Features and design of the chimney

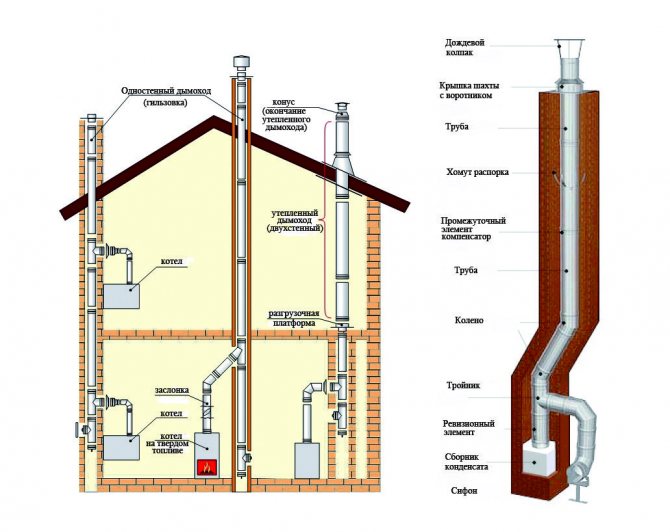

The design of a brick chimney coming from a fireplace, stove, solid fuel and gas boiler is a shaft that forms a straight channel or with turns. The upper part of the structure is displayed above the roof, and a protective cap is put on from above.

Principle of operation

When the boiler is on, the temperature at the bottom of the duct is higher than at the outlet. Due to the differential, a pressure difference is formed. The higher the number, the better the traction. The combustion products are freely discharged to the street, and oxygen enters the furnace to support combustion.

Dymovoy

In the case when the chimney structure does not meet the fire safety requirements (the chimney needs to be repaired or when building a new house the chimney is built with deviations from building codes), sometimes it is possible to reconstruct the “old” chimney - this is the insertion of a new chimney into the chimney channel (chimney sleeve) ... The chimney sleeve is used when restoring the chimney operability, when it is not possible to rebuild the entire chimney channel.

When casing the chimney, an insert is installed in the old brick flue duct - a new sealed stainless steel pipe (sleeve) or a flexible synthetic pipe. The optimal diameter and shape of the new pipe is selected taking into account the features of the chimney and the characteristics of the heating device.

The flue gas duct sleeve (sleeve, sleeve, insert, liner), in most cases, is carried out in a straight vertical brick chimney. When the chimney channel has bends and fractures, then the chimney liner with steel pipes can be carried out only with partial destruction of the partitions and the old chimney.

The need for a chimney sleeve

A modern chimney is an engineering and technical structure, where the fire safety of the house depends on the quality of the pipe material and on the tightness of the channel. Unskilled builders, with the negligence of foremen, use hollow or silicate bricks on cement mortar for laying the chimney, dressing with cracks, a frozen solution hangs on the inner walls, reinforcement and protruding floor slabs in the channel, a narrowed section, for some reason on top of the head some kind of "houses »With tiles.

The careless attitude of the builders to the "new" chimney or the operation of the "old" chimney without preventive maintenance leads to the need to sleeve the chimney.

Casing the flue duct with a modular steel chimney system

The flue duct is plugged by installing a rigid structure of modular pipes into the existing straight chimney. Stainless steel allows you to make an insert of a certain shape (rectangle, oval) or choose a chimney from ready-made modular elements, choosing a sleeve of the optimal diameter and thickness (0.8 and 1 mm).

When the flue gas duct is wrapped with steel pipes, it is possible to provide in the design all the necessary chimney units (revisions and cleaning, condensate trap, gate) in accordance with building codes and fire safety rules. The modular design will create tightness, the circular cross-section of the channel will improve traction, the smooth surface will reduce the formation of soot, and acid-resistant stainless steel (namely steel, not galvanized) will withstand the aggressive effects of condensation.

Chimney sleeve with FuranFlex system

FuranFlex polymer insert is used for liner of chimneys of gas and liquid fuel boilers with flue gas temperature less than 250 ° C.A flexible pipe made of synthetic resin reinforced with fiberglass is inserted into the smoke channel (not only straight).

Under the influence of high temperature, the elastic FuranFlex pipe takes the shape of the chimney channel, and after hardening, the polymer composition creates a rigid sealed channel up to 2 mm thick without joints. The system is designed more to combat condensation than thermal expansion, which is why FuranFlex is not suitable for chimney flues.

Chimney sleeve with flexible stainless pipe

Casing the flue duct with a flexible stainless pipe is not the best solution. The flexible pipe has some disadvantages: the corrugated structure promotes the accumulation of soot and condensation, has a smaller wall thickness and a short service life.

Lining the inner surface of the channel

Lining (plastering) the inner surface of the smoke channel with a fire-resistant mixture allows filling all the cracks with a heat-resistant mass and leveling the surface of the brick chimney from the inside, practically without reducing the channel cross-section. When the lining of the inner surface of the pipe is carried out in high vertical chimneys, a technological hole is created in the lower part of the smoke channel, which is sealed at the end of the lining work. The cost of lining is lower than the cost of chimney liner, but does not guarantee the tightness of the flue duct.

Preparatory work before casing

Before casing the flue duct, it is necessary to perform the following operations: inspection of the chimney, checking the section, determining the degree of contamination and cleaning, checking the operability and tightness. The cross-section of a brick smoke channel, in most cases, is a rectangle of 140x270 mm, therefore, before installation work, it is necessary to determine the design of the plug, the required size and shape of the liner.

It is necessary to carefully calculate the correspondence of the diameter of the outlet of the furnace to the cross-sectional area of the sleeve, since the insert narrows the chimney channel. It is better to install a liner in a brick chimney at the stage of building a house: install each modular element of the liner and gradually brick it up or leave a niche for a future steel insert.

Gilding - modernization of a brick chimney

Casing (plugging) the smoke channel is an alternative option for the reconstruction of a brick chimney. Each option for modernizing the chimney should be approached individually and find the best option for casing the chimney to restore the efficient and safe operation of the stove or fireplace.

Exhaust duct requirements

Good traction is maintained by the tightness of the structure, as well as by the condition of low accumulation of soot and the formation of condensation. These parameters are the basic requirement for all chimneys. It is important to correctly calculate the cross-section so that there is no smoke inside the room.

The essence of the sleeve and its advantages

Before you rush to reconstruct a chimney, you need to understand what a sleeve is, and also find out the advantages of the process.

Most chimneys have a rectangular duct section. For masonry, ordinary red or decorative bricks are used. Over time, large build-ups of soot appear inside the channels, efficiency decreases, and traction completely disappears. The problem lies precisely in the shape of the section, as well as the rough surface of the brick.

Round and oval canals have smooth inner walls. Soot does not cling to the walls.

In order not to build a new chimney, they came up with a sleeve. The procedure involves inserting the pipe inside the channel without destroying the brickwork. A stainless steel sleeve is considered the best option, but ceramics, asbestos or polymer can be used.

Benefits of the chimney duct sleeve:

- traction is enhanced due to the smooth surface of the liner;

- heat loss decreases, efficiency increases;

- no turbulence occurs inside the circular channel;

- the durability of the channels increases due to the resistance of the liner to condensation;

- the tightness of the chimney is improved.

The insert from the sleeve forms a new channel for the removal of combustion products, and the brickwork acts as a casing.

What is chimney sleeve?

The accumulation of soot on the walls of the flue duct and the formation of condensation are the main reasons for the decrease in draft in the chimney. To improve the operation of the heating equipment, you can shift a new shaft or restore functionality using a sleeve. The construction of a new brick chimney requires significant finances and time, therefore, most often the old chimney is reconstructed using the liner method.

Chimney sleeve is the installation of a new line inside the channel without destroying the brickwork. The formation of the insert for the removal of combustion products provides a lot of positive points:

- the smooth inner surface of the liner provides increased traction, the risk of soot clogging is reduced to a minimum,

- the degree of tightness of the line increases,

- the functional characteristics of the chimney system are improved due to the resistance of the liner to condensation.

The sleeve has a positive effect on the efficiency of the heat generator and the terms of the high-quality service of the chimney.

Is there a need for a sleeve?

It is better to install the sleeve during the construction phase of the building. The insert is bricked up as the mine is laid out of bricks. If you did not initially do this, over time you will have to return to the process. The shelling of a completed house is more difficult. We will have to partially destroy the masonry, break the decorative cladding and restore everything again.

The urgent need to sleeve brick chimneys is caused by the following reasons:

- initially, the combustion products removal system was designed and built with errors;

- constant use of a fireplace or stove connected to a brick chimney is assumed;

- long canal length;

- if, according to the project, the mine needs to be sealed, but this was not done;

- the mine passes through a cold attic room and condensation forms due to the temperature difference;

- the chimney is lined with bricks inside the outer wall of the building;

- condensate streaks appear from the seams of the mine's brickwork;

- depressurization of the smoke channel;

- the mine is quickly clogged with soot and requires frequent cleaning;

- smoke evacuation passages were laid not by professional stove-makers, but by inexperienced bricklayers.

In all other cases, the owner performs the sleeve as he wishes.

Benefits of sleeve

As a result of the work on plugging the smoke channel:

- dramatically improved traction due to smoother shiny walls compared to brick or asbestos pipes... It is known that the mirror surface provides the smallest coefficient of friction of the smoke against the pipe walls;

- less heat loss due to the formation of an air gap between the walls of the stainless pipe and the brick channel;

- the formation of unnecessary air turbulence is eliminated due to the use of round pipes with smooth walls;

- increases the resistance of the flue gas duct to the formation of condensate and aggressive acid substancesthat are part of the smoke. Condensation, turning into ice, significantly reduces traction.

Three common sleeve methods and materials used

The main essence of the liner is the insertion of the liner into the brick shaft. The liners differ in the material of manufacture, size, shape. The basic principle of installation is the same, but there are nuances.

Stainless steel

The liners are characterized by a long service life, resistance to high temperatures and condensation. Stainless pipes are suitable for shafts of any length and shape.

Stainless steel inserts differ in execution:

- Round pipes are produced with a cross section from 6 to 100 cm. The wall thickness depends on the metal used and is 0.5–1.5 mm.

- Rectangular pipes are used less often. When requested, inserts with a wall size of 14 × 27 cm are used.

- Oval pipes are made of stainless steel with a thickness of 0.5-0.6 mm. The running dimensions are 20 × 10 and 24 × 12 cm.The section corresponds approximately to a round pipe with a diameter of 15 and 20 cm.

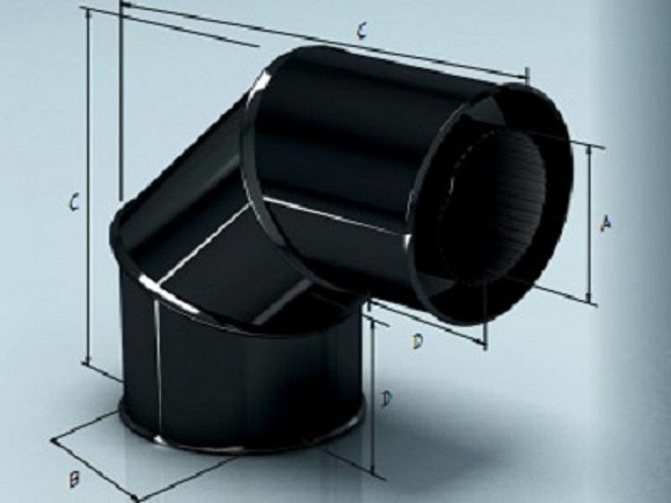

- Corrugated sleeves are made of two layers of different grades of stainless steel. The cross-section varies from 8 to 35 cm. During the installation of a flexible stainless steel chimney, the corrugation must not be bent with a radius of less than two pipe diameters.

Of all the options, a corrugated sleeve is considered the most unreliable. Two-layer stainless steel burns out in four years from exposure to high temperatures, and soot lingers on the ribbed walls.

Polymer sleeve

The sleeve is made of fiberglass mesh impregnated with polymer resin. The one-piece hose is inserted into the shaft without the use of connecting segments. If necessary, use fittings. Maximum sleeve length - 60 m. Thickness - from 8 to 50 cm. Service life - up to 30 years. For high-temperature and low-temperature boilers, sleeves of different composition are used.

FuranFlex polymer systems for gas boilers, fireplaces and stoves are popular in Russia.

FiTFiRE liners are used for low temperature boilers. FiTFiRE HT 1000 is suitable for fireplaces and stoves.

Sleeve sleeve allows you to get a one-piece channel without disassembling the brickwork of the mine. The liner is resistant to condensation and is capable of bending at an angle of 300. Among the disadvantages are the high cost, as well as the impossibility of self-assembly of the flue gas duct without skills and the presence of special equipment.

Ceramics

Ceramic liners are considered reliable and durable. For casing they are more often used in the restoration of destroyed mines. Elements are available in round and rectangular shapes. The connection takes place in a socket or a thorn-groove lock. The diameter of the sleeves is from 12 to 45 cm. Straight pieces of pipe are produced in lengths of 33, 66 and 133 cm. The wall thickness varies from 4 to 20 mm.

Ceramics are not afraid of soot ignition. The downside is the high cost and weight. Installation is not complete without dismantling the chimney shaft.

Key casing errors

The main mistakes are:

- Partial sleeve casing (not along the full length of the shaft).

- Using a knee instead of a special support.

- Crumpled pipe edges (if we are talking about stainless steel) during transportation, connection (segments with each other) or lowering into the mine.

- Jerks of the cable when lowering the sleeve.

- Narrowing of the diameter.

- Too sharp turns (if we are talking about a polymer liner).

- The use of bulk thermal insulation (between the sleeve and the brick shaft).

- Absence of a U-shaped water seal - if the condensate is discharged directly through a hose to the sewer.

Please note: every mistake is serious enough. If they are allowed, then you can complicate your task in the future (if you need to replace the liner), or worsen the operation of the boiler.

We rationalize heating: how to use a heat exchanger on a chimney, and how is it useful?

How to clean the chimney from soot with potato peelings?

Similar posts

Features of mounting liners made of different materials

In modern construction, stainless steel, ceramics or a polymer sleeve are used for the reconstruction of a chimney. Ceramic liner and polymer are difficult to mount. Most often, when casing chimneys with their own hands, they use stainless steel.

Preparatory work

Regardless of the type of liner chosen, a number of preparatory measures are performed before starting the liner:

- Using a powerful flashlight, they inspect the smoke shaft from the inside. Determine the degree of destruction, contamination with soot, the presence of fallen off pieces of mortar, bricks, bird nests.

- They clean the chimney with metal scrapers, brushes and other devices. Bricks protruding from the masonry will prevent the insert from being inserted. They try to knock down all the protrusions with a hammer or a pry bar.

- Measure the length as well as the diameter of the chimney. The dimensions are transferred to the diagram, indicating all the rotations and degrees of the angles.

- The part of the chimney adjacent to the boiler or stove is disassembled. From this point, the installation of the shaped element will begin.

- The bottom of the smoke shaft is cleaned of debris and, if necessary, leveled.

After the preparatory measures have been taken, the liners necessary for the liner are bought.

Installation of a stainless steel insert of a round, rectangular or oval section

The casing of a small shaft with a stainless steel without turns is performed according to the following principle:

- All elements of the sleeve are assembled into one structure. The joints are treated with a heat-resistant sealant, and from above they are wrapped with adhesive tape on an aluminum base.

- Two belts, cables or strong rope are fixed to the bottom of the pipe with a clamp.

- The sleeve is carefully lowered along the shaft until it stops at the bottom. If the length of the chimney is small, a light stainless steel pipe is immersed by hand without using cables.

- The insert from below is connected to the inlet of the boiler or furnace and a condensate collector is installed. From the street, the sleeve is taken out above the brickwork of the chimney, and a protective cap is put on from above.

The stainless steel sleeve of a long chimney with turns is carried out differently:

- The flue duct is disassembled at the entrance to the boiler, as well as all areas where shaped connectors will be installed.

- First, the lower part of the sleeve is assembled from the flat sections of the pipe to the first shaped connector. The liner is lowered to the bottom of the shaft, connected to the inlet of the boiler or furnace, and a condensate collector is installed from below.

- A shaped connector is installed on the second free end of the steel sleeve. A flat section of stainless steel is connected to it until the next turn of the mine. The procedure is repeated until the sleeve is removed from the shaft.

The pipe joining section is similarly reinforced with a heat-resistant sealant and wrapped with aluminum tape. A head is installed on top.

Installation of stainless steel corrugated hoses

Casing with corrugated stainless steel smooth and with turns of the chimney is carried out in a similar way. The difference is the arrangement of the lower and upper exit from the mine. After installing the flexible hose inside the smoke channel, a rigid transition from a stainless pipe is attached from below. This section connects the sleeve to the inlet of the boiler or furnace. A condensate collector is installed below.

At the upper outlet from the smoke channel, the corrugation is brought out above the masonry about 30 cm. For the reliability of the head's attachment, the exit can be made by building up a rigid section of a stainless pipe. At the end of the sleeve, the brickwork of the chimney is restored.

Installation of the ceramic insert

Casing with ceramic liners is more difficult. The process consists of the following steps:

- The roller mechanism is fixed to the holes of the condensate collector. The element in the sleeve is a supporting structure, and the first one descends into the chimney to a depth of 30 cm. Ceramics are heavy. For a safe descent, it is optimal to use a winch.

- The upper end of the condensate collector is treated with a sealant. With the help of a socket or a thorn-groove lock, a flat section of the pipe is fixed.

- To connect the boiler using a universal fitting, a hole is cut out on a flat ceramic sleeve. A part of the liner is lowered into the shaft with a winch. The next element is fixed to the end of the first pipe in a similar way.During the descent, make sure that the sleeve does not turn in the other direction with respect to the boiler inlet with the hole for the fitting.

When the condensate collector reaches the bottom of the shaft, docking with the boiler inlet is carried out. From above, the ceramic pipe is brought out above the brickwork. The protrusion is made equal to the height of the cover plate.

Installation of a polymer sleeve

For casing the chimneys with a polymer sleeve, special equipment is required. Initially, the liner resembles a coiled hose. The sleeve is raised to the roof of the building, introduced through the channel to the bottom of the mine, connected to a compressor and air is supplied. Under pressure, the soft walls of the stocking will expand.

When the sleeve acquires the inner shape of the channel, steam is supplied instead of compressed air. The polymer first softens and then hardens. The condensate collector is being installed below. At the exit from the mine, an extra piece of the sleeve is cut off, and a head is installed on top.

Head device

To install the head, a rigid sleeve is built up on the surface of the chimney, and a cover plate is mounted around it. A collar is attached near the pipe to prevent condensate from entering the brick shaft. The part of the sleeve protruding above the roof of the house is insulated with insulation. In height, the pipe should go beyond the level of the ridge.

Frequent mistakes

When casing any type of liner, it is impossible to allow narrowing of the sections, use a shaped turn for the stop, and also pour loose insulation into the gaps between the liner and the walls of the shaft.

It is not allowed to drain condensate into the sewer through a hose without the arrangement of a U-shaped water seal.

It will be useless to work with a partial sleeve of the mine, as well as the presence of steep corners.

Benefits of refurbishment

The chimney remediation process has undeniable advantages:

- the smooth inner surface of the chimney weakly retains soot;

- the thermal conductivity of the mine decreases, due to which the pressure difference is maintained;

- liner walls made of any material do not absorb condensation;

- a compensator is added for assembling and draining condensate from the channel.

A failed liner is always easier to replace than to re-lay a brick shaft.

Main advantages

Plugging a brick chimney will provide:

- Reducing the release of condensate and draining it into a special container or sewer system.

- Optimum traction level, smoke protection of the room.

- Free access for cleaning from residues of combustion products.

- Tightness of the exhaust duct.

- Protection against heat loss.

- Long service life, since it protects the inner surface from moisture, accumulation of soot, soot, corroding brick.

Sleeve methods: the pros and cons of each

Brick chimney liner is possible in one of the following ways:

For such work, you can use a stainless steel pipe.

Often, work is done with Furan Flex polymer products.

- Installation of stainless steel sleeves inside the chimney. This method can be called universal, suitable for any heating system. The downside is that a stainless steel pipe has thin walls, which quickly burn out under the influence of high temperatures.

- FuranFlex is a system made of polymeric materials. This method is recommended when using gas heating boilers, characterized by a low temperature at the outlet of combustion products. Polymers are designed for temperatures no higher than 250 °. Disadvantages of the method: the impossibility of doing the installation with your own hands, this requires certain knowledge and skills, the cost of building materials is high.

Estimated cost of work

The cost of refurbishment depends on the materials and design of the future chimney plug. For the installation of an insert with a length of 1 m, you will have to pay about 2.5 thousand rubles. After measuring the length of the shaft and multiplying the results by the cost of the selected liner, you can roughly calculate the cost of refurbishment.

We hope that the information provided will help you choose the appropriate sleeve method and do all the work yourself. We suggest subscribing to other useful articles. Share information on social networks. Maybe a person is similarly looking for ways to solve a similar problem.

(

1 estimates, average: 5,00 out of 5)