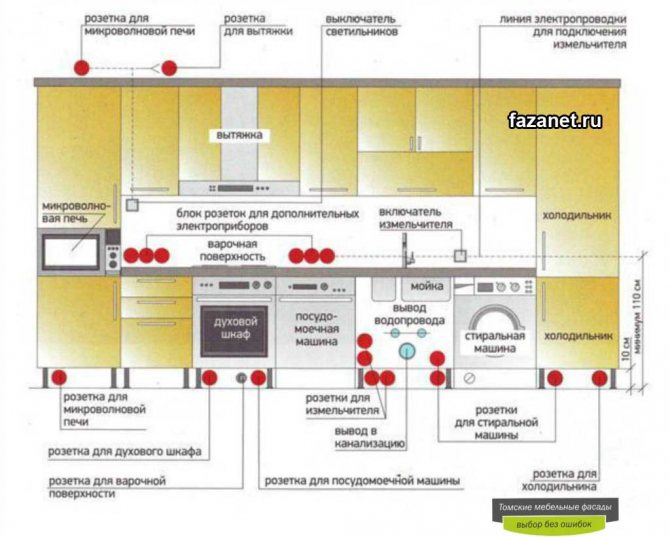

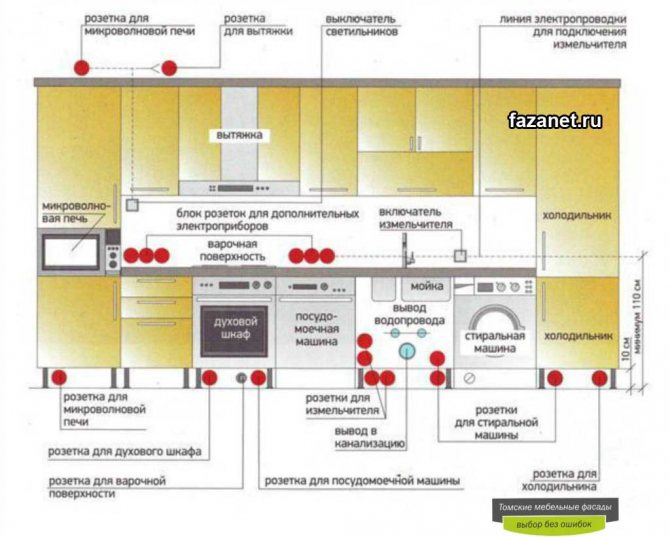

Based on this, the electrical wiring in the kitchen should be carried out by an independent group, or even better by several groups.

In order to understand how to make the arrangement of the furnace in a new way, you should study the requirements for the room, presented by regulatory documents (SNiP).

The walls must be non-combustible. This means that they must provide 0.75 hours before ignition (45 minutes).

They are detailed in the instructions for each gas appliance. Compliance with them is a guarantee not only of safety, but also of the fact that in the event of a failure of the equipment, the user will be able to count on a free replacement of both a separate unit (component) and the entire installation within a specified period. Therefore, the TU for the boiler (stove or other gas equipment) is one of the fundamental documents for the installation procedure.

Construction standards, which are approved by the state for the installation of gas equipment in a residential building, determine the requirements for the room where the boiler will be located. It is imperative to take this into account when installing the system. Failure to follow these recommendations can create a fire or explosive situation.

How to connect a gas double-circuit boiler

A double-circuit device differs from a single-circuit one in that it contains 2 heat exchangers: one is the main one, which heats water for heating, and the other is an additional one, which will heat water for hot water supply. In most cases, such boilers are wall-mounted and represent a high-tech boiler room, where everything is automated and provided.

Connection of a double-circuit gas boiler.

You should pay attention to the figure, which depicts the insides of a double-circuit device. 5 pipes will be connected to it: 1 - a pipe with a coolant from the heating system, which goes for additional heating; 2 - a pipe with cold water going to the heat exchanger in order to heat water for hot water supply; 3 - gas pipe; 4 - pipe for hot water supply with hot water; 5 - pipe with hot heat carrier for the heating system

All automation of double-circuit boilers is arranged inside. The default heating medium, which is heated by the main burner in the boiler, is sent to the heating system and returned to the boiler cooled down again. Thus, there is a boiler-heating-boiler circulation. However, as soon as someone opens a tap on one of the consumers with hot water, cold water will begin to flow into the boiler through the pipe. The three-way valve will immediately redirect the coolant, which will not leave the boiler, but circulate in the main heat exchanger. The coolant will heat the hot water supply until it is no longer used. As soon as the tap is closed, the coolant begins to circulate through the heating system.

Direct connection diagram for a gas double-circuit boiler.

In practice, a two-circuit gas apparatus is not able to provide a large amount of water for hot water supply. The boiler does not have time to heat it up in the required volume.That is why they are used exclusively in small families, and in order to heat a larger volume of water, a water heater is additionally used.

According to this scheme, the coolant only heats the water in the boiler, and the water supply system itself to the 2nd circuit will be closed. This makes it possible to significantly increase the durability of the dual-circuit device, which suffers greatly from hard tap water.

Connection diagram for a gas double-circuit boiler with an indirect heating water heater.

After about a year, the additional DHW heat exchanger becomes clogged and fails. In this regard, the circulation of a clean coolant in the 2nd circuit is a more economical solution. However, it makes no sense to use a two-circuit design. It is much more profitable and practical to install in this case a single-circuit boiler of higher power.

Connecting a gas wall-mounted boiler paired with an ordinary electric boiler as a storage tank for hot water is also permissible. In this case, hot water will enter the boiler from the boiler, and when its amount decreases to a critical point, the boiler will start heating water again in order to fill the boiler. An option is possible in which the boiler is filled with hot water from the boiler, and its further temperature will be maintained using a heating element.

How to connect boilers of different types to the heating system?

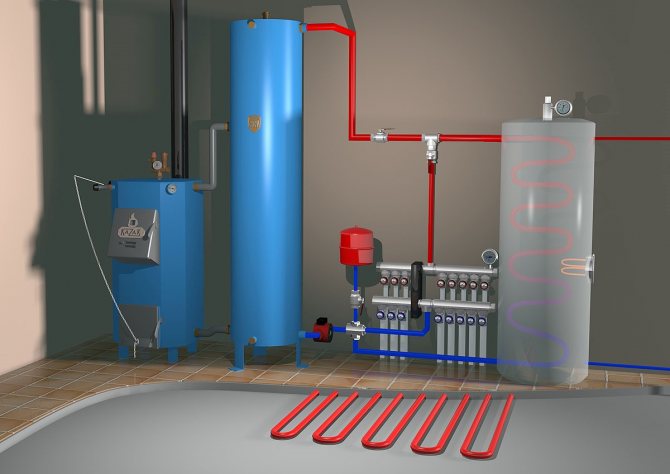

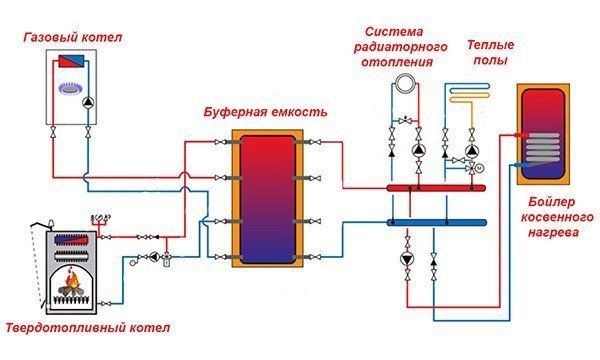

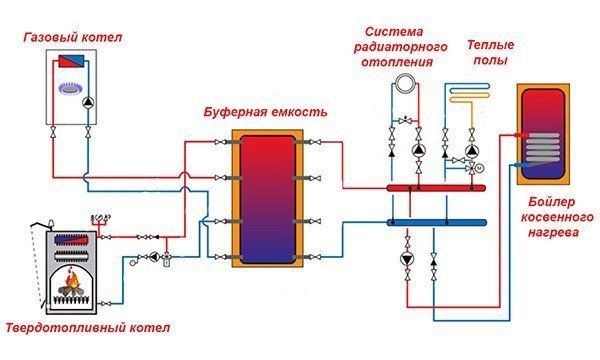

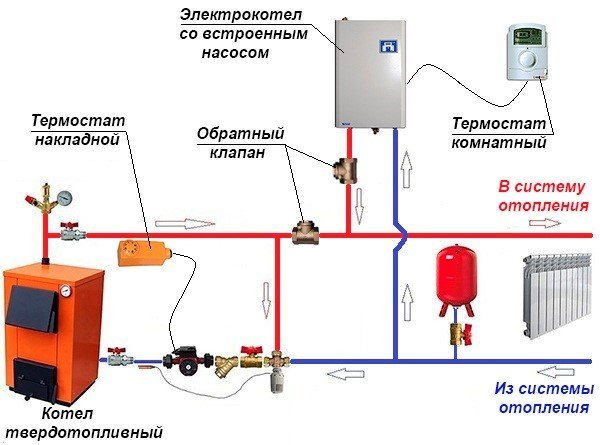

Often, if it is possible to connect to the gas pipeline, many homeowners install the main gas boiler, and the solid fuel boiler is connected as an additional source of heat.

In this case, both the connection diagram and the requirements for the boiler room will differ.

- The main differences relate to the area of the room - it must be at least 15 m3. The more power the boiler has, the larger the boiler room should be (to calculate this parameter, you need to multiply the power indicator by 0.2 m3, provided that the ceiling has a height of at least 2.5 m).

- Also, the room must have an opening window with a size of 0.45 m2, and the front door can only go outside and have a width of 80 cm.

Gas and solid fuel boilers

If you plan to use gas equipment and a solid fuel boiler at the same time, then you should pay attention to a number of features:

- sequential installation of a solid fuel, and then a gas boiler. In this case, a non-return petal valve is necessarily fixed between them, which is installed on the supply pipeline. In this case, the main load is on the solid fuel boiler, and the gas boiler turns on when the fuel has already burned out and maintains the temperature regime;

- the possibility of installing a heat exchanger to separate the closed and open circuits. A different type of boiler is connected to each circuit. The task of a solid fuel boiler is to heat the secondary circuit, as a result of which the temperature of the coolant can reach 115 ° C. The scheme of work is similar;

- the third option is the use of a buffer tank in order to maintain the temperature of the coolant. In this case, a solid fuel boiler is connected according to the standard scheme, and the use of a gas boiler allows heating radiators in a buffer tank - this takes from 2 to 4 hours.

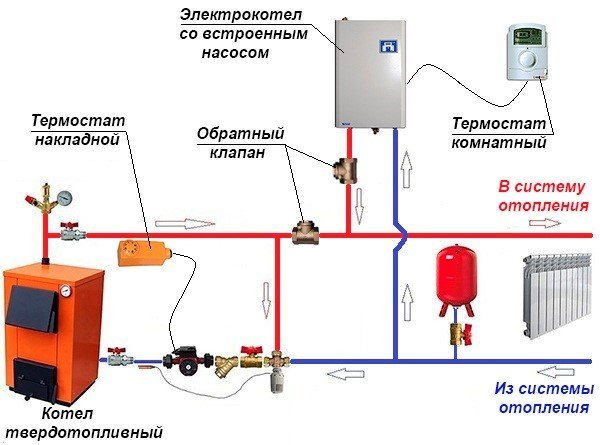

Solid fuel and electric boilers

An electric boiler, when connected in the same system with a solid fuel, performs the same function as a gas one. It turns on after the firewood burns out and allows you to automate the process of maintaining the temperature in the house.

Also, such a system and the presence of an intermediate tank ensure the supply of coolant simultaneously to radiators and heated floors.

When the next batch of firewood burns out, the sensor detects a decrease in the air temperature in the room and the electric boiler is turned on.To turn off the pump of a solid fuel boiler, the system device is equipped with an overhead thermostat, which records the temperature drop in the supply pipe. At the next ignition, the process of circulation of the coolant is resumed.

Requirements for the use of RCD

Requirements for the use of RCDs for electrical safety purposes are regulated by the PUE, chapters 1.7, 6.1, 7.1. The tripping current of an RCD installed for electrical safety purposes should not exceed 30 mA (use an RCD with a trip current of 10 mA and 30 mA).

The RCD rating for the trip current is selected in accordance with the requirements of clause 7.1.83 of the PUE. The total leakage current of the network in normal operation should not exceed 1/3 of the rated current of the RCD. Since there are no data on leakage currents, the calculation of leakage currents is carried out in accordance with the requirements of this paragraph. When calculating, the leakage current of the electrical receiver is taken as 0.4 mA for each 1 A of the load current, and the leakage current of the network is 10 μA for each meter of cable length.

Requirements for the installation of an RCD in order to protect against fire are regulated by the following documents:

- PUE, clause 7.1.84 “To increase the level of protection against fire in case of short circuits to grounded parts, when the current value is insufficient to trigger the maximum current protection, at the entrance to an apartment, individual house, etc. it is recommended to install an RCD with a tripping current of up to 300 mA ";

- Federal Law of July 22, 2008 N 123-FZ "Technical Regulations on Fire Safety Requirements". Article 82, part 4 “The power supply lines of the premises of buildings and structures must have protective shutdown devices to prevent the outbreak of a fire. Installation rules and parameters of residual current devices must take into account the fire safety requirements established in accordance with this Federal Law. "

In accordance with these requirements, an RCD with an actuation current of 100 mA or 300 mA is installed at the entrance to the apartment. Such an RCD is called a fire safety device.

If the calculation shows that the total leakage current of the apartment board does not exceed 10 mA, then you can save money and you can install an RCD with an operating current of 30 mA on the input to the apartment. This RCD will act as a "fire-fighting" RCD and RCD used for electrical safety purposes.

Otherwise, a "fire-prevention" RCD with an actuation current of 100 mA or 300 mA is installed at the entrance to the apartment, and an RCD with an actuation current of 10 mA or 30 mA is installed on outgoing lines (where the installation of an RCD is required for electrical safety purposes).

At what height should the socket be installed.

Determining the location of the outlet is much more difficult than in the case of a switch. According to the so-called "European standard" sockets should be installed at a height of 30 centimeters from the floor level. This mounting height allows you to hide the power cords from your household electrical appliances.

But with such an installation, one should take into account the fact whether there are elderly people in the family. After all, in order to use the outlet, they will have to bend over. For the young it will not pose any problems, but for the elderly it will be difficult. It is better then to install the outlet a little higher, at a level of 40-50 centimeters from the floor.

Low installation of sockets can be dangerous if there are small children in the house. But this problem can be easily dealt with using conventional plugs in the sockets. Or install sockets with a special secret.

And for complete confidence, also connect them through a residual current device (RCD).

In the event that the socket will stand near your desktop, then every time you bend over to turn on the charger from the laptop or from the phone, or something else there, will not be very convenient. I would advise you to make a socket 10-15 centimeters above the table level. So it will be much more convenient to use it.

The height of the sockets in the kitchen.

Special attention should be paid to the electrical wiring of the kitchen. The fact is that often all powerful electrical appliances are located in the kitchen.And there can be about 10 of them (oven, microwave, dishwasher, electric stove, water heater, washing machine, and so on).

When installing electrical wiring in the kitchen, I always advise laying a separate wire with a separate machine for each outlet. And the outlet itself should be installed in the place where electrical appliances will be located.

Of course, such an installation requires a large amount of wire and, as a result, a large financial investment. But it is better to spend money once, and then use electrical wiring for a long time. How to connect the wires with a "loop", and then have a bunch of problems.

Also, if you have a gas boiler, then in any case a separate line is needed for it. Since it is very sensitive to voltage surges. Therefore, when mounting the socket under the boiler, you need to take into account the fact that you may have to install a voltage stabilizer.

The socket for built-in appliances and a washing machine can be installed at a height of 5-10 centimeters from the floor. And it can be higher, the main thing is that they can reach it.

For hoods and lighting, power points can be made above the cabinets. The switch for the backlight can be made somewhere on the side, so that it is convenient to turn it on and off.

All other small appliances are usually placed on the table. This means that the sockets must be installed at the level of this technique. And if you do not have a kitchen unit, but you have already ordered it, then you definitely need to find out its height in order to correctly plan the locations of all the outlets.

I can also advise you to make a few more outlets in the kitchen. Suddenly, in the future, you will want to purchase some other electrical device.

Watch a video clip on how to place sockets in the kitchen.

Another video clip.

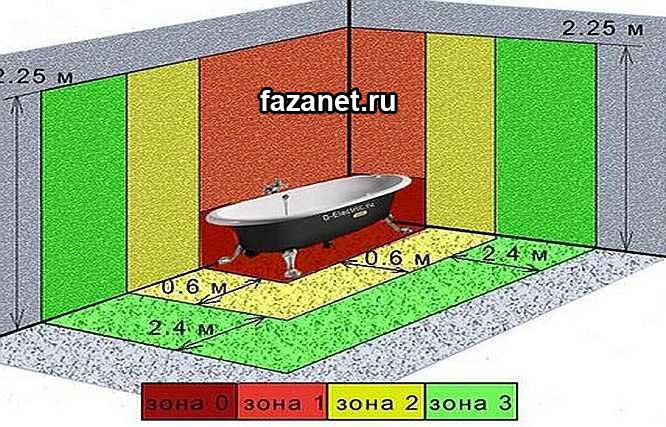

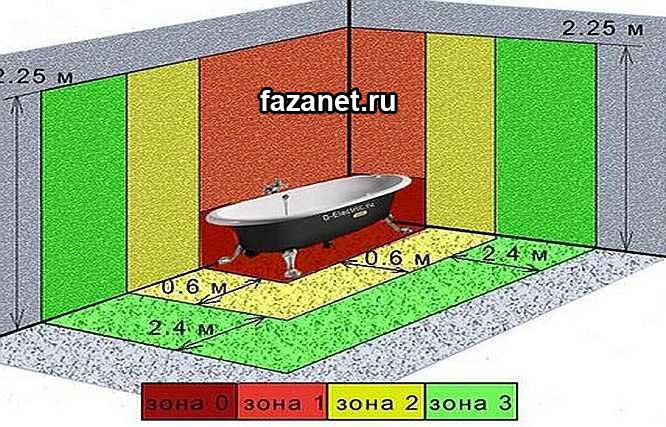

Sockets in the bathroom.

A bathroom is a room with a high level of humidity. Therefore, the sockets must be installed at a safe distance so that no water gets on them. The bathroom can be conditionally divided into three zones. Look at the picture.

In the red zone, there is a huge possibility that water may get on the outlets. Therefore, they cannot be installed there.

A water heater and a lamp can be installed in the yellow zone.

But in the green zone, you can already install sockets, only the minimum distance to the water source should be 60 centimeters or more.

Connecting a gas boiler to a chimney

The diameter of the chimney must be equal to or greater than the diameter of the outlet in the device.

In most cases, the chimney diameter depends on the power:

- 100 kW - 230 mm;

- 80 kW - 220 mm;

- 60 kW - 190 mm;

- 40 kW - 170 mm;

- 30 kW - 130 mm;

- 24 kW - 120 mm.

Ordinary chimneys are led upwards, 0.5 m above the ridge of the house. They are arranged both inside the wall of the house and inside the house or behind its wall. No more than 3 bends are allowed on the pipe. The first section of the pipe that connects the boiler to the main chimney must be no more than 25 cm. The pipe must have a closable opening for cleaning. For boilers with ordinary chimneys and an open combustion chamber, a large air flow is required. It can be provided either with an open window or with a separate supply pipe.

The chimney must be made of roofing sheet or other material that is resistant to acids. The corrugated boiler must not be connected to the main chimney. A brick chimney cannot be used either.

The coaxial chimney must be installed horizontally and led out into the wall. This type of chimney is a pipe in a pipe. It should move at least 0.5 m from the wall. If the boiler is ordinary, then the chimney should have a slight slope towards the street. If the device is condensing, then the slope should be towards the device itself.Thus, the condensate will be able to drain into a special pipe, which will need to be discharged into the sewer. The maximum length of coaxial flues is 5 m.

ROOM REQUIREMENT FOR EQUIPMENT INSTALLATION

Attention! The list of basic requirements for the boiler room:

- area not less than 7 m2;

- the presence of effective supply ventilation (the section of the ventilation duct depends on the power of the heat generator - from 8 cm per 1 kW);

- the site for installing the boiler should be located at a distance from the walls so that a gap of at least 50 cm remains between the unit and the walls;

- the floor covering must be made of a non-combustible material (concrete, tile), a non-combustible sheet material is laid in front of the firebox, usually a steel sheet;

- the diameter of the chimney must correspond to the parameters of the flue gas outlet of the boiler unit;

- water supply and installation of electrical wiring is carried out taking into account all fire safety requirements.

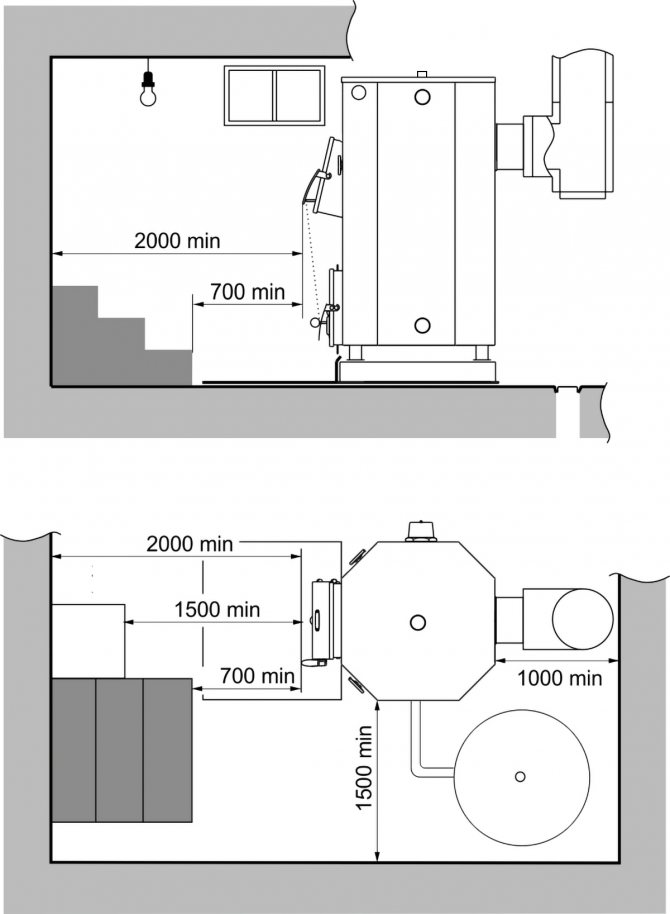

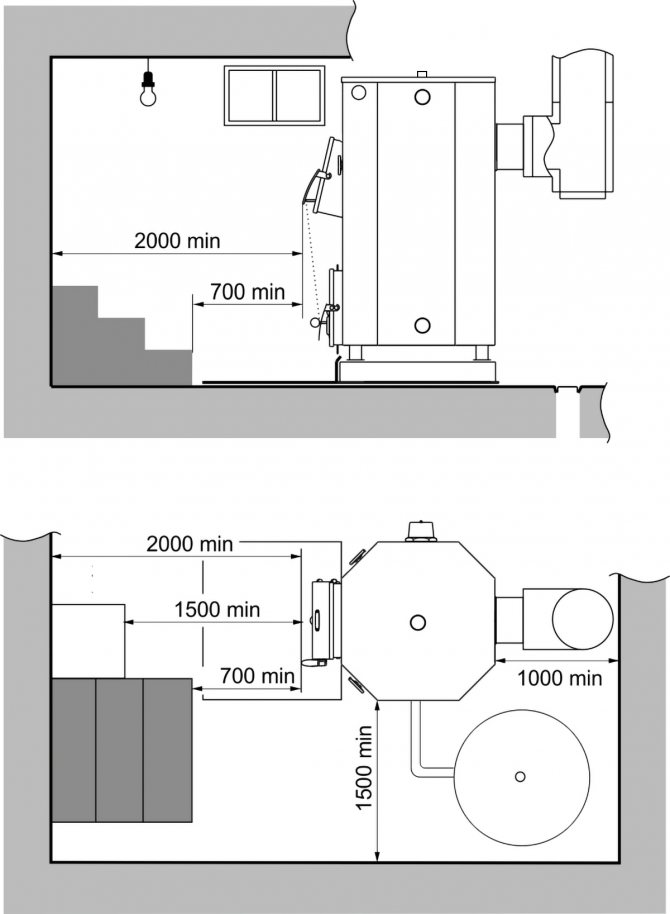

Installation of boiler and related equipment should be carried out in a dedicated room or in a separate boiler room. The room in which the boiler is installed must be equipped with an individual chimney and ventilation. Natural ventilation should provide three times air exchange within one hour, excluding the air required for combustion. The rooms where the boiler is installed must be provided with sufficient natural light, and at night - with electric lighting. Places that, for technical reasons, cannot be provided with natural light, must have electric lighting. Illumination must comply with SNiP II-4-79 "Natural and artificial lighting". For boilers with a grate length (serviced from the front (front wall)) no more than 1 m, the distance from the front of the boilers or protruding parts of the furnace to the opposite wall of the boiler room must be at least 2 m. It is allowed to install pumps in front of the boiler, as well as store supplies solid fuel for no more than one change of boiler operation. In this case, the width of free passages along the front of the boiler should be at least 1.5 m, and the installed equipment and fuel should not interfere with the maintenance of the furnaces and the boiler. The width of the passages between the boiler and the wall of the room must be at least 1 m. The width of the passage between the individual protruding parts of the boiler, as well as between these parts and the protruding parts of the building, ladders and other protruding structures - not less than 0.7 m. side service, the width of the passages between the boiler and the wall of the room must be at least 1.5 m.The width of these passages, as well as the width between the boiler and the rear wall of the room, must be at least 1 m.When installing the boiler near walls or columns, the boiler must not should be close to the wall of the room, and be at least 70 mm away from it. The floors of the room where the boiler is installed must be made of non-combustible materials with a non-smooth and non-slip surface; they must be level and have devices for draining water into the sewer. When installing the boiler on a wooden floor, a floor protective screen must be installed under it, or a fire-retardant gasket must be installed beforehand, in front of the boiler a fire plate is arranged.

Rules for placing pipes and sockets

When laying an electric cable, it must be borne in mind that it heats up from currents, and a nearby heater also heats up the surrounding air. Therefore, it is better to avoid laying wires near gas and heating pipes altogether. But if it does not work, it should be remembered that the norms of the PUE (rules for electrical installations) regulate that the air temperature in such cases should not exceed + 25˚С, therefore, in order to comply with fire safety rules, the distance from cables and wires to heating pipes must be at least 100 mm, and up to gas pipes - 400 mm. When crossing wires with hot pipelines, the distance between them must be at least 50 mm, and with gas pipelines - at least 100 mm.

The switch, the socket from the gas pipe must be located at a distance of at least 0.5 meters.This requirement is due to the fact that there is a flammable gas in the gas pipeline, and in an emergency, the slightest spark from the outlet or switch will cause irreparable trouble.

An outlet close to a gas pipe can cause an emergency, since electricity is adjacent to flammable gas.

Connection of power and cable cross-section

There is a direct relationship between the power of the connected electrical equipment and the cross-section used to power the conductors (cable or wires).

Note: Speaking about the cross-section of the cable, we are talking about the cross-section of the cable cores included in its structure.

The essence of this connection is as follows. Each conductor is capable of conducting electric current up to a certain value without heating. The larger the cross-section of the conductor, the more current it can conduct.

Since there is a mathematical relationship between the current strength and the power of the connected device, that is, a mathematical relationship between the cross-section of the cable cores and the power, in our case, of an electric heating boiler.

This dependence is called "the choice of conductors for heating" (PUE-6, chapter 1.3.). You do not need to count anything, you can use the PUE tables.

This is for the wires

This is for the cables

Using tables is not difficult.

- According to the maximum power of the boiler, consider the load current (divide the power by 220 or 380 V);

- Look for the load current in the table;

- See the permissible cross-section of the conductors;

- If necessary, round up the section.

To check, we use table 3 (pue 1.3.8).

- Boiler 10kW at 380 volts. Load current 26.3 Amperes (round up to 27 Amperes). We look at the table. We need a cable with a cross section of 2.5 sq. mm in copper.

- The same boiler for 220 volts. Load current 45.5 Amperes (46 Amperes). We look at the table. We need a cable with a cross section of 6 sq. mm in copper.

- For cables with aluminum conductors, you need to select the cross-section of the conductors one step more than for copper, that is, for a 10 kW boiler, you need 4 mm and 10 mm.

Do I need to ground a gas heating boiler and why

- Breakdown of automation - boilers equipped with an electronic microprocessor are sensitive to any voltage surges in the network. Failure, automation can also from static voltage. A gas boiler without grounding will not work for long. Replacing the automation board will cost about half the cost of boiler equipment.

- Explosion hazard - Build-up static voltage is one of the most common causes of fire in gas equipment. The positive effect of grounding on the operation of the boiler lies in the fact that the appearance of a spark that leads to an explosion in the event of a gas leak is completely prevented.

PUE 1.7.103 specifies the parameters and requirements for connecting heating equipment. Before issuing a certificate for checking the grounding of the gas boiler, the inspector will check that the installation of the circuit complies with the specified standards.

What are the rules and regulations for installing a wall-mounted gas boiler

Installation of a heating boiler is not an easy task. The boiler cannot be hung up somehow, since the safety of people living in the house often depends on how correctly the wall-mounted boiler is installed. This is due to the fact that the installation of this device is carried out in strict accordance with the technical requirements and standards adopted in Russia at the legislative level.

That is why installing a wall-mounted boiler with your own hands is an extremely time-consuming and difficult process for a beginner.

Connecting heating to a boiler that runs on gas

Wiring diagram for a double-circuit boiler with a storage / water heater.

The location of the pipes may vary. This will depend on manufacturers and models.

If the heating system has already been operated before, and at the moment only the boiler will be replaced. you will need to drain the coolant from the system and flush it several times.A large amount of various salts settle on the walls of radiators and pipes, and therefore it is necessary to flush the system.

Both antifreeze and water can circulate in the heating system. In the technical documentation, be sure to read about whether it is possible to use antifreeze in the selected model.

It makes sense to use antifreeze as a coolant in the heating system when the boiler is turned on only periodically. In this case, the water in the pipes can freeze, but the antifreeze does not. However, if the user is constantly in the house and the boiler does not turn off during frosts, then water can be used as a heat carrier.

- Circulation pump (if needed).

- Ball valve.

- Coarse filter.

- Ball valve.

- American connection.

The circulation pump must always be stopped on the return line. Ball valves are needed in order to easily disconnect the system without draining the coolant and quickly remove the filter for cleaning and maintenance. A coarse filter in the heating system is needed in order to protect the heat exchanger from salt clogging. It should be placed directly in front of the boiler, preferably on a horizontal section with the catcher downwards.

DHW connection diagram to a gas double-circuit device:

- Coarse water filter.

- Ball valve.

- Magnetic filter or fine filter.

- Ball valve.

- American connection.

In order to maximize the service life of the additional heat exchanger of a 2-circuit boiler and to ensure its protection against scale, a magnetic filter and coarse cleaning must be installed on the supply pipe with cold water. If the last filter has already been installed before, then it is not necessary to install it in front of the boiler.

All connections will need to be sealed with tow, special plumbing paste or FUM tape.

Boiler house extension

Refractory bricks are used for individual extension boilers

When it is not possible to allocate a separate room for the boiler in the house, an annex for the boiler room is arranged. The existing norms stipulating the height of the ceilings and other characteristics of the room are the same as for individual rooms. Additionally, the following requirements are taken into account:

- the boiler room is allowed to be attached only to the main wall, the windows and the door in it are located at a distance of up to one meter;

- the materials from which the annex walls are made (brick, cinder blocks, etc.), according to technical conditions, are non-combustible, withstand intense heating for 45 minutes;

- the walls of the extension are not connected to the main building, the foundation is made separate.

The extension is subject to mandatory registration with documentary evidence of the right to connect the gas pipeline. Without official documents and permission, no one has the right to arrange the boiler.

Why keep distance

The kitchen is the most loaded area with electrical appliances. Refrigerator, microwave oven, exhaust system, dishwasher - this is a small fraction of household appliances, without which it is impossible to imagine. Therefore, safety in this part of the apartment should come first. Electricity, gas and water supply are useful inventions, but in the hands of a hack or an irresponsible person, they cause fires, injuries, accidents. To avoid such troubles when developing a kitchen design, you need to carefully consider all the details of the interior, as well as carefully consider the location of the sockets in relation to the gas pipe, hob, and heating appliances. Health, well-being, and sometimes the life of a person depends on this.

The minimum distance of the outlet to the pipeline or gas pipe is 50 cm.

Is it possible to install a gas boiler with your own hands?

When designing a heating system, one should take into account the requirements of gas services, which they impose both on the place of installation of a wall-mounted gas boiler, and on the installation process itself.If all the technical requirements and building codes are met, some work can be done by hand.

Photo 1: Commissioning of the wall-mounted boiler by a gas service representative

It should be remembered that it is only allowed to independently place the wall-mounted boiler in the prepared room in accordance with the project developed by the gas service. Connection to the gas main and all commissioning work must be carried out by certified specialists who have permission to carry out these works.

Note also that not all manufacturers allow the installation of gas boilers with their own hands. Many large companies that produce heating gas equipment, such as Bosch, Ariston, Viessmann, void the warranty for a wall-mounted boiler if the installation was carried out by an unqualified employee.

Back to the table of contents