Selection features

The radiator brush is one of the varieties of painting tools specially designed for painting the bends of a cast-iron battery. Not every such tool can perform a similar procedure.

The radiator brush is characterized by the presence of a long handle, medium hardness of the pile and a sharp tip. Then it will be possible to cover the entire area of the battery with a layer of paint, getting to hard-to-reach places. On the advice of experienced craftsmen, it is better to use several types of such products.

Odorless radiator paints

There is a separate category of paints and varnishes - odorless dispersion acrylic paint for radiators. And although it cannot be said that she has no smell at all, however, it is not harsh and almost imperceptible. Please note that it is necessary to purchase a paint specially designed for radiators, designed for use at high temperatures - these indicators are indicated by the manufacturer on the label.

It is worth noting that odorless battery paint is quick-drying, it is applied conveniently and lays down in an even layer, does not fade or crack. You can choose from semi-gloss and glossy shades.

Before painting the surface with water-based paints, it must be primed so that rust does not seep through the pigment.

Among the well-proven types of paint, one can name Master Lux Aqua 40 from the Dulux trademark - when applying the first layer, add water to it in a ratio of 10: 1. The rest of the paint layers do not need to be thinned.

In addition, you can purchase Element paints from Eskaro, Aqua-Heizkorperlack from Dufa, as well as odorless materials Triora, Thermo, Dufa Retail and others.

Using the handbrake

This tool is characterized by a round shape. A metal rim connects the bristles to the handle. It is the length of the handle that is an important factor in the successful operation of the tool. The pile length can be more or less short. In the case of using a brush with too long bristles, a rubber wrap is practiced. This simple trick will help in reducing the area of the bristles. Then the paint will be applied more accurately, it will not smudge.

Using a handbrake is a good starting point for painting if the object has wide sections. Such a tool has a diameter of 25 - 50 mm. Experts believe that the best choice is a brush with bristles up to 38 mm in length. Then the painting will take place quickly and without splashing.

Acrylic paints

In terms of surface texture, dried acrylic enamel is similar to plastic, both in visual and tactile sensations. The advantages of acrylic paint for heating radiators are that it adheres well to the surface and is easy to clean. Some varieties of such enamel are practically odorless, since they are made on a water basis. However, the choice should be made of heat-resistant acrylic paint for batteries.

For these purposes, you can purchase paint brand VD-AK-1179. True, it requires a preliminary priming of the painted surface. This enamel dries 2 hours between layers and 24 hours completely.

Another type of acrylic enamel for heating radiators is "Thermacrill" from ALP ENAMEL. This paint has a specific odor, however, it contains anti-corrosion additives. It can withstand temperatures up to 120 ℃, is used for surfaces made of any metal, in particular, low carbon and stainless steel, titanium and aluminum alloys, protects them from oxidation. Has a wide palette of shades. Partial drying for re-painting occurs after 20-30 minutes at 20 ℃, and the paint is completely dry after 2 days.

There are a lot of options for acrylic enamels, so everyone can choose the paint to their liking.

Classic Radiator Brush

This tool communicates its purpose by the very name. The radiator brush is an excellent product for painting hard-to-reach areas of a cast-iron battery. With the help of a long handle, the device easily falls into bends and crevices. Pile quality ranges from medium to hard.

The bristles of the brush are 20-100 mm in length. Radiator brush 50 mm long is the best option for successful work.

Expert advice

In order for the staining of batteries to be of the highest quality, it is recommended to heed the recommendations offered by professional painters. The tips are pretty simple but effective:

- Painting is carried out in the warm season when the heating system is not used. On a hot surface, the paint will flow and will not stick. Using this tip will promote even paint application and a neat appearance of the painted radiator.

- When buying a brush, it is important to study which company is its manufacturer. The goods must be supplied with a quality certificate in accordance with GOST standards. This advice will allow you to avoid buying a low-quality tool, the fluff of which may remain on the painted surface. Or a low-quality tool will surprise you with the departure of the metal rim, the weak attachment of the handle. Careful attention to the choice of the tool will save you from the listed troubles.

- Despite the direct purpose of the radiator brush, which implies painting the battery, for greater efficiency it is recommended to use several types of such tools of different sizes. For hard-to-reach places, choose a curved narrow brush, and paint over the outer surface with a wider brush.

- The choice of brushes with natural bristles will allow you to get a better finish, while synthetic bristles have a longer service life. Such products are more durable.

Paint for cast iron heating radiators

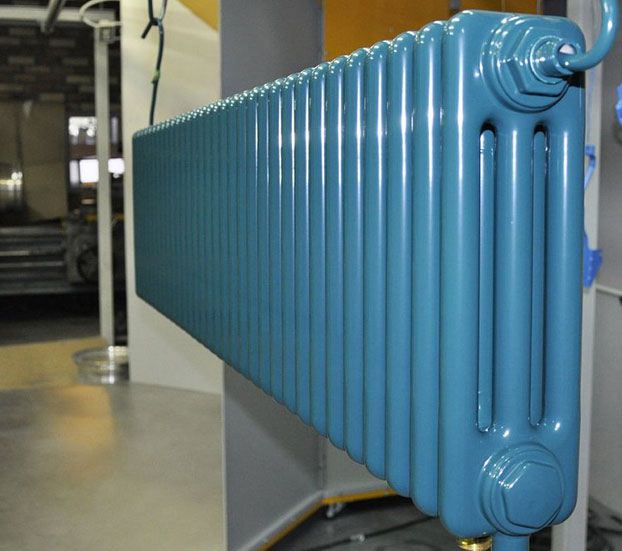

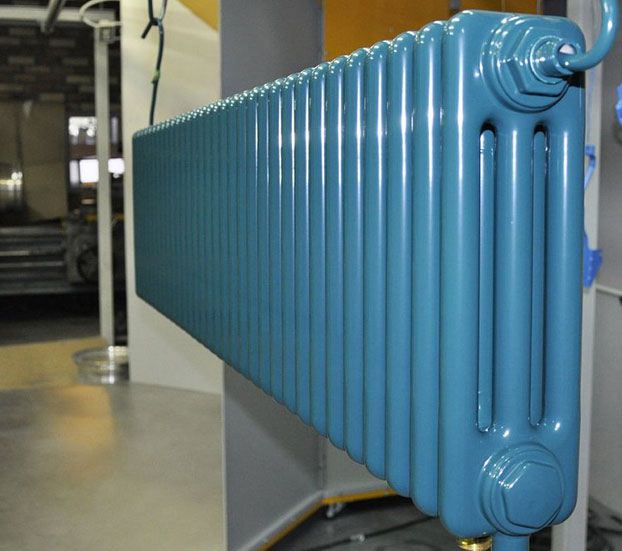

Cast iron heating radiators - heating systems veterans

You are going to make repairs at home - you have a lot of plans, projects, ideas that you so want to bring to life. Go out around the apartment, assessing the scope of work, making notes - what to repair, what to replace, what to refuse in principle. The list of jobs is growing rapidly, the list of projected financial expenses is growing even faster. And now your gaze comes across a "grandfather" of venerable age in the living room - a good old cast-iron radiator. And you wonder - leave and restore or throw away and replace with something more modern?

Don't rush to give up on these veterans of heating systems - if handled correctly, they are quite capable of serving you for a long time and faithfully... Did you know that cast iron heating radiators were invented back in 1857 by the Frenchman Franz San Galli and since then have been faithfully used to heat any type of room. There are good reasons for this, namely the following qualities:

- Excellent heat dissipation;

- High temperature inertness - that is, our batteries heat up for a long time, however, they cool down for a very long time, leaving the room warm and heated for a long time;

- Low hydraulic resistance - the coolant, circulating inside the radiators, meets almost no resistance and there is no need for forced circulation;

- Durability - just look how many years these "dinosaurs" can serve, practically without losing their qualities;

- Corrosion resistance - cast iron is slightly corrosive, which significantly affects the durability of the product.

As you can see, there are a lot of advantages and it is too early to write off old heating batteries in the trash heap. And as for the unattractive appearance - after all, the product can always be painted, this will surely solve the problem.

Preparing heating radiators for painting

So, before painting, you need to properly prepare the surface of the battery. This is necessary in order for the paint to lay down evenly, correctly, so that good adhesion to the surface is ensured, so that over time the coating does not break off and does not fall off. So, let's look at the preparation process in stages:

- First you need to thoroughly wipe the surface of the unit, completely removing dust, debris, and various kinds of pollution;

- As a rule, our "veterans" are covered with old paint multilayered and reliably to the point of fossilization - all this must be removed before painting. For this purpose, we use various types of chemical washes based on solvents and acids. We carefully read the instructions, apply the substance to the surface, wait for the time indicated in the instructions and proceed to removing the "fossils";

- Old paint softens under the influence of chemical washes and we can remove it with a spatula and special hard brushes. However, it must be remembered that removers do not work on paints released before the middle of the last century, since they were made from natural ingredients;

- So, the old coating has been removed and you can proceed to the next stage - sanding the surface with sandpaper. We agree - the work is dreary, requiring remarkable patience, but absolutely necessary if we want to paint our battery with high quality;

- And at the end, the surface should be primed with a special primer so that the paint lies well and adheres tightly.

The choice of paint for radiators

Now is the time to ask yourself a legitimate and quite pertinent question:

"How would it be better to choose what paint to paint our battery?"

There are a number of possible coating options for cast iron radiators, and which one to choose is up to you, of course.

Our coating must have the following properties:

- Heat resistance - that is, it does not collapse under the influence of temperatures up to 80 degrees Celsius;

- Environmental friendliness - the coating should not have any negative effects on the human body;

- The coating must protect the surface of the unit from corrosion;

- The ability to maintain its original color for a long time.

Consider how we can paint our battery

- Alkyd enamel is quite durable, strong, capable of maintaining the integrity of the structure for a long time. However, after application, a specific chemical smell lasts for a long time. Therefore, if you decide to paint the surface with this enamel, put on a respirator;

- Water-dispersive acrylic enamel - dries quickly, does not have a pungent odor, is durable and strong. The disadvantage is that only special heat-resistant enamels need to be chosen for painting heating radiators;

- Acrylic enamel with solvent - does not require surface priming, is well applied, dries quickly, does not have a strong chemical odor. However, there are difficulties with solvents and this paint does not lend itself to shading with the desired color.

It is possible to cover the battery with regular oil paint, but this is unlikely to make the unit more attractive - oil paint is simply not designed for such purposes. And there is an opinion that heat transfer may suffer from this.

Be sure to pay attention to an important detail - batteries must be painted cold! When painting a heated surface, the paint lays down unevenly, bubbles, wrinkles. Therefore, all work of this kind should be carried out in a non-heating season.

Conclusion

So, as you have seen, you should not rush to get rid of old cast-iron radiators. When they are in good working order, when painted correctly, they can look attractive and will provide warmth to you and your home for a long time.

Painting works

In addition to the intricacies of choosing a paint radiator brush, it is important to take into account the peculiarities of painting work.The advice of experts will also help here:

- When starting work, the tool is soaked using warm water and soap solution. This softens the pile, removes dust and dirt, and the paint becomes smoother and softer.

- The paint must be pre-prepared in the required amount, which will be sufficient for the painting work.

- If you combine several paints of different colors and production, the result can upset the painter. Then, in addition to the spoiled product, the surface will also be poorly painted.

- In order for the result to be of high quality and durable, the radiator is painted in several layers. It is recommended to start work from the top of the battery.

- To preserve the brush, it must be cleaned of paint as soon as possible. For this purpose, a special solution is used. The tool is washed with kerosene, and then the remnants of this liquid are washed off with soapy water. The dried brush must be wrapped in paper to ensure long-term storage of the tool.

Preparing to paint the heating battery

Before preparing the battery for painting, remember that preliminary cleaning is required not only for the old, but also for a new battery, where there are always some irregularities and dirty areas. The surface of the radiator must be properly cleaned and then degreased.

Not everyone can determine when painting heating batteries can begin without any preparation, and when it is simply impossible to do without all the above procedures. For this, the following three states of the heating radiator can be taken into account:

- The old paint layer does not have any cracks or chips. This means that the previous painting of heating radiators was done as correctly as possible, therefore, in this case, you can proceed directly to applying a fresh coating.

- In the event that the surface of the battery has small areas with chipped and peeling paint, this means that these areas require sanding to get a smooth surface, and only then paint.

- Provided that the old coating has come off almost completely, the heating of the radiators can be painted only under the condition of serious preparatory work, which requires the use of a brush equipped with an iron bristle, or a special washing solution with the addition of a certain amount of alkali.

It so happens that areas exposed to rust appear on the old radiator. In this case, you can use all sorts of compositions that destroy this plaque, which are always available in any hardware store.

Before painting the old battery, you need to thoroughly wash the heating device from dust that has settled on it and treat it with any liquid that can degrease the surface, for example, acetone.

Flute brush

This tool has a comfortable grip. Badger hair is used to make bristles. The radiator flange brush has a flat shape with a length of 25 - 100 mm. This tool is ideal for removing sagging from other brushes. Since experts recommend using several types of tools, this option will work well with a curved brush.

Form matters

Most people have to manage their resources sparingly with old tools. This is not the correct method. Such savings are not rational, as they take a lot of time and effort. Instead of a small brush with round bristles, it is better to use a large, flat brush that can paint a large area of the surface with a single stroke.

A small round brush is best when painting a small work surface.Such a tool is used to cover areas of special places, for example, round pipes.

Hard-to-reach places are painted with so-called corner brushes. This saves a lot of time.

Stayer

It is made of natural bristles with a light color. The dimensions of the radiator brush of this model are 50 mm. Natural wood was used for the manufacture of the handle.

Thanks to the elongated shape of the tool handle, you can paint over all areas of the battery as comfortably as possible. This brush is best used with solvent-based paints.

Thanks to the special ergonomic shape that is characteristic of the handle, the paint will not flow on the hands. It is convenient, simple and reliable to work with such a tool. This shape also guarantees a comfortable grip so that the tool does not slip out of your hands.

For the handle itself, a solid wood material is selected so that moisture is not absorbed inside. Such characteristics provide an extension of the operational period.

In the manufacture of the tool body, a high-quality metal alloy is used, which protects it from the effects of corrosion. Hair will not fall out of such a brush, as they are securely fixed.

The most comfortable use of the brush is made by the presence of a special hole on the handle. The tool can be hung for long-term storage. This product is manufactured in accordance with GOST. The Stayer Radiator Brush is a great choice for painting cast iron batteries.

Training

All pipes and radiator should be sanded with sandpaper, old paint should be removed, where it does not adhere well. After that, it will not be superfluous to wipe everything with a damp sponge and dry. All places near the radiator should be sealed with paper masking tape. It is not critical to protect the walls prepared for wallpaper - the wallpaper adheres well to the paint and, as a rule, if the wall is putty with white putty, white spots of paint will not show through even through thin wallpaper.

The ceiling, in the place where the pipe exits, should also be "bounced". Even stretch ceilings will not be damaged by masking tape if you tear it off no later than two days after gluing. If acrylic enamel is used, and there is linoleum on the floor, it is not necessary to cover it - if drops of paint get in, rinse them off immediately.

The laminate on the floor should still be covered with something; it will be difficult or impossible to wash the paint from the seams.

Let's sum up

To achieve a productive result, you must use high-quality painting tools. If the task is to paint a cast-iron battery, then even this, not the most exciting, lesson can be performed comfortably.

Experts advise choosing several types of brushes. The Angled Radiator Brush is perfect for getting into tight spots. This instrument can be made from natural or synthetic material. The former provide a more uniform paint application. The latter are more durable. The Stayer radiator brush is a rational choice of a product designed in accordance with all the requirements of GOST. It is best to use products from a trusted manufacturer.

What batteries can and should be painted

From the point of view of common sense and to ensure safety, it is imperative to paint heating devices that are prone to corrosion, that is, made of steel and cast iron. But it has long been a tradition that window slopes and window niches are painted white, radiators also prefer white. In any small store, the entire range of heating devices is painted white, and only in construction hypermarkets you can occasionally see aluminum or colored radiators.

Cast iron

When they talk about painting batteries with their own hands, first of all, cast-iron radiators come to mind - reliable, heavy, "eternal". If you have such radiators in your heating system and suit you for the safety of heating your house or apartment, then it may not be worth changing them. If you live in an apartment building, then replacing the heating system in general can lead to disagreements with the heat supply organization. In a private house, cast iron has its drawbacks, but it also makes no sense to change it for no reason. But periodic cleaning and painting with your own hands cast iron is necessary.

Aluminum and bimetallic

You can also paint aluminum heating devices and bimetallic ones on your own, but this painting is mainly performed for aesthetic reasons. Do-it-yourself aluminum painting requires special primers. In bimetal, the steel core is usually not visible, and the aluminum shell is painted.

Copper

Copper batteries oxidize, darken, and become less attractive. Therefore, copper radiators and pipes are also painted with their own hands. For copper heating systems, use a special primer for non-ferrous metals.