Furnace design problems

If the stove still smokes even when the fire door is open, you should think about the competence of the stove-maker who put it down. The most common mistake inexperienced craftsmen make is not broad enough

... Its dimensions depend, in particular, on the power of the heating unit. For example, for a stove with a capacity of 3.5 to 5.2 kW, the chimney diameter must be at least 189 mm, and the cross-sectional area (if rectangular) must be at least 0.028 m². Otherwise, carbon monoxide gases will tend to go outside not only through the pipe, but also through the firebox.

Reason 6 - burning does not occur in the oven

Sometimes you can observe such a phenomenon when portions of smoke and sparks fly out of the oven in whole bursts. This is due to the fact that combustion in the furnace does not occur in the firebox itself, but in the smoke ducts, and is of an impulsive nature.

Elimination of this cause depends on the specific oven. There is no one-size-fits-all solution. In some cases, simple draft control will help. However, many stoves will “shoot” hard at any draft. To cope with the problem, you can simply try to lay less firewood. It's better than waiting for the stove to shoot and the room is filled with smoke.

The main causes of smoke

There may be several reasons why the smoke does not go into the chimney, but into the room:

- Raw wood is used. It is easy to solve this problem - you just need to take care of drying the wood in advance and store the fuel under a shed.

- The dimensions of the chimney and combustion chamber are incorrect. It is worth creating drawings based on the standard ratio: with a firebox measuring 70 by 70 cm, a chimney with a diameter of 110 mm is made.

If the potbelly stove smokes, the problem may be in the excessively large size of the ash pan. For the stove to work properly, it must be made 3 or more times smaller than the firebox.

- The chimney is not long enough. For high-quality implementation of traction, the outer pipe should rise 1.5-2 meters above the roof.

- The pipe is dirty. During operation, various substances accumulate in the chimney, which must be removed periodically.If there is an incorrect exit of smoke from the stove, not related to design features, it is necessary to check the chimney and take several preventive actions.

Smoke generation factors

Why can the stove smoke?

Possible causes of smoke are banal blockages in the chimney.

If the draft in the chimney stops or drops sharply, look inside - large debris appears there. This happens if a protective cap is not installed over the pipe. The missing element leads to the entry of carbon monoxide into the room. In windy weather, air currents create turbulence in the chimney, and in quiet weather, there are no smoke clouds in the house.

Pulls, but not there

If the stove has not been used for a long time, the effect of "reverse draft" may occur - the cold air lock accumulated in the chimney does not allow the warm stream to pass through, and the smoke enters the room. What to do? Increase the temperature in the pipe! To do this, open the flaps before adding fuel - and throw burning paper through the cleaning door.

The chimney will warm up, the heated air will go up, and the draft will be restored. If this does not happen, the operation must be repeated again. But now the paper must be thrown directly into the pipe directly from the roof. After the fire goes out, light a piece of wood in the firebox and see where the smoke goes.

We suggest that you familiarize yourself with: The better to paint the bath inside

If you go outside, then you can lay firewood.A special nozzle - a deflector - will help to exclude the appearance of a backflow. This is a cylindrical metal product that is installed on the chimney from above. Due to its design, the attachment creates a low pressure area, increasing thrust.

How to determine the back draft in the chimney?

The back draft in the chimney is formed in the furnace during firing, if it has not been heated for several days.

An "air lock" forms in the chimney, which prevents smoke from escaping. A violation occurs in a system with any design, regardless of the air temperature outside the dwelling. What to do in this case? Back draft is eliminated by heating the air in the chimney. This can be done in several ways:

- open the highest pipe flap;

- reveal the hog that is in the attic;

- if the first two methods did not produce the desired effect, you need to throw a couple of lighted pieces of paper through the chimney from above.

With regular use of the system, the back draft of the flue ducts does not occur.

How to check the chimney

If it smokes smoke in a room from a potbelly stove, the check begins with this element:

- The presence of foreign objects is checked. Often, the simple presence of objects blocking the chimney prevents normal functioning.

There are special soot cleaners

- The presence of soot on the walls of the chimney is determined. The formation of this substance has an extremely negative effect on the traction force. The reason may be the wrong construction of the chimney or irregular cleaning.

The appearance of soot after long-term operation without cleaning or the use of low-quality fuel can be the answer to the question of why the potbelly stove smokes through the door.

We recommend that you also study on this topic:

Brick smokehouse device: design and construction schemes

Having decided to equip a corner in the country where you can cook aromatic food, it is not necessary to purchase small smokehouses presented in specialized stores. You can build a smokehouse with your own hands from bricks - a reliable structure that can also become a garden decoration. Drawings and simple step-by-step instructions for performing work will help you create a model on your own.

If the gas boiler smokes

In addition to errors associated with improper installation of equipment, fuel quality plays an important role in the operation of the unit. This issue is especially relevant when using liquefied gas from a cylinder.

After the combustion of clean fuel, a small amount of dry soot remains. Flakes of this substance accumulated in the pipe can be easily removed. It is enough to knock on the chimney from the outside and remove the crumbling soot through the technical window.

After combustion of gas with a large number of impurities on the walls of the chimney, gradually narrowing the gap, greasy soot sticks. It is quite difficult to cleanse this substance. A regular pipe brush may be useless. In such a situation, it would be best to disassemble and clean the smoker separately.

Quite often, a gas boiler smokes due to improper adjustment of the flame intensity. If the user, in violation of all instructions, turned on the burner of a cold boiler at full power, then the appearance of smoke will be a natural result. The problem can be avoided by gradually increasing the combustion temperature after kindling.

Lights up, but not in the camera

It so happens that sparks suddenly start flying out of the firebox, and after them streams of smoke appear. This usually happens when the combustion process moves from the combustion chamber to the flue duct. Most often, this disadvantage is eliminated when adjusting the traction. But sometimes, even with strong air currents, the stove still continues to smoke and spark. Try to put less wood in the firebox: check experimentally how much fuel will be optimal for the normal operation of the stove.

Other reasons

Smoke can go into the house if too much firewood is hammered into the firebox and the entrance to the wells is blocked, and the fuel has not yet had time to ignite.

How to be here - they decide according to the circumstances.

If the firewood is just burning up, you can carefully pull out a few large logs (if smoke comes from them, take them out into the street).

https://youtu.be/pHnKO7iYNK0

When the fuel has started up, a poker is used, with which they try to stir up the pile and lay it down more compactly.

How to clean a pipe

If, due to contamination, the stove smokes when you open the firebox door, you can do one of the following:

- Perform mechanical cleaning. If the soot layer exceeds 2 mm, and there is calm weather outside without precipitation, you can work with a scraper, and then clean the pipe with a brush with gentle movements. If the blockage is not removed in this way, a cannonball tied to the cable should be used and thrown into the hole in the pipe.

- To resort to chemical compositions in the form of powders, liquids or briquettes. Suitable if there is a plaque of no more than 2 mm.

- Use special equipment. It creates a strong pressure of water that will knock down all foreign objects and remove plaque.

We advise you to read what to do if the boiler blows out through the chimney on our portal.

The weight is also used to determine where a blockage has formed in the pipe, which affects the smoking of the stove.

The following publications will perfectly complement this material:

Smoke in a brick stove

Why does a brick stove smoke when the door is opened? The reasons largely coincide with the malfunctions of a conventional oven and are eliminated by analogy with it.

Poor solution

The use of ordinary cement-sand mortar for ordinary repair work is unacceptable. It does not withstand strong thermal loads and aggressive environmental influences. And carbon monoxide, which will penetrate through the cracks in the masonry, is dangerous to human life. It is prohibited to use the oven in a defective state. Eliminating such blunders turns into a complete re-laying of the oven or endless cosmetic repairs.

For normal operation of the oven, you need:

- lime mortar - for the foundation and chimney,

- clay,

- masonry sand.

Much attention is paid to the preparation method, the balance of the components and the consumption of the solution. There are proportions for each element and model of the structure.

Large seams when laying

The use of old dry bricks or large seams during the construction of the furnace contributes to the rapid destruction of the furnace structure. The adhesion between the materials is initially weakened, gaps appear, which have to be checked and strengthened every season. The same problems arise in new ovens that are not sufficiently dried before use.

Lack of lining

The absence of lining reduces the period of maintenance-free operation of brick furnaces if the furnace is made of cast iron or steel. The consequences are not critical. Such potbelly stoves are simply inspected more often and the problems that have arisen are eliminated.

Cracks

The slots of the brick stove are pre-brushed with a metal brush to the hard surface of the brick. The space is covered with a margin, especially in the case of a mesh of cracks.

Cracks in a brick stove

Work order:

- surface treatment with a primer - cement is diluted with water to a liquid state,

- the solution is applied to the surface,

- cracks are filled with high-quality glue or other suitable composition,

- after drying, the surface is plastered, the planned types of finishing work are performed.

For furnace departments use - refractory mixtures and sealants,

For the rest - heat-resistant solutions.

Cracks in metal structures are permissible on metal that is not yet fractured, no more than 5 mm wide. In these cases, the patch is welded on. In other situations, damaged parts must be replaced and reassembled.

Preventive measures

It is necessary to clean from the formation of plaque not only the chimney pipe, but also other parts of the stove. Thus, attention should be paid to the following parts of the design:

- Layers of soot are also formed in the ash drawer, the blower and the space under the oven, due to which the potbelly stove can smoke.

- It will not be superfluous to check the structure for flaws and cracks that could have formed due to improper assembly of the furnace. Correcting these shortcomings will help to correctly direct the draft of the smoke.

- Sometimes the stove smokes because the door does not fit snugly enough. In this case, either the element is replaced, or the surface of the stove is leveled.

Only high-quality raw materials should be used as fuel and should not be replaced with sawdust and straw.

Troubleshooting solid fuel models

Solid fuel boilers may have the same chimney-related causes of smoke as the gas appliances described above. When firing, it is necessary to use well-dried raw materials. It should be stored in well-adapted places with low humidity levels. Do not use synthetic materials as fuel.

Wood-fired boilers such as Buderus Logano SW, Stropuva S and Zhitomir D should only be fired with dry wood. To be able to use different types of fuel, you need to purchase combined devices such as KST or Smoke. You can experiment with the degree of opening of the gate in hot air models, such. If smoke appears, make the chimney opening larger.

Provide air supply to the boiler room. For safety reasons, the window must be constantly open during the operation of the boiler during the heating season. The solid fuel apparatus must be cleaned regularly. This is especially true if it is coal or diesel, working on mining, since these types of fuels clog the burner especially quickly.

Cracks in the walls and in the chimney

Over time, a thick layer of soot settles on the inner walls of the furnace, and the masonry begins to crack under the influence of thermal loads. Taken together, all of this can also be the cause of smoke. You can try using aspen wood to remove soot. Their combustion is accompanied by a very high temperature, at which the deposits on the chimney are loosened and carried out together with the smoke.

However, this method is more effective as a preventive measure: if ash and soot have settled for many years, then aspen firewood is unlikely to help. Various chemicals in the form of special tablets, briquettes or pellets are also not a panacea. Best of all is mechanical cleaning. To do this, you will have to purchase tools - a core, a scraper and a ruff on a flexible cable.

Remember to open all flaps and close all doors before starting work. Having fixed on the roof, remove the cap from the pipe and remove the soot at a distance where your hand can reach. Then place a ruff in the chimney and, scrolling, gradually move it lower and lower. If you come across an obstacle that you can't break through, use the core.

Cracks must be repaired! Even a child can make the stove solution, which is necessary in order to cover them up. Mix well sifted sand and regular clay in a ratio of 2: 4, break up the lumps, and then splash in some water. The consistency should be like that of plasticine, so it is important not to overdo it with water.

Preparing the oven mortar When covering the slots, cover them with your hand on the back side if possible, otherwise the solution may end up inside the oven. Each time, before starting to work on the next crack, dampen it a little with water. After the mortar on the masonry has dried, see if its integrity has been compromised.

We invite you to familiarize yourself with: Roof drain pipes

How to increase chimney draft?

There are several simple ways to increase chimney draft. The simplest of these is the cleaning of flue gas ducts. It is carried out in the summer season, since in dry warm weather, soot and carbon deposits are easier to clean off from the pipe walls. Preventive manipulations are performed with a special device - a steel rope with a metal ruff and a sinker at the bottom. Through the inlet, reciprocating movements are made with a brush, while the soot, scraping off the walls, goes inside the furnace. In the summer, it is advised to do other work:

- sealing of flue ducts - elimination of cracks and cracks by covering them with a solution;

- installation of a draft regulator on the outlet pipe. The device will regulate the quality of removal of combustion products regardless of weather conditions;

- installation of the deflector on top of the pipe. The procedure provides pressure drop and improved traction;

- chimney vane fasteners. The measure protects the system from the ingress of precipitation inside, and has a characteristic structure, from which it removes gases along the flow of the wind.

- fixing the fan to improve the draft of the domestic chimney. The device operates on the principle of creating an air flow inside. The device is connected to the electrical network following safety precautions.

Subject to the technology of work, the sequence of designing the firebox, smoke does not form. Problem found? Try to identify it yourself, following the above algorithm.

Article Rating

How to make a chimney for a stove through the wall

If, during the search for the reason why the potbelly stove smokes when the door is opened, it was found that the problem is not in contamination, then the matter is in the wrong design.

You can make and install a chimney yourself. For a potbelly stove, a metal version is more suitable than a brick one. For these purposes, the most suitable will be alloy steel with a special coating that protects the surface from the effects of oxides. Just don't use aluminum pipe - it will melt.

During the manufacture, you will need the following elements:

- Metal pipes for the base of the chimney. A diameter of 16 cm is suitable.

- Docking knees. Their number will depend on how many times the direction of the pipe will be turned.

- Protective cap for the upper part of the chimney.

- Condensation pocket.

- Seam sealant.

- Pipe clamp.

- Thermal insulation.

Drawing for the manufacture of a chimney for a stove through the wall

After all the materials are ready, you can proceed with the installation:

- First of all, a through hole is made in the wall. Moreover, if the wall is wooden, a special metal box is installed with a hole in the center, which is 5 mm larger than the diameter of the pipe. For a brick wall, a pass-through glass is used.

The box is filled with basalt glass wool, and the hole is filled with asbestos strips.

- Next, the first section of the pipe is placed on the potbelly branch pipe. At the same time, the design is complemented by a heat-resistant seal and a special clamp that will prevent the breakthrough of gases.

- A knee is placed that leads the pipe towards the wall.

- After the pipe is brought out, a branch pipe and an elbow are placed.

Example of an external chimney pipe

- Insulation of the outer chimney pipe is in progress. To give stability, you can fix the structure with brackets.

- A protective cap is placed on the top of the pipe.

Having figured out how the chimney is installed through the wall, you can also pay attention to the options for the chimney through the window for the stove and through the roof.

Thus, having studied all the necessary instructions, you can take a number of actions to clean the finished pipe or create a new one. Such measures will help get rid of the smoke of the potbelly stove.

We recommend that you also study on this topic:

Potbelly stove on working off: pros and cons

Many motorists, with the onset of the cold season, a natural question arises - how to heat the garage, especially if it does not have a centralized heating system or the heating main runs far enough to be able to connect to it. In this case, the option of installing the oven will come to the rescue. Most often, for small rooms in which there is no permanent stay of people, for the purpose of heating, the most practical and inexpensive version of the furnace is used - a potbelly stove on waste oil products.

We recommend that you also study on this topic:

Do-it-yourself potbelly stove in the garage: options for wood and working off

In winter, it is very cold to be in the garage, so many motorists install home-made stoves in the room. These ovens quickly heat up the garage and can be used to cook food. Most often, garages install stoves on wood or waste oil.

Tags: door, smoke, iron, opening, stove, why

«Previous post

When the stove can smoke

Indoor smoke is always a deterioration or lack of draft. Incorrect flue gas movement is caused by several reasons.

With good traction, the fuel burns out completely, generating maximum heat. If it is bad, the stove smokes. There is not enough oxygen for combustion, volatile combustion products (smoke) are formed, which rush into areas with low pressure and high vacuum - into the room.

One of the main reasons for the smoke of new stoves is a violation of the smoke exhaust system. The pipes are installed in accordance with the following parameters:

- Chimney height - 500 mm above the highest point of the roof with a ridge distance of up to 150 cm.

- Chimney height = ridge height, if the distance between them is 150-300 cm.

- Not lower than 10º relative to the horizon of the ridge, at a distance of more than 300 cm from it.

- The minimum length of the flue duct is 5 meters from the stove.

- If the chimney is more than 120 cm above the level of the ridge, then it is strengthened with stretch marks.

If the oven is installed in a room with sealed plastic windows and

Without ventilation ducts, then the following happens:

- the heating device draws in combustion air from the room;

- over time, a lack of oxygen forms, a rarefaction occurs;

- air streams rush through the chimney;

- the stove goes out, the room is filled with smoke.

Many home owners install the hood only in frequently used functional areas - the kitchen and the bathroom. However, a separate channel is also equipped in other places where the movement of air masses is required: in a steam bath, a washing room, a boiler room.

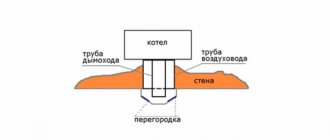

It is a rare case when two heating devices are installed in a house with a common smoke exhaust channel without a dividing partition. When the smoke streams go towards each other, one of the stoves will smoke. To prevent air masses from colliding and creating turbulence, a junction box is installed under the pipe. With a partition, you don't have to heat the stoves in turn.

The mistake of the master stove-maker leads to a violation or weakening of traction, as a result of which the smoke enters the room. More often than others, there are three miscalculations:

- wrong section of the chimney: the diameter of the minimum pipe clearance for a bath is 100 mm, for a house - 150 mm;

- understated location of the inlet to the well relative to the edge of the door - smoke enters the room, one has only to open the stove;

- the use of elements of different sections and shapes when assembling the chimney - air turbulence occurs at the joints.

If the first three errors are eliminated by re-laying the stove by the master, then the gaps can be repaired yourself.

If the prevailing winds are determined during the construction of the building, chimneys are installed from the windward side. Otherwise, air vortices appear in the ridge, directed downward, blowing smoke into the chimney lumen. This can be avoided by observing SNiPs for the installation of chimneys.To compensate for gusts of wind without rebuilding the chimney, an anti-wind deflector is used.

We offer you to familiarize yourself with: Fireplace firebox (53 photos): projects of firebox for stoves, do-it-yourself firewood stand

There is a golden rule: before removing smoke, you need to decide at what moment the stove began to smoke. This will help identify the breakdown and quickly fix it. There are 3 options for when the stove can start to smoke.

When kindling

https://youtu.be/QX_6bTDgz6E

In winter, the stove most often begins to smoke when firing up, that is, immediately after lighting it up. This problem occurs with stoves that are used periodically. For example, the unit is in a country house or a bathhouse.

When opening the door

The old used stove is working properly, but the door was opened a little, and a column of smoke started to flow - most likely the temperature on the view is more than optimal. This often happens with iron stoves that are in the garage.

First you need to look into the firebox (the place where the firewood is laid) - it will be completely filled with white flame or yellow-red waves that go into the hailo.

With the wind

Under normal conditions, when everything is installed correctly, even a strong wind should not contribute to the smoke of the stove. If this happens, then the wind is blowing into the pipe. The effect is called "overturning or weakening of thrust".

Practical advice on choosing firewood and kindling

The stove in the bathhouse can smoke also due to improper kindling. To avoid smoke, it is enough to follow some simple rules:

- Clean ash pan and firebox. This must be done before each use of the oven.

- Open the latch and place the kindling fire on the grate. A torch, birch bark or dry chips will do.

- Open the blower door slightly and light the kindling. Then load the firebox with wood. Lay them in tight horizontal rows.

- Close the firebox and open the blower door fully.

- Re-load firewood in 30-40 minutes. During this time, the previous batch should burn out to coarse coals. Try not to open the firebox in the intervals between the tabs so that cold air does not enter the stove.

- Regulate the combustion process with a blower and a valve. The flame should be calm, straw-colored. If the fire turns pale, you need to close the blower door - this will reduce the flow of air. If it gets dark, then the door must be opened.

- For the last bookmark, it is best to use aspen firewood. They form a long flame and burn off the accumulated soot.

- After the last batch of firewood has burned out, rake the remaining coals onto the grate. The latch can be closed when the coals are darkened and no bluish lights appear above them.

Important! Overheating the oven is not recommended. Obvious signs of overheating are red cast iron fittings, high temperature of brick walls (more than 90 degrees).

Many people believe that you can heat with any material. If only they burned. With this approach, sooner or later the question arises as to why the stove smokes when the door is open or when firing up. The reasons may be as follows:

- Small debris does not burn out completely. Light particles are picked up by the air flow and deposited on the walls of the chimney.

- Remains of glossy paper will clog the grate.

- Damp firewood causes excessive soot formation.

Birch firewood

It is best to use dry birch firewood, which is approximately the same size, as fuel. Other hardwoods found in the middle lane are also suitable - aspen, ash, alder, poplar, oak. Willow gives little heat and burns unevenly.

If you have eliminated all possible causes, and the stove continues to smoke, do not be heroic and contact a specialist. Violations in the operation of the stove can lead not only to the appearance of a specific smell, but also to carbon monoxide poisoning or fire. Be careful!

Why stoves smoke: eight common reasons

- What circumstances accompany smoking?

- When did the smoke start: immediately or after a while?

- How long has elapsed since the beginning of smoking?

So, other observations will help in determining the causes.

Stove fumes can be caused by the so-called draft overturning. It usually occurs after the stove has not been heated for several days. At the same time, the traction was excellent in the past. Such idle time leads to the fact that the air flow changes direction to the opposite and does not go out into the street, but enters the dwelling.

https://www.youtube.com/watch?v=ytpolicyandsafety

To eliminate the back draft in the chimney, it is necessary to promptly increase the air temperature in the chimney. This can be done in several ways:

- through the highest located chimney cleaning door;

- opening hogs in the attic;

- throwing lighted paper into the outlet of the pipe. This method is used if the first two did not bring results. It should lead to the restoration of traction.

When the normal draft can be restored, it is maintained in the future with regular heating of the stove. Traction rollover should no longer be a concern. You can find one more - folk - the name of this phenomenon - "airlock". It is completely unfair to blame the stove-maker for its origin. It absolutely does not depend on its work, and the overturning of the draft can occur in any stove.

Reason 2 - wind

The owners of houses with stoves are sometimes faced with the fact that when gusts of wind on the street, smoke is thrown into the room.

The cause can be eliminated by increasing the height of the chimney head. Changing the configuration of the headband visor also helps.

If the smoke of the stove is observed from the very beginning of its use, then the problem lies in its design. The mistakes of the master stove-maker led to the fact that the draft is not strong enough, and the smoke enters the room. Most likely, the chimney cross-section is too underestimated.

It is impossible to eliminate this cause without the help of an experienced master. Only a good specialist can correct the defect. It is better if this can be done without re-laying, but perhaps it will still be needed.

It happens that the stove has served faithfully for many years, but over time it gradually began to smoke. And the further, the more. In this case, the reason lies in the aging of the structure. Soot and ash gradually accumulate in the chimney and narrow the section. Perhaps the inner lining of the chimney has collapsed.

To eliminate this cause, you can clean the oven yourself. It is necessary to remove soot in all accessible places, to free the chimney from the collapsed masonry elements, to seal up all the cracks that led to the depressurization of the furnace with an oven solution. If all the measures taken did not restore traction, then you cannot do without the help of a qualified master. He will professionally inspect the stove and chimney and find a way to eliminate the defect.

It so happens that when the oven door is closed, it does not smoke at all, or very little smoke is observed. But if you open the door, immediately the stove starts to smoke heavily. And this happens all the time. Now you need to understand why the stove smokes when the door is open? In this case, the reason is the poor quality masonry of the stove.

The scheme of the furnace, where the wrong draft is due to the underestimated entrance to the first well

Since in the structure shown in the figure, the upper edge of the door opening is noticeably higher than the upper edge of the entrance to the well, it is easier for the smoke stream to escape through the door. And if the problem does not manifest itself with a closed combustion hole, then with an open one the smoke is very strong.

The indicated reason is eliminated by re-arranging the entrance to the well. It must be positioned so that the top edge is a couple of centimeters higher than the top edge of the door opening.

Re-laying the entrance to the well is not always possible. Therefore, you can use another method.Inside the furnace, you need to build a wall, the upper edge of which will be higher than the top of the furnace door by the same couple of centimeters. This will cause good draft, and a stream of smoke will rush into the well.

Placement of an additional wall inside the furnace to increase traction and eliminate smoke

Sometimes you can observe such a phenomenon when portions of smoke and sparks fly out of the oven in whole bursts. This is due to the fact that combustion in the furnace does not occur in the firebox itself, but in the smoke ducts, and is of an impulsive nature.

Elimination of this cause depends on the specific oven. There is no one-size-fits-all solution. In some cases, simple draft control will help. However, many stoves will “shoot” hard at any draft. To cope with the problem, you can simply try to lay less firewood. It's better than waiting for the stove to shoot and the room is filled with smoke.

https://www.youtube.com/watch?v=ytadvertise

If there are two stoves for which one common chimney is used, then smoking in such a situation is probably due to the fact that there is no junction box in the chimney.

Installation of a junction box in a common chimney for two furnaces

Smoke in stoves can be observed through small cracks that have formed at the junction of the masonry with different elements of the stove structure. However, the stove does not smoke due to the presence of cracks. Smoke in this case is explained by the reason, which is considered under number 4. And nevertheless, it is necessary to fight with the cracks. An oven solution is used to seal them.

The procedure is as follows:

- The solution is prepared from sand and clay, which are mixed in equal proportions. A small amount of water is added to the mixture so that the consistency is thick enough. The solution must be kneaded well with your hands.

- You need to open the door and remove the mugs. Each gap should be moistened with water immediately before sealing.

- You need to stick your left hand inside the firebox. The palm will need to close the cracks from the inside. You can also use a piece of metal for this. The slots are closed to prevent the solution from spilling out into the oven.

- When the gap (or part of it) is closed, you can move on to the next one. Again starts with wetting, etc.

- If cracks appear on the dried fresh solution, do not worry: this is a natural phenomenon. They need to be sealed with oven solution. The procedure may need to be repeated a couple of times.

- If there is lime whitewash in the places where cracks have formed, then first it must be removed. The oven solution will not last long on such a coating. It lays down only on a cleaned, pre-moistened surface.

- It is strongly discouraged to try to reinforce the seams with strips of metal. It quickly heats up and expands, therefore, being inside the dried solution, it will simply lead to the fact that the entire seam will fall out of the gap.

Conclusion

We've covered 8 of the most common stove smoking problems. Summing up, we hope that the question "why does the stove smoke and what to do?" this article is fully answered.

The stove is the main attribute of the bath. How much heat and steam will be in the steam room depends on her work. Therefore, it needs to be given special attention. Sometimes there may be problems with the stove, and the main one is the appearance of smoke in the room. To eliminate it, you need to know the possible reasons why the stove smokes in the bath.

Furnace types

It is necessary to choose which type of stove will be installed at the stage of construction of the bath.

Today there are different types of stoves, but most often traditional ones are chosen that run on wood. Such ovens create incomparable comfort. And of course they have been modernized over time.

Many sauna owners prefer brick-built stoves. It is hard enough to do it with your own hands, since this business requires experience and knowledge of nuances. As a rule, from the very beginning of using a stone stove, heating problems arise.Most often, there is no craving and as a result, the smoke goes into the bath.

Quite often in the baths you can find homemade iron stoves. Often they are made by a handicraft method using welding. If it was done by a professional, then there will be no problems during operation, and you can safely enjoy the bath procedures. It is not worth saving on the stove, otherwise you can get a completely unusable design.

Even at the design stage of the steam room, it is necessary to purchase a stove. The bathhouse itself is built depending on the features of its design. In addition, the stove affects what kind of thermal insulation of the room to organize, what structure to make the roof of the building, where to lead the chimney.

The oven must be installed on a solid and fire-resistant base. It is best to install the stove on concrete. Without fail, thermal insulation must be installed in front of the stove door and covered with a metal sheet. It is strictly forbidden to place the stove near wooden walls. Usually a separate room is allocated for it.

After the stove takes its place, they begin to install the chimney pipe. The best option is a straight pipe, since it provides reliable traction and there is no reason why the stove smokes in the bath. The best option would be if the installation of the chimney is carried out by a specialist, since this is a rather difficult task.

The problem is in the pipe

If, during the first use, the stove in the bathhouse smokes, then the cause of the problem is incorrect installation or design errors. Here you should seek advice from the master.

The reason why the stove smokes in the bath when the door is open may lie in the chimney. According to all the rules, the chimney must end above the roof ridge. If this rule is violated, then the operation of the sauna stove will be ineffective. To solve this problem, it is necessary to increase the height of the pipe. The pipe can be made of brick or stainless steel.

It happens that the stove smokes in strong winds. In this case, the reason may be the absence of a protective cap on the pipe. To check if this is really the problem, put two stones on the pipe, and on top of them slate or a sheet of iron. If the stove has stopped smoking and the flame in it is bright and uniform, then the problem is the lack of protection on the chimney.

Violation of the technology of stove masonry

Violation of the oven stacking technology

If a new stove smokes, most likely any technological norms and standards were violated during its laying. Perhaps too narrow chimney openings were created or the design of the furnace wells was broken. Unfortunately, it is not possible to get rid of this with your own hands. The oven will have to be repositioned again.

Miscalculations during the laying of the stove well - what to do now?

In some cases, smoke gets into the house at the moment when the door of the firebox is opened. With the door closed, carbon monoxide gases are evacuated as usual. In this case, the reason lies in the inexperience of the oven master.

When the door is opened, smoke occurs if the entrance to the well is located too low and the shortest path for heated air with carbon monoxide runs towards the doorway of the firebox.

We suggest that you familiarize yourself with: Chimney for a bath: which one is better to choose

For any responsible person, when the stove in the house smokes, what to do is the main and paramount question. The problem can be solved if a wall is built inside the firebox, the upper edge of which will be several centimeters higher than the upper edge of the door.

Thus, hot air with carbon monoxide will move to the well opening even when the furnace door is open.

In the article, we examined the most likely causes of smoke generation inside the house, as well as what ways you can cope with it. It is noteworthy that in most cases the work is not difficult and can be done independently.

You have not asked yourself the question: why does the stove smoke? So you're in luck. Lucky so far. But at any moment everything can change and then a headache called “the stove smokes” will come. What to do? I have passed this test and will share with you so that you, my reader, know how to avoid this problem.

How did it all start?

One of the most unpleasant moments of my country life came on a frosty evening in early March 2014. As usual he began to light up the stove. He threw the logs into the firebox. Set fire to birch bark. The fire began to slowly swing, with its small flame it picked up new pieces of bark, reached the wooden twigs.

Everything is as usual. I went for coal. He returned in fifteen minutes. And horror appeared in my eyes. Everything around is in smoke. Smoke completely in all rooms. It is not possible to breathe. I can not see anything. A real smoke screen. Like in fog. With great difficulty, I opened the windows and doors. He began to choke. I had to run out into the street.

So I ran several times. Until I threw out all the logs. An hour has passed. The smoke faded away.

It is clear: there is a problem with the boiler. I lit logs of wood several times and over and over again the smoke poured from the stove into the room. I didn't want to go down the pipe. The night passed in a cold house. Thanks to the electric heater, saved. In the morning to the neighbors for help and advice. They recommended to go to the stove-maker Vasily. He knows everything, will figure it out. I went.

Why is the stove smoking?

Thanks to the internet for his knowledge. I read it, began to understand that the problem is the lack of traction. She's definitely not there. You bring a burning match into the furnace and you do not see the deflection of the flame.

Why is there no craving? There may be several reasons, but the essence is the same. Somewhere something is hammered and does not allow air to pass.

He began to find out how everything was done with me. Stoves are different. But each should have a place for cleaning soot. Everywhere they write about cleaning doors. I do not have them. I went back to the neighbors. Instead of a door in the wall, they have a brick that performs this task. You take it out and clean everything. Should be near the boiler. From the opposite side, I begin to probe the wall and look for roughness. It seems to have found it. I'm ripping the wallpaper off the wall. And I see this.

Here it is a cherished brick. Definitely there is. I take it out and start cleaning the contents of the oven channels. He took out three buckets of incomprehensible rubbish mixed with ash. Now there should be success, I have been cleaning for a lot of time. I light the stove and nothing has changed. Same. The reason is different.

Well, let's start to understand further. A neighbor came, but he couldn't tell me anything specifically. Everything is clear with him - one brick. True, he advised to find a stove-maker and completely shift the stove. I didn't want to bear the inconvenience and additional costs. What does it mean to shift the stove? Better to find the reason.

There is only one way - to the roof.

path to the roof of the village house

Climbed in. Looked around. There is such a thing, which includes a chimney from the street and a chimney into the stove. I called this structure a compensator.

furnace expansion joint

furnace expansion joint

I knocked on the pipe that goes out into the street, something fell. And with that sound. The fall seemed promising. I decide to open and clean the contents of the expansion joint. I open it, or rather, I also pull out the brick from the masonry. I try to do everything very carefully. I cleaned it. He took out two bags of soot. I repaired everything and ran contentedly to set fire to firewood, to heat the house. There was no result. The smoke is pouring into the house, as before.

We suggest that you familiarize yourself with: How to make a stove in a bathhouse drawings

I went to the neighbors. No one knows. Everyone says there should be one brick for cleaning. I found it and cleaned everything up there. He tapped the pipe and cleaned everything too. What's the problem then? It's getting colder. There are no solutions. The second night is spent in a cold house.

Sleep is not possible, constantly all sorts of thoughts come into my head. The reason is somewhere nearby. But where? I start to analyze. Cleaned: boiler - oven passage - roof expansion joint - chimney outside. I understand that there is somewhere else unknown to me place.I suppose, most likely, it is located at the place where the stove exits from the room to the roof.

In the morning I examine the wall. Everything is smooth. Wallpaper is pasted on the wall again. Could there really be a second place for cleaning under them? There is nothing to do - I rip off some of the wallpaper and start examining the wall. Surprise! I found a small part of the wall that was covered with mortar and here I made the decision to hammer and look for the coveted brick.

There are many types of stoves. I have a stove with a built-in water heating boiler. In my opinion, the most important thing is the chimney, smoke channels and cleaning points.

Smoke ducts. You need to know their location, quantity, how they pass and whether they are in your oven.

If there are smoke channels, then there must be places for cleaning. Cleaning doors are usually installed. I don't have them, I have to do it. In places where the stove is clogged, ordinary bricks are located. They are simply pulled out and, after cleaning, are reinserted into place, sealed with a solution. It is very uncomfortable.

I have two places for cleaning. One is located on the back wall of the furnace opposite the boiler. The second is in the location of the gate, on the back wall. Do you know what a gate is? I didn't know either, now I know. What an interesting name - gate. A gate is called a conventional damper, which allows you to close the smoke channel after the firebox, changing the intensity of the draft. My gate looks like this.

This reason, perhaps, can be attributed to violations of the technology of the masonry of the stove. It differs from ordinary smoke in that it is characterized by the appearance of smoke precisely when the door is open. This can be explained by the improper design of the wells, in which the traction flows disrupt their natural course. That is, when the door is closed, there is enough draft to bring the smoke out, and when it is opened, its strength decreases, allowing the stove to smoke into the house.

The elimination of this problem should be dealt with by a specialist. Because, most likely, you will have to shift the wells in such a way that the level of the first one is higher than the opening of the furnace door.