Temperature threshold for burning wood of various species

Depending on the structure and density of wood, as well as the amount and characteristics of resins, the combustion temperature of firewood, their calorific value, as well as the properties of the flame depend.

If the tree is porous, then it will burn very brightly and intensely, but it will not give high combustion temperatures - the maximum indicator is 500 ℃. But denser wood, such as hornbeam, ash or beech, burns out at a temperature of about 1000 ℃. The burning temperature is slightly lower for birch (about 800 ℃), as well as oak and larch (900 ℃). If we are talking about such species as spruce and pine, then they light up at about 620-630 ℃.

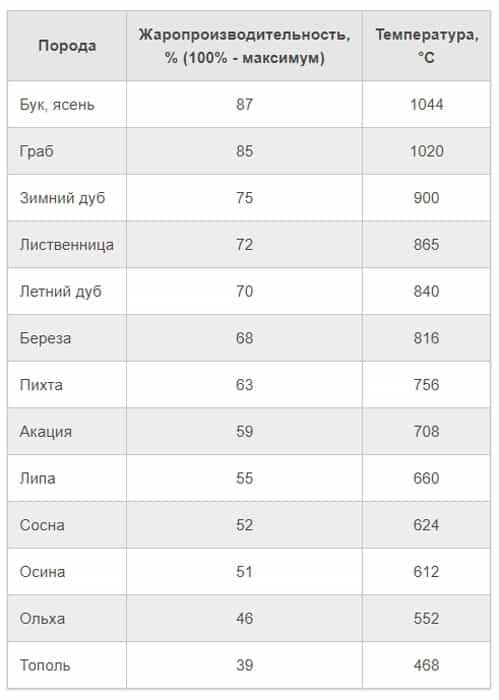

Firewood heating performance: table of main species

Considering different types of wood, in the end, you can notice some differences: some of them burn very brightly and perfectly, while there is a strong warmth, while others just barely smolder, leaving almost no heat behind. The point here is not at all in their dryness or moisture, but in their structure and composition, as well as the structure of the tree.

However, it is worth paying attention to the fact that a wet tree ignites and burns very badly, while a large amount of ash remains, which has a bad effect on the chimney, they become heavily clogged.

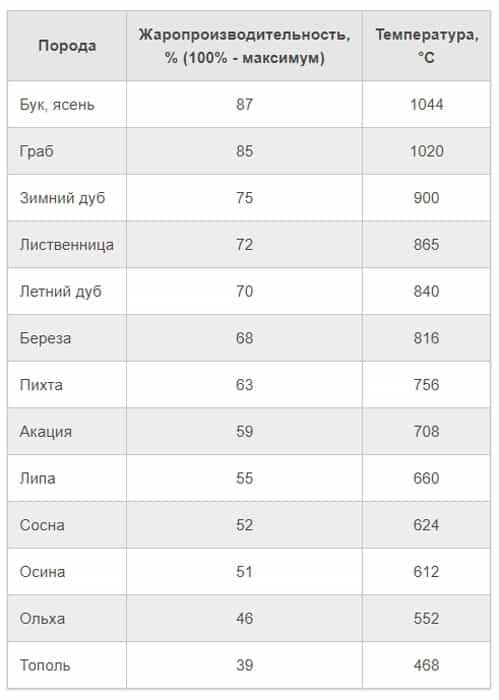

The highest heat output is found in oak, beech, birch, larch or hornbeam, but these species are the most unprofitable and expensive. Therefore, they are used very rarely, and then in the form of shavings or sawdust. The lowest heat transfer is found in poplar, alder and aspen. There is a table showing the main rocks and their heat output.

Table of some of the main rocks and their heat transfer:

- Ash, beech - 87%;

- Hornbeam - 85%;

- Oak - 75, 70%;

- Larch - 72%;

- Birch - 68%;

- Fir - 63%;

- Linden - 55%;

- Pine - 52%;

- Aspen - 51%;

- Poplar - 39%.

Conifers have a low burning temperature, so it is better to use them for lighting an open fire (fire). However, pine wood catches fire very quickly and is capable of smoldering for a long time, since it contains a huge amount of resins, so this species is able to retain heat for a long time. But nevertheless, it is better not to use coniferous species for heating, since when it burns, a lot of flue gases are formed, which settle in the form of soot on the chimney and it must be cleaned, since it quickly clogs up.

Thermal characteristics of wood

Wood species differ in density, structure, quantity and composition of resins. All these factors affect the calorific value of the wood, the temperature at which it burns, and the characteristics of the flame.

Poplar wood is porous, such firewood burns brightly, but the maximum temperature indicator reaches only 500 degrees. Dense wood species (beech, ash, hornbeam), when burned, emit over 1000 degrees of heat. Indicators of birch are slightly lower - about 800 degrees. Larch and oak flare up hotter, giving out up to 900 degrees Celsius. Pine and spruce firewood burns at 620-630 degrees.

Birch firewood has a better ratio of heat efficiency and cost - it is economically unprofitable to heat with more expensive woods with high combustion temperatures.

Spruce, fir and pine are suitable for making fires - these conifers provide relatively moderate warmth. But it is not recommended to use such firewood in a solid fuel boiler, in a stove or fireplace - they do not emit enough heat to effectively heat the home and cook food, burn out with the formation of a large amount of soot.

Low-quality firewood is considered to be fuel made from aspen, linden, poplar, willow and alder - porous wood emits little heat when burning. Alder and some other types of wood "shoot" with coals during combustion, which can lead to a fire if the wood is used to fire an open fireplace.

When choosing, you should also pay attention to the degree of moisture content of the wood - raw firewood burns worse and leaves more ash.

Thermal properties of wood

Different types of wood make different amounts of heat. For example, dry, aged wood generates more heat than freshly sawn wood. This is attributed to the fact that at the initial chemical reaction, all the heat passes into the vaporization of water from the tree. The less moisture there is in the material, the sooner heat can be obtained. Hardwoods burn longer than softwoods and emphasize more heat. Some of the most valuable tree specieswith good thermal parameters are:

However, the wood of such trees is expensive, due to this, industrial waste and logging is used as fuel in most cases.

In this video, you will know how to check the moisture content of firewood:

The use of wood based on its heat capacity

When choosing a type of firewood, it is worth considering the ratio of the cost and heat capacity of a particular wood. As practice shows, the best option can be considered birch firewood, in which these indicators are best balanced. If you buy more expensive firewood, the costs will be less efficient.

For heating a house with a solid fuel boiler, it is not recommended to use such types of wood as spruce, pine or fir. The fact is that in this case, the combustion temperature of the wood in the boiler will not be high enough, and a lot of soot will accumulate on the chimneys.

Low heat efficiency values are also found in alder, aspen, linden and poplar firewood due to its porous structure. In addition, sometimes alder and some other types of firewood are shot with coals during the combustion process. In the case of an open furnace, such micro explosions can lead to fires.

Types of wood

There are several patterns that determine the difference in the combustion of different types of wood. First of all, this is the presence of resins - they noticeably add the calorific value of firewood. Soft wood burns more easily due to its low density. Heavy rocks sustain combustion for a long time.

While the density of wood varies significantly from species to species, their calorific value per unit mass is almost the same (with the exception of coniferous resinous species). Regardless of what types of trees were used for firewood, humidity is the main factor affecting both the combustion process and the thermal result.

Knowledge of different types of wood allows you to get comfortable burning with less firewood consumption

A list of features of some wood species:

- acacia - burns slowly and gives a lot of heat, dries quickly, emits a characteristic crackling in the fireplace;

- Birch - burns out quickly, easily ignites even when wet, gives an even and stable fire;

- beech - high-calorie fuel, leaves little ash;

- oak - high calorific value, emits a pleasant smell during combustion, dries for a very long time;

- poplar - low heat of combustion;

- fruit trees - burn slowly and evenly;

- conifers - fragrant smoke, can shoot tar, form a lot of soot.

Knowing the basics of handling wood as a fuel allows you to get comfortable combustion with less firewood.

It is only important not to forget the main thing: an uncontrolled open flame can be very dangerous for living beings. In addition to burns from flames and embers, fire can bring incomparably more disaster when it burns into a fire.

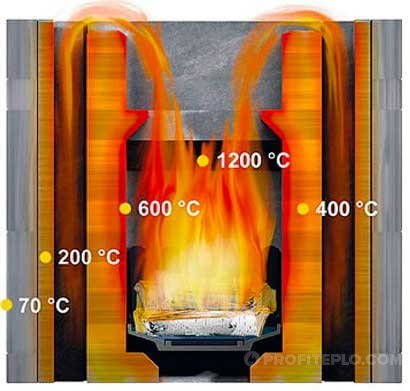

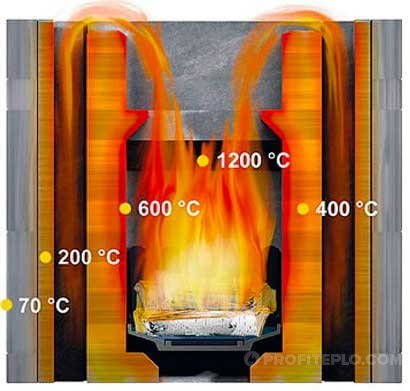

Combustion temperature and heat transfer

There is a direct relationship between the temperature of burning wood in the stove and heat transfer - the hotter the flame, the more heat it emits into the room. The amount of generated heat energy is influenced by various characteristics of the tree. The calculated values can be found in the reference literature.

It should be noted that all standard indicators were calculated under ideal conditions:

- the wood is well dried;

- the furnace is closed;

- oxygen is supplied in precisely metered portions to maintain the combustion process.

Naturally, it is impossible to create such conditions in a home stove, so less heat will be released than the calculations show. Therefore, the standards will be useful only for determining the overall dynamics and comparison of characteristics.

The measurement of the combustion temperature of wood in the fireplace can only be performed with a pyrometer - no other measuring devices are suitable for this.

If you do not have such a device, you can visually determine the approximate indicators based on the color of the flame. For example, a low temperature flame has a dark red color. A yellow light indicates too high a temperature obtained by increasing the draft, but in this case, more heat immediately evaporates through the chimney. For a stove or fireplace, the most suitable combustion temperature is at which the color of the flame will be yellow, as, for example, with dry birch wood.

Modern stoves and solid fuel boilers, as well as closed-type fireplaces, are equipped with an air supply control system to adjust heat transfer and combustion intensity.

The combustion temperature of wood determines the heat transfer rates of the fuel - the higher it is, the more heat energy is released during the combustion of firewood. In this case, the specific heating value of the fuel depends on the characteristics of the wood.

Heat transfer indicators in the table are indicated for firewood burned under ideal conditions:

- minimum moisture content in the fuel;

- combustion takes place in a closed volume;

- oxygen supply is dosed - the amount that is necessary for full combustion is supplied.

It makes sense to focus on the tabular values of the calorific value only for comparing different types of firewood with each other - in real conditions, the heat transfer of the fuel will be noticeably lower.

What is combustion

Combustion is an isothermal phenomenon - that is, a reaction with the release of heat.

1. Warming up. The piece of wood must be heated with an external fire source to the ignition temperature. When heated to 120-150 degrees, the wood begins to char, and coal is formed, capable of spontaneous combustion. When heated to 250-350 degrees, the process of thermal decomposition into gaseous components (pyrolysis) starts.

2. Combustion of pyrolysis gases. Further heating leads to increased thermal decomposition, and the concentrated pyrolysis gases flare up. After the outbreak, the ignition gradually begins to cover the entire heating zone. This produces a stable light yellow flame.

3. Ignition. Further heating will ignite the wood. The ignition temperature in natural conditions ranges from 450 to 620 degrees. The wood ignites under the influence of an external source of thermal energy, which provides the heating necessary for a sharp acceleration of the thermochemical reaction.

The flammability of wood fuel depends on a number of factors:

- volumetric weight, shape and section of a wood element;

- the degree of moisture in the wood;

- traction force;

- the location of the ignited object relative to the air flow (vertical or horizontal);

- density of wood (porous materials ignite more easily and faster than dense ones, for example, it is easier to light alder wood than oak).

For ignition, good, but not excessive traction is required - a sufficient supply of oxygen and a minimum dissipation of the thermal energy of combustion are required - it is needed to warm up adjacent sections of wood.

4. Combustion.Under conditions close to optimal, the initial outbreak of pyrolysis gases does not fade, from ignition the process turns into stable combustion with a gradual coverage of the entire volume of fuel. Combustion is divided into two phases - smoldering and flaming combustion.

Smoldering involves the combustion of coal, a solid product of the pyrolysis process. The release of flammable gases is slow and they do not ignite due to insufficient concentration. Gaseous substances, when cooled, condense, forming a characteristic white smoke. In the process of smoldering, air penetrates deep into the wood, due to which the coverage area expands. Flame combustion is provided by the combustion of pyrolysis gases, while the hot gases move outward.

Combustion is maintained as long as there are conditions for fire - the presence of unburned fuel, oxygen supply, maintaining the required temperature level.

5. Attenuation. If one of the conditions is not met, the combustion process stops and the flame goes out.

To find out what is the burning temperature of wood, use a special device called a pyrometer. Other types of thermometers are not suitable for this purpose.

There are recommendations to determine the combustion temperature of wood fuel by the color of the flame. Dark red flames indicate low-temperature combustion, white flames indicate high temperatures due to increased draft, in which most of the heat energy goes into the chimney. The optimal color of the flame is yellow, this is how dry birch burns.

In solid fuel boilers and stoves, as well as in closed fireplaces, it is possible to adjust the flow of air into the firebox by adjusting the intensity of the combustion process and heat transfer.

The calorific value indicates how much heat energy is released during the combustion of firewood. But solid fuel has another characteristic, knowledge of which can be useful in practice - heat output. This is the maximum temperature level that can be reached when burning wood and depends on the properties of the wood.

Low-density wood burns with a light high flame and at the same time emits a relatively small amount of heat; dense wood firewood is characterized by increased heat production at a low flame.

| Breed | Heating capacity,% (100% - maximum) | Temperature, ° C |

| Beech, ash | 87 | 1044 |

| Hornbeam | 85 | 1020 |

| Winter oak | 75 | 900 |

| Larch | 72 | 865 |

| Summer oak | 70 | 840 |

| Birch | 68 | 816 |

| Fir | 63 | 756 |

| Acacia | 59 | 708 |

| Linden | 55 | 660 |

| Pine | 52 | 624 |

| Aspen | 51 | 612 |

| Alder | 46 | 552 |

| Poplar | 39 | 468 |

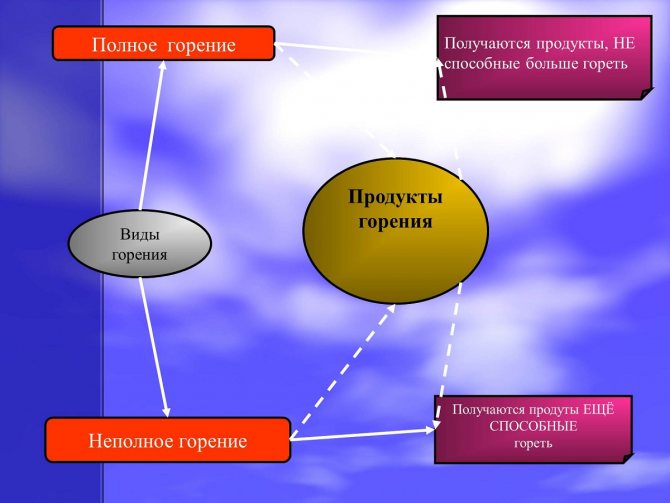

Complete and incomplete combustion: what is released when wood burns

Not only wood can burn, but also its products (chipboard, fiberboard, MDF), as well as metal. However, the combustion temperature is different for all products. For example: the combustion temperature of steel is 2000 degrees, aluminum foil - 350, and wood starts to ignite already at 120 - 150.

Burning wood eventually produces smoke, where the solid is soot. The entire composition of combustion products depends entirely on the constituents of the tree. Wood is mainly composed of the most important constituents: hydrogen, nitrogen, oxygen and carbon.

If 1 kg of wood is burned, then the products of combustion in a gaseous state will be released somewhere between 7.5 and 8.0 cubic meters. In the future, they are no longer capable of burning, except for carbon monoxide.

Wood combustion products:

- Nitrogen;

- Carbon monoxide;

- Carbon dioxide;

- Water vapor;

- Sulphur dioxide.

Burning in character can be complete or incomplete. But both of them occur with the formation of smoke. In case of incomplete combustion, some combustion products can still burn later (soot, carbon monoxide, hydrocarbons). But if there was complete combustion, then the products that were formed in the future are not capable of burning (sulfur and carbon dioxide gases, water vapor).

The fire hazard of wood is determined by the laws of its thermal decomposition under the influence of external heat fluxes, which begins at a temperature of 110˚С.Further heating is accompanied by the removal of free and bound moisture from the wood. This process ends at a temperature of 180˚C, after which the decomposition of the least heat-resistant components begins with the release of CO 2 and H 2 O. At a temperature of ~ 250˚C, wood pyrolysis occurs with the release of gaseous products: CO, CH 2, H 2, CO 2, H 2 O. The evolved gas mixture is flammable and can ignite from an ignition source. At higher temperatures, the thermal decomposition of wood is accelerated. The bulk of combustible gases, containing up to 25% hydrogen and up to 40% combustible hydrocarbons, are released in the temperature range from 350 to 450˚С.

One of the important factors that determine the fire hazard of wood is its ability to ignite and spread combustion when heated in air.

Burning wood occurs in the form of fiery combustion and smoldering. Under fire conditions, the main amount of heat is released during the period of flaming combustion (up to 60%) and ~ 40% - during the decay period.

Fire hazard indicators for some types of wood are shown in Table 4.

Table 4 - Indicators of fire hazard of various types of wood

Temperature indicators of the fire hazard of wood - the temperature of ignition and self-ignition - are determined by the laws of its thermal decomposition. The values of these indicators for different types of wood, as can be seen from Table 2, are in a fairly narrow temperature range.

Dry wood of all species is a highly flammable (B3) highly combustible (G4) material with a high smoke-generating ability (D3). In terms of the toxicity of combustion products, wood belongs to the group of highly hazardous materials (T3). The linear velocity of flame propagation over the surface is 1-10 mm / s. This speed depends significantly on a number of factors: wood species, its moisture content, the value of the falling heat flux, the orientation of the burning surface. The rate of smoldering is also not a constant value - for various types of wood, it ranges from 0.6 to 1.0 mm / min.

In construction, wood-based finishing materials are widely used: chipboards, fibreboards, wood panels, slats, plywood. All of these materials are flammable. Modified panels, slats, plywood. All of these materials are flammable. Modification of wood with polymers, as a rule, increases its fire hazard.

Table 5 shows the flammability characteristics of some wood-based building materials.

Table 5 - Flammability of wood materials

Flame spread over the wood surface

Experimental studies of flame propagation over the surface of wood materials using different test methods have shown that not only the conditions of external heat exposure, but also the type of wood affects the characteristics of flame propagation.

The influence of wood species can be traced to some extent when considering the values of the so-called flame spread index (FLI).

IRP according to GOST 12.1.044-89 is a complex indicator, since when calculating it, in addition to the speed of flame propagation in individual sections of the sample surface and the maximum propagation distance, it also uses data on the maximum temperature of the exhaust flue gases and the time to reach it. Materials with IRP≤20 are classified as slowly spreading flames, with IRP˃20 - as rapidly spreading flames. All types of wood belong to the latter group of materials. Their index exceeds 55.

Table 4 shows the IRI values for untreated wood samples with a thickness of 19-25 mm.

Although most types of wood belong to the 3rd, the most dangerous, class in terms of their ability to spread a flame over the surface of ceiling structures during a fire, some coniferous species, as follows from Table 6, have lower values of the IRI and belong to the 2nd class.

Table 6 - IRP value and class according to the ability to spread the flame

| Type of wood | Flame Spreading Class |

| Red cedar | |

| Yellow cedar | |

| Spruce white | |

| Silver spruce | |

| White pine | |

| Pine Lodgepole | |

| Larch |

An increase in heat flux to the surface of the wood causes a significant increase in the speed of flame propagation. The termination of the process is possible if the heat flux from its own flame becomes less than critical for a given material.

Tests of wood-based finishing building materials under conditions simulating the development of a real fire showed rather high rates of flame propagation along them (table 7).

Table 7 - Velocity of flame propagation over wood-based claddings

Smoke-generating ability and toxicity of wood combustion products

The release of toxic fumes is the dominant fire hazard. It manifests itself in the toxic and irritating effect of combustion products, as well as in the deterioration of visibility in a smoky environment. Decreased visibility makes it difficult to evacuate people from the danger zone, which, in turn, increases the risk of poisoning by combustion products. The situation in the event of a fire is further complicated by the fact that flue gases quickly spread in space and penetrate into rooms far from the fire source. The concentration of emitted smoke and its nature depend on the structural features and chemical composition of the combustible material, combustion conditions.

More than 200 compounds - products of incomplete combustion - have been found in the flue gases formed during the combustion of wood. The maximum value of the optical density during combustion of each of the types of wood depends in a complex way on the density of the external heat flux. The smoke production coefficient during decomposition and smoldering combustion of different types of wood depends on the density of the external heat flow (Figure 14).

1 - spruce; 2 - pine near Moscow; 3 - thongkaribe pine; 4 - ilim karagach; 5 - acacia keolai; 6 - chestnut; 7 - acacia; 8- eucalyptus bacdan.

Figure 14 - Characteristics of smoke generation.

A similar extreme character of the curves for the dependence of the toxicity index of wood combustion products on the density of the external heat flux (Figure 15). In the mode of smoldering combustion of spruce wood, the CO yield is 70-240 times higher than the CO yield during flame combustion.

In the smoldering mode in the temperature range of 450-550 ° C, all types of wood manifest themselves as highly hazardous in terms of the toxicity of combustion products and belong to the T3 group. With an increase in the intensity of the thermal effect up to 60-65 kW / m 2 (which corresponds to a temperature of 700-750 ˚С), according to the toxicity of combustion products, wood of different types passes into the group of moderately hazardous materials T2.

1- linden; 2 - birch; 3 - ilim karagach; 4 - oak; 5 - aspen; 6 - pine; 7 - spruce.

Figure 15 - Toxicity of combustion products from heat exposure temperature.

When wood burns, a fairly intense smoke formation occurs. The largest amount of smoke is emitted when burning wood materials in the smoldering mode (table 8).

Table 8 - Smoke-generating capacity of wood materials when tested in the smoldering mode

4 Fire safety measures in the construction of wooden buildings

The combustion temperature of wood has already been briefly mentioned in our publication about "", and today we will delve into this issue.

We are all used to believing that the fuel itself is burning. And although combustion is impossible without it, the gas released by the fuel during combustion is actually ignited.True, in order for the wood to begin to emit a sufficient amount of this gas for ignition, it needs a high temperature. And this temperature is different for different types of wood and for different conditions. The structure, density, humidity and other features affect the speed and amount of gas released, because some types of wood quickly flare up, give a lot of heat and light, while others are very difficult to ignite, and they emit much less heat than we would like. This becomes very important when, and especially when choosing materials for kindling. The table below shows the combustion temperatures of some common types of wood.

In fairness, it should be noted that the Celsius degrees indicated in the table are given for ideal conditions (closed space, dry wood used and controlled oxygen supply in optimal volumes for combustion), which are achieved only in boilers, but not in a fire made in the middle of the clearing. But, despite this, as a guide, these tables are quite suitable.

The higher the combustion temperature of your chosen tree species, the more heat it will need to absorb before flammable gas starts to evolve from it.

For kindling, it is better to use rocks with a low combustion temperature, and rocks with a high temperature as the main firewood. Otherwise, you may run into two types of problems:

- The burning temperature of the selected wood is higher than the temperature generated by yours. Because of this, the fuel simply will not ignite, or will require additional processing, preparation and preparation.

- The combustion temperature of the selected wood is low, and as a result, insufficient heat is generated. For this reason, you may need to change the species as you burn fuel or more wood.

From the data in the table, we can conclude that the combustion temperature of poplar makes it a good kindling, because it will start to burn actively already at 468 degrees Celsius, while, for example, pine will have to be warmed up to 624 degrees. If there is nothing at hand except oak, then to ignite it, you will have to sweat a lot to raise the burning temperature to 840-900 degrees, and only then add oak logs. The low combustion temperature makes poplar a good kindling, but it is better not to use it as the main fuel because of its low heat output, indicated in the second column of the table. For this role, pine, birch, or the same oak are much better suited. These rocks produce more gas, hence more light and heat.

I don't see much point in remembering the values of all table columns. it is much easier to use it as a reference point for building your own charts of tree species, taking into account the peculiarities of the flora of your region. A simple sequence like “first we burn rock X, then switch to rock Y” in three or four steps is much easier to remember and use in the field. If you do not have a choice in the field, and you have only one type of wood at hand, you will have to work with it, but if there is still a choice, it is better to make it consciously and deliberately. And although the combustion temperature indicated in the table is characteristic only for ideal conditions, speaking of them, it is also worth mentioning two factors that directly affect the combustion temperature: humidity and contact area.

Factors affecting combustion temperature

The burning temperature of wood in the stove depends not only on the type of wood. Significant factors are also the moisture content of the wood and the traction force, which is due to the design of the heating unit.

Influence of moisture

In freshly cut wood, the moisture content reaches from 45 to 65%, on average - about 55%.The combustion temperature of such firewood will not rise to maximum values, since the heat energy will go to evaporate moisture. Accordingly, the heat transfer of the fuel is reduced.

In order for the combustion of wood to release the required amount of heat, three ways are used:

- almost twice as much freshly cut firewood is used for heating rooms and cooking (this translates into an increase in fuel costs and the need for frequent maintenance of the chimney and gas ducts, in which a large amount of soot will settle);

- freshly cut firewood is pre-dried (logs are sawn, split into logs, which are stacked under a canopy - it takes 1-1.5 years for natural drying up to 20% moisture);

- dry firewood is purchased (financial costs are compensated by the high heat transfer of the fuel).

The calorific value of freshly cut birch firewood is quite high. Fuel from freshly cut ash, hornbeam and other hardwoods is also suitable for use.

| Wood species | Pine | Birch | Spruce | Aspen | Alder | Ash |

| Calorific value of freshly cut wood (moisture content about 50%), kW m3 | 1900 | 2371 | 1667 | 1835 | 1972 | 2550 |

| Calorific value of semi-dry firewood (humidity 30%), kW m3 | 2071 | 2579 | 1817 | 1995 | 2148 | 2774 |

| Calorific value of wood that has been under a canopy for at least 1 year (moisture content 20%), kW m3 | 2166 | 2716 | 1902 | 2117 | 2244 | 2907 |

By limiting the supply of oxygen to the furnace, we lower the combustion temperature of the wood and reduce the heat transfer of the fuel. The duration of the combustion of the fuel insert can be increased by closing the damper of the boiler unit or stove, but fuel economy turns into a low combustion efficiency due to non-optimal conditions.

С 2Н2 2О2 = СО2 2Н2О Q (heat)

Carbon and hydrogen are burned when oxygen is supplied (left side of the equation), resulting in heat, water, and carbon dioxide (right side of the equation).

In order for dry wood to burn at maximum temperature, the volume of air that enters the combustion chamber must reach 130% of the volume required for the combustion process. When the air flow is shut off by the dampers, a large amount of carbon monoxide is formed, and the reason for this is a lack of oxygen. Carbon monoxide (unburned carbon) goes into the chimney, while the temperature in the combustion chamber drops and the heat transfer of firewood decreases.

An economical approach when using a solid fuel boiler on wood is the installation of a heat accumulator, which will store the excess heat generated during fuel combustion in the optimal mode, with good traction.

With wood-burning stoves, it will not work to save fuel in this way, since they directly heat the air. The body of a massive brick stove is able to accumulate a relatively small part of thermal energy, while in metal stoves, excess heat goes directly into the chimney.

If you open the blower and increase the thrust in the furnace, the intensity of combustion and heat transfer of the fuel will increase, but the heat loss will also increase. With a slow combustion of wood, the amount of carbon monoxide increases and heat transfer decreases.

If an insufficient amount of oxygen enters the furnace, the intensity and temperature of wood combustion decreases, and at the same time its heat transfer decreases. Some people prefer to cover the blower in the stove in order to extend the burning time of one bookmark, but as a result, the fuel burns with a lower efficiency.

If firewood is burned in an open fireplace, then oxygen freely enters the firebox. In this case, the draft depends mainly on the characteristics of the chimney.

C 2H2 2O2 = CO2 2H2O Q (heat energy).

This means that when oxygen is available, the combustion of hydrogen and carbon occurs, which results in heat energy, water vapor and carbon dioxide.

For the maximum combustion temperature of dry fuel, about 130% of the oxygen required for combustion must enter the furnace.When the inlet flaps are closed, excess carbon monoxide is generated due to lack of oxygen. Such unburned carbon escapes into the chimney, but inside the furnace the combustion temperature drops and the heat transfer of the fuel decreases.

Modern solid fuel boilers are very often equipped with special heat accumulators. These devices accumulate an excessive amount of thermal energy generated during the combustion of fuel, provided there is good traction and high efficiency. This way you can save fuel.

In the case of wood-burning stoves, there are not so many opportunities to save firewood, since they immediately release heat into the air. The stove itself is capable of retaining only a small amount of heat, but the iron stove is not capable of this at all - excess heat from it immediately goes into the chimney.

So, with an increase in the thrust in the furnace, it is possible to achieve an increase in the intensity of fuel combustion and its heat transfer. However, in this case, heat loss increases significantly. If you provide a slow combustion of wood in the stove, then their heat transfer will be less, and the amount of carbon monoxide will be more.

Please note that the efficiency of a heat generator directly affects the efficiency of burning wood. So, a solid fuel boiler boasts 80% efficiency, and a stove - only 40%, and its design and material matter.

The temperature reached in the first stage of spontaneous combustion is noticeably higher than the same indicator for the flameless period of combustion of decomposition products. At the initial stage, a thin layer of coal is formed only on the surface of the wood, and at first it does not burn, despite the fact that it is in a red-hot state.

The fact is that at this stage, almost all oxygen is consumed to maintain the flame and has limited access to other combustion products. Coal begins to decompose only from the moment when the stage of fiery combustion is completely completed.

The ignition temperature of the wood material, which ensures the maintenance of stable combustion, for most varieties is 250-300 degrees.

A good example of such an arrangement is the rafters and roof sheathing. As a result, their mutual heating is inevitable with a simultaneous increase in air thrust in longitudinal directions.

All of the above forces builders to take special measures to protect timber structures from the effects of open fires.

Fire temperature in a firewood fire

For a good flame, air is needed, during combustion, a chemical reaction and organic matter occurs, contained in wood is converted to steam and carbon dioxide, giving off heat.

Firewood prepared from different types of wood burns differently. Some burn quickly and brightly, others leave a lot of ash, and burn tediously and for a long time, others burn out for a long time and their coals give a lot of heat.

The highest temperature is given by beech and hornbeam firewood - up to a thousand degrees Celsius. Poplar gives the lowest temperature, not even half the heat of the latter. Alder, aspen, pine, linden, acacia, fir, birch, oak, larch burns stronger than poplar.

The combustion temperature is influenced not only by the species of wood, but also by the availability of access to oxygen, the design of the furnace. For example, in a large stone stove, firewood burns quickly, but the stove perceives their heat and can give it to the environment for a long time. On the contrary, a small stove - a potbelly stove does not retain heat, immediately giving it to the room.

What is the combustion process

An isothermal reaction in which a certain amount of thermal energy is released is called combustion. This reaction goes through several successive stages.

In the first stage, the wood is heated by an external fire source to the point of ignition. As it heats up to 120-150 ℃, the wood turns into charcoal, which is capable of spontaneous combustion.Upon reaching a temperature of 250-350 ℃, flammable gases begin to evolve - this process is called pyrolysis. At the same time, the top layer of wood smolders, which is accompanied by white or brown smoke - these are mixed pyrolysis gases with water vapor.

At the second stage, as a result of heating, the pyrolysis gases ignite with a light yellow flame. It gradually spreads to the entire area of the wood, continuing to heat the wood.

The next stage is characterized by the ignition of the wood. As a rule, for this, it must warm up to 450-620 ℃. In order for the wood to ignite, an external source of heat is needed, which will be intense enough to rapidly heat the wood and accelerate the reaction.

In addition, factors such as:

- traction;

- moisture content of wood;

- section and shape of firewood, as well as their number in one tab;

- wood structure - loose firewood burns faster than dense wood;

- placement of the tree relative to the air flow - horizontally or vertically.

Let's clarify some points. Since damp wood, when burning, first of all evaporates excess liquid, it ignites and burns much worse than dry wood. Shape also matters - ribbed and serrated logs ignite more easily and faster than smooth and round ones.

The draft in the chimney must be sufficient to ensure the flow of oxygen and dissipate thermal energy inside the firebox to all objects in it, but not blow out the fire.

The fourth stage of the thermochemical reaction is a stable combustion process, which, after the outbreak of pyrolysis gases, covers all the fuel in the furnace. Combustion takes place in two phases - smoldering and burning with a flame.

In the process of smoldering, the coal formed as a result of pyrolysis burns, while the gases are released rather slowly and cannot ignite due to their low concentration. Condensing gases produce white smoke as they cool. When the wood smolders, fresh oxygen gradually penetrates inside, which leads to a further spread of the reaction to all other fuels. The flame arises from the combustion of pyrolysis gases, which move vertically towards the exit.

As long as the required temperature is maintained inside the furnace, oxygen is supplied and there is unburned fuel, the combustion process continues.

If these conditions are not maintained, then the thermochemical reaction passes into the final stage - attenuation.

Warming up process

Heating is called heating a piece of wood surface from a separate heat source to a temperature sufficient for ignition. 120-150 ° C is enough for the wood to start charring very slowly.

Later, the process continues with the appearance of coal. At a temperature of 250-350 ° C, wood, under the influence of high degrees, actively begins to decompose into components.

Further, it smolders, but there is no flame yet, and white or brown smoke begins to appear. With further heating, the percentage of pyrolysis gases increases and a flash occurs, after which the wood ignites.

Heat output of wood

In addition to the calorific value, that is, the amount of heat energy released during fuel combustion, there is also the concept of heat output. This is the maximum temperature in a wood-burning stove that a flame can reach at the time of intensive wood burning. This indicator also completely depends on the characteristics of the wood.

In particular, if the wood has a loose and porous structure, it burns at rather low temperatures, forming a bright high flame, and gives quite little heat. But dense wood, although it flares up much worse, even with a weak and low flame gives high temperature and a large amount of thermal energy.

Ignition temperature of various rocks

To get a complete picture of the thermal parameters of wood, it is better to learn the specific heat of combustion of each type of wood and be aware of their heat transfer. The latter can be measured in a wide variety of quantities, but it is not necessary to rely entirely on tabular data, since in reality it is unrealistic to achieve optimal conditions for combustion. However, the wood burning temperature table will help you not to be mistaken with the choice of wood according to its properties.

The values given in the various tables for the burning temperatures of various wood species are flawless in nature and are intended to represent the whole picture, but the practical temperature in the oven will never reach such values. This can be explained by 2 common and clear factors:

- the highest temperature will not be reached, because it will not be possible to completely dry the firewood at home;

- wood is used with a wide variety of moisture levels.

Humidity and combustion intensity

If the wood was recently felled, then it contains from 45 to 65% moisture, depending on the season and species. With such raw firewood, the combustion temperature in the fireplace will be low, since a large amount of energy will be spent on the evaporation of water. Consequently, the heat transfer from raw wood will be quite low.

There are several ways to achieve optimal temperature indicators in the fireplace and release a sufficient amount of heat energy to warm up:

- Burn twice as much fuel at a time to heat the house or cook food. This approach is fraught with significant material costs and increased accumulation of soot and condensate on the walls of the chimney and in the passages.

- Raw logs are sawn, chopped into small logs and placed under a canopy to dry. As a rule, firewood loses up to 20% moisture in 1-1.5 years.

- Firewood can be purchased already well dried. Although they are somewhat more expensive, the heat transfer from them is much greater.

At the same time, raw birch firewood has a fairly high calorific value. In addition, raw logs from hornbeam, ash and other types of wood with dense wood are suitable for use.

The main stages of wood combustion

Combustion of wood material can be represented as two successive stages. At the first stage, the decomposition products are burned in gaseous form, which is accompanied by the formation of a bright flame.

The second stage of this process is the flameless afterburning of the coal formed at the initial stage.

The decisive influence on the fire resistance of a wooden structure (a private house, for example) is exerted by the first of these stages, during which optimal conditions are created to maintain the propagation of combustion.

Despite the limited time, this process is accompanied by the release of a significant amount of heat.

For a while, both of these processes proceed almost simultaneously, after which the release of gases stops, and only coal continues to burn. In this case, the rate at which the bulk of the building's wood material burns out is determined by the following factors:

- volumetric weight of the entire structure;

- moisture content of the original building material;

- ambient temperature;

- the ratio of free spaces to the volume occupied by wood.

A wood material that is denser in structure (oak, for example) burns more slowly than the same aspen, which is explained by the difference in their thermal conductivity.

When wood with a high moisture content is ignited, a certain amount of heat is spent on moisture evaporation. As a result, less heat energy is spent on decomposition of the material. Naturally, dry wood, taking into account all of the above, burns much faster.

Constructive protective measures

Fire-retardant measures in relation to most wooden houses and other structures are provided with appropriate design solutions, as well as due to their treatment with special chemical reagents (fire retardants).

The protection of this type is realized by increasing the mass of individual elements, with the exception of pointed edges and strongly protruding parts ("sharp edges"), using wood elements devoid of voids.

Heat-resistant insulation materials are also used, fire protection of the surfaces of wooden structures with special coatings. Protective coatings are used in the form of asbestos-cement (gypsum) sheet blanks and plaster up to 1.5 centimeters thick.

In addition, in order to reduce the flammability index, the design deliberately reduces the number of structures with parallel wood elements and voids between them.

Additional measures to counter the spread of fire require compliance with the norms for the formation of fire breaks.

To this can be added the breakdown of buildings with special partitions and the corresponding arrangement of wall openings (windows and doors) and fire-resistant roofs. All these measures make it possible to strengthen the structure in terms of its ability to resist the spread of fire.