Types of plaster for facade finishing

Wet facade plaster - the most common way to refine the surface to be treated and protect it from the effects of precipitation and ultraviolet radiation. It is performed on a pre-leveled, cleaned and primed base. A ready-made layer is created not only for decorative, but also for protective purposes, which does not require additional finishing, which has a peculiar texture, as well as a certain color.

The classification of plaster mixes is made according to several principles - structural differences, composition, method of application... There are ready-made solutions immediately suitable for use after mixing and dry mixtures that require dilution with water.

Views by invoice:

- bark beetle;

- pebble;

- lamb (fur coat);

- mosaic.

When applied to the surface of a building, each of the varieties gives a different relief, a certain structure.

Classification by composition:

- mineral;

- silicone;

- acrylic;

- silicate.

Of all the above varieties, mineral plaster for facades is provided by manufacturers in dry form, the rest are ready-made.

According to the methods of application, the mixtures are divided into:

- universal destination;

- mechanized application;

- for manual use.

Universal solutions can be used for both machine and manual application.

Back to content

Sgraffito method in decoration

This is a complex technology for applying plaster, which is performed only by true masters. Layers with different colors are used, they are applied alternately. There are no special requirements for the selection of colors, but care must be taken that they are all in harmony with each other.

The application technique assumes that multi-colored layers will be applied one on top of the other. After drying with a chisel or a sharp spatula, certain layers are carefully removed so that a pattern of a different color remains. As a result, against the background of the last layer, bright and beautiful patterns resembling applications are obtained. If you remove a small amount of the layer, then the color will be completely different. After all the drawings have been completed, it is recommended to carefully grind the surface.

Other working methods can be used. For example, purchase ready-made mixtures for decorative plasters. But even for their use, it is required to follow all the recommendations exactly. It is advisable to have at least minimal experience, otherwise it will be a waste of money, and the plaster is not so cheap.

For example, bark beetle and Venetian plasters are characterized not by technical features, but by the composition of the mixture. It is important to choose the right composition, and only then follow the conditions of application to the wall. There are beautiful masses with mineral inclusions, which, after mixing and applying, resemble the surface of a smooth and shiny marble. Decorative plaster contains particles of natural minerals, most often marble. After the mixture has been carefully applied and smoothed over the wall, it must be left to dry. Then the surface needs to be literally polished so that it shines, only in this case all the advantages of the plaster will be visible.

Decorative plaster is a type of quality finish. Unlike facade mixtures, solutions for interior work allow you to create coatings that imitate not only the surface of wood, but also metal, natural silk.A master who knows how to work with decorative plaster is able to create real masterpieces. Such a surface will become very sophisticated and stylish. Today, manufacturers offer various mixtures for such work, you can use a variety of application methods.

Textured plaster

Its structure is a decorative and aesthetic parameter. It has no effect on the duration of operation or strength. The implementation of each type of texture is carried out through the use of materials with a certain grain size of the filler. Allocate textures traditional, as well as modern... The former are structured from old, time-tested mixtures, and the latter are innovative in their composition.

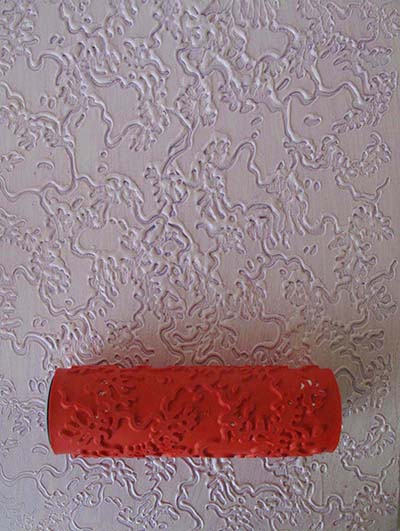

They form a relief using different techniques, devices:

- special graters;

- trowels;

- sponges;

- textured rollers.

Surfaces give absolutely any structure you like or apply a bas-relief pattern. There are standard - the most commonly used types of plaster to form the desired texture.

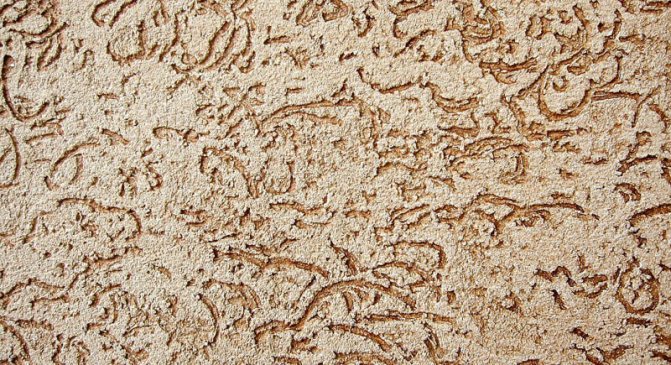

Bark beetle plaster - the most common and has many variations. Traditional methods include vertical, horizontal, circular and cross-cutting. For lovers of a creative approach, you can advise a wave-like texture or your own version.

A relief is formed by grouting the plaster layer with a plastic float. The drawing depends on which direction and with what movements to rub the solution applied to the surface of the building.

Pebble plaster - a universal tool for making a textured pattern for exterior decoration of buildings. The material allows making drawings of varying complexity, carved compositions in different colors - "sgraffito", small and large bas-reliefs, traditional ones - "fur coat", "polka dots". It is a coating densely sprinkled with crumbs with a fraction of 1-3 mm.

The structure is given to the coating with a plastic float by grouting. Special rollers, palette knives, trowels, brushes, a spatula for scratching, smearing, printing patterns and textured elements are used. Various shapes can be drawn on the surface.

Mosaic plaster - a separate variety, which is performed exclusively in the form of a flat, transparent surface. It contains granules of stone chips of natural origin - strong mineral rocks. From an aesthetic point of view - the noblest texture.

It is applied in one layer and rubbed to a state of uniformity. Astringent components - silicone or silicate give lightness and transparency to the coating. It does not need further painting or varnishing.

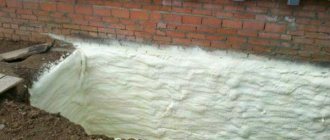

Lamb plaster or fur coat - the traditional method of shaping texture. It is done by throwing the solution onto the wall and does not require further grouting. For the formation of such a relief, cement-sand, cement-lime mixtures are suitable.

Back to content

Decorative plaster application technology

Preparing the walls is an important and mandatory step before using decorative plaster. Without this, it will be impossible to get a beautiful and even surface. The wall must be cleaned of the old coating, leveled and dried. There should be no traces of mold or mildew on it, all holes and cracks must be repaired immediately, and not left for later. If a relief coating is used, then small irregularities must be left in order to give the coating a special expressiveness.

Wall priming is used to ensure that the plaster adheres better to the base of the wall.Despite the fact that manufacturers are trying to literally impose a primer of their own production, claiming that other mixtures will not work, various solutions can be used. You just need to select them based on their wall material - for concrete, brick, wood, metal.

Tools for applying decorative plaster.

The base coat is also important, although its application is extremely simple. To do this, dilute the dry mixture, apply a layer to the wall using a spatula or a special sprayer. This rule applies only to those plasters for which one starter coat is sufficient. For a Venetian finish, many very thin base layers are needed, which will provide the desired play of halftones. Only specialists can do this work with high quality, it is unlikely that it will be possible to cope with the work with their own hands without proper experience.

The finishing coat is an external coating, the application technique of which depends entirely on which plastering method will be used. In some cases, it is enough just to shape with a spatula and then polish the wall. Sometimes additional work is required, covering the wall with a special varnish.

Features of the composition of building mixtures

The active components of the solution and its high-quality base are the key to successful repairs. Building mixtures facilitate labor and have good technical characteristics. The peculiarity of the use of each of them is due to their composition. There are ready-made plaster solutions, as well as dry ones, which must be diluted with water.

| Type of facade plaster | Release form | Appointment | Structure | Layer thickness | Properties |

| Cement | Dry mix | Execution of textured patterns, drawings | Cement, mineral filler, modifiers | 2-5 mm | Plasticity, wear resistance. |

| Acrylic | Ready solution | Pebble, traditional relief | Acrylic resin, sand filler, modifiers | 3-4 mm | Durability, ease of use, high adhesion to the surface |

| Silicate | Ready mix | Suitable for all types of textures | Silicate binder (liquid glass), modifiers | 4 mm | Water resistance |

| Silicone | Ready solution | Universal | Silicone resin, mineral filler, modifiers, emulsifier | 3-4 mm | High resistance to mechanical damage, high adhesion. Elasticity, antiseptic properties. |

Whatever material you choose, the plaster for the facade, if applied correctly, will create the necessary relief, and will also delight you with a high-quality result.

Back to content

Varieties of compositions

Today, manufacturers offer a large selection of plastering compounds, of which the options for outdoor decoration differ in quality and visual indicators. Some mixtures for facade plastering can be prepared by hand.

Of sand and cement

If you prepare the mixture yourself, then this finishing option becomes the most affordable. The material turns out to be so strong that they are allowed to plaster the basement of the building.

To prepare a solution for cladding a house, you will need:

- binder - cement material M 350 and above;

- medium-fraction sand washed from impurities;

- additional ingredients that increase aesthetic performance.

We sift the sand through a sieve, pour water in a volume of two to three liters into a container of a suitable size, pour cement in portions, constantly mixing the contents, add sand and other components, mix everything thoroughly.

The ratio of cement and sand is one to three. The consistency of the prepared solution can be changed in the desired direction by adjusting the amount of sand or water.

To improve plasticity, it is recommended to add thirty to fifty milliliters of dishwashing liquid to the batch.

Ready-made cement composition

Facade walls are plastered with mixtures from the manufacturer, which are resistant to the effects of a humid environment and perfectly tolerate temperature extremes. When choosing a material, one should take into account the time required for the complete drying of the plaster - it takes more than for other types of mortars.

An important feature is the use in the manufacture of special additives that give the compositions different textures.

There are other materials used to decorate the outside of the house. Their differences are the graininess of the structure, methods of application, but in each result, relief is seen that imitates a certain material. To achieve the desired result, you should use one of the following mixtures for facade work.

Mineral

Plaster composition containing natural stone chips is deservedly popular. It is based on cement. It is easy to work with such a mixture, but certain skills will be needed. The color palette is limited, but this drawback is eliminated by coloring.

Acrylic

Polymer material based on acrylic resins, has excellent moisture resistant characteristics, long operating period.

Unfortunately, the coating is exposed to ultraviolet light, attracts dust and quickly becomes dirty. They should not decorate street walls built of aerated concrete material, because the plaster mixture does not have sufficient vapor permeability.

The composition is elastic, it is easy to work with it.

Silicone

A good finishing material, but its cost is high, which limits the scope of use of the plaster. Perfectly resists the effects of climatic precipitation and temperature changes, without changing its quality indicators. An important advantage is considered to be vapor permeability and the ability to close up small defective areas. Houses plastered with such a mixture always look attractive - the material cleans itself in the rain.

Silicate

In the manufacture of the mixture, "liquid glass" is used. Silicate components added to the solution endow it with important characteristics - resistance to fire, odorlessness, antistatic properties. The solution has good vapor permeability, therefore it is recommended for decorating the walls of the house from the outside, erected from aerated concrete. As a disadvantage, fast setting is noted, and therefore the batch has to be worked out immediately.

The textures of plaster mixes differ in their characteristics, they are able to imitate different finishing materials and be painted with paintwork materials. The most popular are:

- fur coat, terrazzite or lamb;

- Venetian, imitating marble stone or onyx;

- bark beetle, craquelure, Marseilles wax;

- sea breeze or wet silk.

To get the desired texture, use different tools.

Advantages and disadvantages

It cannot be said unequivocally that all types of material have the same advantages or disadvantages - it all depends on the composition, purpose and properties of the plaster, but some features can be distinguished.

Benefits:

- Ecological cleanliness. Thanks to the use of natural, non-toxic ingredients.

- Fire resistance. The coating does not burn and does not contribute to the maintenance of the combustion process.

- Ease of operation. The facade of the building is easy to repair and clean.

- Frost resistance.

- Thermal insulation. Provides heat conservation in the room.

- The work can be carried out manually, as well as without the involvement of specialists.

- Aesthetic beauty.

- Modest weight. The weight of the plaster is very small, so no additional repair work or reinforcement of the foundation is required.

disadvantages

- Low mechanical strength.Low resistance to mechanical stress is possible if no reinforcing mesh was used, the facade plastering technology was not carried out. Then chips and cracks may appear on the surface of the building.

- Labor intensity of installation work. The laboriousness lies in the need for strict adherence to the recommendations for applying the mixture and professionalism. The creation of the texture takes a long period of time.

- The dependence on seasonality forces us to focus on the temperature regime not lower than +5 degrees, which limits the time and possibilities for carrying out repair work. If this requirement is not observed, the applied solution will dry for a long time and adhere poorly to the base.

- The material is expensive - the cost of decorative plaster is higher than usual.

Back to content

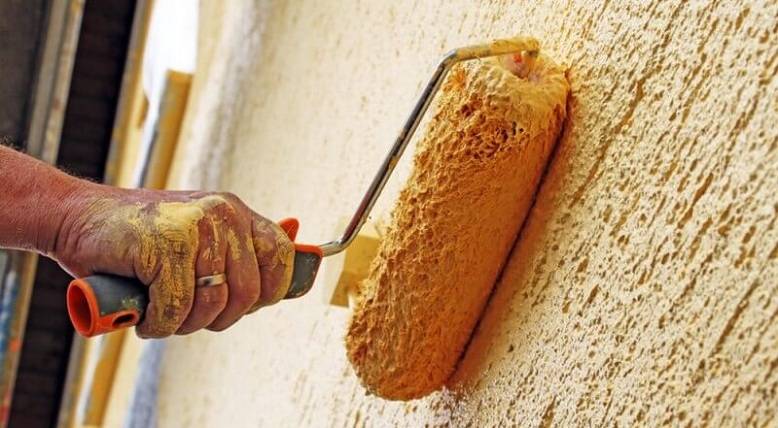

Hatch-fleece method and roller punching

This option is used quite often, it is unusual and beautiful. The work consists in the fact that the 1st layer is applied and, without waiting for it to dry, the fleece is performed with a metal brush. Within a day, the surface dries, with a sponge or spatulas, all excess plaster is carefully removed from the surface. This will make it possible to remove all the particles that do not hold well, the wall will then not crumble. When this work is done, you need to make sure that there is no dust left on the surface. The wall is painted with the paint of the selected color if the plaster mass was used without coloring.

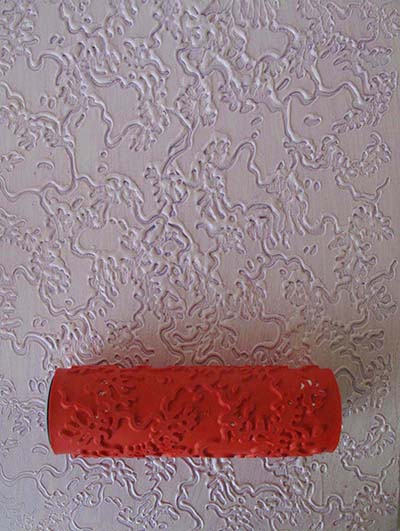

A beautiful surface is obtained by using an embossed roller. For work today, you can purchase rollers with various patterns. If there is no roller, then you can do it yourself, creating an original and unique pattern.

For example, stalks of grass can be created by winding a rope with pronounced fibers. After drying, a beautiful and graceful pattern will remain on the surface. This decoration will look especially beautiful if the surface of the wall itself is painted in a delicate green color, reminiscent of young grass in spring. This finish is great for kitchens, living rooms or hallways.

Tips for choosing a plaster

Finish type is best pick up on your own, focusing on your taste - smooth, textured. The rest of the features you can take into account when choosing a building mixture. Which is better - decide after reading the recommendations for choosing a plaster.

- For high strength a silicone solution is suitable.

- It is advisable for beginners to use ready-made mixtures.

- Interested parties save time can work with a ready-made colored solution.

- Consider what surface the material will be applied to - this is important.

- Use a reinforcing mesh for coating thickness over 50 mm.

Facade decoration with decorative plaster is of the highest quality if silicone mixtures are used. They are immediately ready for work, very plastic, easy to use and easy to paint. At the same time, costs will be minimized.

Back to content

Use of ready-made mixtures

Using textured plaster is a laborious process. You need to navigate the proportions, features of the application of the material. In order for the repair to be successful, those who do it for the first time are recommended to use not dry mixtures, but ready-made ones:

- they are easier to transport, keep well;

- the complexity of the process is reduced - no need to waste time mixing the solution... There is no need to rush to apply the pasty mass until the end of its viability;

- increased efficiency of consumption - no need to spend money on a primer, protective paint and other additional materials.

What matters is the specific gravity and efficiency of the solution in operation, so do not be alarmed that the finished mixture more expensive, and its mass is less than that of the material in dry form.

Back to content

We select plaster for different surfaces

Each surface interacts in its own way with the building materials used for cladding the outside of the building, so it is necessary to consider which mixture to apply to a particular type of substrate.

| Base material | Type of facade plaster | Features of the |

| OSB board | Acrylic | Requires good elasticity of the coating |

| Tree | Silicate | Needs several coats of priming |

| Brick | Cement, silicone | For medium fraction of filler |

| Aerated concrete | Silicate, silicone | Good adhesion required |

| Insulation | Acrylic | Using reinforcement |

| Rest | Silicate | Depends on coating thickness |

When purchasing material for facade work, consider what is written in the instructions, as well as on the packaging. Check out the technology for applying the mortar, necessary for creating the texture with tools. Select a primer composition and paints and varnishes that are similar in components to the plaster mixture in order to improve the quality of the coating and extend its service life.

After getting acquainted with the types of plaster for facade work, the pros and cons, advice on choosing, the appropriateness of the application. After all this, you can begin to perform textured work, and if you follow the application technique, you can count on a long service life of the coating and its resistance to atmospheric influences.

Methods for applying decorative plaster

The technology for applying decorative plaster can be different, it is necessary to focus on what kind of end result is needed. Today, there are many application methods, among which the following are relevant.

When applying patterns with a stencil roller, the depth of the patterns is about 0.5 cm.

The spraying method is considered the simplest, usually not even the most experienced craftsmen can cope with such work. If you know how to work with such materials, then this type of plaster can be applied by yourself. The technique is extremely simple:

- First, the base is applied, i.e. the 1st even layer, which should dry completely.

- The second layer is no longer applied with a spatula, but with other tools, up to brushes and a broom, with which the solution is literally sprayed over the surface. The technology is also called "snowball", because after drying, the wall seems to be covered with snow.

- The solution is collected in a convenient container, a brush is dipped into it. You need to take a brush in one hand, and a stick in the other. Strike the stick with a brush so that the spray scatters along the wall. The size of the flakes can be different, it all depends on what kind of result you want to get. To make the surface of the walls spectacular, you can use one color for the main 1st layer, and a completely different color for the 2nd spray.

The Italian finishing technique resembles the one already described. The stages are the same except for one. The 1st layer after application and leveling does not need to be left to dry, the 2nd layer is applied immediately, the area of which should be significant.

Until the material has time to harden, it must be smoothed over the surface.

The procedure for applying decorative plaster.

In this case, be sure to use 2 different colors for the layers. For example, the bottom layer will be lighter, and the top one will be green or light green. You can select various combinations, decorate the interior in the desired style.

The textured method is the ability to design in an antique style. Several layers of material are used, after which they are stained. The technology for applying such plaster is complex, it requires attention and skill, you can hardly cope with your own hands.

Topic number 14. "Technology of facades plastering"

Conventional plasters are made of unpainted lime, lime-gypsum, cement-lime or cement mortars. All mortars, except for lime-gypsum, are used for plastering on bricks and concrete.Only wooden surfaces are plastered with lime-gypsum.

Plastering is most often performed on lighthouses. Grouting is best done with a race; Plinths are always plastered with a 1: 3 or 1: 4 cement mortar. It is advisable to deepen the plaster into the ground 5 - 6 cm below the level of the sidewalk. After grouting, it is better to smooth it with a spatula or trowel. The upper part of the plinth is always beveled. It is customary to make trunks on the base. However, they often break off, so it is best to round or chamfer them a little. All this must be coordinated with the architectural or construction supervision.

Decorative plasters are made of colored mortars with aggregates of different sizes. Solutions are stained by adding dry paints to them. Paints must be light and alkali resistant. They should not destroy the binding agents or reduce their strength. Fillers for such solutions can be coarse sands, marble or granite chips, red brick chips.

Depending on the materials used and the processing method, facade plasters are subdivided into lime-sand, terrazitic, stone and acid-treated plasters.

The scaffold racks must be installed at a distance of at least 400 mm, and preferably 500 - 600 mm from the wall, so that the mortar can be applied behind the racks, near the racks and in places where the flooring is arranged. In this case, the bearing fingers of the scaffolds do not bring to the wall, and the gap between the posts and the wall is closed with removable boards.

Lime mortars are prepared from lime and sand. The lime dough must be aged for at least three weeks. The longer the lime paste is aged, the higher the quality of the mortar. The amount of sand introduced into the lime dough is 1-4 hours and depends on the fat content of the lime dough. The composition of the solution should be 1: 1; 1: 1.5; 1: 2; 1: 2.5, etc. In all cases, the solution should be of normal consistency, since fatty solutions crack strongly, and lean ones do not have the proper strength.

Having selected the composition of the solution, its constituent materials are measured using dispensers, loaded into mortar mixers and mixed until a homogeneous mixture is obtained.

Lime-gypsum solutions are prepared from a lime mortar with the addition of gypsum to accelerate the setting. Usually 2-3 hours of lime mortar are taken for one part of gypsum.

Cement-lime mortars consist of cement and lime mortar. The compositions of the solutions can be different: for 1 hour of cement, take from 1 to 3 hours of lime and from 6 to 15 hours of sand. The best solutions for plastering facades are 1: 1: 6 and 1: 2: 8. The composition of the solution is indicated in the project.

Cement mortars are used in different compositions: from 1 to 6 hours of sand is taken for one part of the cement. The best composition is 1: 3. This solution is not very greasy and not very skinny, it does not crack much, and it is convenient to apply.

Usually, these solutions are prepared in the form of a dry cement mixture, supplied to workplaces and water is added there as needed, since cement mortars must be used in business within an hour.

The solution is applied both manually (with a spatula, scoops and buckets), and using machines and mechanisms.

When plastering facades with any mortar, the usual technological sequence is observed.

Finishing is always done from top to bottom. In buildings with a cornice, first, soil is applied to the walls under the cornice, the rules are hung and the crowning cornice is pulled. The rules must be firmly entrenched, as the crowning cornices usually have a large overhang. The bottom rule is attached to the wall or supported by a bracket.

When hanging the rules for pulling the cornices on the facades, it is recommended to let the lower ends of the rules go around the corner of the wall for a length equal to the length of the slide. The upper ends should extend beyond the end of the rod by 80-100 mm, so that the eaves can be pulled out completely to the very end (trunnion) with a template.

There are two ways to add rules.According to the first method, the lower rule is hung in the usual way, and the upper one is attached with the help of strips to a thin log (podpotnik) or to thick boards laid in the gutter. It is forbidden to tap the slats under the gutters to fix the rules, because the slats will raise the gutter, and the hammered nails will pierce the roof.

According to the second method, the sled of the template is made with a width of 400-500 mm. The templates are moved according to the two lower rules, fixed on wooden brackets. The distance between the rules is 400-300mm, which makes the template stable. Wooden brackets are placed at a distance of 2-3 m from one another. This distance can be slightly increased if you make more durable brackets and thickened rules that do not bend when the template moves.

After pulling out the crowning cornice, they begin to plaster the walls. In the course of work, window slopes and platbands are trimmed, interfloor belts are pulled out, pilasters and other architectural details are trimmed. Especially carefully it is necessary to rub husks, trunks and chamfers. They must be strictly vertical, and the chamfers must be exactly the same in width.

The plinth is plastered after the walls are completely finished. Since the basement is subject to prolonged exposure to moisture, it is plastered with cement or mixed mortar. If a thrust must pass along the top of the base, it is pulled out after the beacons are arranged on the base, or after it has been plastered.

Types of textures

If, when finishing the facade, the goal is not only to protect the walls, but also to decorate them, you should pay attention to the various textures of the mixtures. Now the most popular are:

- Kameshkovaya

- Mosaic

- Bark beetle

In order to visually choose the most interesting option for yourself, it will be useful to view a photo of facades with plaster with a decorative structure.

Product price and reviews about it

The price of facade plaster depends on the brand name of the manufacturer, composition, decorative qualities and performance characteristics. Here are a few examples of options popular among Russians:

- facade plaster "Ceresit" costs around 800 rubles for 25 kilograms of mineral mixture, 1000-1300 rubles for the same volume of acrylic or silicone, 300 rubles for 25 kilos of cement plaster.

- facade plaster "Knauf" costs from 260 rubles for 25 kilos of cement plaster, 500-800 rubles for a similar volume of mineral mixture, about 1100 rubles for silicone and acrylic.

If consumers clearly express their preferences regarding brands of plaster, then opinions about the types of mixtures are vague. The majority writes, like Leonid, who spoke on the Stroimdom forum: - “It is difficult to answer unequivocally that it is better, since each type of plaster has its own advantages. If there was one universal, best mixture, there would not be the assortment that we see in stores. "