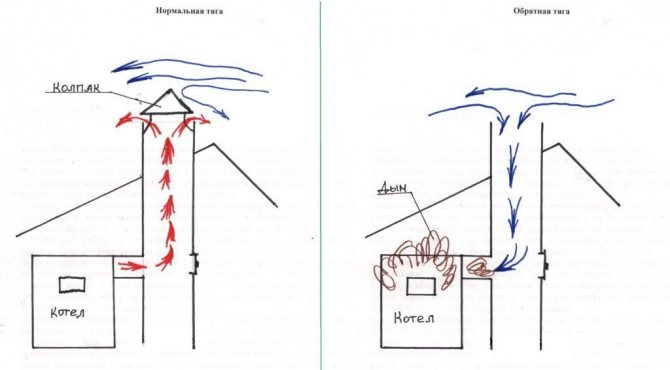

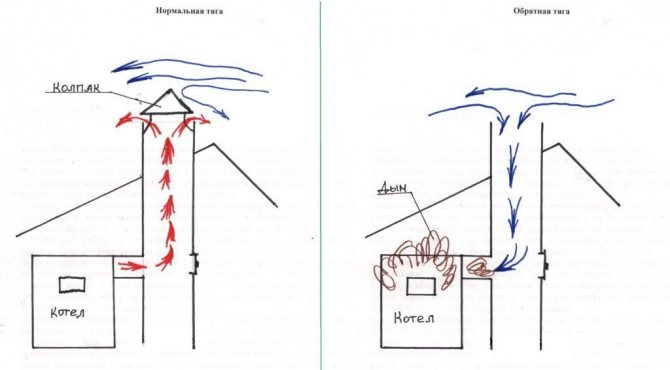

The most important parameter of the chimney system is draft. Everyone knows that it is very important for the operation of a furnace or boiler, but few people know - what is draft? This parameter determines the speed and volume of flue gas movement through the chimney It is necessary to remove gases and oxygen to maintain the combustion process. The very phenomenon of draft arises from the different densities of cold and hot air. The hot one is less dense and, accordingly, is replaced by the cold one. This is how the hot streams move from bottom to top.

The thrust efficiency can depend on several parameters:

- Internal section of the chimney. The smaller its diameter, the faster the rate of release of hot gases. But when they reach a certain minimum size, they will begin to fall into the interior of the room. If the pipe is too large, then the flow of cold air can form the so-called reverse draft.

- The amount of soot deposited on the walls of the chimney. It can significantly reduce the effective pipe diameter, resulting in a loss of thrust speed.

- The number of turns in the chimney. Each turn or bend is an additional obstacle to the passage of smoke.

- Tightness of the system. If there are slots in the structure, then cold air can enter the system through them, forming a cold curtain and preventing the passage of smoke.

- Weather. Low atmospheric pressure and high humidity reduce the rate at which hot air is replaced by cold air in the heater.

Failure to comply with the above conditions is often the cause of poor traction. But how can this indicator be determined without special instruments and devices?

Determining thrust yourself

If the efficiency of the furnace (boiler) has noticeably deteriorated, then there are several ways to check the draft. You can use a special device - an anemometer, but in most cases, purchasing it for home use is economically ineffective. It is best to resort to proven folk methods:

- Candle. If you light a candle, bring it to the chimney and immediately extinguish it, then in the direction of the smoke movement you can see if there is a draft.

- Smoke level in the room.

- A thin piece of paper. The degree of its deviation may indicate the presence of thrust.

Once the problem has been identified, you can begin to resolve it.

Ways to improve traction

There are several ways to improve your cravings, and each one is effective in its own way. But before proceeding with the implementation of one of them, a number of preventive procedures should be done with the very design of the chimney:

- Soot removal (read about it here). To do this, use a special set consisting of a ruff, a sinker and a steel rope.

To do this, you need to climb to the roof and lower the ruff into the outlet of the chimney along the entire length of the pipe. Then, with progressive movements, begin to clean the walls of the chimney. At the same time, layers of soot will begin to fall into the furnace, which are then removed.

- Complete sealing of the chimney... Using one of the above methods, it is necessary to check the structure for the absence of cracks or holes. This problem is typical for brick chimneys, when in the process of operation there is a partial destruction of the masonry.

If after these measures the thrust has not improved, then you need to resort to more radical methods.

Draft regulator

This device is installed on the outlet of the chimney.

After preliminary adjustment, it compensates for the pressure in the pipe with external pressure.In this case, not only the normalization of the heater's operation takes place, but the thrust speed is the same, regardless of external weather conditions.

Deflector

This additional structural element is also installed on the outside of the chimney.

Its outer diameter is much larger than the cross section of the chimney itself. This is necessary for the appearance of the effect of pressure drop when the air flow around the obstacle. Those. When the air flow around the deflector design creates a low pressure area within it, which contributes to the creation of conditions for a better thrust speed.

Chimney weather vane

An original design that can not only improve draft, but also protect the chimney from atmospheric precipitation.

Its operation is based on the principle of a deflector and flue gas outlet only from the leeward side. This makes it possible to reduce the external air resistance and thus to normalize the thrust speed.

Smoke fan

One of the most effective methods is to install a special fan on the chimney.

Hood deflectors

This is a fairly common option for forced ventilation. A deflector is an aerodynamic device that is installed above the chimney. It increases the draft in the chimney by changing the air flow. The essence of its work lies in the pressure drop when air flows around the obstacle, as well as on the principle of changing air flows. It turns out that its shape allows you to increase the draft in the chimney. Made of stainless steel, they are resistant to corrosion, acids and high temperatures.

It cannot be called a full-fledged fan, since the deflector has a simple shape, without working mechanisms. But, there are varieties of smoke deflectors designed specifically for chimneys.

- Volpert deflector.

- Deflector Grigorovich.

- Round or spherical deflector.

It is the round deflector that can create rotational movements under the influence of the wind and remove smoke from the room. But, again, the disadvantage of the product is that it is ineffective in the absence of wind. The principle of operation of this draft amplifier of ventilation pipes and chimneys is demonstrated in the video *

In addition, weather vans, umbrellas and similar structures are often installed on chimneys. But they cannot do all that a high temperature chimney fan can do. Let's take a look at how they work and what makes them special.

Reasons for poor chimney draft

From time to time, the owners of fireplaces note the deterioration of the operation of their heating device. What is the reason, naturally, they do not know. Experiments with changing fuel, usually, also lead nowhere. Experts say that poor draft is the reason for the poor performance of the fireplace.

Reasons for poor chimney draft

"Classic problems":

- Too large or small pipe diameter. The pipe must be of the correct size. If its diameter exceeds certain norms, then reverse thrust occurs. Bring the fan to the chimney, if its blades begin to move - it means that you have a reverse draft. Too narrow a pipe leads to a decrease in thrust to critical values.

- Rotary elements and bends in the pipe. The chimney must be straight, otherwise you will have to install a chimney draft amplifier. Excessive turns and bends reduce this parameter significantly.

- Lack of tightness. This problem often occurs in brick fireplaces as a result of faulty construction technology. When a small hole appears in the wall, it starts to work like a black hole, sucking in air due to the pressure difference. Additional air will have a negative effect on traction. This is the same as placing the fan on the side of the air going up.

If none of the above problems are similar to yours, then the amplifier will help solve the problems with traction.

Smoke draft deflector

https://youtu.be/8HDcwaT7I8A

Smoke fan

The chimney exhaust fan is a heat-resistant electrical device. It is mounted directly on the chimney to increase the draft in the chimney. It is important not to confuse a chimney fan with a fireplace fan, which is used to supply air to maintain combustion. Here the principle of operation is different. Simply put, a chimney fan is an electric motor with blades that allow the smoke to be forced out of the chimney and directed outside. For full operation of the fan, you will need to be powered from a 220V network.

In fact, a fan in a chimney to improve draft is somewhat reminiscent of a deflector, only for its operation no wind force is required at all. He works constantly, doing an excellent job of his task. In addition, you can find economical models on sale. They work in two modes: when there is a strong wind outside, the rotation occurs naturally, without the use of electricity. And in calm weather, an electric motor starts up. It is the perfect chimney solution.

Varieties of fireplace fans

Depending on your wishes and individual characteristics of the heating system, you can buy and install one of the following designs:

| Variety | Description and features |

| Deflector

| It is distinguished by its strength, durability and resistance to rust and corrosion. The installation plays the role of a reflector or element that projects the direction of air flows. The traction force is increased by reflecting currents from the roof and side walls. The disadvantages include the ineffectiveness of the fan in calm weather. However, at the same time, the overturning of such a device is completely excluded, even with a very strong, squall and gusty wind. The main selection criteria are compliance with the chimney diameter and the calculation of the wind load. |

| Vane

| One of the simplest and most inexpensive options. Its functionality and the effect of traction force directly depends on the intensity of the wind. The design consists of a canopy and a wing with small dimensions. Also, the design is complemented by a special blade that fixes and fixes the weather vane on a given section of the chimney. The weather vane is most often used to increase the draft level in solid fuel boilers operating on simple logs or purchased briquettes. |

| Rotary turbine

| The work of such mechanical means is carried out by rotating turbines from wind flows. Due to the presence of special nozzles built into the structure, the rotation is carried out exclusively in one direction, regardless of the direction of the wind itself. The advantages of this type include high-quality protection against the ingress of various dirt, leaves, foreign objects and precipitation into the inner part of the chimney. Such fans-amplifiers are capable of efficiently removing air, which is especially important in a non-heating season. Suitable for solid fuel and gas boilers with a maximum temperature limit of 250 degrees. |

| Electric smoke exhauster

| This variation is intended for stoves and fireplaces using solid fuels. The advantages of such devices include their versatility in operation (in conditions with exposure to high temperatures, the formation of a large amount of condensate, soot and other combustion products). The maximum permissible temperature regime for such devices has a limit of 800 degrees. The work and functioning is carried out by means of special temperature sensors, which, if necessary, are capable of both slowing down and increasing the fan speed. |

Features of chimney designs

Since the smoke has a high temperature and constantly affects the structure, the chimney fan is made heat-resistant. The material is able to withstand temperatures up to 250 degrees. This is enough to serve faithfully for many years. Typically, products are made of specially coated die-cast aluminum. The engine has life-long bearing lubrication and is also heat-resistant.

As for the types of fans, it all comes down to differences in their shape and power. After all, chimneys are different, respectively, you need to choose a device that would fit inside and have the shape of a chimney. These are the features of the choice of products for the chimney. Usually the design is made in a square or round shape.

Inlet valve to increase traction

Without air entering the room or directly into the stove, the chimney will not work. A vents or slots in old windows are not the best method for getting air in.

The disadvantages are obvious:

- Cold air enters the room through the cracks even when the stove or fireplace is not working.

- In winter, outdoor air constantly changes the indoor environment. At the same time, the relative humidity of the air drops sharply, which is harmful to health. A person's mucous membranes dry out, conditions for colds arise.

- The window must be opened and closed manually.

It is much more efficient to provide air flow with a valve. It closes automatically when oven equipment or gas heaters are not working.

This is what a wall supply valve looks like, which is installed in rooms with stove heating or gas equipment to improve air flow

The heaters require a boiler room valve to operate. The device has other characteristics than similar structures for room ventilation.

The supply valve is placed diagonally or above a heated surface so that cold air rises to the ceiling. But it is best if oxygen is supplied directly to the furnace. At the same time, the humidity and temperature conditions in the room are not disturbed.

Completely change the chimney as a last resort. It's worth starting with simpler methods.

First, the old chimney must be cleaned of soot and dirt. Use special metal brushes for this.

If during the construction phase the canals and the pipe were not insulated, it is worth doing this. Warm gases are removed more efficiently than cooled ones. In addition, it is necessary to exclude convective currents inside the chimney, when the air goes down along the cold wall, interfering with the upward currents.

Another effective way to increase traction is to reduce the number of bends in the smoke exhaust system. Partial rebuilding of the chimney is less expensive than a complete system replacement.

A popular way to increase chimney draft is to install a deflector. The wind becomes a helper, and does not create gusts of reverse thrust

You can also use a rotary turbine. During the wind, the turbine spins the impeller, which provides additional vacuum at the outlet of the chimney.

An equally effective way to increase traction is to increase the height of the chimney. The speed of movement of gases and, accordingly, the performance of the system as a whole depends on the height of the chimney.

We looked at passive ways to increase traction. But there is another effective method, which is discussed below.

We offer you to familiarize yourself with Iron stoves for a bath with your own hands how to make a stove in a metal bath photo

Popular fan reviews

MMOTORS JSC BO VO 90/25 T (+ 150 ° C)

An excellent circular fan used for intermittent or long term operation. Its productivity is 60 m 3 / h, with a power of 16 W. The product has an IP44 protection class. The landing diameter is 9.9 cm, and the depth is 2.5 cm. The fan produces 2.5 thousand revolutions.The product can be installed in channels with a short length. Thanks to the low-noise electric motor, which has double-encapsulated ball bearings, the device can work as much as 30 thousand hours. In this case, the fan can be mounted both vertically and horizontally. The body is made of an aluminum alloy that cools quickly and can withstand temperatures up to 150 degrees. The warranty is 3 years. The cost is about $ 38.

MMOTORS JSC BA VA 9/2 T (+150)

Unlike the previous version, the fan has a square shape, as for the parameters, they practically do not differ in anything. Power - the same 16 W, performance, protection class, speed and other indicators are the same. But the landing diameter is 9.3x9.3, with a depth of 2.5 cm. Warranty - 3 years, cost - $ 38.5.

MMotors BOK 150/120 (+ 150 ° C)

The fan is also used for a round chimney. It is much more powerful than the previous options. With a power of 18 W, the device has a capacity of 240 m 3 / h. Fitting diameter - 12 cm. Protection class IP44.

The model has a different cross-section along the fan axis, which allows it to be adapted to conventional air ducts. The material is heat-resistant, and the engine will last 30 thousand hours of operation. Manufacturer's warranty - 3 years. The cost is $ 90. Having bought such an exhaust fan for the chimney pipe, you can forget about the weak draft.

Prevention and methods of verification

Before the onset of the heating season, it is imperative to check if there is air movement in the chimney. There are special devices for testing. For example, an anemometer. It allows you to measure the flow rate very accurately, but this technique costs money. The absence of wind outside or its speed of less than 1 m / s alone explains why there is no draft in the chimney.

There are also old tried and tested methods for testing. A lit match should be brought to the firebox and observed where the flame is directed. If towards the oven, then this indicates good traction. The fire does not fluctuate - there is no air movement in the chimney. A flame directed away from the firebox is clear evidence of reverse flow.

The same can be seen and with a piece of paper... If you attach it to the open opening of the firebox, you will see where it deviates.

How dynamically the air moves and what is its direction can be judged by the color of the flame. If everything is normal, then the fire has a golden color, and the resulting smoke immediately evaporates into the chimney. With very strong thrust, the color is dazzling white, a rumble is heard in the pipe. Red indicates a problem in the chimney or pipe.

Poor hood - reasons

Before talking about the use of forced draft devices for the chimney, let us dwell on the essence of the process, as well as the reasons for the drop in draft in the chimney.

The set of factors affecting the efficiency of chimney extraction can be conditionally divided into three groups:

- Internal conditions in the house;

- Conditions for moving air flows inside the room.

- Air temperature in the heated area of a residential building.

- The total volume of air inside the premises, which are linked to the furnace compartment of the furnace through a blower.

- The number of other oxygen consumers living in the house - people or animals.

Features of increasing thrust depending on the design

If the device of the deflector on the pipe is not included in the design documentation, its installation is agreed with the employees of the gas service. Only then can traction be increased using this device.

Deflector TsAGI

Deflector designs differ:

- TsAGI deflector;

- round fixture;

- disc type;

- in the form of a star;

- H-shaped device;

- turbo deflector.

The deflector model is selected according to the value of the average wind speed in the area and the diameter of the flue duct.The devices are effective only in the presence of wind, in calm weather they do not work and can reduce thrust. An increase in smoke removal occurs with a different direction of the wind flow, except for the horizontal one, when vortices occur inside and the path of combustion products is blocked. The problem is solved by installing a reverse cap.

Improvement in the chimney of a gas boiler

If gas is used for heating, not all models of deflectors can be installed, since some are intended only for installation in the ventilation system. In order not to block the flow of exhaust gases, you need to consult with specialists.

In systems with a gas boiler, a deflector-vane is used. It is designed so that smoke comes out of the leeward side and increases chimney draft. The device is made of heat-resistant metal that resists heating and does not collapse from condensation. The bearing assembly helps to avoid rolling problems. Chimney weather vane is unstable in strong winds.

For solid fuel boiler

Correct installation of the deflector on different pipes for a solid fuel boiler

Wood-fired and coal-fired boilers use a mechanical, non-volatile draft control device. The device eliminates the need for manual adjustments and saves fuel. The regulator coordinates the amount of oxygen supplied by opening the oven damper.

A thermomechanical device automates the process:

- when the fuel burns, the energy carrier in the system is heated and the liquid in the working cylinder of the device expands, drives the mechanism and activates the spring;

- the lever loosens the chain, the damper closes, and the air passage decreases, smoldering begins instead of burning;

- cooling the antifreeze leads to the reduction of the spring and the opening of the firebox door, the process is repeated regularly.

The device regulates draft, prevents overheating of the heat exchanger, coordinates pressure and ensures independence from the weather.

In the chimney of a garage stove

Such stoves are capricious about traction, since almost all the heat is spent on heating the garage. The temperature of the outgoing smoke is low, the channel does not warm up, and condensation falls out. The phenomenon can be prevented by increasing the height of the pipe (up to 2-3 meters). A cylindrical or circular chimney section is used to prevent turbulence. The pipe of the garage oven is insulated to improve traction.

A damper is placed at the end of the pipe, partially covering the pipe perimeter. The damper regulates the intensity of the flame during kindling. If you use a large amount of fuel, the heated smoke will go up in a large volume and a kind of plug will be formed on the border with the cold air. In some models of ovens, the gate is sold as a set.

Prevention of the condition of the chimney

So that there is no need to use means of forced exhaust of the chimney from a heat-resistant material, it is necessary to use preventive measures to maintain it in working order.

Since the main reason for reducing the intensity of flue gas extraction is a decrease in the passage of the pipe with soot accumulated on the walls, we will consider means of combating this phenomenon.

These ways can be:

- Burning naphthalene in the furnace of about half a tablespoon. Vapors of naphthalene decompose soot into loose components, large ones fall out into the furnace and are further removed with ash, and small ones fly out through the pipe together with the furnace gases. This agent must not be used for chimney removal from the fireplace and for pipes of open hearths - after it, a characteristic suffocating smell remains in the rooms.

- Burn from time to time in the potato peeling furnace. They are pre-dried. Starch vapors loosen the soot deposit and it will fall into the firebox. Pure starch acts similarly, which is fed into a well-burnt firebox in the amount of one tablespoon.

- A good pipe cleaner for soot is a nutshell. It burns at high temperatures, burning off soot deposits on the inner walls. A single dose of shells should be no more than three liters. The frequency of use is as it accumulates.

- Aspen firewood has a similar effect on soot. One or two logs are burned at the end of the last firewood. They burn at high temperatures.

The frequency of application of high-temperature agents should be regular, at least twice a week, so that soot does not have time to accumulate. Otherwise, you can cause a serious fire, since the soot burns with the release of a very large amount of heat.

In addition to those listed on the market, there are many anti-soot agents, both chemical and thermal decomposition of soot. The use of preventive measures can eliminate the need to apply coercive measures to improve the exhaust air on the chimney.

What causes cravings to deteriorate

If you do not know what the draft in the fireplace depends on, and for what reasons it may deteriorate, it is important to know about a number of the most common reasons, which are as follows:

- The chimney can be equipped with various tees, elbows and other connecting elements located along the channel through which the smoke passes;

- Installation errors or possible incorrect position of the valve;

- Initially, the diameter and section of the chimney was incorrectly selected;

- If there is no draft in the fireplace, it is possible that the exit is located below the ridge on the roof. Perhaps this has already provoked the "overturning" of this element;

- In the immediate vicinity of the chimney, there are higher and larger houses, structures and other buildings. Thus, a very high or, on the contrary, low pressure can lead to a deterioration in the operation of the traction mechanism.

Chimney, must be raised and installed at the highest point of the roof

Dirt and sediments should not penetrate into the interior of the structure

Interesting to know: in order to carry out diagnostics with your own hands, you just need to turn off the entire heating system and measure the amount and layer of soot and soot accumulated on the walls of the chimney. The thickness of such a layer should not exceed 2-3 millimeters.

Carrying out the device and lengthening

In order to establish the operation of the traction mechanism, one of the following options can be applied in practice:

- Extend the chimney until the optimum size and dimensions are achieved;

- Apply additional fittings and details;

- Supplement the structure with a purchased electric type smoke exhauster;

- Buy traction stabilizers.

Cleaning and caring for the product is a rather complex and time-consuming process that allows you to maintain the functionality and productive operation of the device

Scheme with measurements and dimensions of electrical variation

Important: make sure that the pressure in the inside of the chimney varies between 10 and 20 Pa. In order to determine this criterion, it is recommended to use special devices, for example, you can use an anemometer, the price of which depends on the chosen model and manufacturer.

Interesting to know: the instructions for lengthening the chimney says that the optimal total length of this element should not be less than 5-7 meters, depending on the design features and number of storeys of the house. In this case, knees and narrowings should be encountered as rarely as possible.

Expert tips and tricks

Installation was made on a brick chimney