Purpose, advantages and disadvantages of MC 140 radiators

The technical parameters of MC 140 cast-iron radiators allow them to be used in steam heating systems of any buildings with practically no restrictions: in private houses, country cottages, apartments in apartment buildings, administrative offices, public buildings, industrial, warehouse, retail premises. The equipment is designed for operation in temperate and cold climates (UHL).

Advantages of heating radiators MC 140

- Long service life. It is one of the most durable types of radiators with a service life of 50 years.

- Reliability. A hundred-year history of this type of radiator on the heating equipment market has confirmed in practice its high reliability.

- Anti-corrosion resistance. Cast iron does not deteriorate over time when exposed to water.

- Undemanding to the quality of the coolant. Cast iron radiators are not sensitive to the quality of the water used inside them. The presence of sand, dirt, high content of salts, acids, alkalis in water does not have a strong effect on the life of cast iron radiators.

- Simplicity of steam heating systems. Cast iron radiators can be used in networks with natural circulation of water, without using a pump. They are compatible with all types of boilers - solid fuel, gas, pellet, liquid fuel.

- Thermal inertness. Cast iron heats up for a long time, accumulates heat well, cools slowly. In a heating system, this is considered a great advantage, since after the burner is turned off, the cast-iron radiator remains warm for a long time, giving off heat to the room.

Cons of heating radiators MC 140

- Sensitivity to water hammer.

- The tendency to slagging of internal surfaces, which over time leads to a decrease in heat transfer.

- Radiators are assembled from separate sections, the joints of which are sealed with rubber gaskets. The life of the gaskets is much shorter than that of cast iron. In order to avoid leaks, after several years of operation, failed intersection gaskets must be replaced.

- The appearance of such radiators is not sophisticated enough; the surface requires painting.

Why does the modern buyer choose cast iron batteries?

Cast iron radiators have many advantages. Judging by customer reviews, people highlight the following advantages:

- High corrosion resistance.

- Excellent thermal inertia.

- Long service life.

- An impressive cross-section of radiators.

- No possibility of electrochemical corrosion.

The excellent corrosion resistance of the radiators described in this article, according to users, is due to the fact that the surface is covered with dry rust during use. It excludes the development of corrosion processes. Among other things, cast iron is durable. Therefore, it is not harmed by debris and stones that get inside from the heating pipes. Buyers like the MC-140 cast iron radiator, the technical characteristics of which will be presented below, also for the reason that it has good thermal inertia.

Technical characteristics of radiators MC-140 - 500

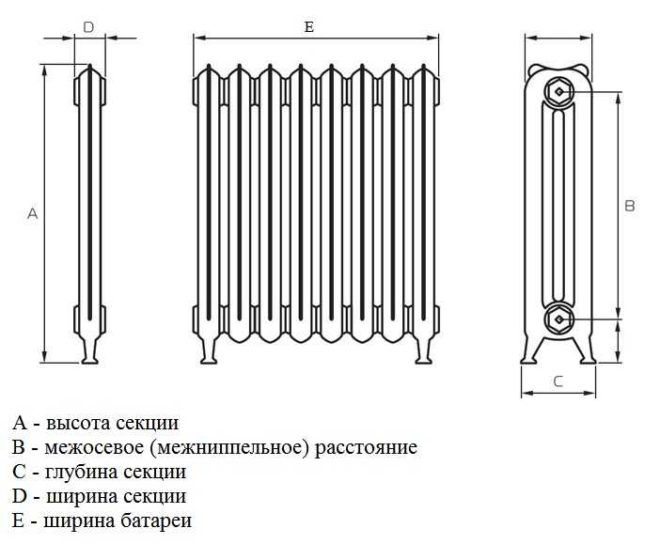

Radiators of the MC group belong to the category of sectional ones - they are assembled into a single whole from separate sections.

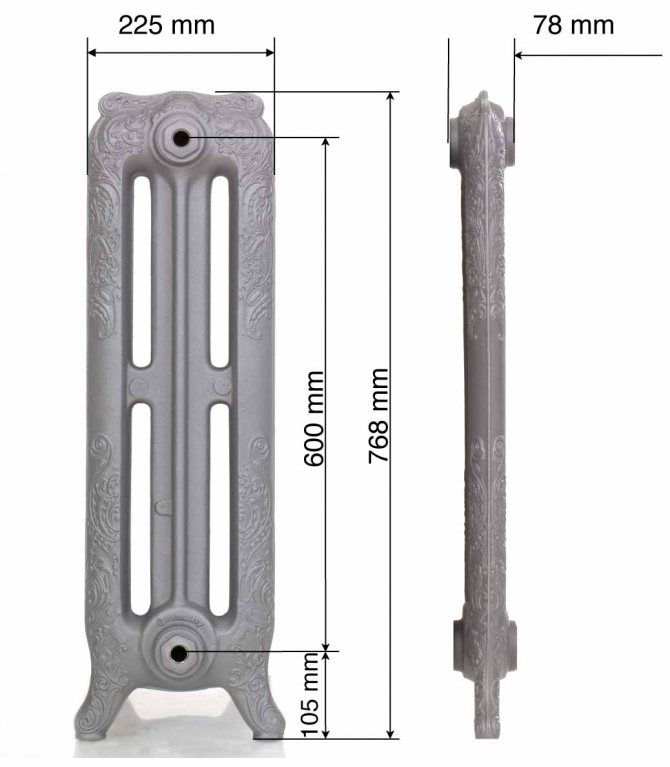

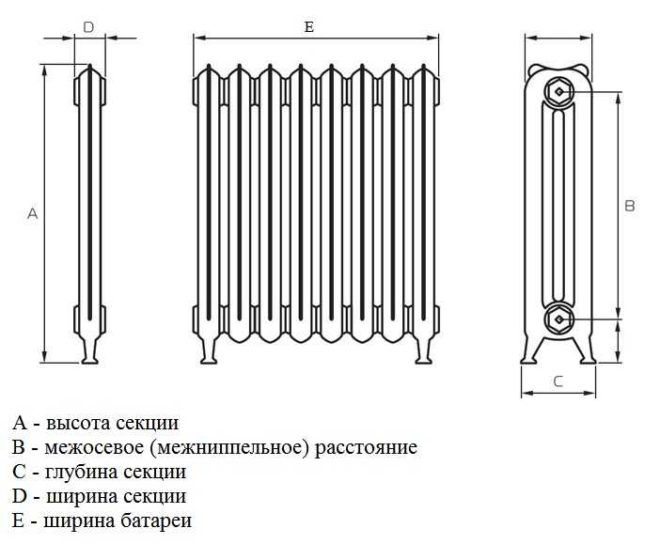

Section of the cast iron radiator ms 140.

The sections are connected to a radiator using intersection gaskets.

Cross-section gasket for ms 140 cast iron radiator.

One section is pressed against another with a nipple.

Cast iron radiator nipple ms 140.

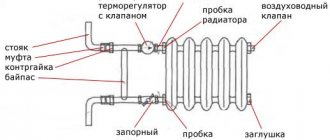

The ends of the radiator are closed with plugs, which can be shut-off and straight-through.

Radiator shut-off plug ms 140.

Radiator through plug ms 140.

Sections are cast from gray cast iron with graphite additives. Individual parameters of MC 140 radiators may vary slightly in models from different manufacturers.

The main characteristics of the MC 140 cast iron radiator:

| Radiator type | sectional |

| Number of channels for the coolant, pcs | 2 |

| Number of sections, pcs | from 2 to 10 |

| Nominal heat flux of one section, W | 160 |

| Outer shell cover | primer GF-021/0119 |

| Section material | gray cast iron in accordance with GOST 1412-85 |

| Cross-section spacer material | rubber in accordance with GOST 1412, capable of withstanding temperatures up to + 150ºC |

| Nipple material | cast iron or steel. GOST 1412 or 1050 |

| Heating area of one section, m2 | 0.195 |

| Center distance, mm | 500 |

| Nipple hole thread size | G11 / 4 |

| Coolant type | water |

| Maximum coolant temperature, 0С | + 1300C |

| Working excess pressure of the coolant, MPa (kgf / cm2) | 0.9 |

Other technical data:

| Number of sections, pcs. | Weight, kg | Length, mm | Rated heat flux, kW | Capacity, dm3 (l) |

| 2 | 12.8 | 227 | 0.32 | 2.50 |

| 3 | 18.8 | 331 | 0.48 | 3.75 |

| 4 | 24.8 | 435 | 0.64 | 5.00 |

| 5 | 30.8 | 539 | 0.80 | 6.25 |

| 6 | 36.8 | 643 | 0.96 | 7.50 |

| 7 | 42.8 | 747 | 1.12 | 8.75 |

The basic characteristics of a radiator can be identified by the model name and markings.

for instance, model MC-140-500-0.9-7 denotes a radiator with the name MC, depth 140 mm, center distance 500 mm, ultimate pressure in the system 0.9 MPa, with the number of individual blocks in the radiator equal to 7.

Advantages and disadvantages of cast iron radiators

Like all other heating devices, cast iron products have their good and bad sides. Experts attribute the following characteristics to the main advantages of such products:

- Reliability - manufacturers give a 50-year warranty for such devices.

- The products themselves, especially with proper care for them, can last much longer.

- Versatility - cast-iron radiators are allowed to be mounted in different versions of heating systems: central, autonomous.

- Low hydraulic resistance makes it possible to use them for systems with central circulation.

- Low likelihood of corrosive processes.

- Affordable price.

- Resistance to aggressive heat carrier.

- Resistance to high temperatures - they can withstand 130 degrees.

- Radiation heating - a cast-iron battery is better than a steel one, capable of heating objects located nearby.

As for the negative aspects of the product of MC models, some experts consider these to be:

- A large mass - one product with an axle distance weighs about 6-7.5 kg, while a whole battery in this case will weigh from 36 to 75 kilograms.

- The need for care - cast iron, even after priming, needs to be painted every 2-3 years.

- Mechanical shocks can crack the structure.

Some features of cast iron batteries can be both an advantage and a disadvantage of the product. Wide channels: this feature causes the need for more water, but also makes it possible to avoid clogging the system.

Technical instructions

1. The installation of heating equipment should be trusted by organizations specialized in the field of construction and installation work, which have an appropriate license.

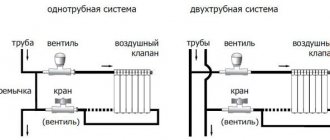

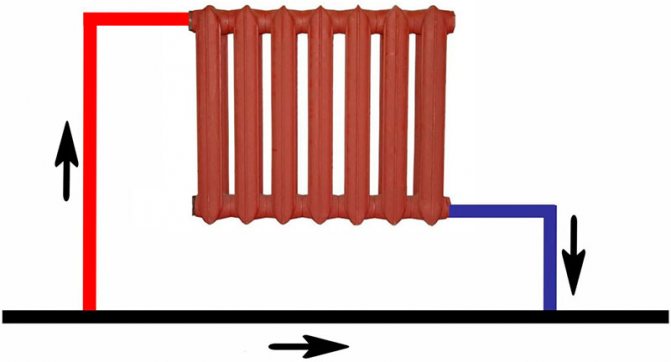

2. Connecting radiators with less than 10 sections can be done in any way - bottom, top, diagonal. If there are more than 10 sections, then it is recommended to connect in a diagonal way: the coolant inlet is top, the outlet is bottom.

Diagonal connection of the radiator ms 140.

3. Before installing the radiator, it is necessary to carry out a hydraulic test of the integrity of the device, the tightness of the gaskets, the strength of the nipple connections. For this, hydraulic testing is carried out under a pressure of 1.5 MPa. If a leak is detected due to loosening of the nipple connections, they must be tightened and the test carried out again.

four.When changing (increasing or decreasing) the number of blocks in the radiator, it is necessary to use only gaskets that are established by the requirements of GOST 1412. After assembling the radiator, the strength of the intersection connections is checked.

This is done in a standard way - hydraulic tests are carried out under a high pressure of 1.5 MPa, exceeding the maximum permissible loads. During the test, the prefabricated structure shall not leak or allow air bubbles to pass through.

5. After the completion of the installation work, the entire water heating system is pressurized, based on the results of which an act on the commissioning of the facility is drawn up.

Installation

The number of sections has been calculated, the radiators have been purchased, it remains to be installed. There are two options here - contacting specialists, spending money, or doing everything yourself. Let's consider the second option.

Installation process

We select mounts

The first step in the installation is to select a mount for the radiator. In the photo you can see the different types of mounts.

For example, pin and corner brackets are used for sectional radiators. The first ones are used to fix the battery on a brick or plaster wall, and the corner ones are used if the wall is wooden. It should also be remembered that for corner fastening, you need to stock up on self-tapping screws and dowels.

Types of fasteners. As you may have guessed, for our case, attachments No. 3 and No. 4 are applicable

Direct installation

At this stage, you need to choose the places for installing the brackets. Remember that you need at least three brackets for one radiator. Then, using dowels and a drill, you need to fix the brackets.

The next step is to attach the radiator to the brackets.

Advice. There is no need to immediately rip off the protective film from the radiator, first install it on the brackets, and then, without fear of scratching the radiator, remove the film.

Connection examples

Carefully connect the supplied pipes to the radiator. Fasten carefully and carefully, but do not damage the threads, otherwise you will get water leak from the system. Before watching, check out the installation video in our gallery.

It is important to observe certain distances during installation. For example, the installation height above the floor should be approximately equal to 10 centimeters. The distance between the wall and the battery should be 2 to 5 cm.

Find out also about the features of electric double-circuit heating boilers.

Operating conditions

The radiator is used in water / steam heating systems with any kind of boiler, in which the heat carrier is ordinary water, without specific requirements for its quality.

Installation should be carried out only in a heating network that is designed, installed and operated in accordance with the regulatory documentation adopted by state industry organizations.

For Russia, such a normative act is the rules of SP 60.13330.2012 or 73.13330.2012.

Consumer Recommendations

Cast iron radiators MS-140 500, the technical characteristics of which are presented in the article, must be installed after choosing the right place. There must be 3 or more brackets per radiator. Using dowels and a drill, the brackets are fixed. At the next stage, judging by the feedback from consumers, you can start attaching the radiator. Do not rush to remove the protective film from the device. First you need to install it on the bracket. Otherwise, the battery could be scratched.