A high-quality floor screed is needed for a good renovation. If the floor is uneven, low strength, or sagging, there will be problems with finishing coatings. Therefore, you must immediately choose which floor screed is better.

The customer needs to think over all the stages of its installation in advance, otherwise there will be a need for additional costs in the process. The latter depend on the thickness of the layer, the area of the premises and the option of the floor arrangement.

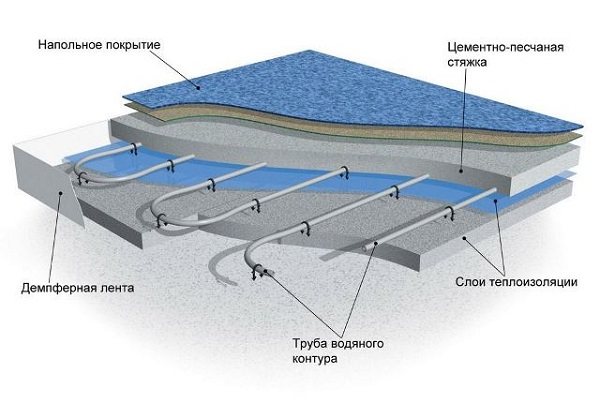

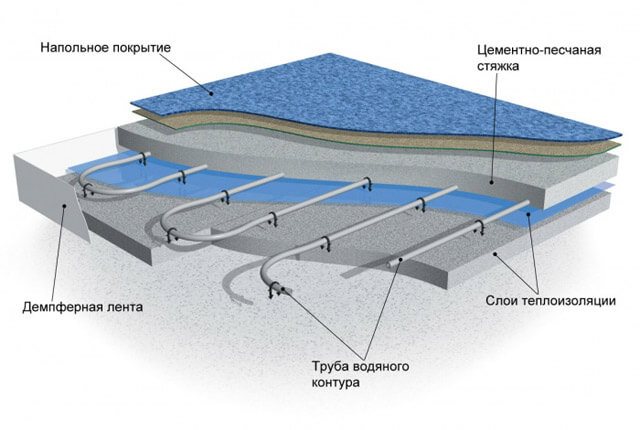

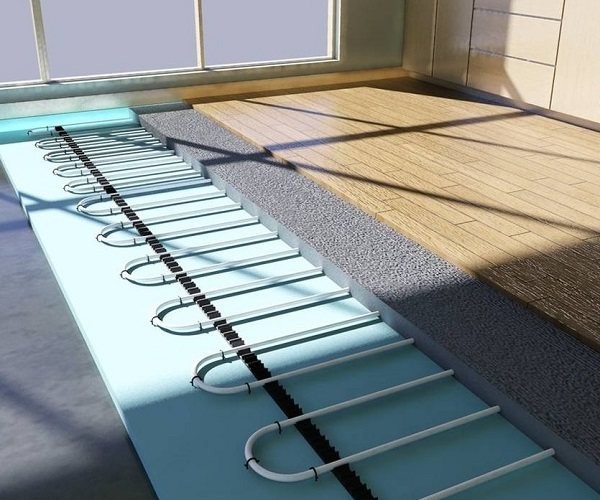

Warm water floor device

The "warm floor" system assumes the presence of several layers, laid in a certain sequence. If we look at the pie of the system from the bottom up, we can see the following order:

- First, the rough base is equipped.

- This is followed by a waterproofing layer.

- Then a layer of thermal insulation is laid.

- Heating elements.

- Concrete screed.

- Finishing floor covering.

When determining the minimum thickness of the screed over the underfloor heating pipe, it is best to take the Sanitary Standards and Rules as a basis. It is in this document that it is indicated that when using a metal-cement composition, the thickness of the screed over the heating pipes should not exceed 2 centimeters. The minimum thickness of the classic cement mortar above the pipe communications, which are located inside the floor, must be at least 4 cm.

Modern craftsmen make screed from self-leveling mortars, which are characterized by increased strength. The use of such materials allows you to make a screed of minimum thickness, slightly covering pipe communications. However, in this case, it is recommended to use tiles as a finishing floor covering.

As for the electric underfloor heating, here are completely different calculations. The fact is that the strength of the heating cable is much higher than that of the water floor tubes. Consequently, the top layer of the screed is more of a heat transfer function than protection against mechanical stress and damage.

Minimum thickness

Underfloor heating screed thickness

- The presence of an existing subfloor;

- And the so-called rough screed (allowing further work on a flat surface).

A thin layer is unacceptable in technical rooms, such as a garage, and rooms with more intensive loads, for example, a kitchen, bathroom, hallway.

Sometimes developers offer to level the floor level differences, due to the thickness. Consequences - non-uniform heating. This was the case for my colleague. Level differences in one of the rooms reached 13 cm (!). He did not agree, and the builders "solved" the problem by adding crushed stone, sand, expanded clay, as well as a jackhammer.

We lay the pipes

The exact definition of the figure, what is necessary to make the maximum floor thickness for the screed, is not given by any regulatory construction document. However, there are standards that allow you to optimally calculate the heat distribution. So, in residential premises, concrete coatings, under which water communications are laid, must withstand a static load of 2 kN / m².

This implies that the screed over the pipes must be at least 45 mm. When using reinforcement such as wire mesh with 100 x 100 mm mesh and 3 mm diameter, the thickness of the screed can be reduced by 10 - 15 mm.

Based on them, SNiP 3.04.01-87 considers that a layer of 55 - 65 mm will be optimal for a standard water floor (this indicator also takes into account the floor covering).

Experts recommend adhering to the following ratio, in which the thickness of the solution depends on the diameter of the water pipe:

- For MV 12 pipe - 60 mm;

- For MV 17 pipe - 65 mm.

Taking into account possible loads for housing, it is not recommended to exceed 100 mm. In non-residential premises, for example, cafes-restaurants, car dealerships, fitness and the like - no more than 200 mm. And a thickness of 300 mm is used in industrial premises, hangars, etc.

The inevitable thickening of the screed can be justified in several cases:

- If the foundation of the building is at the same time the floor. In this case, for example, a 150 mm mono-brace will be an element of the overall supporting structure;

- When installing a warm floor in a room with an increased load (the same utility block or garage).

- When arranging the floor on heaving and problem soils.

Underfloor heating scheme

https://www.youtube.com/watch?v=7vkTW3SQ8R4

A thick screed, in addition to additional capital costs, promises some more incidents. These include: longer warm-up times and higher energy costs.

That's all for now. Hope you find the information helpful. Yes, I will add: some companies offer “calculators for calculating the thickness of the screed” on their websites, however, often manufacturers of pipes for underfloor heating (Valtec, Herz, Stamar, etc.) recommend different thickness parameters.

Read, ask, subscribe to the blog. Send links to friends and acquaintances. Good luck and optimal screed thickness for your warm floor!

Quote of Wisdom: Don't lose your sense of humor. Humor is to a person what scent is to a rose.

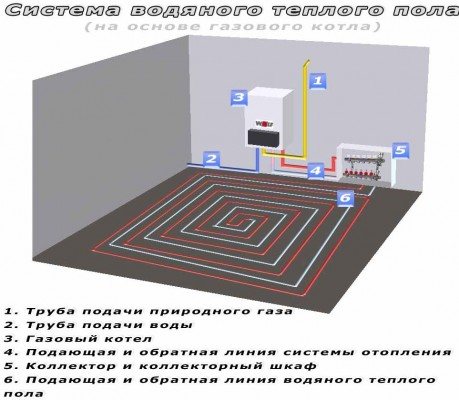

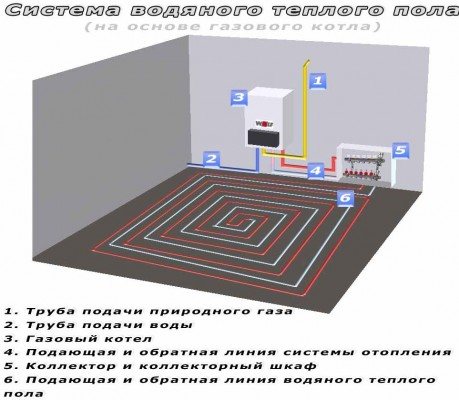

The desire to create maximum comfort in the house leads to non-standard solutions in the installation of heating. Traditional radiators are giving way to underfloor heating systems. The most economical and efficient in operation is the construction of a water floor, consisting of a closed loop of pipes with hot water.

Even temperature distribution, more free space in the room, safety - these are some of the advantages of the new product. Several factors affect the duration and reliability of the system's functioning: high-quality pipe material, adherence to installation technology and the thickness of the screed made for a water-heated floor. Ceramic tiles are often used as a topcoat, which is characterized by its durability and ability to retain heat.

Pipes and elements of the water circuit are filled with a screed. There are two ways to prepare it:

- mortar based on cement and sand;

- special dry mix of factory production.

Which of the fillings is better, each consumer decides for himself, based on the characteristics of the room and his own preferences. The main advantage of the special mixture is the short drying time. Using such a composition, it becomes possible to glue ceramic tiles faster and start using a water-heated floor.

Today, underfloor heating is one of the most popular types of heating systems used in various premises.

Due to its reliability and ability to create a cozy microclimate in the room, maintaining the required temperature, this type of heating has lured many people "to its side".

When installing a heating flooring, there are certain nuances that should be emphasized, one of which is the thickness of the screed for a water-heated floor.

Water underfloor heating is a rather complicated heating system that requires some attention, especially during installation.

A heated cover of this type has a layered structure, the observance of which during construction work is necessary if you want to get a good result.

Tile conducts heat well from a heated screed

For a warm floor and its installation, the following materials are often used:

- rough floor slab;

- waterproofing cover;

- a layer of thermal insulation materials;

- reinforcing mesh made of metal or fiberglass;

- specialized heating pipes for a warm water floor;

- screed for a water-heated floor;

- floor finish (tiles and tiles from other materials).

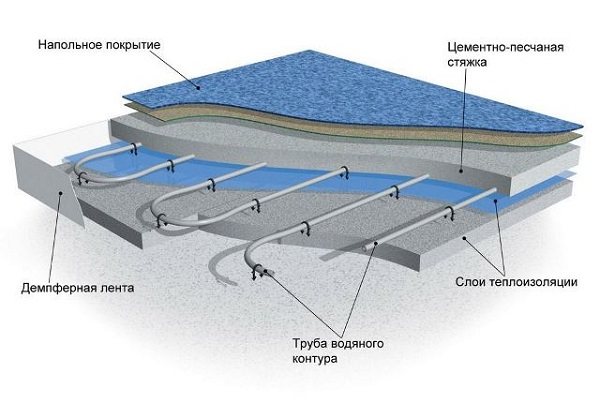

The rough screed under the water circuit must be extremely flat

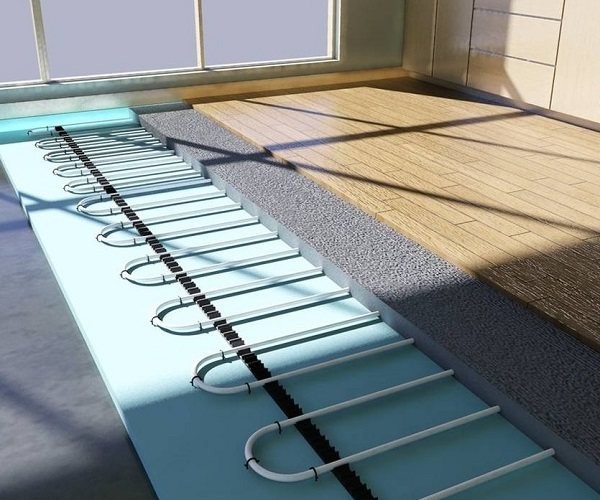

To organize a good quality warm cover, you need to reliably create each layer of the cake. A rough screed for a water subfloor (or floor slab) should be leveled as much as possible, since the quality and evenness of subsequent layers, including the finishing one, depends on this process.

Correctly organized heat and waterproofing layers help to create high-quality heating (without heating the floor) and protect the surface from moisture from the outside.

The screed thickness depends on the pipe thickness

The finishing screed for underfloor heating has a very important purpose. If it is not done properly, malfunctions may occur with the heating system, as a result of which an accident (pipe breakage) may occur and the finishing tile will collapse.

Influence of screed height on system performance

There are no instructions in SNiP regarding the maximum thickness of the screed over a water-heated floor, however, it makes no sense to exceed the optimal thickness values when arranging a warm floor in a private house. This will cause the following factors:

- Large consumption of building materials, as a result of which the arrangement of a warm floor will cost much more.

- The inertia of the surface heating process will increase.

- The usable living space will decrease significantly.

We suggest you familiarize yourself with: How to install floor joists

In most cases, the optimal thickness value is exceeded if it is necessary to make the surface as flat as possible or when arranging a warm floor at the same level in adjacent rooms. Although it would be more correct to do this at the stage of creating a rough base. Due to the different thicknesses of the top screed, the floor surface will heat up unevenly.

Due to the fact that the screed is created independently of other structures, energy consumption will not increase due to uneven heating of the floor. But this factor can affect the inertia of the floating screed heating. In general, the screed will transfer the amount of heat that the heating elements will give it.

You should pay attention to one more fact: when equipping a screed of a warm water floor in living quarters, it is best to create a uniform layer of optimal thickness. But in places where there is a significant load on the floor surface, to protect the heating pipes of the warm water floor, you can increase the layer of the finishing screed. Such premises include a garage or various technical buildings.

Before starting the installation, it is worth figuring out what thickness of the screed is considered optimal. This indicator depends on:

- heat capacity of the floor;

- uniformity of heating;

- lifetime.

A thin layer heats up quickly, starting to warm the room, but soon the concrete coating begins to crack from the high temperature. This is especially noticeable in the locations of the pipes. Heating above normal deteriorates the finish flooring. Excessive centimeters above the water circuit will require more energy for heating.

In addition to the accumulation and distribution of heat, the screed performs a protective function in relation to pipes with hot water. Insufficient coverage of the circuit will lead to high loads and shorten its life. Protection of the water system is especially important if the installation of heavy furniture is planned in the room.

The minimum thickness of the screed must exceed 6.5 cm, it is recommended for tiles that are not afraid of overheating. The optimum filling of the pipes is 10 cm.This parameter is provided for underfloor heating systems in residential premises. For industrial buildings or warehouses, the maximum concrete thickness can be up to 20 cm.

The size of the layer depends on the diameter of the pipes, if we calculate from the surface of the contour, then the indicator without taking into account the heat-insulating cake will be 2-5 cm. The installation technology allows excluding the metal mesh from the cake under the contour and replacing it with fiber in the composition of the solution. In this case, the thickness of the screed over the pipes of the water-heated floor increases, the minimum mark is 4.5 cm. Compliance with the recommended values will ensure uniform heating and safe use of the warm floor.

Preparatory work

The technology of pouring a warm floor is quite simple, but in order for everything to work out well, everything must be carefully calculated and the necessary materials must be prepared. So, one of the important stages of work is the installation of beacons and the preparation of a cement mixture.

How to install beacons

Lighthouses are needed so that the screed turns out to be even over the entire area of the room. For a reliable connection of the solution with the base in the heat-insulating layer, it is necessary to make through holes with a diameter of about 2.5 cm in the amount of 4-5 pcs for 1 m². In large rooms, they are needed in order to prevent the screed from moving. In this case, a border is made around the perimeter of the room.

The thickness of the screed on a warm water floor is calculated so that it does not reach the threshold of the door, so the marking should be started from this area. First, you need to find the highest point of the floor using stretch marks or a laser level - this will be the zero point of the surface. Depending on it, the concrete layer for the screed will be determined (at least 3 cm).

Lighthouses should be installed strictly parallel to each other so that it is as convenient for you to put a rule on them and stretch the solution along the floor. First, install the outermost beacons 20 cm from the walls, and then tackle the intermediate ones. Too much distance from the walls can cause the corner between the floor and the wall to bend. The best way to find out the distance between the wall and the outermost beacon is to make it 10 cm less than the length of the rule.

If the room is large and you need to expose more than two beacons, first install the outer beacons and pull a fishing line or cord between them - this will be a guideline for installing intermediate elements.

Progress:

- Find the zero point for the warm water floor and mark this level on opposite walls of the room.

- Fix several dowels at this level and pull the fishing line between them.

- It is very convenient to use metal profiles as a beacon, and adjust their height with wooden blocks. Some specialists still prefer to work "the old fashioned way", installing beacons on concrete mortar. If you plan to do the same, then you should wait a day for the concrete to harden and the beacons are firmly fixed on the surface.

- Position the beacons so that they are located strictly at the level of the stretched line, retreating from the walls the desired distance.

- Screw the beacons to the floor with self-tapping screws.

- If the profile sags between the fasteners, place additional support bars.

- Using a knitting wire, screw the profile to the self-tapping screws to strengthen the fixation of the beacons.

- Lay a damper tape 5-10 mm wide around the perimeter of the room to prevent deformation of the future screed.

Thermal insulation of the base

Before installing the heating system, it is necessary to insulate the base. The insulating layer will protect the water circuit from heat loss going into the basement or foundation of the house. Used as insulation:

- Styrofoam;

- extruded polystyrene foam;

- foil-coated substrate.

The listed materials are distinguished by their high strength to mechanical stress, resistance to moisture and temperature extremes. The thickness of the insulation is 30-50 mm, it is laid on a layer of waterproofing polyethylene film. The canvas is laid with an overlap on a clean, dry base, it will become a protection against wetting for the insulation. Insulation boards are stacked end-to-end, the joints are coated with glue or blown out with foam, the excess of which is cut off.

Penofol or a similar reflective insulation sheet is placed on top. The layer of aluminum foil is directed upward, this will reflect the bulk of the heat back towards the room. The joints of the foil insulation are glued with special tape. Penofol will protect the insulation from the aggressive effects of concrete.

Wet, semi-dry and wet screed

The dry contains expanded clay, foamed vermiculite, perlite or expanded polystyrene. The granules are covered with moisture-resistant drywall - the technology is quite fast, but there are also disadvantages. When water penetrates into the floor, mold will form and the structure will have to be completely dismantled. In addition, drywall is not able to withstand heavy partitions.

For a semi-dry screed, you will need a pneumatic blower, a mixing and grinding machine. Plasticizers and water are added to the solid sand-cement mixture. Products of the KNAUF or REHAU brands are suitable.

From the pros: lay the tiles in a couple of days. For laminate and linoleum, the terms are slightly longer - moisture will be released for about a month. Other advantages of a semi-dry screed include:

- good sound and thermal insulation;

- minimal shrinkage;

- moisture resistance.

The third type is wet screed. Often it is a concrete mixture or cement-sand mortar, so this option is suitable for floors with ceramic and stone finishes. A strong screed will withstand massive partitions, and the dried layer will completely pass for the final finish - just touch up the surface. Additional advantages: reliable sound and thermal insulation.

Screed tasks for underfloor heating

Floor screed

First, to protect the water pipes from damage;

Secondly, for uniform heat transfer on the floor surface;

Thirdly, for heat and sound insulation from the side of the lower floor levels.

Let's start by listing all the "classic pie ingredients."

Upwards:

- On the base of the floor - concrete screed;

- Waterproofing (if necessary, based on the proximity of groundwater);

- Insulation. It is needed to prevent (reduce) heat loss to the ground, an unheated sub-floor or a neighbor's ceiling below. Usually it is expanded polystyrene with a density of 40 kg / m³ and higher or basalt slab of special "floor" brands. Insulation thickness - requires calculation based on a number of conditions;

- Dense polyethylene film, in two layers;

- A water pipe laid on a reinforcing mesh and fastened to it with clamps. In those places of the pipes where the expansion joints pass, they put on a corrugation;

- Concrete screed, for example, is a great and affordable option;

- Substrate. Its material depends on what the finish will be (for tiles, laminate, parquet, etc.);

- Finish coating.

This is a classic pie. Depending on the specific situation, the "filling" and technology change.

What determines the thickness of the screed: From the design features of the premises and the customer's intentions, of which the main ones are:

- a) characteristics of the floor (soil, floor slab, etc.);

- b) materials of the finishing (floor) coating;

- c) expected surface loads;

- d) the temperature of the coolant and the required air temperature in the room.

To figure out how to make a screed for a warm floor, let's define more precisely its tasks. First of all, remember that screeds are fundamentally divided into tied and floating. The floating screed is not connected either with the base of the floor or with the walls of the room.If, conditionally, you look at a floating screed, then this is a separate, more often, concrete slab in the room performing its tasks.

The tasks of a floating floor heating screed include:

- Retention of pipes or cable underfloor heating;

- Be a heat exchanger between the underfloor heating system and the room, ensuring uniform heating of the floor surface;

- Take on the power load of the operation of the room.

It is for the solution of these problems that specific requirements for the device of underfloor heating screed are directed.

Semi-dry floor screed

When choosing which floor screed is better, you should immediately pay attention to options with semi-dry compounds. They have the following advantages over wet ones.

- No need to waterproof the base.

- The structure is monolithic, since the beacons are rubbed from the same material.

- No shrinkage.

The amount of solution is determined after installing the beacons. To do this, first dowel-nails are screwed into the floor to the height of the future screed. The screed is prepared from a mixture of sifted sand and cement in a ratio of 3: 1. A little water is added to it so that it sticks together easily. The estimated amount of sand concrete is scattered on the floor and moistened with water. It is then collected in a pyramid while continuing to add water. For some time, the composition settles, absorbing moisture evenly.

Throughout the kneading process, fiber is added, which is evenly distributed in the mixture. As a result, the structure of the solution is strengthened and its reinforcement occurs. The whole work seems to be laborious, but an experienced team of workers of 5 people in one shift lays a layer 80 mm thick in an apartment with an area of 90 m2.

Preliminarily, at the level of screwed-in dowels, beacons are prepared from a smaller amount of sand concrete, and then the screed is laid between them. The solution is compacted and leveled, and then a separate area is processed with a grinder. After that, the seams are cut, ensuring that the screed shrinks while it gains strength. After a day, the entire surface is wetted and further repair work continues.

Requirements for the underfloor heating screed

Here is the time to remember about the types of warm floors. Basically, there are two types of underfloor heating: water and electric. In a water-heated floor, heat is transferred to the screed from the water circulating through the system. In an electric underfloor heating, heat is obtained from heating special heating cables laid in the floor.

Note: Speaking of underfloor heating screed, we mean only a water underfloor heating and a cable electric underfloor heating. Zip closure of electric warm mats is not required. Also, the screed is not required for TP (underfloor heating) flooring systems used in wooden houses and in houses with log floors.

What does a water heat-insulated floor consist of?

We bring to your attention not only a list of component materials, but also the principle of their choice.

Pipes. For the installation of floor heating, plastic or metal-plastic pipes are used. Recently, plumbers have received recognition for pipes made of cross-linked polypropylene, which differ from other pipes in their high resistance to deformation, excellent thermal conductivity and a high degree of tightness.

An important condition when choosing pipes is their suitability for use in heating systems. Unfortunately, some unscrupulous sellers, taking advantage of the incompetence of the client, sell pipes intended for plumbing. The result is an inefficient floor heating system. To avoid this, you need to look at the markings that are on each pipe:

- linear expansion no more than 0.025 mm / m;

- thermal conductivity from 0.43 W / m0C.

The required amount of pipe depends on indicators such as the laying spacing and the diameter of the material. See the table for details.

| Step (cm) | Diameter | Number of pipes per m2 |

| 15 | 20/16 | 6,7 |

| 20 | 20/16 | 5 |

| 25 | 20/16 | 4 |

Boiler. You can buy gas, electric or solid fuels. The choice will be determined by the region of residence.For example, if there are power outages, then it is better to buy a gas boiler. If we talk about power, then it depends on many indicators. For a standard house with insulated walls, plastic windows and a ceiling height of at least 3 meters, the following calculation is made: the specific power per square meter should be 100 W or 1 KW per 10 m2. Knowing the total area of the house, you can calculate the power of the boiler. In this case, it is better to include a power reserve, about 20%.

Collector. Ensures the operability of the entire water floor and maintains the temperature set by the thermostat. It is best not to save money, but to buy a collector consisting of a flow sensor, a drain valve and a Mayevsky valve (bleeds air that has entered the system). Additionally, you will need to select a shield.

Circulation pump. Purchased if it is not already built into the boiler. This device circulates water in the system and can be equipped with a thermostat that will control the water flow rate and thus regulate the temperature in the system. The ideal solution is a three-speed pump with a temperature controller (installing a temperature controller will require knowledge in the field of electrical engineering and not everyone can do it). You can find out how to choose a pump by performance from the table:

| Area, m2) | Productivity l / min. |

| Up to 120 | 1,5 |

| Up to 160 | 2,0 |

| Up to 200 | 2,5 |

As for the company, it is better to give preference to European manufacturers. The German company Grundfos has proven itself to be excellent.

Components. This includes couplings, threads, fittings, ball valves, etc. The required number is calculated individually, based on the characteristics of each water floor heating system. Floor heating in each particular house has to be calculated and planned individually.

The purpose of the screed

A damper tape is installed along the perimeter of the room in which the water-heated floor is installed. This element will allow the concrete base to expand safely.

The elastic strip compresses under load, and then restores its shape. If the damper tape is neglected, the screed can damage the pipes of the heating system or the floor covering (tiles, laminate) when the temperature changes. This will result in complex and expensive repairs with material replacement.

The underfloor heating screed is designed to perform the following functions:

- Protection of heating elements from mechanical stress.

- Heat transfer and even distribution over the surface.

To complete the first task, it is necessary to make a sufficiently thick screed, and for effective heating, a minimum screed for a water-heated floor is required. In other words, to perform both functions, you need to choose the best option.

When determining the thickness of the screed above the water-heated floor pipe, several factors should be taken into account:

- What material will be used as a finishing floor covering (laminate, parquet or tile).

- The diameter of the heating tubes.

- For what purpose is the underfloor heating installed (main or additional heating).

- The value of the expected load on the screed.

Option 2. DSP

Wet concrete underfloor heating screed is made using floating floor technology, based on a solution of cement, sand, gravel and water. For the independent preparation of the solution, it is necessary to make a solution of B22.5 (M300) with the obligatory (!) Addition of crushed stone or gravel of fractions of 5-15 mm to the solution.

The classic M300 concrete mortar (B22.5 concrete) is made on the basis of M400 cement. The proportions of concrete (Cement: Sand: Crushed stone) - 1: 1.9: 3.7.

We offer you to familiarize yourself with: Warm pool in the country

It is important to note that this concrete grade belongs to heavy concrete and is difficult to install.The load of such a screed per 1 m2 of flooring will be 125 kg, with a screed thickness of 50 mm. And this is without taking into account the weight of the "pie" of the warm floor.

All this reveals the disadvantages of the "concrete" option:

- When placing concrete, the pipes (cable) of the warm floor may be damaged;

- Failure to tamp, may lead to the formation of air bubbles;

- The difficulty of leveling concrete will require an additional layer of leveling screed.

The floating concrete screed (6) must be reinforced with a mesh (2), welded in the nodes, with cells of 10 by 10 cm.The reinforcing mesh not only holds the screed itself together, preventing it from cracking during drying and the operation of the warm floor, but also serves as a base for fastening ( 4) pipes (5) water floor and electric floor cable. It is important (!) To ensure the rise of the mesh (3) by 10 mm from the insulation (film) (1).

The concrete screed must be insulated from the walls with a damper. This is a special tape or any dense insulation no thicker than 1 cm.

A cement-sand screed of a warm floor is made using the floating floor technology, based on a solution of cement, sand and water with the addition of a plasticizer and fiber, or on the basis of ready-made dry mixes.

Important! Plasticizer and / or fiber are mandatory in underfloor heating screed.

- If you are doing TP in the house, cement M200 is enough to prepare the DSP solution. The sand needs to be clean. Sand / cement ratio, 3/1 (three sands - one cement).

- If the underfloor heating is done in the garage, then the cement grade is taken higher from M300 to M500, optimally M400.

An indispensable element in the solution of CPC TP is the fibers of the reinforcing fiber and plasticizer. Fiber is added in a volume of 900 gr. per cube of solution. Fiber plays a reinforcing role.

Important! A plasticizer (this is not a fiber) is added to any type of DSP underfloor heating. It (plasticizer) compensates for the thermal expansion of the warm floor, protecting the DSP from cracking.

The screed DSP TP is separated from the base of the floor. Why a layer of polyethylene with a thickness of 200 microns or more is laid on the base. For better heat transfer, a layer of heat insulator with a thickness of 20 mm or more is placed under the screed. Important! The foil backing is not insulation.

Important! For trouble-free operation of underfloor heating, the underfloor heating screed should be laid only on a flat, solid base. Unevenness in the substrate can lead to the formation of air pockets, which can shrink under load. If the base of the floor is uneven, under the underfloor heating screed, you need to make an additional leveling connected screed.

The DSP screed will separate from the walls of the room, for which a damper tape or strips of any solid insulating material 5-10 mm are fixed around the perimeter of the room.

The floating screed DSP is necessarily reinforced with a mesh with cells of 10 by 10 cm. The reinforcing mesh not only holds the screed itself together, preventing it from cracking during drying and underfloor heating, but also serves as a base for fastening the pipes of the water floor and the cable for the electric floor. It is important to ensure that the mesh is lifted 10 mm from the film.

The thickness of the screed layer, in the case of a cement-sand screed without fiber with a reinforcing mesh, cannot be less than 10 cm. It is such a layer that will ensure the creation of a durable floating slab. In this case, the thickness of the screed must ensure that the pipes (cable) are covered with a layer of at least 30 mm, otherwise there will be strip heating of the floor.

There are many manufacturers producing ready-made mixtures (leveling agents), including those suitable for the installation of underfloor heating screeds. A solution from such a mixture is made by adding water in the proportion indicated on the package. The roving is laid on the beacons or without them, depending on the brand and manufacturer.

To simplify the work on the installation of underfloor heating, firms began to produce special plates of noteworthy designs. On the one hand, these plates are ready-made channels for laying cables or pipes for underfloor heating, on the other hand, they take on part of the operating load and create a layer of heat insulator.

In this version of a warm floor, a semi-dry screed is usually made, based on cement-binder mixtures with the addition of plasticizers. The best quality of such a screed can be achieved using ready-made mixtures of levelers for underfloor heating or buying ready-made semi-dry mixtures of factory production.

- Semi-dry screed does not require reinforcement and dries much faster than wet screeds.

- Semi-dry screed is installed with a damper tape.

- The thickness of the screed must ensure that the pipes (cables) of the warm floor are covered with a layer of 40-60 mm.

Minuses

- However, a semi-dry screed, porous and in the construction of a warm floor will significantly increase its inertia;

- In addition, a semi-dry screed requires serious professional skills, which makes it difficult to recommend it for independent use.

A mixture of cement, sand and water is the most common filling option. To create a reliable base, M300 cement and sifted sand are taken. The addition of a plasticizer will improve the physical characteristics of the concrete screed under the tiles. Its use is especially important for filling with a small thickness (up to 3 cm).

The preparatory stage includes removing debris from the base and waterproofing it. As a material, bituminous mastic, roofing felt or a thick plastic film are suitable.

The next step is thermal insulation, its technology is described above. Laying the mortar starts from the corner of the room. The mixture is distributed by the rule according to the level of the previously exposed beacons. The surface is carefully leveled to create a smooth base for the flooring: tiles, laminate, linoleum.

The final finishing of the floor begins after 1-1.5 months, this period is necessary for the concrete to dry. During this time, the surface of the base remains under the plastic wrap to prevent rapid water loss. If necessary, the concrete is periodically moistened.

Such an indicator as heat capacity perfectly combines tiles and a warm water floor system. Durable, beautiful and easy to care for, the material is able to maintain a comfortable temperature for a long time. Ceramic tiles will not be spoiled by temperature fluctuations, humidity, with high-quality gluing, they will last a long time.

A special mixture is diluted with water, the volume of which is indicated in the instructions. When choosing a material, preference is given to a composition with modifiers that ensure the strength and ductility of the screed. The solution is considered ready for use when no liquid is released during compression, and the composition forms a lump. The "semi-dry" mixture is laid on a clean base covered with polyethylene or roofing material waterproofing.

The solution is sequentially laid along the floor zones and leveled with the rule. After 1-2 hours, the surface is sanded with a machine with trowels. This process simultaneously levels and compacts the mortar. It is easier to lay tiles on a smooth base. The minimum amount of water in the composition allows you to start finishing the floor in 4-5 days. Among the advantages of dry mix:

- the strength of the created base;

- fast drying - after 12 hours you can move along the screed;

- ease of preparation and pouring according to the manufacturer's instructions;

- the dried mixture does not shrink, no cracks appear on its surface;

- the special consistency of the composition forms a structure with better thermal insulation performance than concrete.

- Do not neglect thermal insulation when creating a cake under the base, a layer of insulation will protect against energy losses.

- Before pouring the concrete screed, a test run of the water underfloor heating system is carried out. You need to be confident in the quality installation of the system.

- For the manufacture of concrete screed, only high-quality cement is used, without signs of long-term storage. The durability and strength of the prepared solution depends on this.

- The recommended thickness of the pour is 10 cm, but individual changes are permissible due to the diameter of the pipes and the characteristics of the base.

If the installation of the contour of a water-heated floor requires knowledge and skill, then the implementation of a screed under the tiles is available to everyone. By taking on the work yourself, you can save money, the main thing is not to disrupt the technological sequence of the process.

The exact sequence of actions depends on what kind of screed for a certain warm water floor is chosen in the end. Nevertheless, the following expert advice will come in handy when reproducing specific technological processes with your own hands.

We offer you to familiarize yourself with: How to make a pool from polypropylene with your own hands - Polypropylene for pools - Infopolymer

Before pouring a rough screed of a water-heated floor, it is necessary to install power cables and other engineering lines. The walls and ceiling are leveled with plaster mortar. If you carry out the work in the reverse order, you will have to wait until the screed hardens. Next, it will be necessary to clean it from new contaminants.

When forming these building structures, the perpendicularity of the corners is controlled to ensure the tightness of the joints with the insulation plates. On a well-created surface, differences of more than 5-6 mm in height are not permissible for one contour. This will prevent air jams from forming.

When choosing boards made of expanded polystyrene with sufficient density, special precautions are not needed. With this, the products will withstand the weight of an adult without deformation and damage. However, you should check the cleanliness of the shoes, remove potentially dangerous dirt from the sole and from the surface. It is better to install ladders from boards for movement. It should not be forgotten that when pouring building mixtures, heavy loads will have to be moved.

Garage floor screed - which one is better?

The garage floor must first of all be able to withstand the load from the vehicle.

Mechanical influences from it are produced several times a day. In addition, racks are placed in the garage, the weight of which is also significant.

The screed material is also affected by chemical loads from oil products, antifreeze and other liquids. Their hitting the floor is inevitable, no matter how carefully the liquids are handled.

The floor must be made correctly so that it can withstand all the loads. This requires a concrete base. Before pouring, laying of waterproofing made of polyethylene or roofing material is required. Reinforcement with a metal mesh or other material is mandatory. You can lay a slab, but pouring is cheaper.

Concrete is quickly abraded from above and impregnated with petroleum products. Therefore, the floor is covered with ceramic tiles. Porcelain stoneware is usually used, but paving slabs are also suitable. Now they began to use rubber tiles resistant to the effects of fuels and lubricants. Painting is a budget option, but with intense abrasion, the floor screed must be renewed every six months. What is the best surface for keeping durability high with minimal maintenance?

An advantageous option is the impregnation of the top concrete layer, which increases the abrasion resistance.

Design features

- ensuring the protection of pipes from possible damage;

- promoting an even distribution of heat over the floor;

- creation of a sound barrier and strengthening of thermal insulation.

Common screed patterns

When arranging for heating an already familiar water floor, it must be borne in mind that the thickness of the screed depends on the following factors:

- variety;

- thermal conductivity;

- strength;

- lifetime.

Underfloor heating base and pie

The value of thermal conductivity is determined in the need to ensure rapid heating of the plate after turning on the water circuit. Strength and durability is ensured if the thickness of the screed was calculated correctly at the design stage.

In different conditions, a screed performed over a water-heated floor can be of several varieties:

- wet - from cement-sand mortar;

- semi-dry - with a reduced content of water in the solution;

- dry - with a complete lack of water.

The classic version of the KNAUF dry screed

If the layer is thin, then it objectively warms up faster, ensuring, after the start of the operation of the water circuit, the spread of heat in the room without long waiting. At the same time, in such conditions, it is more likely that cracks appear in the screed, which negatively affect the uniformity of floor heating.

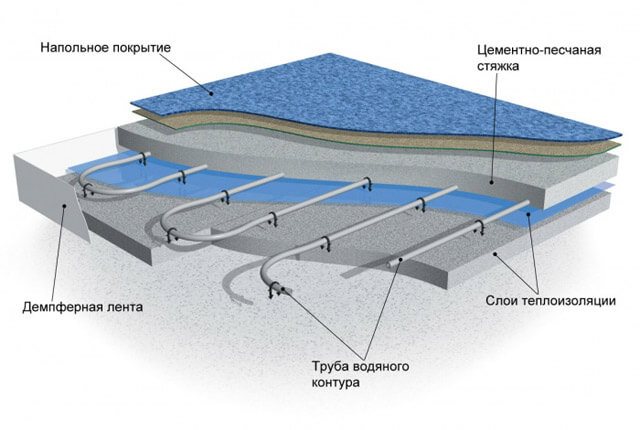

Laying scheme of layers for a water-heated floor

An excessively thick layer has good heat capacity, so it retains heat longer, allowing it to be distributed along the plane of the floor, but it takes longer to warm up. There is also a large load, which has a negative effect and can cause the screed to rupture. To avoid this phenomenon, it is recommended to arrange expansion joints.

When making a decision to level the floor with a screed, it is necessary to understand that the thickness of the layer to be equipped with a wet, semi-dry or dry method will be different, therefore, uniform heating cannot be achieved.

Two parameters are important in the thickness of the screed. The first is the total thickness of the screed, which is usually left outside the brackets. The second parameter is the thickness of the screed layer above the pipes. First, about the first.

The total thickness of the underfloor heating screed, namely the screed, and not the entire structure of the underfloor heating, should be as follows:

- If the underfloor heating is installed over an unheated room, basement, or ground, the minimum screed thickness is 85 mm. This normative value is very controversial (more on this below);

- If the transformer substation is made on a concrete slab, the total minimum thickness consists of 10 mm of the screed under the pipe (cable), the diameter of the pipe (cable) and the admissible technological thickness of the screed above the pipe.

- It is recommended NOT to make the maximum screed thickness more than 100 mm, due to the high inertia of the system. Thick screeds will heat up for a long time and spend heat not to warm up the room, but to warm up the screed itself.

Note: if you want to raise the overall floor level, you do not need to do this with a heated floor screed. You must first make a leveling screed, and then mount the warm floor, and not try to solve all problems in one screed.

I'll tell you about strength right away. The following rule works here: the thicker the underlying insulation in the TP structure, the greater the thickness of the screed over the pipes should be. For the climate of the middle zone, a sufficient thickness of the insulation is 2, maximum 3 cm.

To answer the question about the relationship between the thickness of the screed over the pipes and uniform heating, let's look at the thermal diagram of a warm floor.

As you can see, the heat from the pipes rises along the screed along a kind of cones. Optimum floor heating will be if these cones "run out" on the screed surface. If the screed is made thinner, then not so much the screed will heat up, but the finishing coating, which is bad. If the screed over the pipes (cable) is made thicker, then the heat will not reach the screed surface.

As you can see, it is the thickness of the screed above the pipes that is the most important technological parameter of the TP screed. The load on the floor in residential premises is moderate and the load on the floor does not affect the thickness parameter.

When installing a warm floor on a concrete base, with a layer of insulation no more than 20 mm, the thickness of the screed above the pipes should be:

- Not less than 30 mm for wet mortar with the addition of plasticizer and fiber;

- Not less than 50 mm for wet mortar (concrete or CPM mixture);

- Not less than 45 mm for a semi-dry machine made mortar.

Minimum thickness

Several practical issues should be noted in this example:

- An ideal foundation in domestic construction is a rarity. Therefore, it is necessary to eliminate cracks and other defects in floor slabs.To solve the problem, creating a screed with a thickness of 4-6 cm will help.

- Fastening of screed pipes of a water-heated floor can be done in different ways. Depending on the option chosen, the cost of the project, the speed of implementation and the complexity of the work will change.

- One layer of thermal insulation is sufficient, but modern materials must be used to obtain good results.

- Experts recommend maintaining the surface temperature of the underfloor heating system at a level of 28 ° C to 30 ° C. But to fulfill this condition, it is necessary to take into account: the step of laying the pipeline, the type of the main screed, the type of finish coating.

From this information, it can be concluded that the thickness of the screed over a water-heated floor depends on many different factors. It cannot be considered separately. It is necessary to coordinate with other technical parameters of the heating system project.

Parquet laying

Principle of creation

After you have prepared the foundation, you need to:

- Create high-quality waterproofing of the screed. Roll roofing felt or other insulating materials over the surface. Be sure to place the roll on the roll at least 10 centimeters and glue them together (resin, tape, special membrane glue, high temperature).

- Create an insulating layer. It is needed so that the cold from below does not penetrate into the room, and the heat from the pipes does not go to a depth. As a heater, high-density foam or extruded polystyrene foam is usually used. The thickness of the insulation layer depends on many factors: the location of the house, the capacity of the system, the coefficient of thermal insulation, etc. Usually, they try to make this layer at least 5 centimeters thick.

- Make a high-quality vapor barrier. It is necessary so that condensation does not form on top of the insulation. For this, either an ordinary plastic film or a special membrane is used. It is also necessary to lay these materials overlapping and insulating the seams.

- Create a reinforcement mesh. Usually, a road mesh with cells of 100 by 100 mm or 150 by 150 mm is used for this.

- Lay pipes. Usually, classic metal-plastic pipes are used to create a warm floor. It is necessary to lay them on the surface so that there are no joints in the future screed. The length of the pipe should not exceed 75-80 meters (with a longer length, the coolant has time to cool down and the floor heats up unevenly). If you are missing a piece of 870 meters, then create two branches. The pipes can be fastened to the fittings with clamps.

- Fill the pipes with screed or self-leveling mixtures. Wait until it is completely dry - and your system will be completely ready!

Filling pipes with cement-sand screed

Note:

you can fill the screed only after you have filled the system with water and created a working pressure in it. If there are no drips anywhere, then do not drain the water or relieve pressure until the screed hardens. This will prevent the pipe from deforming.

The last stage in the installation of a water-heated floor in a private house is laying the topcoat. It can be linoleum, laminate, parquet, carpet, ceramic tiles, etc.

findings

The article discusses several options for screed floor heating:

- Screed TP in a room with increased load. It is made with B22.5 concrete, possibly on soil with a thickness of 85 mm, with obligatory mesh reinforcement. Concrete floor heating system.

- The TP screed in the house (apartment) is made with a cement-sand mixture reinforced with mesh or plastic fiber on an insulating substrate 2-3 cm with the obligatory addition of a plasticizer.

- The semi-dry screed technology is NOT recommended for independent use, excluding small rooms (bathroom, toilet) due to the complexity of technological processes in the manufacture of mortar and its installation.