Do not know how to decorate the house from the outside so as to get by with minimal costs, while obtaining a durable and effective facade as a result? In fact, it is quite possible if you choose the right budget options for finishing materials. Consider the main options for finishing materials that can be used in order to cheaper to decorate the walls of the house from the outside.

How to choose the right materials for cladding a house outside

First of all, when choosing a material, one should take into account the fact that the material of the exterior finish should have a higher vapor permeability. In this situation, high air humidity, which is quite common in houses, will be regulated by removing excess moisture in a natural way, which occurs as follows:

In case of violation of this principle of selection, all moisture that will tend to leave the room will begin to accumulate between the layers of material and form condensation. This phenomenon becomes the ancestor for the occurrence of fungus, rotting and other aspects of corrosion. Considering winter time, the wall simply freezes through, which leads to a decrease in thermal insulation qualities and unnecessary heating costs, not to mention the fact that such a phenomenon destroys the material of the building and ultimately there is a need for its dismantling and replacement.

But considering the characteristics of vapor permeability, it should be noted that only wood has this characteristic at the proper level, but there are a sufficient number of various finishing materials. Accordingly, there is a solution to this problem. And you can protect yourself in two ways.

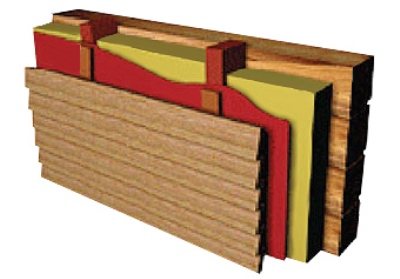

The first of these is the creation of a ventilated facade. Its design implies the presence, between the finishing layer and the wall itself, an air gap, which creates a sufficient level of ventilation, which, accordingly, will protect against surface "diseases". The gaps in this situation are arranged up to 15 centimeters. At the same time, there are ventilation openings in the lower part, the area of which should be 75 square centimeters per 20 square meters of finishing area.

The second way is to equip an internal vapor barrier, which allows fixing the finishing material directly to the wall. In this situation, it is necessary to provide for an improved ventilation system through which excess moisture will be removed.

Recently, the most common option is using a vapor barrier, which makes it possible to clad the house from the outside with any material that meets the operational requirements of the region. And given the emergence of new materials that improve thermal insulation, which actually reduces heating costs, this option becomes the most acceptable.

Requirements for facing materials

Exterior finish is important

Cladding materials are used to create a comfortable environment in the house, prevent dampness and give the structure an attractive look. All of them must meet a number of requirements:

- Thermal conductivity should be minimal, which will reduce heat loss.

- The vapor permeability of the inner layers of the material should not allow condensation to occur.

- The level of moisture resistance should prevent the penetration and stay of moisture in the material.

- The degree of heat resistance should be as high as possible, which will allow the cladding not to deform and not to ignite under the influence of high temperatures.

- Do not enter into chemical interaction with substances that fall on the facing material and do not change their properties when exposed to them.

- The material must be protected from biological factors and not be food for animals.

- The properties and characteristics of the material should not be affected by sunlight.

The effectiveness of the cladding can be maximized not only when it is securely fixed to the surface of the walls, but also when the installation technology is observed.

Wooden cladding of the house outside

The oldest material used in construction, both in the construction of buildings and their cladding, is wood. Its application became relevant many centuries ago, and will not lose its popularity for many years. Such material has a rather attractive appearance, and in addition has a good advantage, in particular the property of regulating the microclimate of the premises.

This material is at the moment the only one that can remove excess moisture from the room, without collapsing.

The most popular in recent years have become materials such as block house, or measuring timber. In addition, quite often you can find the use of lining for outdoor decoration. Among the differences of such a material, it should be noted that it is rather thick, compared with the analogue used for interior decoration.

Considering materials of the block-house type, it should be noted that they look like a rounded log. In this case, the front part of the material has a rounded shape, while the back is perfectly flat. Considering the imitation of a bar, it should be noted that it is quite similar to a planed bar. Each of these two types of facing materials is fixed to the lathing, after which they are necessarily sanded and treated with protective compounds.

Answering the question of how to sheathe a house from foam blocks, it should be noted that the option with a wooden surface cladding becomes the most acceptable. In this case, installation is also carried out on a crate made of wood or metal. It is also possible to provide insulation. Its type is becoming a rather important factor - only basalt insulation can be used, note that the use of expanded polystyrene and polystyrene foam is strictly prohibited.

The cost

When considering the pricing policy, it can also be noted that wood occupies a leading position among materials for exterior decoration of buildings. At the same time, the cost range is quite large. Considering the cheapest option, both among wood products and in general among all finishing materials, it becomes an ordinary planed board.

The material itself has a thickness of 4 centimeters, the installation is carried out according to the same principle as the installation of a lining or block house. At the same time, the elements are equipped in such a way that the top, with its edge, goes 1-2 centimeters onto the board from below, which creates a beautiful appearance. This can be called the bump effect. It is this material that fully answers the question of how cheap to sheathe a house from the outside.

Of course, a material such as wood also has a number of inherent disadvantages, among them the following should be noted:

- Pest damage

- Putrefaction

- Loss of appearance

Thus, good care is necessary for the wood sheathing, otherwise it will lose its qualities rather quickly. If you are more interested in a finish option that will allow you to forget about anxiety and wasting time for caring for it, then wood is clearly not suitable.

Step-by-step finishing with facade bricks

When to choose a brick for cladding:

- If you need to protect low quality and unattractive timber.

- When you need to carry out additional thermal insulation.

- If a frame house is built.

Warming

Insulation can be put both outside the house and inside. If you choose the second option, then the space of the rooms will be reduced. For this option, you should not take foam insulation. It has too many disadvantages. Better to use basalt. In this case, a vapor barrier must be placed on both sides. After that, sheathe the walls with clapboard or imitation of timber.

For insulation of the house outside, a mineral wool or basalt material is suitable, which must be covered with a vapor barrier membrane. Then you can proceed directly to the finishing itself.

Table: calculation of the number of bricks

| unit of measurement | The size bricks | Excluding mortar joints, pcs. | Taking into account mortar joints. PC. |

| 1 m3 of masonry | 1 | 512 | 394 |

| 1,5 | 378 | 302 | |

| 2 | 242 | 200 | |

| 1 m2 of 0.5 brick masonry (wall thickness - 12 cm) | 1 | 61 | 51 |

| 1,5 | 45 | 39 | |

| 2 | 30 | 26 | |

| 1 m2 of masonry in 1 brick (wall thickness - 25 cm) | 1 | 128 | 102 |

| 1,5 | 95 | 78 | |

| 2 | 60 | 52 | |

| 1 m2 of 1.5 brick masonry (wall thickness - 38 cm) | 1 | 189 | 153 |

| 1,5 | 140 | 117 | |

| 2 | 90 | 78 | |

| 1 m2 of masonry in 2 bricks (wall thickness - 51 cm) | 1 | 256 | 204 |

| 1,5 | 190 | 156 | |

| 2 | 120 | 104 | |

| 1 m2 of masonry in 2.5 bricks (wall thickness - 64 cm) | 1 | 317 | 255 |

| 1,5 | 235 | 195 | |

| 2 | 150 | 130 |

Brick finishing stages

Now you can go to the cladding. For this:

- Clean the wall surfaces well from unnecessary parts and treat them with an antiseptic.

- Install vapor barrier material.

- Make a horizontal batten with the distance between the battens 2 cm less than the width of the insulation material.

- Fix the insulation using disc dowels.

- Apply another layer of vapor barrier material.

- Leave a small gap up to the brick for ventilation (20–40 mm).

- Throw plumb lines from the corners of the building. This will ensure that the brickwork is being laid correctly. Control the process with a level.

- Tie the wood wall and brickwork with mesh reinforcement. To do this, one end of the reinforcement is attached to the wooden surface of the wall, and the other, without protruding, rests against the brickwork.

- Do the cladding in half a brick.

- In the first and last rows of masonry, leave small gaps (1–0.5 mm) for air circulation. The distance between them is no more than 4 m.

House cladding with siding

It should be noted that lumber is not available in every region, and in this case, sheathing the house with siding would be a good solution. Speaking about when such a material is used for cladding a house outside, it can be clearly noted that such a finish will help forget about yourself for many years. The only care for it will be a sink, because in heavy rains, the material will be splashed with dirt, especially at the base. And this factor, in turn, will significantly worsen the appearance of the decoration and the house as a whole.

The use of siding will be a fairly correct answer when asking the question of how to sheathe a wooden house from the outside.

The fastening of the material is carried out on the frame, which creates a ventilated facade, when building a house from a bar or other type of wooden materials that independently remove excess moisture from the room, this option is most acceptable. Thus, the siding becomes good, and most importantly, a fairly budget finishing option. At the same time, the material is universal and can be used as a cladding in the construction of buildings from any other types of building materials.

Among the types of siding, the following can be noted:

- Vinyl;

- Metal;

- Basement;

- Fiber cement siding.

Each of them has its own characteristics. Next, we will consider separately all types and, accordingly, the features of each of them.

Cladding technology for wooden buildings

Wooden houses are prone to shrinkage. Sheathing of a building can be carried out after a certain time after its construction. If the house is built from felled trees, then the shrinkage process will take up to 2 years.

When using beams, this period will be reduced to 6 months. If profiled timber was used as the main material, then the cladding can be carried out immediately after the construction of the object.

Before installation, make sure you have the basic tools you need: grinder, level, punch, hammer, jigsaw, etc. Their complete list depends on the type of material chosen for decoration.

Regardless of the material, there are general stages that are characteristic of any base.

- Wall treatment with special solutions. Their main purpose is to ensure the safety of wood. They prevent fungus infestation and insect spoilage of wood.

- Creation of a vapor barrier layer. It is necessary to create natural circulation in the walls of the building. It can be foil, vapor barrier, plastic wrap, etc. There must be a natural space between the vapor barrier and the wood.

- Carrying out thermal and waterproofing of a wooden structure. The following can act as a heat insulator: foam plates, mineral wool and penoplex. Mineral wool is of particular importance.

It is an environmentally friendly and non-flammable material. Air flows well through it. Mineral wool slabs are installed in the assembled frame system. On top of them, waterproofing tiles are applied.

Important! The waterproofing film is attached to the mineral wool with a rough wall, and a smooth one on the outside.

- External finishing. Depends on the cladding budget and the goals pursued by the owner of the house.

Decorating the house outside with vinyl siding

The main material that is used in the manufacture of siding is polyvinyl chloride, which is why this type got its name. Considering the type and structure of the material, it can be seen that it is a strip (board) of PVC with a width of 20.5 centimeters and 25.5 centimeters, while the thickness is 1.1-1.2 millimeters. Along the edges, there is a lock on one side, for fastening several strips, on the other, perforation is made for fastening to the frame.

Fastenings of this type of siding are carried out on the crate. The best option is metal, but processed wood bars are also used here. Self-tapping screws are usually used for fastening, while they should not be screwed in completely, leaving a small gap to compensate for temperature changes, in particular, changes in the shape and structure of the material during climate change. This solution will avoid material destruction due to sudden changes in temperature conditions.

It should be noted that such material for cladding a house from the outside has a rather low price, in addition, it is quite simple to install, which allows you to fix the siding with your own hands.

Of course, there are certain disadvantages, including a high level of material burnout, which leads to the use of only not bright colors, unless, of course, you want the building to soon lose its appearance.

But such a disadvantage, when using not bright colors, is practically not noticeable, in addition, it is compensated by a rather large temperature range in which it can be operated. Thus, the material can withstand temperature drops from -35 to +50 degrees Celsius without changing. Of course, even with slight frosts, PVC freezes, which makes the product more susceptible to mechanical damage.

Also, we note that the most suitable option for siding is for buildings with broken architecture. Further, in the photo, you can see that with a straight configuration of the walls, without various kinds of protrusions, such material does not betray beauty to it, but on the contrary, creates a not as attractive appearance as we would like.

Wall preparation and vapor barrier

First of all, it is necessary to treat the walls with special agents against fungus, mold and parasitic insects. It is very important not to skip this stage, because after the complete cladding of the structure it will no longer be possible to do this without disassembling the cladding.

You can use any vapor barrier material

Foil, polyethylene and bituminous roofing material can act as a vapor barrier material. But most often, a polyethylene film is used for vapor barrier of wooden structures. It does its job well and is inexpensive.

When using polyethylene as a vapor barrier, leave a small space between the walls and this layer.

If the house is built from round logs, you need to make a rack frame. The thickness of the slats is 20–30 mm. They must be nailed vertically to the wall at a distance of 400–500 mm from each other. And already on them to mount polyethylene.

The vapor barrier is installed in 3 stages:

- Make small holes (diameter 200-300 m) in the battens along the edge of the perimeter of the wall.

- Use nails or a construction stapler to attach the film to the frame with an overlap of 150 mm.

- Using special tape, glue all the joints of the vapor barrier, as well as the places where it is material to the frame.

Metal siding

The next type is metal siding. This material is the same strips as vinyl, including, the system of its fastening is completely identical to the previous version. The difference is the material of manufacture. If in the past version PVC acts as its role, then in this case it becomes aluminum or galvanized steel, which is additionally processed with protective compounds and decorative coating.

Additional decorative coating is made of polymers. This solution gives the material reliability, and most importantly, resistance to fading and external factors, which vinyl siding does not have. The main drawback in this case is only a rather modest choice of shades.

Powder painting is another option. In this case, such a disadvantage as a small assortment of colors is excluded. At the same time, the coating lasts for many years without the slightest signs of peeling.

When looking for a good material that can be used to sheathe a house outside for many years, with high requirements for reliability, while the brightness of the finish, metal siding will be a good solution. It should also be noted that such material does not break, even under the most severe weather conditions it can bend a little, but no more.

Speaking of installation, the process is quite simple; to carry it out, you only need metal scissors, self-tapping screws and a screwdriver or screwdriver. There are no special factors for fixing, everything is carried out in the same way as in the case of vinyl, the only difference is the possibility of installation at any temperatures.

Among the features of the material, there is significant durability, but speaking of the appearance, the building with such a cladding will not be too attractive. Metal siding has a more industrial look, which ultimately gives the structure the appearance not of a beautiful residential building, but of some kind of warehouse or production site.

Basement siding

And the last type is the basement siding. At its core, it is a type of vinyl material. But due to a completely different configuration, thickness and general appearance, it is quite often singled out into a separate group. Initially, the development of this type was carried out purely in order to protect the basement, but over time, such siding gained popularity when cladding the facade.

The material is made in the form of masonry, while considering the assortment, you can notice a fairly large number of variations in colors and varieties.In addition, in some cases, the coating is performed so well that it is visually impossible to distinguish it from real masonry. In this case, in reality, you can determine what this siding is only by touching it.

Installation of this type of material is carried out in the same way as in the case of its other analogues. The only difference is the shape of the material, if metal or vinyl products are made in strips, then the basement siding is made in the form of a section of the wall with curly edges, with which it joins.

Note that the frame in this case must be adjusted to the size of individual siding fragments. During the installation process, each element is initially fixed with the lock of the previous one, after which it is already fixed with self-tapping screws. It is also necessary not to tighten the fasteners, as is the case with vinyl, so that the material can freely "move" when the temperature changes.

Considering the frame itself, it can be noted that both wooden elements and a plasterboard profile can be used for its arrangement. More details about the installation of such a peculiar type of siding can be found in our other articles.

Block house

He is one of the varieties of lining. The block house is a natural wood board. Its front side is spherical. There is an external resemblance to a rounded bar. The back is flat. It has technological ventilation slots. The ribs are equipped with mounting elements, which is also the case with ordinary lining.

Fiber cement slabs and siding

More recently, fiber cement products have begun to gain popularity, which are presented in the form of slabs and siding. Such products consist of the following components:

- Wood fiber;

- Quartz;

- Mica;

- Cement;

- Chlorine;

- Asbestos.

Compounds of these materials are formed into sheets, which are further dehydrated and fired. After that, a certain kind of protective coating is applied to them. Such coverage can be presented in the following forms:

- Acrylic. Has a fairly high level of fade resistance besides being inexpensive.

- Hydrofilter-ceramic. Resistant to water, moreover, does not fade or rub off. But such coverage is quite expensive.

- And the last is photoceramic, which is capable of retaining color for a long time, while being resistant to water and abrasion. The cost is average.

If you are still wondering "What is the best way to sheathe a house outside?", Then fiber cement products will be a pretty good solution. We also note that they are quite easily mounted on any type of surface using various types of materials.

The finish coating itself can be presented as smooth, for example, matte or glossy, or textured, imitating brickwork or wood.

The installation of the material is carried out on guide profiles that are fixed to the wall. In the case of not knowing how to sheathe the frame house from the outside, such a material is well suited, since it creates an airtight connection, which in turn will protect the premises from the penetration of precipitation.

Considering directly siding from this material, it should be noted that it fully corresponds to manufacturing technologies, the same as in the case of slabs. The difference is the formation of the product in strips of 3.6 * 0.19 * 0.012 meters. The material is easily processed using a jigsaw, and is mounted to a wooden crate.

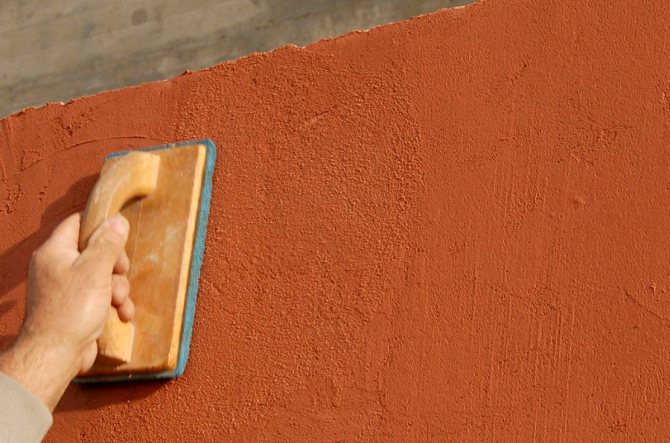

Textured plaster for facade cladding

It is difficult to imagine a material for finishing outside, which would be even cheaper than facade textured plaster. It is she who is most often chosen for wall cladding, realizing that in addition to the affordable price, the material has other advantages.

Plaster is an excellent heat insulator, increases the degree of sound insulation of the house, prevents premature resolution of the walls under the influence of external manifestations of the weather.

There are several types of facade plaster, which can be used to decorate the walls from the outside:

- decorative;

- silicone;

- mineral;

- acrylic.

Let's consider in more detail the features of each of the types.

Characteristics of different types of finishing plasterers

Let's start with decorative plaster, which allows you to give the facade of the house a finished perfect look with minimal costs for material and work. High quality decorative plaster does not require additional staining, since it already has a color due to the addition of color pigments to the mixture.

Another option for plastering for budget finishing of the walls of the house from the outside is silicone. It is she who leads the rating of the most popular mixtures for facade cladding. The plaster is based on silicone resin, due to which it becomes especially strong and durable.

Silicone plasters do not allow water to pass through, do not lose color saturation when exposed to sunlight and temperature extremes. Compared to other types of plasters, silicone is the most expensive.

Mineral plaster is most often used for inexpensive finishing of industrial buildings. Its peculiarity is a structure of increased density with cement and sand in the base, resistance to high and low temperatures, mechanical damage.

Acrylic plaster is better suited for finishing the facades of private houses and cottages, it allows you to mask small surface defects, creating a protective film that is resistant to temperature extremes and moisture. The material is inexpensive and easy to use, justifies itself in cases when it is important to decorate houses close to the roadway. The lack of coverage is insufficient vapor permeability.

The facade plaster for the aerated concrete wall is a separate feature. The material is convenient in that it allows not only to level the surface of the walls from the outside, but also to protect them from external influences. Such plaster is perfect for the role of material for inexpensive and durable finishing, especially when you consider that the cladding can be done by hand.

Thermal panels

Another material for decorating a house from the outside is thermal panels. These products simultaneously perform several functions, among which, first of all, cladding, in addition, additional insulation of the house. Such products are a layer of thermal insulation, on which a decorative coating is additionally applied. Moreover, it can be made by imitation of marble or stone, in addition, it has a sufficiently high level of water resistance.

The production of the material is carried out on the basis of expanded polystyrene, mineral wool or foam. Installation, respectively, is carried out depending on the selected base.

- In the case of expanded polystyrene and polystyrene, the material is glued in accordance with the technologies for carrying out insulation work with this type of heat-insulating material.

- When using mineral wool panels, installation is carried out on a special system of profiles.

This solution is becoming more and more popular, due to the ability to simultaneously insulate the house, and at the same time perform its facing. Of course, it should be noted that such material is quite expensive, but compared with separate thermal insulation and finishing, almost one figure will come out in cost, with a slight difference.

The only negative factor is the lack of feedback on the material, which makes you trust only the manufacturer's words. This is due to its novelty, and there is no great experience of use, therefore, you have to trust.

So, we answered the question of how to sheathe the house from the outside, the photos will help you to visually familiarize yourself with the appearance of each type of finish. The cost of each material is different, then it is up to you to decide, based on the financial capabilities and the requirements for the material.