Condensation on the gas boiler pipe is formed due to the temperature difference between the environment and the walls of the flue duct. In winter, condensate freezes, and icicles form on the head of the chimney, and ice plugs in the chimney. Over time, the ice thaws, moisture flows down the pipe, the chimney and adjacent structures get wet and gradually collapse.

Condensation in the gas boiler pipe also leads to negative consequences. Water vapor, which is contained in the products of fuel combustion, condenses on the cold walls of the chimney. As a result, moisture is formed, which combines with the salts of the flue gases. This produces corrosive acids that destroy the chimney and other surfaces.

How to avoid negative consequences

The flue duct is designed to remove fuel combustion products from a boiler or other heating device using natural draft. This is an important link in the home gas supply system. Not only the life and health of residents depends on the correct arrangement of the chimney, but also the trouble-free operation of gas equipment. As a result, strict requirements are imposed on the chimneys of gas boilers, the observance of which guarantees the efficient and safe operation of the equipment. There are several main criteria that a smoke exhaust system must meet:

- thermal insulation;

- anti-corrosion;

- water resistance;

- tightness.

A condensate trap with a condensate drainage pipe is also required. When installing a "correct" chimney, it is prohibited to install fungi, umbrellas and other elements. In this case, there is a risk of carbon monoxide entering the dwelling.

Signs of condensation accumulation in the chimney

Is it possible to connect two stoves to one chimney

Note!

According to clause 3.70 of SNiP 2.04.05.-91 * U "Heating, ventilation and air conditioning", for each individual stove it is necessary to design a separate chimney.

The exception is two stoves located on the same floor in one apartment.

In this case, when connecting two stoves into one pipe, it is necessary to provide for a chimney cut with a thickness of 12 cm and a height of at least 1 m from the place where the stoves are connected to the chimney.

Studying the question of how to make a pipe for a stove, you should still avoid such a connection. If the second stove is connected to an existing chimney, the cross-section of which was not designed for this, there is a high probability that the chimney will not cope with the presented load.

If the stoves to be connected are located on different floors, then for each of the stoves the chimney will have a different height and, therefore, a different draft. A stronger draft of one heater will interrupt the draft of another.

Did you like the article? Subscribe to our channel Yandex.Zen

Chimney types

Modern boilers have a high efficiency and are extremely economical. As a result, the temperature of the exhaust gases is low, it is not enough to warm up the gas duct. The equipment is periodically switched off, which entails the formation of condensation in the flue gas pipe. It is important to take into account the peculiarities of the boiler operation when choosing a material for the chimney. Condensation flows down the smooth and water-resistant pipe without destroying it. If the flue duct has a porous and uneven structure, condensate is absorbed into it, which leads to destructive consequences. There are several options for chimneys.

Brick chimney collapses quickly

Classic brick

A brick flue accumulates heat and maintains traction. At the same time, it has a lot of negative properties.The complexity of construction, high cost, intense destruction due to the absorption of condensate - this is not a complete list of the disadvantages of a brick chimney. These problems can be solved by “sleeve” - mounting a stainless steel channel into the chimney.

Stainless steel

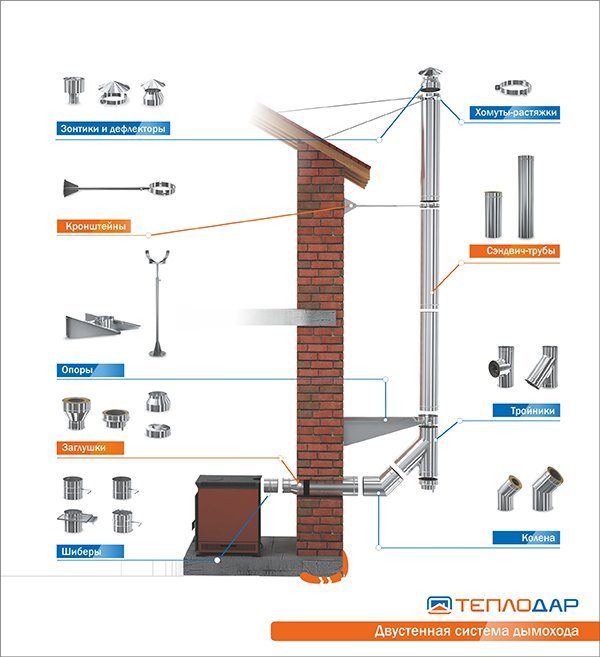

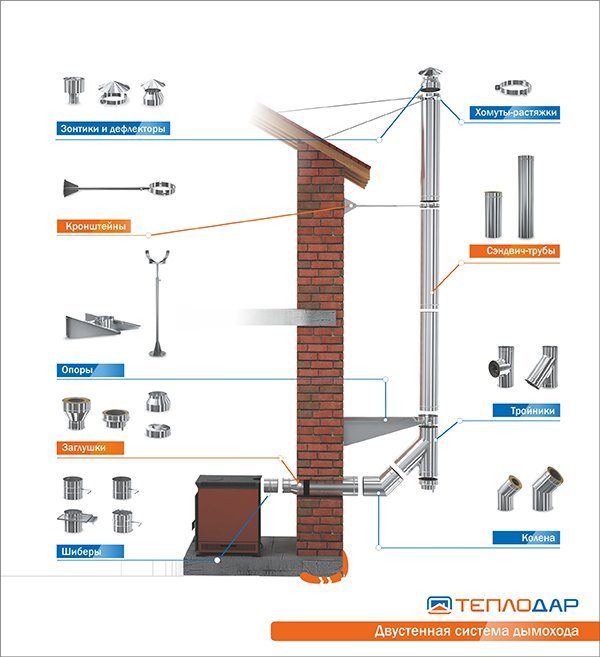

The chimney is made according to the principle of a sandwich system - in a pipe of a larger diameter there is a pipe of a smaller diameter, between them there is a mineral wool insulation. The heat-insulating layer can have different thicknesses depending on the purpose and location of the chimney.

There are a lot of adapters and fittings on sale, which allows you to assemble a chimney of any complexity. At the same time, it meets all the necessary requirements, has a perfectly smooth inner surface, and does not accumulate soot and condensation. Another undoubted advantage is its high resistance to aggressive acids.

Stainless steel system - best value for money

Coaxial chimney

The system is built according to the pipe-in-pipe principle. At the same time, they are connected with each other using jumpers and do not touch. Coaxial chimney is fundamentally different from other designs. The main difference is that it performs two functions: the removal of fuel combustion products to the outside and the intake of fresh air to maintain the combustion process in the chamber. Thus, in principle, condensation does not form on the air intake pipe of the gas boiler.

Coaxial flue gas venting has many advantages

The advantage is the small length of the structure - no more than 2 meters, as well as the fact that the installation is carried out through the wall of the room. The design helps to increase the efficiency of the entire heating system, which ensures complete combustion of the gas. At the same time, air is taken from outside the room, which makes the operation of the system comfortable and safe.

Video advice on how to improve the design:

Ceramic

Ceramic products are strong and durable. The ceramic chimney has the same qualities. It is a reliable and acid-resistant construction. Among other things, the system is easy to maintain and has fire-fighting properties. Ceramics heats up quickly and cools down for a long time. It should be noted that the system is expensive and the installation process requires the participation of specialists.

Ceramic chimney reliable and durable

General requirements for the installation of structures

First of all, to start the installation, you should draw up the correct diagram for your chimney. We advise you to contact a specialist. He will arrange a detailed plan for how to make the chimney in the bath and install the outlet through the ceiling and roof. The choice should first of all be based on the oven installed in the bath. Each unit has its own requirements and the pipe should be chosen based on these indicators.

Then it is necessary to select the material of the bend. If you plan to carry out the installation yourself, we advise you to take a closer look at the metal options.

Now let's take a look at the step-by-step instructions for installing and passing the pipe into the bath through the ceiling.

- Step 1. Insulate the passage in the ceiling for the chimney in the bath. It is important to leave a gap of ten centimeters between the bend and the surface. We recommend using glass wool for fencing.

- Step 2. Install the unloading assembly. It is this part of the chimney that takes over all the loads and dampens lateral vibrations.

- Step 3. Assemble the starter sandwich. An important point - this part must fit snugly to the main pipe, otherwise you can allow the room to smoke.

- Step 4. Place clamps or fasteners on all pipe connections. This will maintain the tightness inside the system.

- Step 5. Close the chimney passage through the ceiling in the bath.To prevent warm air from escaping, use mineral wool to block the hole.

- Step 6. Passage of the ceiling and roof for the pipe in the bath. After insulating the hole in the ceiling, drill a hole in the roof. The chimney outlet must be half a meter above the roof level.

- Step 7. How to fix the chimney pipe on the roof? Install the accessory and fix it tightly. This will be enough for the element to hold firmly.

Chimney for a bath: installation diagram

The chimney device in the bath is planned before the start of construction. In the diagram, the stove in the steam room is positioned so that the pipe leading to the roof is placed as close as possible to the ridge or to the outer wall. Channels with horizontal sections of more than 1 m do not provide good traction. Light furnaces are equipped with packed pipes, and large ones with free-standing massive root pipes.

We suggest that you familiarize yourself with: How to prepare clay for laying a stove?

The basic requirements for the size of the chimney are as follows:

- Channel diameter. They are chosen depending on the heat output of the furnace. The minimum size is 150 mm, and if the oven is brick, the flow section of the pipe must be at least the area of 1 brick (25x12 cm). The cross-sectional area of the channel for electric furnaces is from 8 cm² per 1 kW. If the duct is too large, the rising smoke will quickly cool down and cause condensation to form, and the narrow duct will not be able to generate the required draft.

- The height of the internal chimney for good draft should be at least 5 m (from the hearth of the stove to the upper edge) and be located on the roof closer to the ridge. If this distance is less than 1.5 m, the pipe should be 50 cm higher than the ridge. For flat roofs, the optimal pipe height is 1.2 m. The structure above 1.5 m must be additionally secured with braces.

- Thickness. The walls must allow the chimney to cool slowly. For an internal structure, their thickness should be at least 12 cm, and for an external one - 38-40 cm.

Channels made of ceramic or brick keep warm for a long time. Less than others, a sandwich is covered with drizzle, which is a structure of two pipes nested one into the other with thermal insulation between them. For a bath, its layer of expanded clay or basalt wool should be at least 50 mm.

It is important that the inner surface of the canal is smooth, not porous. This provides traction and prevents large amounts of soot from accumulating on the walls. Irregularities hinder the movement of smoke, so it is better if the inner part has a circular cross-section.

The regulations for gas boilers differ depending on the type of burner. Chimney systems installed on open-type boilers include the following rules and regulations:

- the pipe has no more than 3 elbows (45-90 °);

- only non-combustible material is used;

- pipes must be protected by thermal insulation;

- an opening with a damper is provided through which the chimney is cleaned;

- the height and parameters of the chimney section correspond to the requirements recommended by the boiler manufacturer;

- there is another hole in the pipe for collecting condensate;

- to protect the chimney from dirt, leaves, etc., a special umbrella is provided.

Requirements for chimneys on boilers with closed air exchange:

- the diameter of the outlet pipe is less than the diameter of the pipe itself;

- the minimum distance of the horizontal chimney from the surface of the earth is 2 m;

- the chimney pipe is located at least 2 meters from windows, doors, ventilation openings;

- the minimum vertical distance from the pipe to the window openings is 1 m;

- there should be no walls, fences or other obstacles closer than 1.5 m next to the pipe;

- when arranging the pipe, the angle of inclination of the pipe should be 6-12 ° for the natural removal of condensate.

Perhaps it will be useful for many to find out the requirements for chimneys for solid fuel boilers:

- it is allowed to use one outlet duct for two heating devices, if the distance between them is at least 750 mm;

- pipes must be completely sealed;

- the optimal type of section is round;

- perfectly smooth inner walls (finished with galvanized or stainless steel).

Now is the time to go directly to the calculations themselves.

Installation diagram of a sandwich chimney.

General rules for the operation of chimneys

When installing a chimney, it is important to ensure:

- drainage of condensate using a condensate collection tank;

- maximum tightness of the system;

- system isolation;

- good traction;

- the vertical shape of the chimney;

Important! The head of the pipe must rise above the roof surface by at least 0.5 m so that it does not fall into the zone of wind support.

Roof chimney layout

Chimney installation and maintenance is a vital process that does not tolerate negligence. From time to time, professional regular cleaning and inspection of the chimney is required. After all, a visit of a specialist will help not only solve pressing problems, but also reveal shortcomings in the future.

Often, when the furnace is fired, a black oily liquid with a characteristic unpleasant odor flows out of the pipes. This means that condensation forms in the oven. Condensation forms when water vapor settles on cold walls. Water vapor is always present in flue gases. Their source is the moisture in the wood. The damp the wood, the more steam is generated. In addition, water is formed during the combustion of hydrocarbon fuels by combining two parts of oxygen with 1 part of hydrogen. When the temperature in the chimney, chimney or bell part of the furnace drops on the walls, water vapor condenses on the walls. Condensate, mixed with combustion products, forms a black liquid, which is absorbed into the brick and after a while appears on the surface of the stove in the form of dark spots. This leads to rapid destruction of the brickwork.

Condensation also causes metal pipes to “burn out”. True, the pipes do not burn out in this case, but are destroyed due to corrosion. The fact is that there is sulfur in the fuel. When it burns, sulfurous anhydride is formed, which, mixing with water, forms sulfuric acid. In this case, the destruction of pipes occurs not in the lower, hottest part, but at the very top, where the temperature is lower. Condensation almost always forms in metal pipes. Therefore, for their manufacture, it is necessary to use special resistant steel grades. The most common steel grade used for the manufacture of stove and fireplace pipes is 304 stainless. It is heat-resistant and resistant to weak acids. However, it should not be used for boilers where coal and gas are used as fuel. In this case, 316 stainless steel is used. It is acid resistant steel. And the most resistant to both heat and corrosion is stainless steel 321.

What is the reason for the formation of condensation? Water evaporates and consequently condenses at a temperature of 100 degrees Celsius. Therefore, the temperature at the exit from the pipe must be at least 100 degrees. Better than 120. At the level of the upper gate, the temperature should not drop below 200 degrees Celsius.

To determine the temperature, a splinter is inserted into the shell of the upper gate. After 30-40 minutes, take out the torch and clean off the soot. If the color of the torch has not changed, then the temperature of the gases is less than 150 degrees Celsius. At temperatures up to 200 degrees, the torch turns yellow. If the torch is brown, then the temperature is up to 250 degrees. At a higher temperature, the torch is charred.

A decrease in the temperature of gases in chimneys occurs for the following reasons:

The presence of cracks and cracks in the masonry;

Air suction through the cleaning doors;

Too much or too little air is supplied through the blower of the furnace. With a properly adjusted air supply, the flame is straw yellow;

The length of the flue gas ducts is too long or the volume of the bell part is too high. In this case, a partial or complete alteration of the furnace is required;

In the cold season, condensation can form when the pipe passes through the unheated second floor. Or when the pipe rises very much above the roof. In this case, it is necessary to insulate the pipe by plastering it or other finishing methods. The wall thickness of the pipe passing through the room must be at least 12 cm (laying in half bricks). Pipes behind the walls of buildings are laid with a wall thickness of at least 1.5 bricks.

In order to avoid cooling the pipe wall, do not increase the pipe cross-section beyond the necessary. For ovens up to 3000kcal. h requires a pipe with an internal size of 13x13 cm (in the floor - bricks). For more powerful stoves, the chimney size is 13x27 cm (in brick).

Condensation can form when water enters the pipe. To protect against precipitation, it is necessary to protect the pipe with a cap.

In conclusion, I want to say that it is always easier to avoid such unpleasant things as the formation of condensation than to deal with it later. And for this you need to put the stove correctly. And it is better to invite an experienced craftsman for this than to do the laying of the stove on your own.

Heating in a private house is carried out using different types of stoves, each of which requires the construction of a chimney. The main problems of the flue ducts are the clogging of the pipes and the formation of condensation. If the chimney is clogged, cleaning is required, but it is more difficult to deal with the formation of condensate. Condensation in the flue pipe can lead to its premature destruction.

Modern ovens

Today stoves and fireplaces are back in fashion, being a sign of wealth and high taste of the owner of the house. Bricklaying of fireplaces and stoves is an art that few masters have mastered, which has recently become a rarity. That is why the modern market for fireplaces and stoves successfully promotes factory-made chimney systems.

Long burning tube furnaces

Models of factory long-burning furnaces

Among the latest developments in heating technology, a long-burning tube heating stove, designed for heating residential and non-residential premises with wood and heating or cooking food, has taken a strong position.

The oven with an efficiency of up to 85% is easy to install and requires a minimum of maintenance.

The oven is designed with modern capabilities in mind and has the following features:

- dynamic convection heating of air, which allows you to quickly warm up the room;

- long-term (8-10 hours) combustion mode is provided by a two-channel afterburner system;

- the firebox has a three-turn design;

- small overall dimensions;

- self-cooled or cast iron door;

- fireproof design + increased resource;

- hob;

- convenience and simplicity of operation and maintenance;

- metal pipes for the furnace are selected separately based on the parameters of the heated room and the configuration of the chimney.

Tube furnace diagram

Stoves for baths and saunas

- have a fundamentally different design. The stove is divided into two sections: one is the fuel (wood) combustion chamber. The second section contains heated stones. The heat from the flame passes through the stones and gives them heat, which heats up the steam room.

Note!

The stones are heated to record high temperatures and heat the metal tube of the furnace with their heat.

To avoid burns, the pipes for sauna stoves (their lower element) are usually protected by a fencing grate.

Wood-burning sauna heater with built-in firebox

Sauna stoves have a built-in or outside the steam room (in the dressing room) type of firebox.

The built-in firebox with a fire-resistant glass door helps to create a unique "flickering" atmosphere in the steam room, as well as to monitor the condition of the draft:

- insufficient draft leads to the flow of smoke into the steam room (red flame);

- the excess will release all the heat "into the pipe" (bright white flame);

- a golden yellow flame indicates optimal traction.

The draft is regulated by a chimney damper.

A very important element of high-quality traction for stoves is pipes: their height, cross-section, material, insulation are important.

Mobile ovens for cauldrons

- specially designed models for picnics, designed for different volumes of cauldrons - from 8 to 25 liters.

A stove with a pipe for a cauldron can be equipped with:

- Metal or inflatable wheels and folding table.

- Special heat-accumulating walls of the furnace allow economical use of firewood or coal.

- The chimney for the stove can be removable, high, samovar type. The smoke coming out of the stove at a height of about two meters does not disturb others.

- The cauldron is deeply recessed into the oven, which ensures the most uniform heating of the walls.

- The door of the firebox can be made of a blank or fire-resistant glass, which allows you to monitor the combustion of fuel.

- The amount of oxygen in the furnace is regulated by the blower.

Cauldron oven with pipe and wheels

Causes of condensation

Condensation can form in the chimney for the following reasons:

- chimney clogging. In case of insufficient draft due to clogging of the chimney, the rate of passage of the heated gas decreases, which leads to interaction with air and the formation of moisture;

- large difference between the temperature of the flue gases and the ambient temperature. In late autumn and winter, there is cold air in the chimney, which, when interacting with hot gases, precipitates as a wet sediment;

- use of wet fuel. When firing the stove, it is important to use dry wood or other fuel that has a minimum moisture content. The accumulation of moisture in the wood when exposed to high temperatures leads to the evaporation of the liquid and its settling on the chimneys;

- atmospheric precipitation falling into the chimney.

How to fix the problem

Depending on the cause of condensation, a method is selected to eliminate it, which include:

- chimney cleaning;

- chimney insulation;

- protection from precipitation.

How to clean a chimney

If condensation builds up in the chimney due to blockage, then an immediate chimney is required. To clean the chimney, you can use:

- special chemicals that, when burned, decompose soot deposits. For example, a chimney sweep log;

- mechanical cleaning method.

To manually clean the pipes you will need:

The cleaning device smoothly lowers into the smoke channel from the roof of the house.

- folk remedies that were used in villages. You can clean the smoke channel:

- ordinary salt, sprinkling it during the heating of the stove;

- potato peelings, which are also loaded into the oven during heating.

With any cleaning method, basic safety rules are required.

Insulation of chimneys

If condensation accumulates on the boiler pipe due to the use of heating equipment in the cold season, that is, the reason for the formation of moisture is the temperature difference, it is recommended to insulate the chimney.

You can use as insulation:

- mineral wool;

- any fibrous insulation;

- expanded polystyrene plates;

- plaster.

Mineral wool and fiber insulation are suitable for metal and asbestos-cement chimneys. The brick chimney is insulated by plastering the surface.

To insulate a chimney with fibrous materials or mineral wool, you need:

- cut the material into pieces required to wrap the pipe;

- attach the material with metal wire or clamps over the entire surface of the chimney;

- close the insulation with a metal box or foil.

You can watch the video about how to insulate a brick pipe with expanded polystyrene plates.

Plastering a brick chimney for the purpose of insulating it is carried out in several stages:

- a plaster mesh is attached to the chimney wall for better adhesion of materials. Fastening is required with special bolts with an enlarged head;

- the first layer of plaster mortar is applied, consisting of a mixture of cement, lime, water and fine slag. The thickness of the first layer should not exceed 4 cm;

- after a while, required to dry the solution, the remaining layers are applied, which should be from 3 to 5;

- to give the chimney an aesthetic appearance after the plaster has dried, it can be painted over.

To insulate the pipe, the total plaster layer must be at least 7 cm.

How to protect the smoke channel from precipitation

To protect the chimney from atmospheric precipitation, special ones are used, installed on the upper part of the chimney.

Some headpieces are equipped with built-in deflectors. Such devices not only protect the chimney from precipitation, but also enhance the draft in the chimney.

How to determine the combustion temperature in a wood-fired oven

The measurement of the combustion temperature of wood in the fireplace can only be performed with a pyrometer - no other measuring devices are suitable for this.

If you do not have such a device, you can visually determine the approximate indicators based on the color of the flame. For example, a low temperature flame has a dark red color. A yellow light indicates too high a temperature obtained by increasing the draft, but in this case, more heat immediately evaporates through the chimney. For a stove or fireplace, the most suitable combustion temperature will be at which the color of the flame will be yellow, as, for example, with dry birch wood.

Modern stoves and solid fuel boilers, as well as closed-type fireplaces, are equipped with an air supply control system to adjust heat transfer and combustion intensity.

Prevention of condensation

To reduce the formation of condensation in chimneys, you can:

- install a metal pipe inside the brick chimney. This technique is called gilding. An additional pipe makes it easier to clean the brick chimney, helps to insulate and seal the channel, as well as to drain condensate;

- install a condensate trap in the chimney. The device is installed at the intersection of the vertical and horizontal sections of the chimney and helps to collect moisture from the chimney. The maintenance of the condensate collector consists in the timely removal of water.

Chimney prevention also includes:

- in the use of fuel of proper quality;

- in the timely cleaning of the chimney;

- in conducting the chimney as required.

It is impossible to completely get rid of the condensate accumulating on the chimney, but the set of measures presented in the article will help to significantly reduce the formation of excess moisture and extend the service life of the chimney.

Condensation in the chimney is formed when water vapor passes through a cold chimney. There are 2 options to consider.

Option 1.

When the heating unit is not working. Warm air from the room enters through leaks in the valve, brickwork or gaps with improper installation of pipes. I already described this option in the article Here are some more recent photos

I often drive past this house and noticed the chimneys. Judging by the cross-section, these are chimney flues. On the right chimney, frost is visible on the cap, which is not on the left. I have never seen how the left fireplace is being stoked this winter, but the right one is heated about once a week. When it is heated, the hood heats up, and the condensate flows from the hood onto the otter, on which the icicles growing up are visible. Condensation, which is absorbed into the brick, will destroy it when frozen. I saw one such pipe that fell and broke through the slate. It was in a house with centralized heating.The stove was fired only in the off-season, when it was already cool in the house, and the heating was not yet connected.

Option 2

... Condensation forms during heating. Water vapor in the flue gases also accumulates on the cold walls of the chimney. Where does the water vapor in the flue gases come from?

1. From damp, poorly dried firewood

2. Combustion is an oxidation reaction and the hydrogen in the wood is oxidized to water.

What can you do to reduce condensation?

1. Heat the stove with well-dried wood

... To do this, they need to be split and kept under a canopy for 1.5-2 years.

2. Eliminate air leaks

through the valve and other leaks.

At my oven, I sealed the gap between the frame and the valve with a sealant on the advice of Alexander Kutuzov.

If the suction goes through the leaks of the brickwork, then you need to cover the seams with a solution or plaster

3. Insulate the chimney.

Water will not condense on a warm chimney. I observed this at two neighbors living across the street from each other. They have similar fireplaces and the height of the chimneys is about the same. One of them has a chimney passing through a warm residential attic, and he has no problems with condensation.

4. Ensure that the temperature of the flue gases in the chimney is at least 100 degrees.

Cold smoke comes out of the chimney when a small amount of wood is burned in the massive stove. Brick takes a lot of heat from the flue gases, and they come out cold into the chimney. For example in 5 or 7 channel ovens. To increase the temperature of the flue gases, a straight channel of small section is made from the furnace to the last channel. Such a channel is called burnout, bypass or "ram".

A lot of heat can be taken from the flue gases and the boiler built into the stove. I have seen such a boiler built into a 5-channel oven. The water in the heating system was heated very well, and the furnace mass hardly heated up.

The temperature of the gases leaving the pipe is also low in furnaces operating in a smoldering mode. This happens when the blower door is tightly closed. There is not enough oxygen for normal combustion and the temperature in the furnace is low. In addition to condensate, a lot of soot is formed in the chimneys of furnaces with this operating mode. I will talk about soot in another article.

Well, now a question from a regular reader of my blog Anatoly:

Hello, Alexander!

I propose to discuss this topic in your blog, maybe someone will report fresh solutions. The question is how to assemble a chimney sandwich? It seems to be correct for the condensate so that the condensate does not flow into the gap between the inner and outer pipes. That's exactly what I did. The umbrella is also made for rain - the inner pipe is inserted into the pipe below, the outer part is put on the outer shell of the sandwich located below. On the one hand, this is correct. Rain will not flow between the sandwich pipes and condensation, and rain that has flown into the pipe will drain onto the valve. But! Condensation began to flow out from under the outer shell of the umbrella. When moving in the chimney, smoke enters under the section of the pipe located above, rises upward and, reaching the top, forms condensate, which flows out from under the outer shell of the umbrella. This is bad. How to fix? In the photo, the arrows show the places where the condensate came out, the photo was taken immediately after installation, so the place where the condensate appeared was not visible and had to be marked with arrows.

This phenomenon is observed quite often, even if everything seems to be designed and installed correctly. A feature of the appearance of condensate in the chimney is that it does not consist of only the usual water droplets. The resulting liquid contains many impurities, including resins.

Gradually, they enter into various reactions, as a result of which completely new chemical / compounds are obtained, adhering to the internal cavities of the pipes. Many of the substances (eg acids) are harmful to the chimney.

Pipes for the removal of combustion products are different both in size, configuration, and in the material of manufacture - "galvanized", furanflex (plastic version), brick, asbestos cement. Therefore, it is advisable to consider the most important points regarding all chimneys. The reader himself will understand that from the information provided it will be useful to eliminate problems with condensate in the chimney in relation to the gas exhaust system installed in his house.

Consequences of condensation in pipes

- Destruction of the channel material. This is mainly typical for pipes, the internal cavity of which is characterized by roughness (brick, asbestos-cement).

- Gradual reduction in thrust. This is quite natural, since due to the formation of "build-up" on the inner side of the pipes, their nominal diameter decreases over time.

Reasons for the appearance of condensation in the chimney pipe

Without knowing this, it is impossible to correctly determine the most effective way to combat this phenomenon.

- Wrong choice of chimney scheme. This often happens when the design is carried out independently, only on the recommendations of "knowledgeable" people.

- Reduced temperature of combustion products (less than +100 ºС).

- Insufficient chimney draft.

- Significant temperature difference (indoor and outdoor).

- The ingress of precipitation into the channel (for example, in the absence of a cap, deflector or other protective, auxiliary devices).

- The use of fuels with a high moisture content, its incomplete combustion.

- Irregular chimney cleaning. As a result - excessive clogging of the channel.

- Mechanical damage to the chimney.

- Design and installation errors.

- Systematic operation of the boiler in a gentle mode (when the temperature at its outlet is low).

Humidity and combustion intensity

If the wood was recently felled, then it contains from 45 to 65% moisture, depending on the season and species. With such raw firewood, the combustion temperature in the fireplace will be low, since a large amount of energy will be spent on the evaporation of water. Consequently, the heat transfer from raw firewood will be quite low.

There are several ways to achieve the optimal temperature in the fireplace and release a sufficient amount of heat energy to warm up:

- Burn twice as much fuel at a time to heat the house or cook food. This approach is fraught with significant material costs and increased accumulation of soot and condensate on the walls of the chimney and in the passages.

- Raw logs are sawn, chopped into small logs and placed under a canopy to dry. As a rule, firewood loses up to 20% moisture in 1-1.5 years.

- Firewood can be purchased already well dried. Although they are somewhat more expensive, the heat transfer from them is much greater.

It should be noted that the wood of raw felled poplar and some other species is completely unsuitable for use as fuel. It is loose, contains a lot of water, therefore, when it burns, it gives very little heat.

At the same time, raw birch firewood has a fairly high calorific value. In addition, raw logs from hornbeam, ash and other types of wood with dense wood are suitable for use.

Ways to get rid of condensate in the chimney

Using a steam trap

This device quite effectively solves the problem. In its case (or separately) there is a special compartment for collecting condensate. The installation of a condensate drain greatly simplifies the maintenance of the chimney, which practically comes down to just timely cleaning of the storage tank.

The price of the device is from 786 rubles.

Insulation of the chimney channel (especially in the upper part)

In this case, the influence of temperature changes will be minimized, since the dew point will shift.

Preliminary drying of "fuel"

This applies to solid fuel boilers operating on wood, briquettes, coal, and so on. First of all, it is necessary to pay attention to the order of their storage and storage conditions.

Choosing the right fuel

Maintaining the installation scheme

The chimney should mainly consist of vertically oriented segments. Any slopes on the track, ledges and so on - the cause of the formation of deposits as a result of condensation. The same applies to the invariability of the pipe cross-section along the entire length of the chimney.

Complete sealing of the channel, elimination of the slightest "leaks". Meeting this requirement increases traction and minimizes condensation.

Combustion temperature

Artificial increase in the temperature of combustion products at the outlet of the chimney. This technique is not used so often, but it gives a certain result. One of the options is to install a special / channel (for example, a stainless steel insert) or replace it with.

findings

Thus, birch firewood can be considered the best option in terms of cost savings, as well as combustion efficiency and heat transfer. Since hardwoods with a high heat output are significantly more expensive, they are used as firewood much less often.

Source: www.odrova.ru

Chimney smoke temperature?

The maximum temperature of flue gases in the chimney is regulated, first of all, by the fire safety requirements reflected in SP 7.13130.2013 and, secondly, by the characteristics and properties of the material from which the chimney is made.

- Firstly, the maximum allowable temperature of combustion gases in a metal thin-walled chimney made of heat-resistant steel is allowed no more than 400 ° C.

The temperature is not difficult to determine by the color of the "glow" of the metal when the first segment of the chimney on the stove is heated. The color of the "glow" can be brown (530-560 ° C). Basically, this is the color that we can see first at the moment the metal starts to "glow". Lighter - crimson and red shades of the "glow" of the chimney will indicate its overheating and the danger of a fire in the area of overlapping the ceiling, roof of the building, etc. It should be noted that asbestos-cement pipes, which we categorically do not recommend to use, are not uncommon, especially for furnaces of active flame combustion! In such chimneys, the maximum temperature of flue gases is not more than 300 ° C, and it is practically impossible to control it!

- Secondly, heat-resistant thin-walled steel (0.5-1.0 mm), used in "TMP" for the manufacture of modular chimneys and accessories for them (MD), has a temperature of the beginning of scale formation ("burnout") about 750 ° C. At observance of fire safety restrictions, the chimney will properly serve for a long time. The characteristic properties of thin-walled heat-resistant steel, which are noticeable during the operation of the MD, include the change in color and geometric dimensions of the chimney (especially in the longitudinal ratio) when it is heated. The temperature at which these "characteristic" properties of the metal begin to appear is from 200 ° C and above. We hope that this information will help you to make the chimneys serve you for a long time and safely!

Source: t-m-f.ru