The main / Warm floors - Questions on floor repair, installation. / Pie underfloor heating: Water floor and electric

Underfloor heating systems are a great alternative to radiator heating. Their construction is located under the floor covering, which increases the free space of the room. And the even distribution of heat will create the most comfortable temperature for living. But when installing underfloor heating, there is such a term as - underfloor heating cake. Many beginners are wondering what it is and what is its purpose for the heating system. This article will help answer these and related questions.

What is floor heating cake and its purpose

Each consumer of underfloor heating wants not only to create the optimal temperature for living, but also so that the floor remains flat and fits into the interior of the room. But, as you know, wooden coatings and old concrete screed from time to time give in to deformation and decay. Therefore, if you place one heating system under the floor covering, the heating of the room will not be of high quality, and the system itself will quickly fail. For this reason, the construction of layered installation of warm floors with the use of additional materials was developed, which visually resembles a layer cake.

So, a warm floor cake is a multi-layer construction for all types of heating systems. Each material is laid in a certain sequence and performs certain functions. The general task of the floor cake includes:

- Reduce heat loss at home.

- Prevent moisture from the heating elements of the system and building structure.

- Direct the heat flow in the desired direction.

- Create soundproofing.

In addition, the underfloor heating cake will help protect the heating model from negative environmental influences.

But here it is worth paying special attention to the fact that the model of the warm floor and the overlap of the building affect the design of the cake. Therefore, in order to avoid mistakes, each type of installation of the heating system should be considered in more detail.

Creating a concrete base

Pouring a reinforced concrete base is indispensable to create a durable, high-quality floor (more details: ""). It is best to mark the surface for pouring by means of strips 5 cm wide and 2 meters long. It is worth sticking to a step between them of about 1 meter, which will allow the solution to be poured in strips. A square meter of reinforced mesh with a thickness of 3 centimeters is laid in the center of the room. Along the perimeter of the room, the joint between the base and the walls is glued with a damper tape.

This is done in such a way that it protrudes a couple of centimeters above the level of the future concrete screed. It is best to use concrete mix of the M100 brand. The fill begins from the far corner of the room, opposite to where the entrance opening is located. The strips are poured sequentially, and as the mixture dries, the strips used for marking are removed and the seams are filled with mortar. The screed is covered with polyethylene and regularly moistened for better adhesion and maximum condition.

As soon as the base dries, it is cleaned of dust, debris, various stains and priming is carried out. Next, the installation of a warm floor on concrete into our pie begins, if additional leveling of the base is not required.

Laying diagram of the water system cake

Before you start laying the cake under a warm water floor, you first need to prepare the materials that will be needed for installation.

So, the water system can be made of the following types of pipes:

- Corrugated pipe. This pipeline is made of stainless steel with a protective top layer against oxygen penetration. Such products are selected when the water system is compatible with central heating.

- Crosslinked polyethylene. These flexible, durable pipes are becoming more and more popular when installing underfloor heating. To impart strength and resistance to temperature changes, the material was subjected to high pressure treatment several times.

- Reinforced-plastic pipes. These products have been developed specifically for the installation of underfloor heating. They have good flexibility, effective heat output, strength, fast heating and corrosion resistance.

Regardless of the choice of the underfloor heating pipeline, its outer diameter should not exceed 2 cm.

In addition to pipelines, the water floor heating cake also includes materials such as:

- Heat insulating layer - designed to prevent heat loss. The recommended material thickness should be about - 10 cm.

- Waterproofing material - prevents moisture from entering the heating system. The recommended layer thickness is 5 mm.

- Reinforcing mesh - designed for the strength of the concrete screed and pipe laying. The recommended thickness is 4 mm.

- Damper tape - used as protection against cracking and deformation of the concrete screed.

- Foil layer - used as a good heat reflector.

Having prepared all the necessary equipment and materials, it will be possible to start laying the cake, with different overlaps of the room.

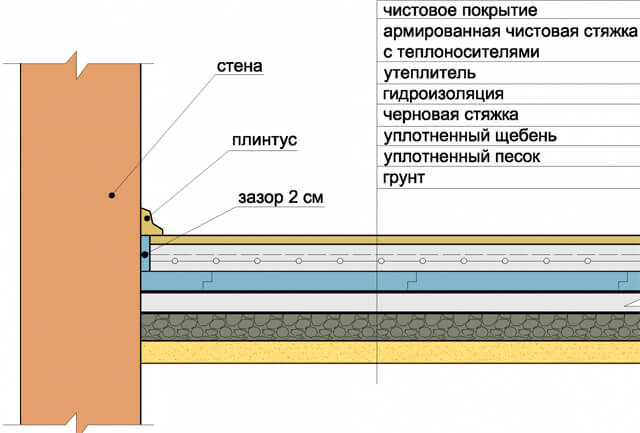

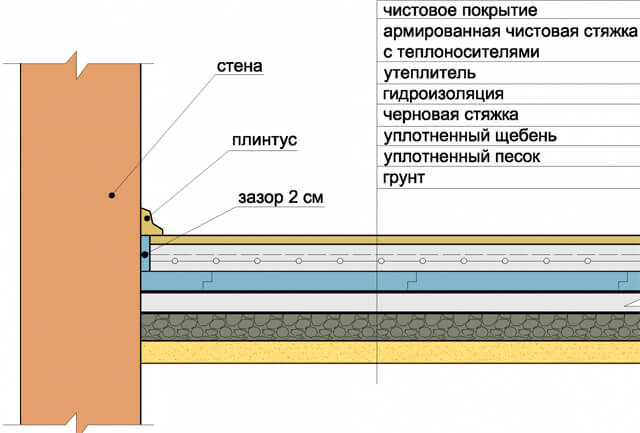

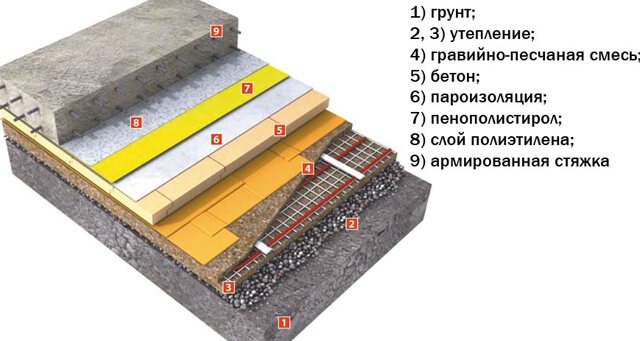

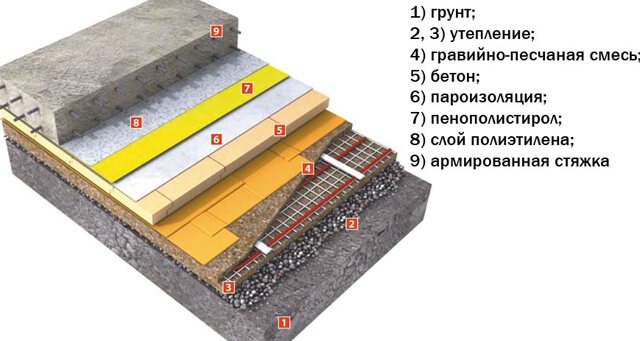

Underfloor heating cake

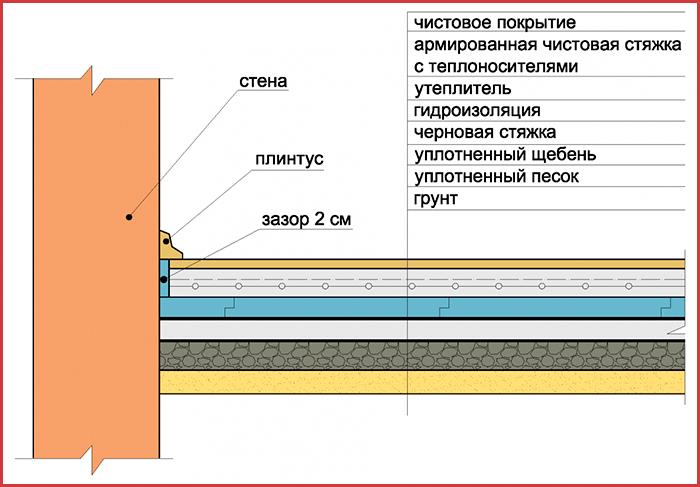

Before proceeding with the implementation of the water system pie under the ground, you first need to prepare the base. To do this, all debris is removed from the soil surface and plants are dug out from the root. Then, having removed the fertile layer of earth, everything is well compacted. Further, sand is poured onto this base with a layer of 10 - 15 cm. Watering the sand twice by air - droplet method, on it 10 cm thick, crushed stone is laid and compacted. Thus, having prepared the base, it will be possible to proceed with the following laying of the floor cake:

- A metal mesh is installed.

- Cement mortar is poured, with a layer of 5 - 10 cm. (Permissible unevenness rates are 2 - 3 mm)

- Waterproofing material is laid (roofing material, PVC or plastic film)

- To creep down the heat-insulating layer. (styrofoam or EPS)

- A red screed is poured.

- Reinforcing mesh is laid for laying and fastening pipelines.

- The contours are laid, in the form of a spiral or a snake.

- A clean concrete screed is poured.

It will take about 30 days to dry the concrete screed, after which the topcoat is installed.

Dry screed pie

A dry screed is a system of free-flowing leveling materials, over which plywood or drywall is placed for strength.

In this case, the underfloor heating cake will be installed according to the following scheme:

- a damper tape is laid along the entire room;

- sand or fine caramzite is poured onto the base of the room.

- the sandy base compresses well;

- the coolant circuit is laid;

- heat distribution plates are installed along the contours;

- drywall is laid on top of the structure in 2 layers.

In order not to damage the heating system during installation, when moving, you can build wooden bridges.

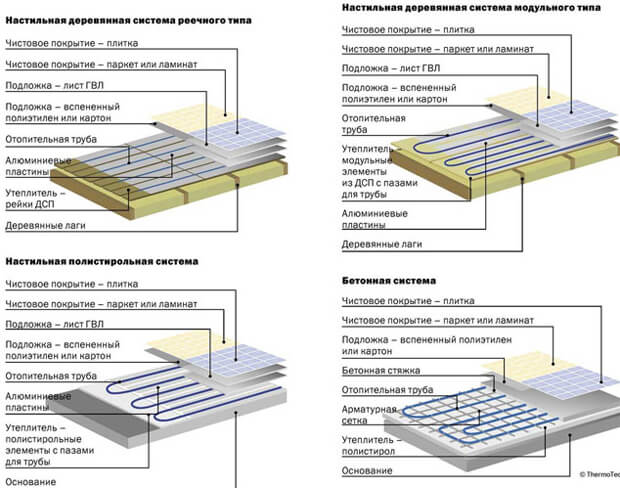

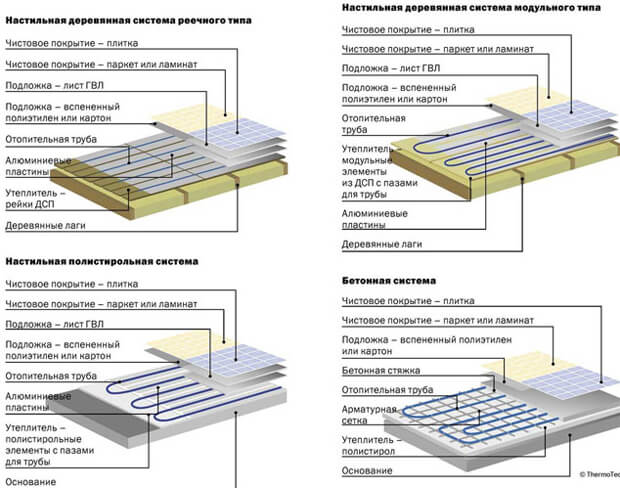

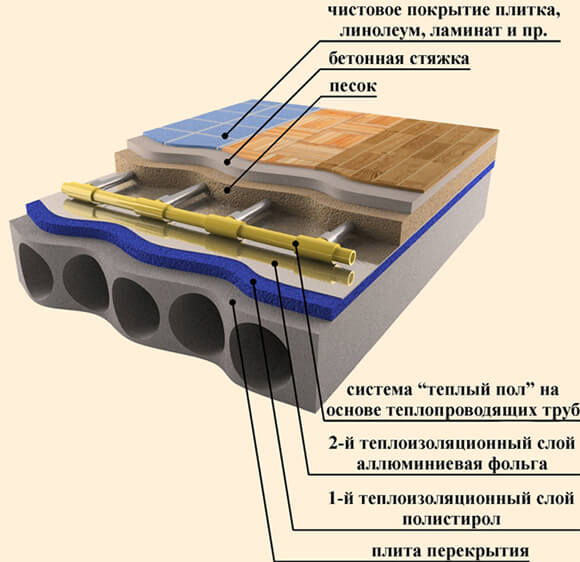

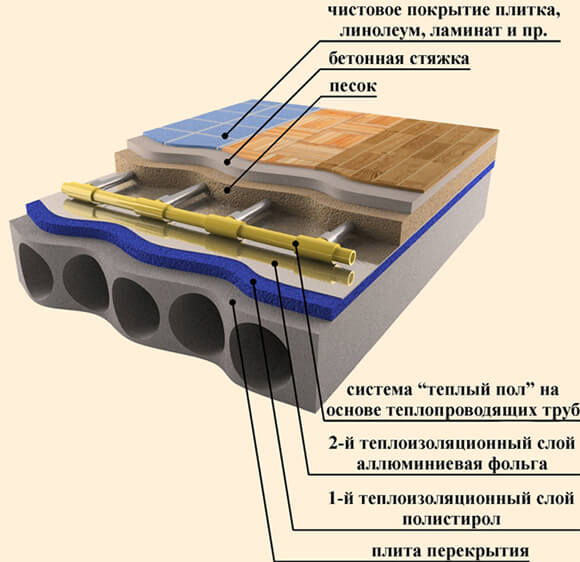

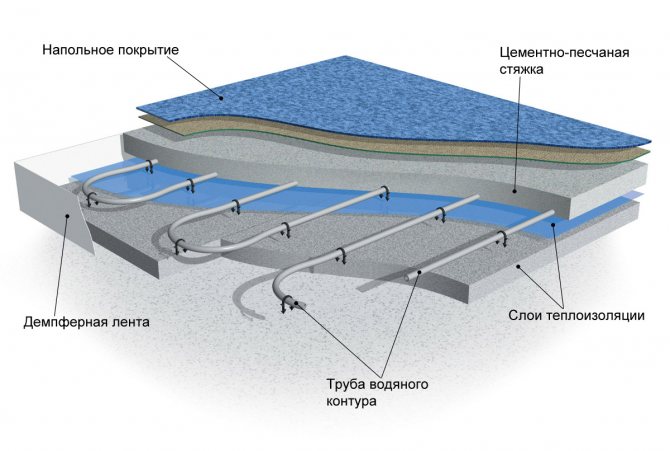

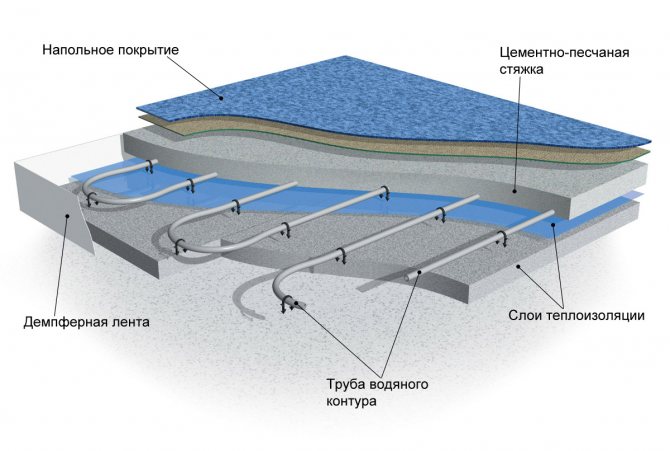

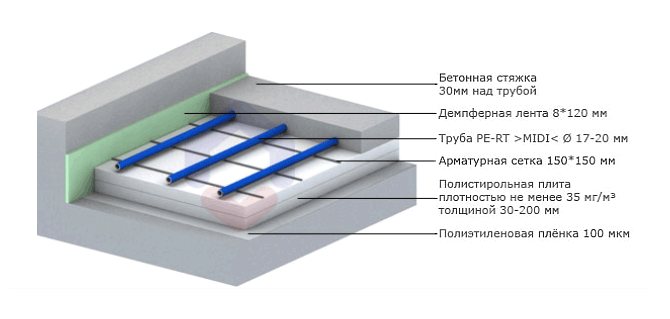

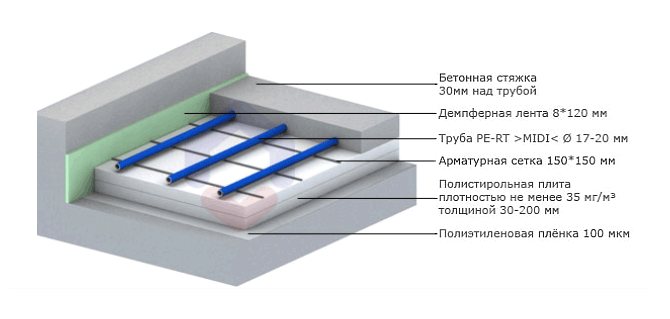

Floor cake for concrete screed

Since in this case a wet screed will be used, the sequence of laying the constituent materials will be slightly different.

So, the floor cake under the concrete screed is performed as follows:

- On the prepared base, along the perimeter of the walls, waterproofing layers are laid on top of each other.

- Lay a layer of insulation, in this case it is better to use foam or extruded polystyrene foam.

- The insulation is covered with foil.

- A damper tape is glued along the walls of the room.

- The contours of the coolants are laid.

- Reinforcing mesh is mounted.

- Beacons are installed on the grid for pouring concrete screed.

- Cement is poured over the lighthouses.

With this installation, before laying the floor covering, it will also take 30 days for the concrete screed to harden and dry.

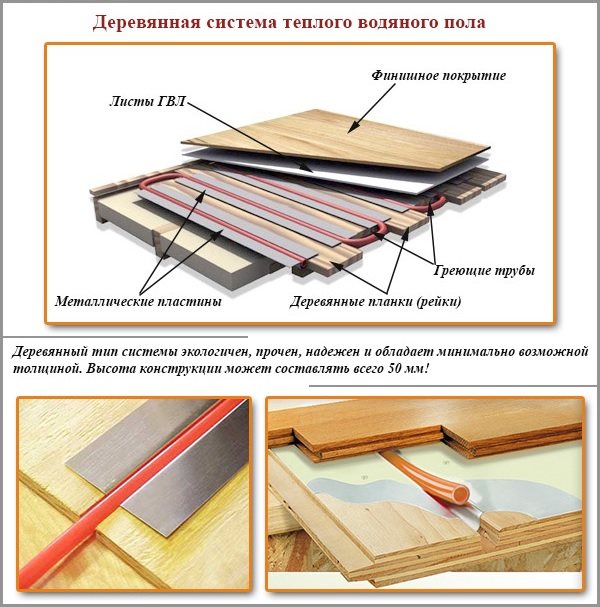

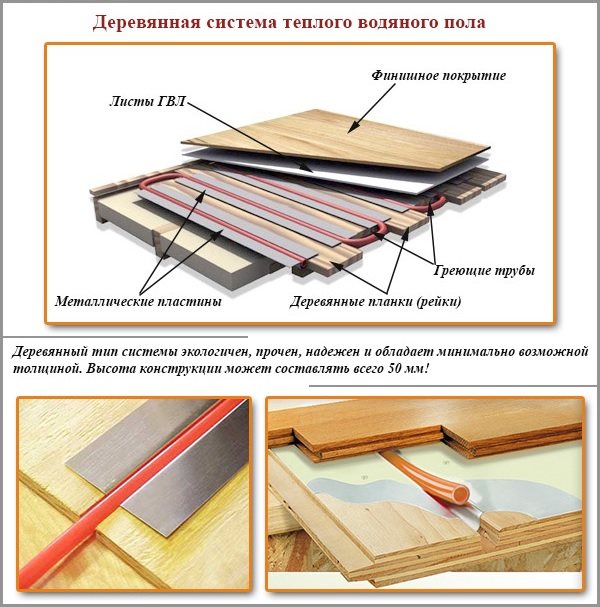

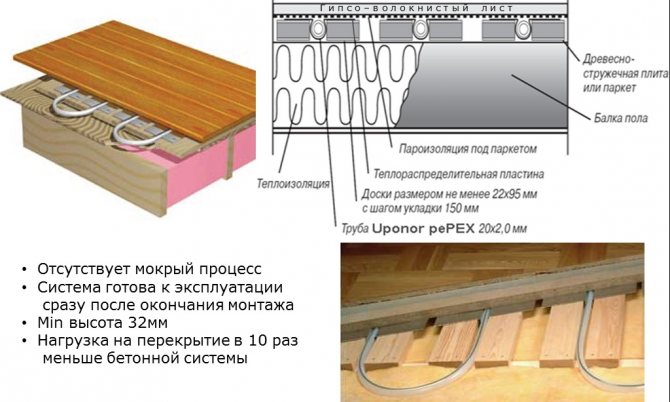

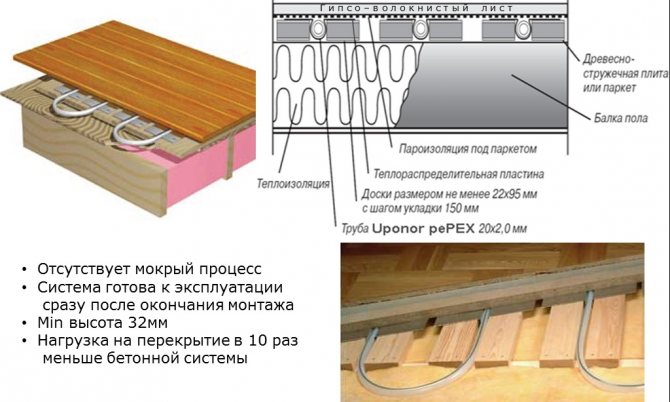

Water system cake under wooden floor

This is a fairly new type of laying underfloor heating, where pipes will be mounted between the joists. The sequence of work occurs in the following order:

- Heat-insulating material is laid on the red floor. Since the entire floor structure will be lightweight, glass wool can be used as insulation.

- This is followed by a layer of foil that will serve as a heat reflector.

- Pipelines are laid between the lags.

- GVL plates are installed as a load-bearing floor.

A distinctive feature of the cake under the wooden floor is that the floor covering can be installed immediately after the structure is laid.

Preparatory stage for soil

So, the device of the subfloor on the ground begins directly with the cultivation of a plot of land. It is important to know the depth of the groundwater table in order to exclude the risk of foundation flooding. To do this, you can prudently install a drainage system that will perform the function of draining water.

Once the groundwater problem is resolved, the foundation creation process can be started. Coarse-grained river sand and crushed stone with a fraction diameter of about 3 centimeters is used for this. The depth of the layer of these materials should be about 30 centimeters. As soon as it is filled up, ramming is performed using a large amount of water. It is unacceptable to use black soil or peat instead of sand, as they are prone to leaching. In this way, a warm floor in the garage is often made, which has proven itself well.

If the soil under the house is not saturated with moisture and is dry, a bedding layer is laid. Otherwise, it is replaced with a material such as geotextile to prevent the penetration of groundwater above this layer. On top, an embankment is made of gravel or crushed stone of a coarse fraction.

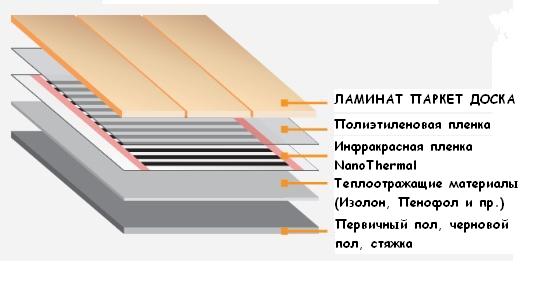

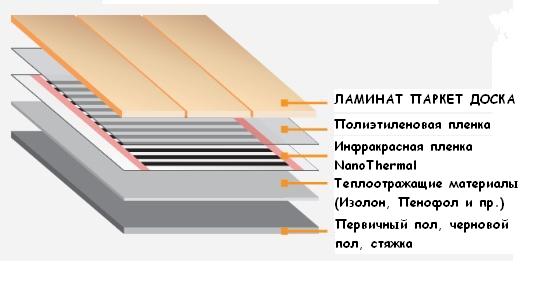

Laying the cake under the electric floor

Unlike a warm water floor, laying the structure of an electrical system does not require a lot of free time. And the installation itself is much easier, since no preliminary work is required to prepare the red base. The main material of the electric floor will be cable mats or infrared film, and as additional equipment, a heat regulator and a temperature sensor.

The very process of laying an electric floor heating cake is performed with the following sequence:

- insulation should be laid on a concrete or wooden base;

- foil-clad polyethylene is laid to reflect heat;

- the heating product is installed and fixed;

- a waterproofing layer made of dense polyethylene;

- at the end of the cake, laminate and plinth are laid.

When installing a warm electric floor, do not forget that it is also not recommended to place it under the overall furniture and electrical appliances.

Principle of operation

The design of water heating is not as complicated as it seems at first glance. The pipes are installed under the floor on a concrete base in a cement screed.Hot water enters the pipes laid at the bottom from the heating boiler and, when passing through them, heats the floor surface, then goes to the return line, where it heats up again. The pipes give off heat to the cement screed, which heats up from them and retains heat for a long time, providing another heating area.

The water floor is connected to the heating system using a manifold with built-in thermostats, they provide the required temperature in the room. The pipes are built into the collector and then they are connected to the return and supply pipes. To disconnect the floor heating from the general system, special shut-off valves are used. And now that we have figured out the principle of work, let's talk about how the cake for the warm floor works.

How water heating works

Tips for beginners

One sequence when installing a warm floor pie will not be enough for high-quality heating of the room. To achieve the desired temperature for a comfortable stay and at the same time extend the life of the underfloor heating system, you must familiarize yourself with the following expert advice:

- It is better to leave the design of the underfloor heating system to experienced professionals.

- The installation of the heating system must be carried out exclusively on a flat surface.

- To reduce the temperature load on the concrete screed, the area of the pouring area should not exceed 40 sq. M.

- Pipelines must be laid at least 10 cm from the walls of the building.

- The water circuit must be made of solid material.

- When laying the cable system, no sharp bends of the heating elements are allowed.

- Laying the floor covering should be carried out only after checking the heating system for functionality.

So, summing up the results of this article, about the pie of the heating water underfloor heating and the electrical system, it is also necessary to add that during installation it is very important to observe the sequence of laying and the thickness of the materials. And also adhere to the advice of experienced professionals. Otherwise, the errors cited at the initial stage of the installation of systems can lead to irreparable consequences, up to the failure of heating models.

AdminAuthor of the article

Did you like the article?

Share with your friends:

Options for flooring in a wooden frame and the main structural elements

Masters advise using the two most common techniques

arrangement of boardwalk in a private house:

- on the ground using logs;

- on floor beams.

The choice of option depends on the design of the object

and should be carried out at the initial stages of design

construction

... In buildings

with two levels and rooms with a basement

the second way is almost always used -

on floor beams

... His

advantage

consists in

complete isolation from the ground

, moreover, such a structure increases the rigidity of the entire structure.

Disadvantage

such

installation of floors on logs in a wooden frame

consists of

increased noise

, but the use of special noise-absorbing gaskets will reduce the noise level.

Option with decking on the ground

provides for the equipment of supports, on which logs are subsequently laid. In this way,

communication with walls is excluded and, accordingly, sound and vibration vibrations are minimal

... The basis for the supports can be red brick or concrete masonry.

Important!

Supports are formed in rows with spans equal to the distance between the lags, usually 0.5-1 meter. A layer of roofing material should be laid under the base of the lag. During work, regularly monitor the lag horizon with a level, their joints should be located only on the support posts.

It will not be superfluous to remove the soil layer to a depth of about 40-50 cm, followed by backfilling the underground space with gravel, crushed stone or river sand.

Depending on the conditions of the functioning of the dwelling plank flooring is divided into two types

:

- single

- for objects intended for seasonal residence; - double

- for premises with a permanent mode of residence.

First option

flooring in wooden log cabins

most often used

in summer cottages

where people spend the summer season.

Double construction

formed

in capital buildings

and implies the use

insulation, as well as layers of steam and sound insulation

.